Feeding device of shearing machine

A technology of feeding device and shearing machine, which is applied in the direction of shearing device, shearing machine accessory device, metal processing equipment, etc., and can solve problems such as bar wear, poor transmission stability, and difficult to meet the requirements of bar product quality , to achieve the effect of improving service life and reducing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further explain the technical solution of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

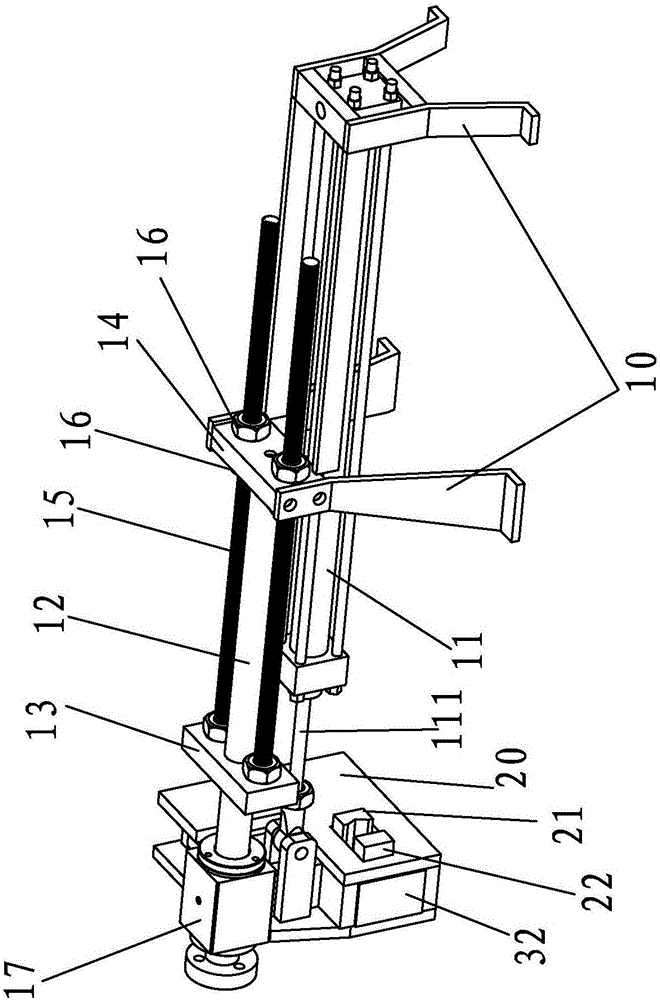

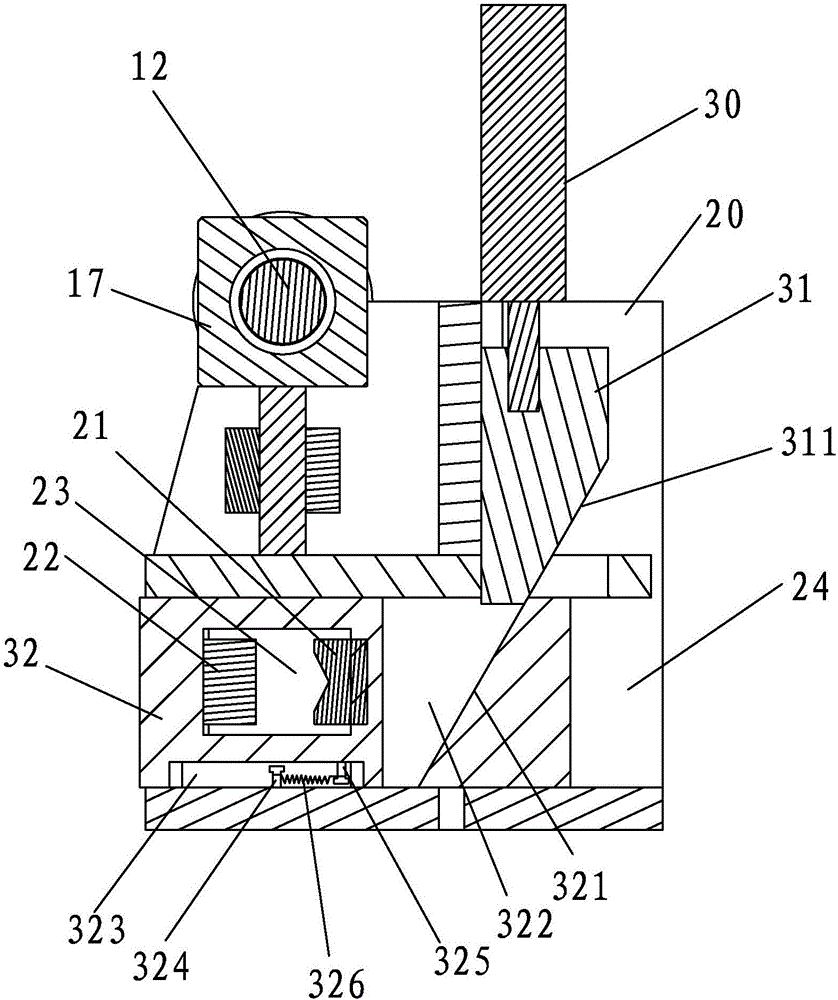

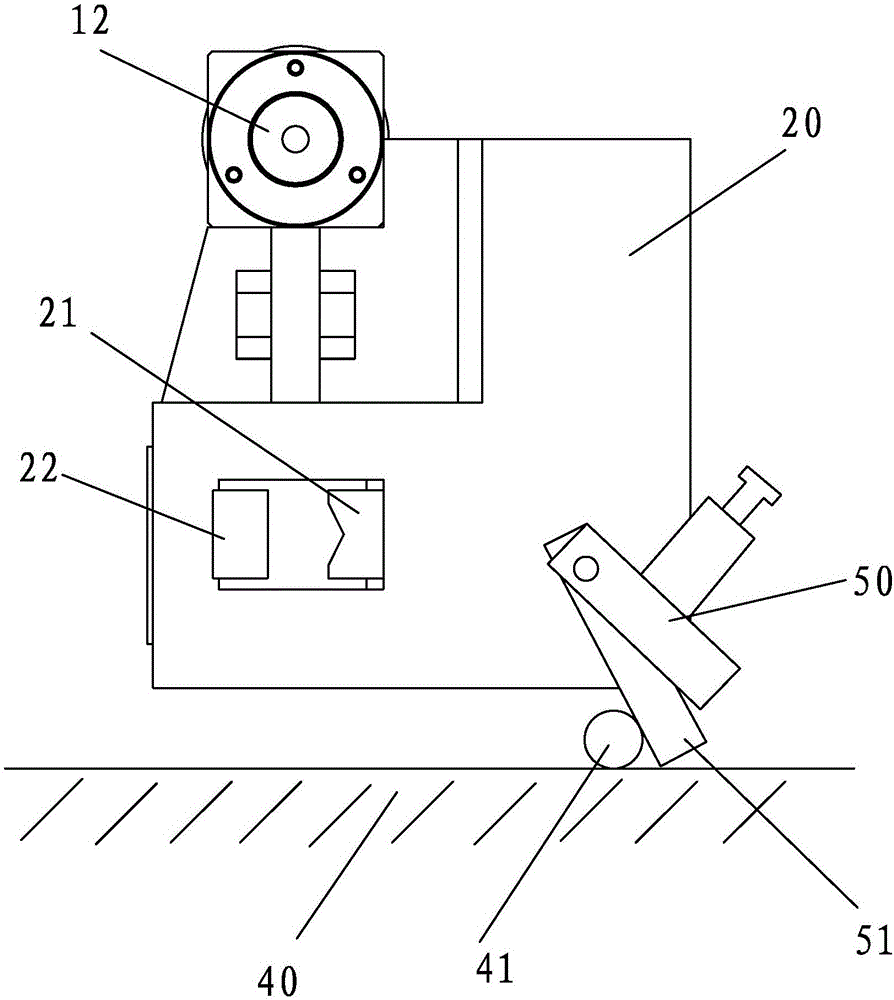

[0046] refer to Figure 1 to Figure 4, the feeding device involved in the present invention is mainly used in shearing machines, such as in the Chinese utility model patent entitled "A Hydraulic Steel Bar Shearing Machine" with the authorized announcement number CN 203265493 U. The feeding device mainly realizes clamping and Feeding to ensure the continuous production of bar shearing. The feeding mechanism of the feeding device of the present invention includes a support 10 and a feeding cylinder 11 for driving the clamping mechanism to move back and forth, and the support 10 is fixed on the workbench 40 of the shearing machine. The feeding cylinder body 11 is connected on the support 10, and also includes a guide load-bearing rod 12, and the clamping mechanism is erected on the guide load-bearing rod 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com