Dismounting device for hydraulic coupler

A hydraulic coupler and disassembly device technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the difficulty of disengaging the hydraulic coupler from the motor drive shaft, which affects the safety of production and economic benefits of enterprises, hydraulic Coupler and motor damage and other problems, to achieve the effect of simple structure, good neutrality, uniform force surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

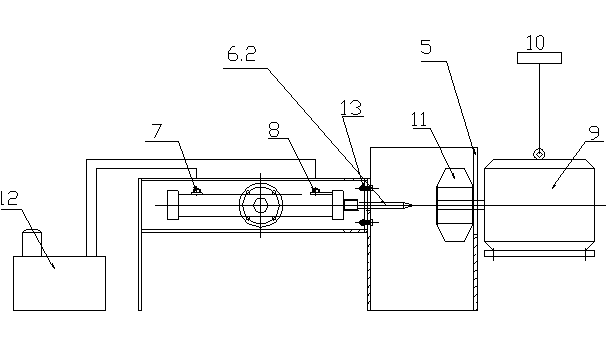

[0011] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings. The invention discloses a hydraulic coupler dismounting device, which is also used for completing the disassembly of the hydraulic coupler 11 and the motor 9 . The dismantling device includes a hydraulic coupling dismantling working chamber 1 and a hydraulic cylinder 2 for placing the hydraulic coupler 11. The hydraulic cylinder 2 is fixed in the hydraulic cylinder fixing frame 3 through a fixing flange 4, and the hydraulic cylinder piston rod 6 is disassembled from the hydraulic coupling. The working chambers 1 are connected to each other, and the hydraulic coupler dismantling working chamber 1 also has a working surface 5 of the hydraulic coupler dismantling chamber that matches the force-bearing surface of the hydraulic coupler. The hydraulic cylinder 2 is connected in the hydraulic cylinder fixing frame 3 through a fixing flange 4 . Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com