Pedal device for injection molding machine

An injection molding machine and pedal technology, applied in the field of pedal devices, can solve problems such as safety hazards, achieve the effects of high reliability, uniform stress surface, and eliminate safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

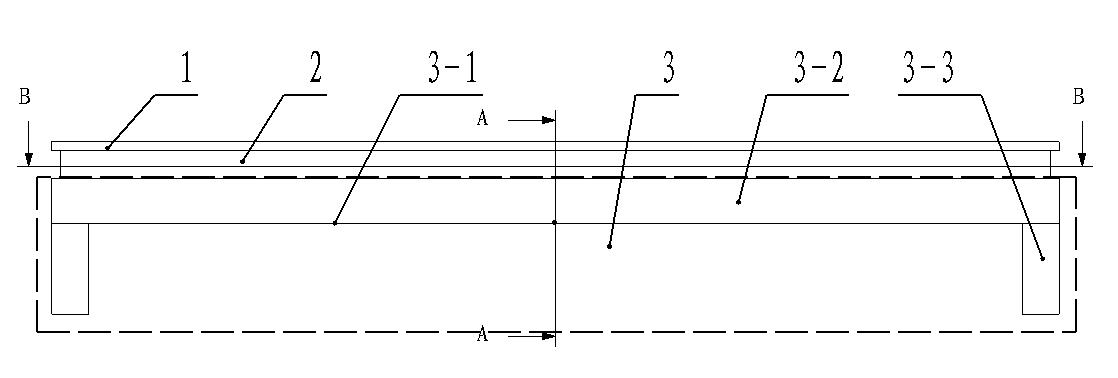

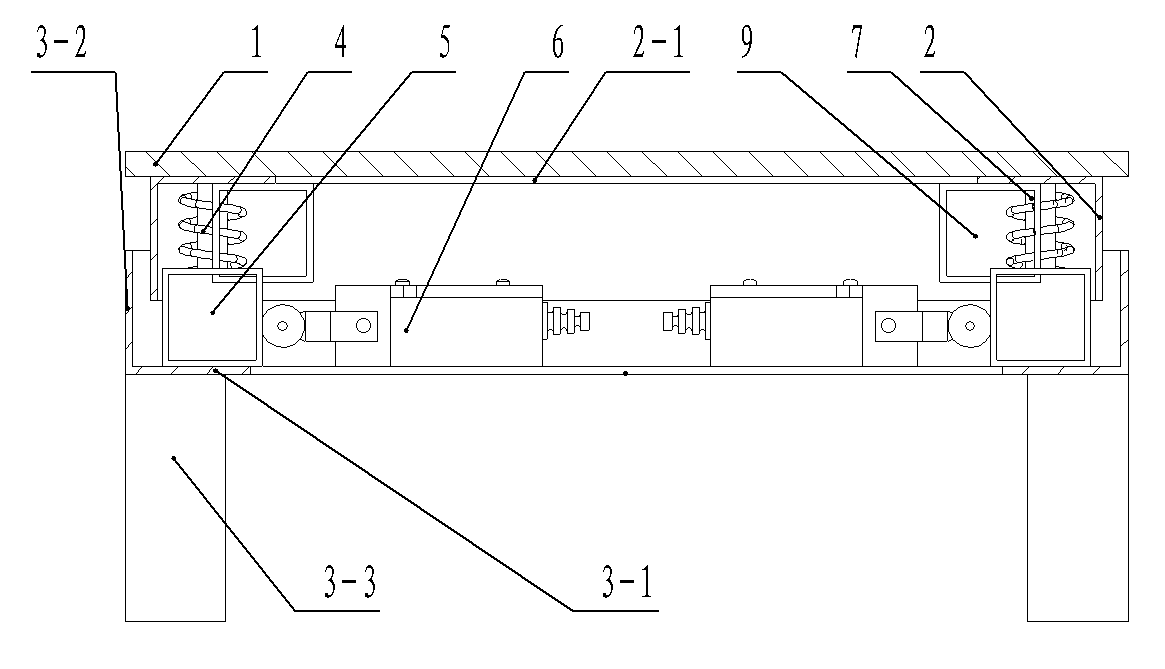

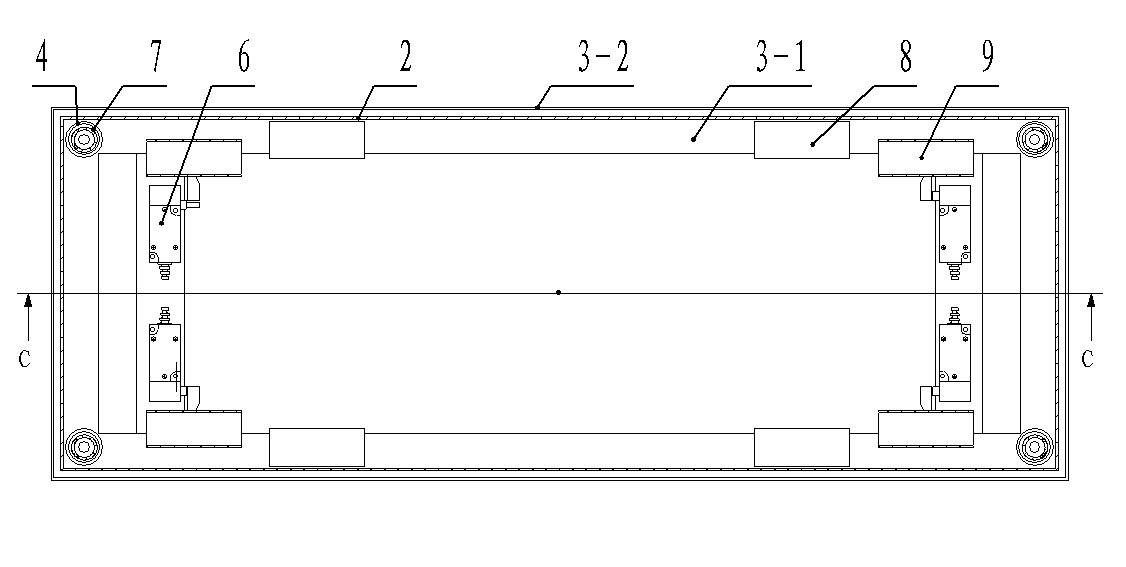

[0020] figure 1 , figure 2 , image 3 , Figure 4 The shown injection molding machine pedal device includes a pedal 1 and a support base 3 placed on the ground between the injection molding machine mold and the fixed mold, and a movable sleeve 2 is installed between the pedal 1 and the support base 3; the pedal 1. The lower end face is connected to the upper end face of a flat plate 2-1, and the lower end face of the flat plate 2-1 is welded vertically downward with the movable sleeve 2; a support base 3 is provided under the pedal 1, and the support base 3 includes a support base plate 3-1, The four support feet 3-3 installed on the lower end surface of the support base plate 3-1 and the sheath 3-2 welded vertically upward on the outer circumference of the upper end surface of the support base plate 3-1; the sheath 3-2 is set on the outside of the movable sleeve 2; The cross-section of pedal 1, flat board 2-1, movable cover 2, the cross-sectional shape of support base pla...

Embodiment 2

[0023] The movable sleeve 2 is formed by cutting the flat plate 2-1 and bending it downward at 90 degrees; the sheath 3-2 is formed by cutting the supporting base plate 3-1 and bending it upward at 90 degrees; the rest are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com