Hot stamping machine

A technology of hot embossing equipment and embossing equipment, which is used in printing, printing presses, transfer printing and other directions, and can solve problems such as uncleanness in the embossing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

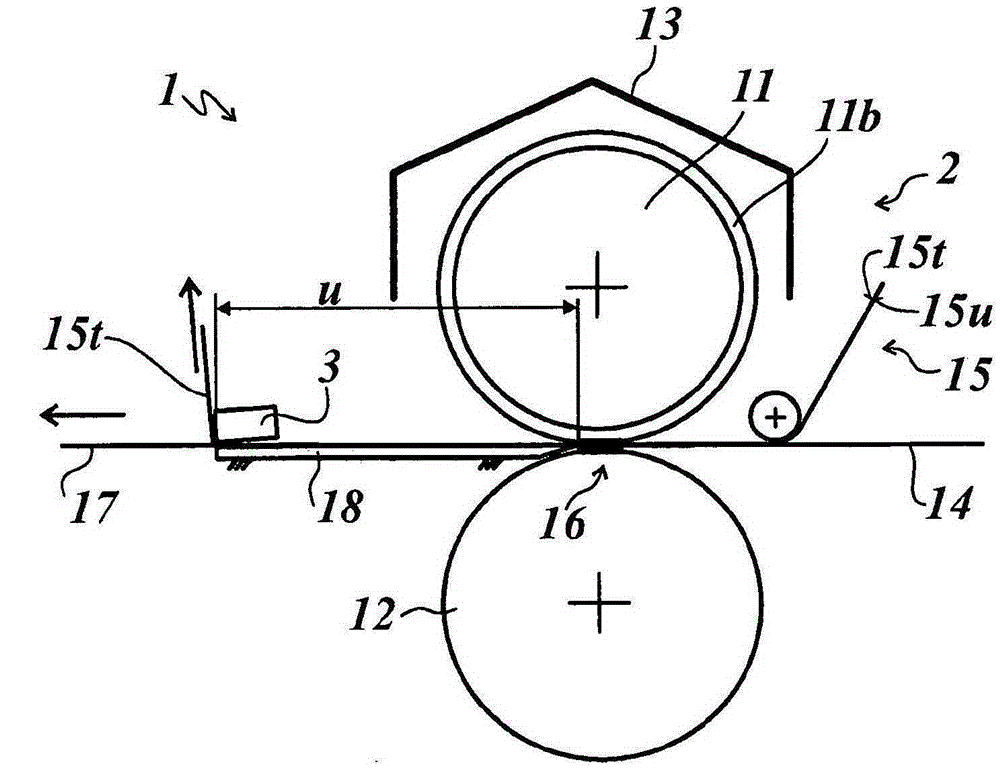

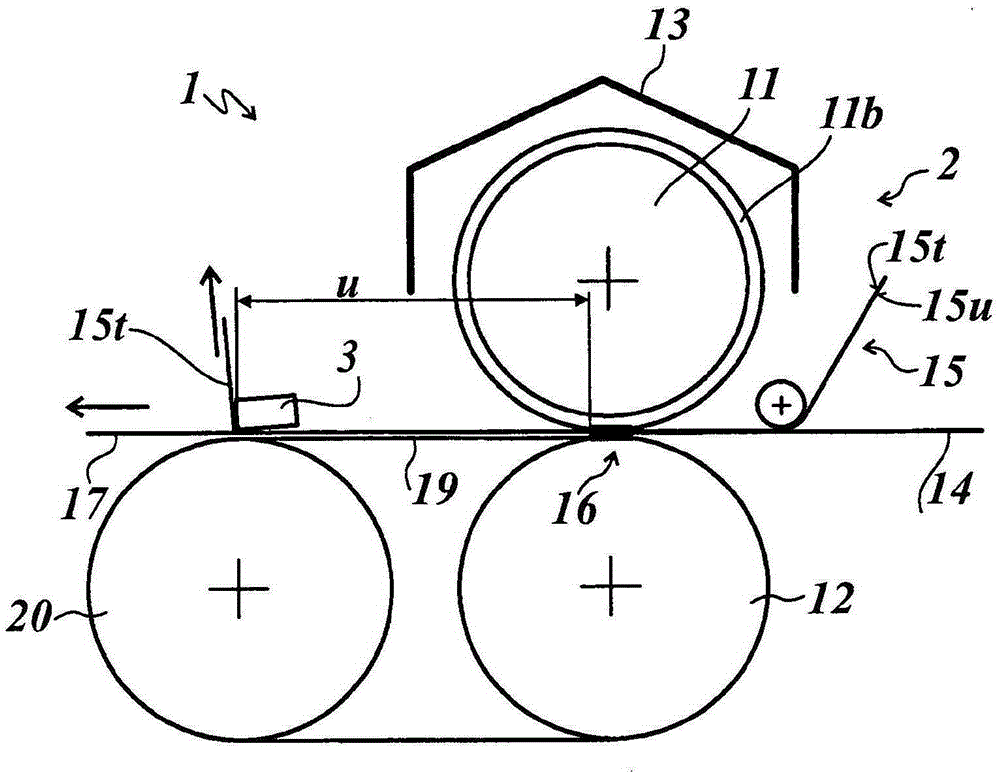

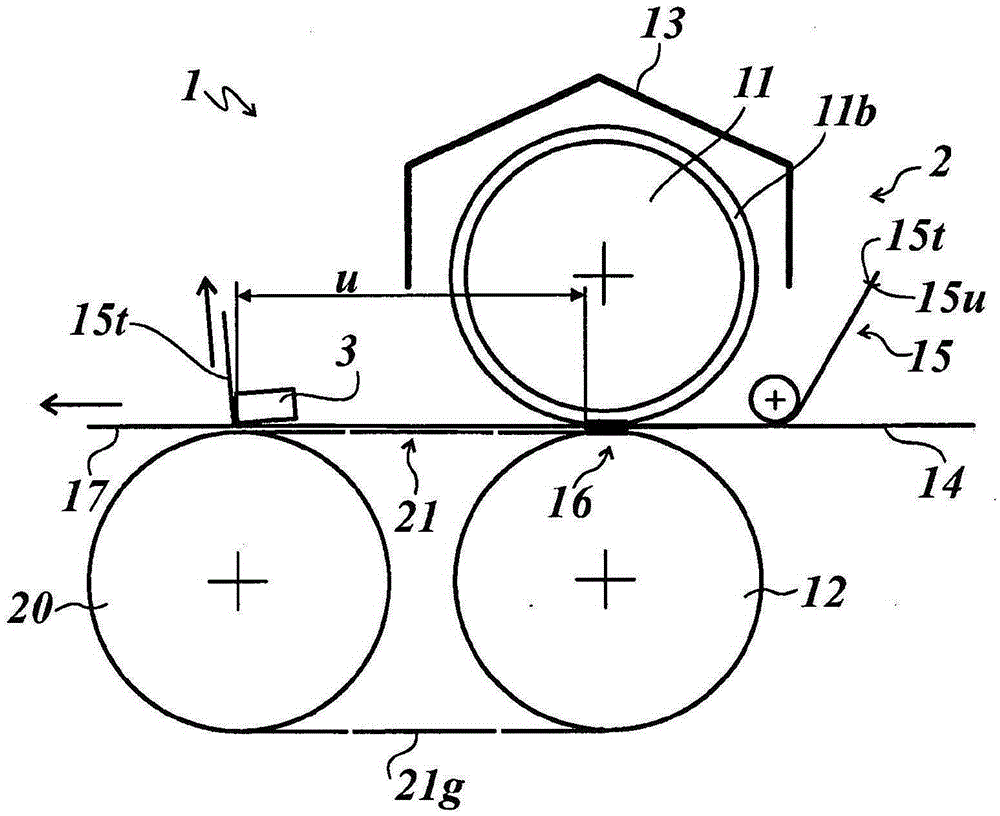

[0031] figure 1 A thermal embossing device 1 is shown, which has an embossing device 2 and a stripping device 3 . The embossing apparatus 2 includes an embossing roller 11 , a counter-pressing roller 12 and a heating device 13 .

[0032] The embossing roller 11 has, on its outer circumference, a coating 11 b made of an elastomer having a thickness in the range of 3 to 10 mm, preferably in the range of 5 to 10 mm. The elastomer is preferably silicone rubber. exist figure 1 In the example shown, the silicone rubber has a hardness of 80° Shore A. The counter pressure roller 12 is made of steel.

[0033] The heating device 13 is arranged above the embossing roller 11 and figure 1 The embodiment shown in is configured as an infrared radiation heating device controlled by means of a temperature controller.

[0034]Upstream of the embossing device 2, the substrate 14 to be embossed and the hot embossing film 15 are fed in, forming an embossing pressure in the embossing gap 16 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com