Automobile roof and automobile

A technology for automobiles and roof covers, applied in vehicle parts, transportation and packaging, additional accessories, etc., can solve the problem that luggage racks are difficult to meet the requirements of lightweight and bearing performance and requirements at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

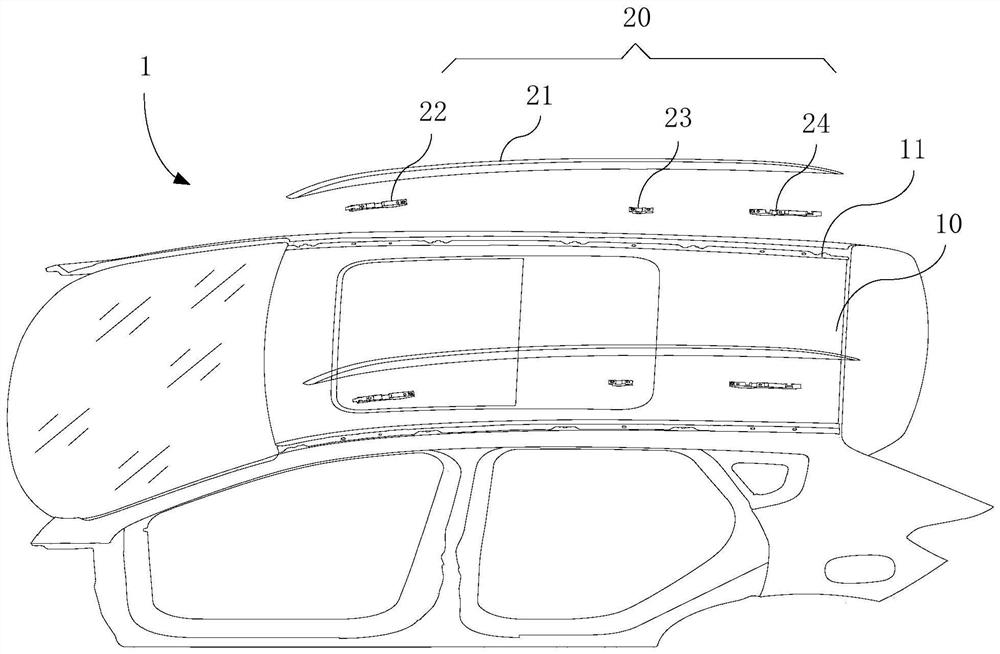

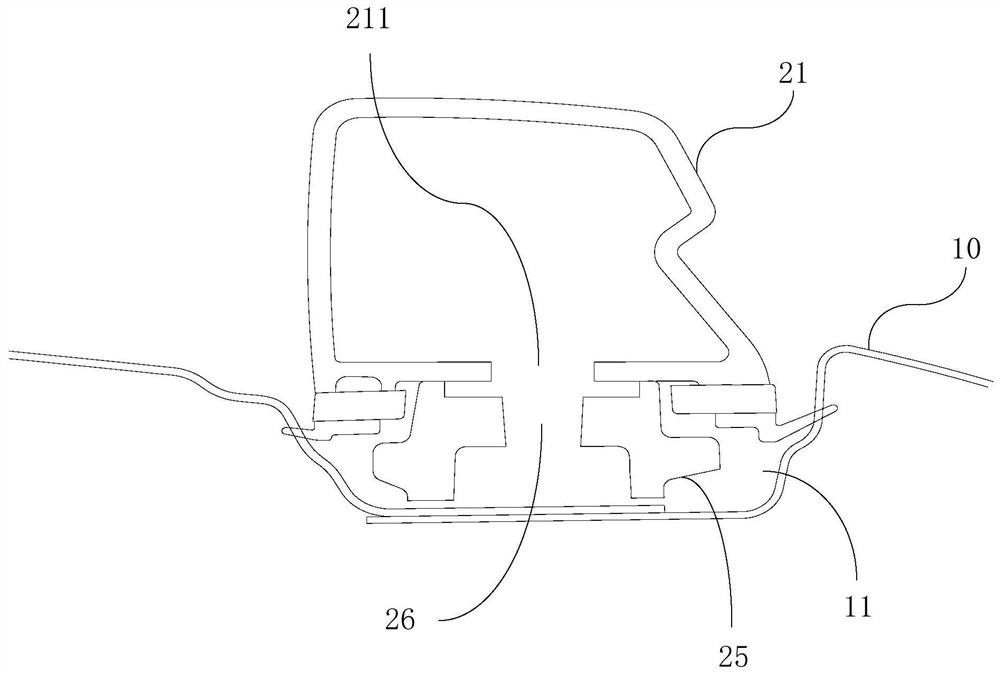

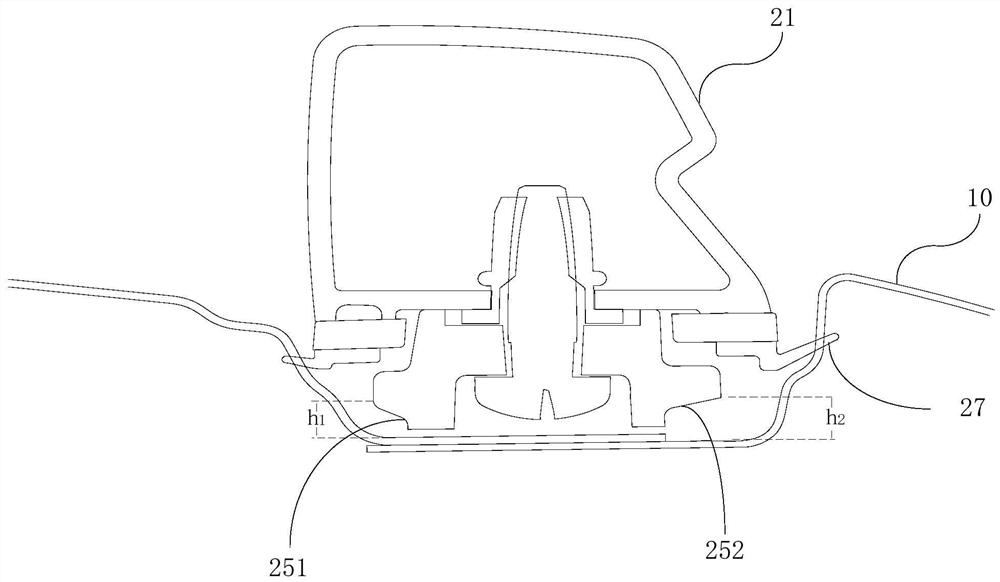

[0050] The present embodiment provides a car roof 1, such as figure 1 and figure 2 As shown, it includes a top cover 10 and a luggage rack assembly 20, wherein the luggage rack assembly 20 is symmetrically arranged on both sides of the top cover 10, the top cover 10 is a cover plate on the top of the car, and the inner side of the top cover 10 is the interior space of the vehicle. , and the outside of the top cover 10 is the exterior of the vehicle, and the luggage rack assembly 20 is arranged on the end surface outside the top cover 10 .

[0051]Specifically, in this embodiment, mounting grooves 11 are symmetrically arranged on the end surface of the outer side of the roof 10, and the mounting grooves 11 are located on the left and right sides of the roof 10. It can be understood that there are openings on the left and right sides of the roof for Install the strip-shaped groove of the luggage rack assembly 20, the assembly groove 11 is close to the position where the doors ...

Embodiment 2

[0073] This embodiment provides a car, such as Figure 8 Shown, comprise: car body, windshield glass, the car door of both sides, side panel, bright bar 30 and the automobile roof 1 in embodiment one, wherein, roof is positioned at the top of automobile, and roof is respectively connected with front windshield. The window glass, the doors on both sides and the car body are connected, the doors are located between the side panels, and the bright strip 30 is located on the upper edge of the door. The bright strip 30 adopts the same material and surface treatment as the luggage rack assembly 20, increasing the vehicle side. aesthetics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com