Automatic-following pressure balance ring-shaped drive device and application method thereof

A technology of driving device and balancing pressure, which is applied in the field of ring driving device that automatically follows the balanced pressure, can solve the problems that small-diameter plunger cylinders cannot meet the requirements of high precision and synchronicity, and that large-diameter driving devices can be placed. Compact, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

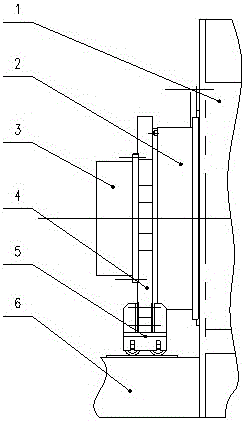

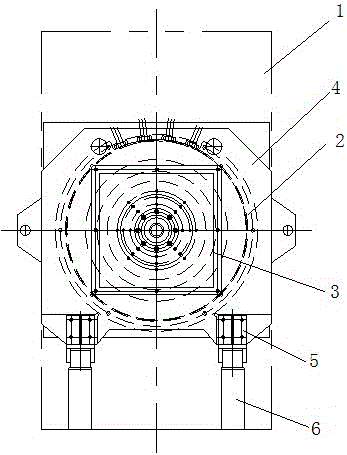

[0020] In order to overcome the problem that the compound molding machine cannot place a large-diameter driving device in the center of the frame, and several small-diameter plunger cylinders cannot meet the requirements of high precision and synchronization, this embodiment provides the following figure 1 and figure 2 A circular driving device that automatically follows the balanced pressure shown includes a frame 1, and a circular driving device 2 is installed on the frame 1 through a hydraulic nut 12. The circular driving device 2 is connected to the water inlet valve body 3 through a connecting device 4, connected to The support device 5 is connected to the bottom of the device 4, and the support device 5 is slidably connected with the track 6 located below; The device 2 is also connected to the industrial computer.

[0021] The principle of the ring drive device that automatically follows the balanced pressure is as follows: the ring drive device 2 pushes the connection...

Embodiment 2

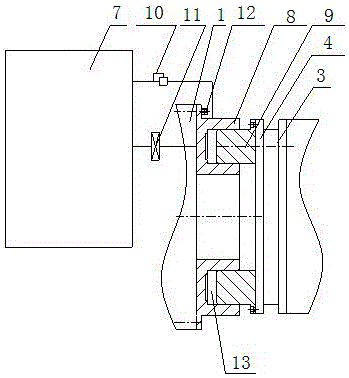

[0025] On the basis of Example 1, such as image 3 As shown, the annular driving device 2 includes an oil tank 7, an annular cylinder 8, an annular push rod 9 and an automatic adjustment circuit 10, the annular cylinder 8 is installed on the frame 1 through a hydraulic nut 12, and the annular push rod 9 is inserted into the annular In the cylinder body 8, a chamber 13 is formed between the annular push rod 9 and the annular cylinder body 8, and the chamber 13 and the oil tank 7 are communicated through an automatic adjustment circuit 10, and a shut-off valve 11 is installed on the automatic adjustment circuit 10; The connecting device 4 is fixedly mounted on the annular push rod 9 .

[0026] The working principle of ring drive device 2 is:

[0027] When the pressure of the water inlet valve body 3 changes, the annular push rod 9 is under the action of the automatic adjustment circuit 10. If the axial force provided by the water inlet valve body 3 is less than the axial force ...

Embodiment 3

[0029] On the basis of Embodiment 1, it should be noted that the connecting device 4 is a weldment composed of two flanges, one of which is connected to the annular push rod 9 through bolts, and the other flange is connected to the push rod 9 through bolts. The water valve body 3 is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com