A double welded seam welded integral forged steel piston

A welded piston technology, applied to pistons, engine components, machines/engines, etc., can solve the problems of scrapping the entire locomotive, wasting energy, and separation of the piston head, reducing the chance of cylinder scuffing, reasonable structural design, The effect of simplifying the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

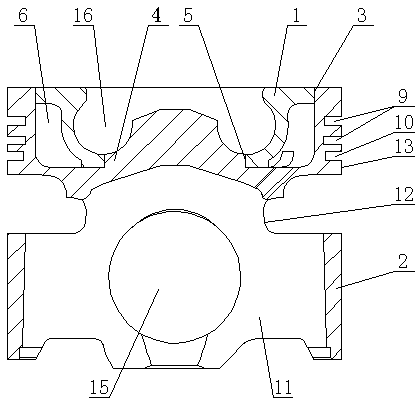

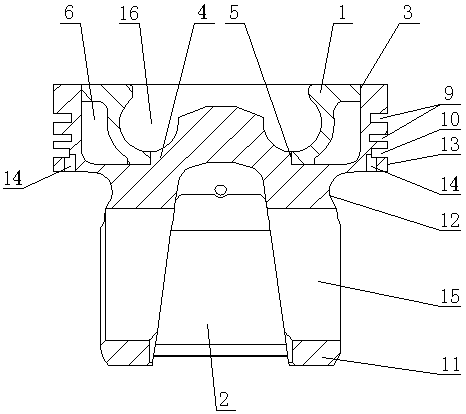

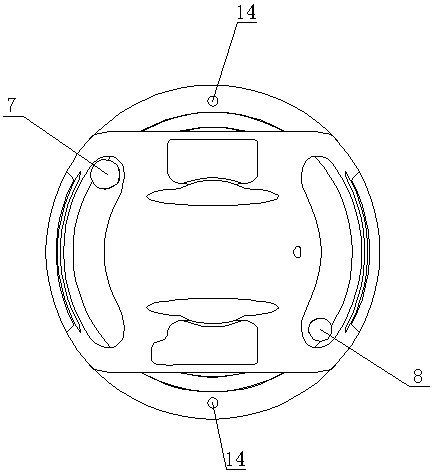

[0030] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0031] like Figure 1 ~ Figure 4As shown, the invention comprises a piston head 1 and a piston skirt 2 made of forged steel. The piston head 1 is a ring body, the diameter of one end face of the ring body is large, and the diameter of the other end face is small. A concave cavity matched with the piston head 1 is provided on the top of the piston skirt 2, and the piston head 1 is located in the concave cavity. A clearance fit is formed between the outer circle part of the end surface with a large diameter of the piston head 1 and the inner wall of the upper part of the cavity, and the inner circle part of the end surface with a small diameter of the piston head 1 and the outer wall of the boss 4 at the bottom of the cavity Create a clearance fit. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com