A tool with a replaceable cutter head and the connection method between the replaceable cutter head and the cutter bar

A connection method and tool bar technology, which is applied in the field of the connection method of the tool and its exchangeable cutter head and the tool bar, can solve the problems of abnormal blade runout, difficult to control interference, abnormal blade wear, etc., and achieve uniform force surface. , The effect of small tool runout and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

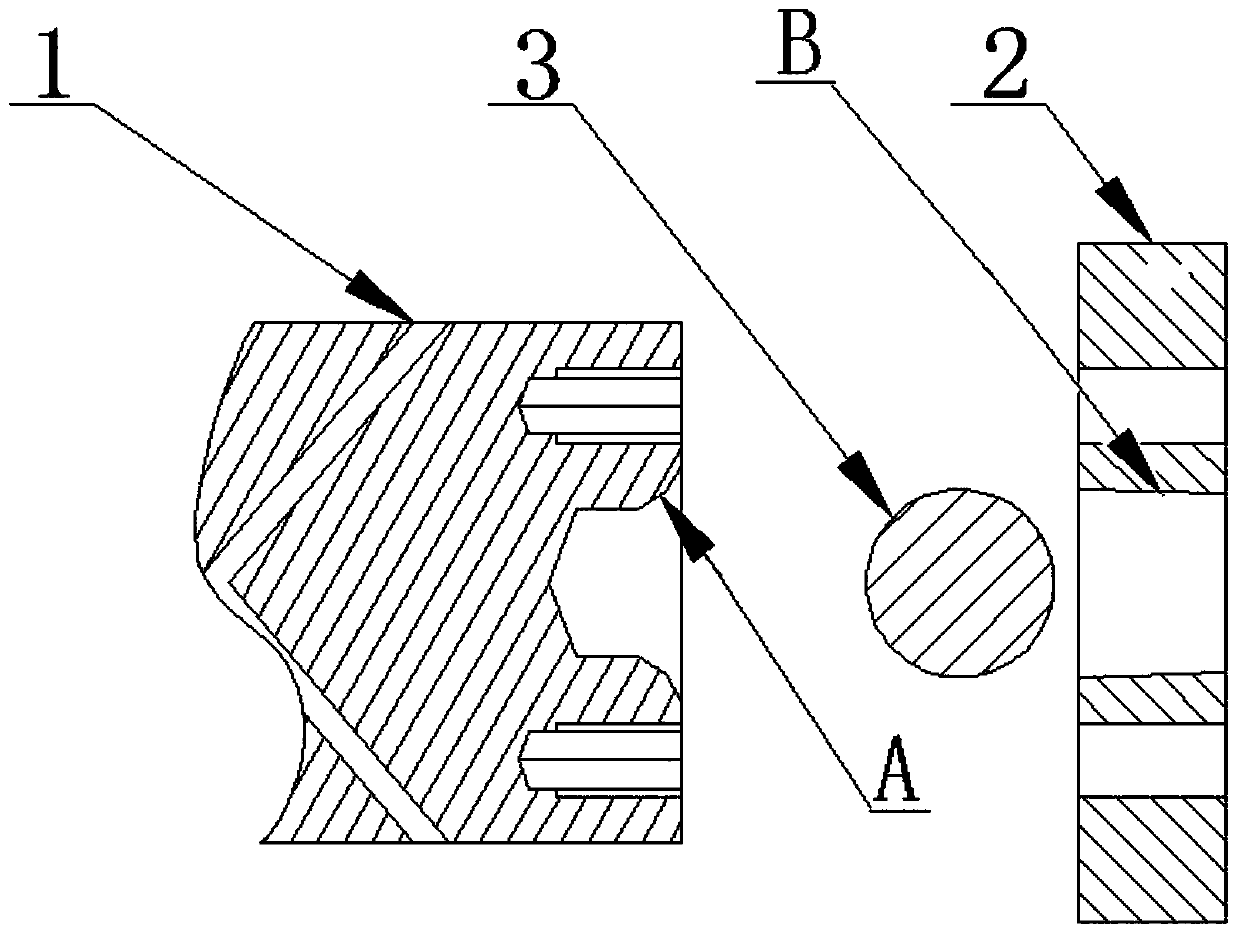

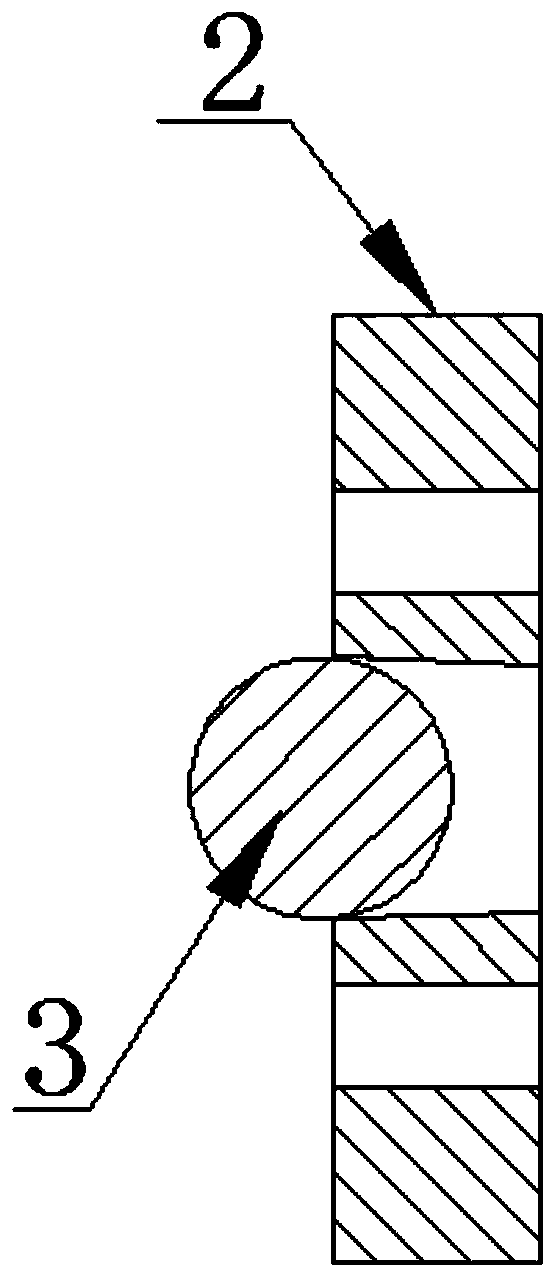

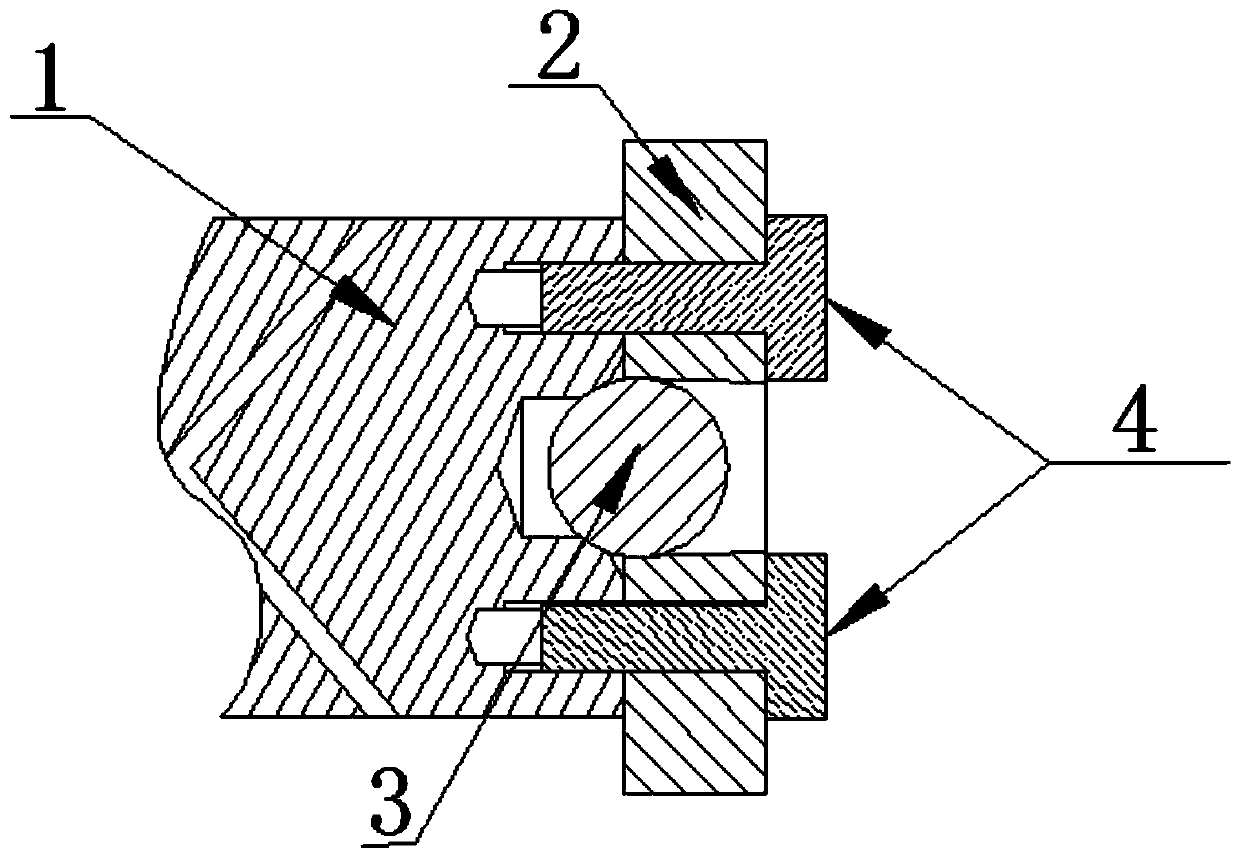

[0023] Example: such as figure 1 As shown, a cutter with a replaceable cutter head includes an inner hole with a tapered surface dug at the very center of the connecting surface of the cutter rod 1, and the angle of the taper surface of the cutter rod 1 is between 20° and 80°. ; An inner hole with a tapered surface is also excavated at the very center of the connecting surface of the replaceable blade 2, and the angle of the tapered surface of the inner hole of the replaceable blade 2 is between 1° and 8°; figure 2 As shown, a steel ball 3 is arranged in the inner hole of the replaceable blade 2; the steel ball 3 is a standard above G10, and the accuracy is within 0.001, as image 3 As shown, the steel ball 3 is pressed into the inner hole of the replaceable blade 2 with a tapered surface. There is a gap of 0.01 mm to 0.1 mm between the cutter bar 1 and the replaceable blade 2 . The connecting surface of the cutter bar 1 and the replaceable blade 2 is provided with a corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com