Improved anti-cracking cement

A technology of cement and portland cement, which is applied in the field of cement, can solve the problems of easy cracks, affecting the bonding strength, affecting the appearance, etc., and achieve the effect of increasing the anti-slip function, increasing the toughness, and increasing the anti-cracking function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

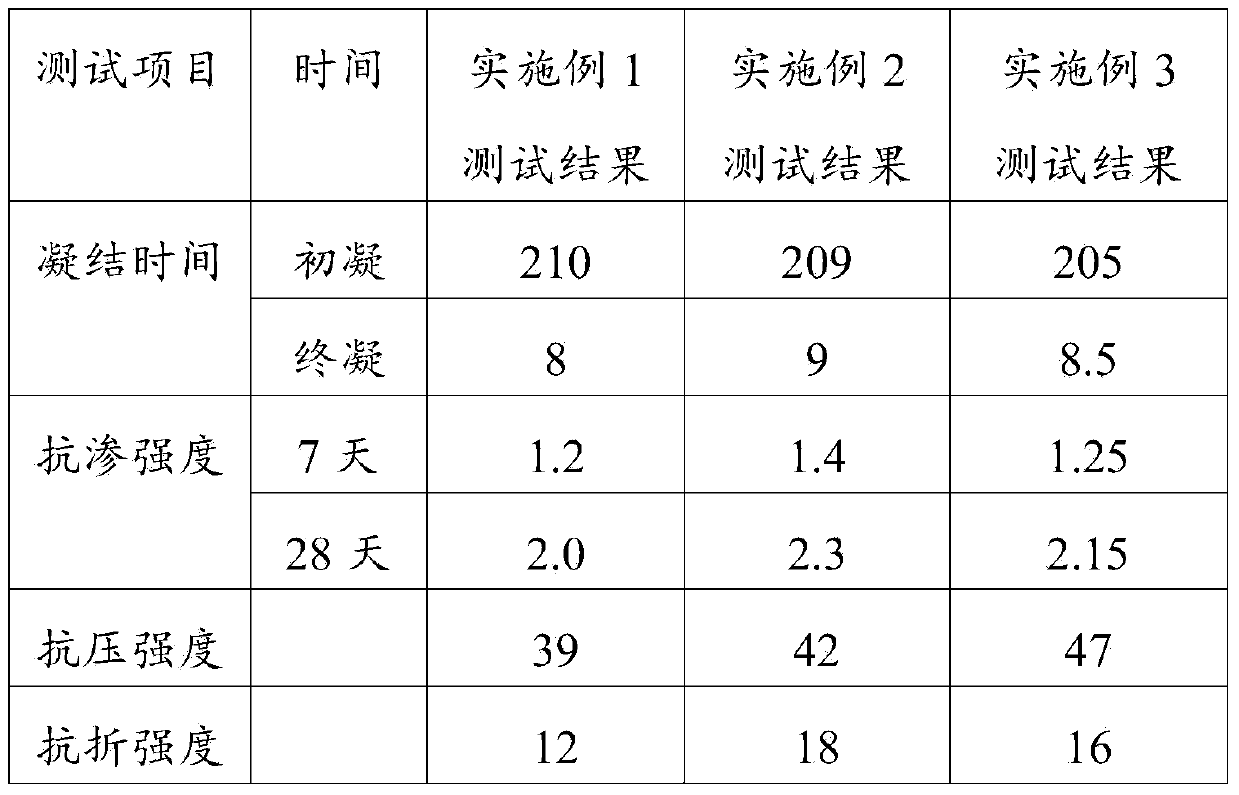

Examples

Embodiment 1

[0014] An improved anti-cracking cement, including the following components in parts by mass: 48 parts of Portland cement, 37 parts of quartz sand, 1 part of water-repellent agent, 8 parts of dispersible rubber powder, 5 parts of nylon fiber, and 3 parts of glass fiber 8 parts, 8 parts of polyethylene rubber powder, 7 parts of elastic latex, 6 parts of closed-cell perlite, 40 parts of water, wherein, 60 mesh quartz sand accounts for 33% of described quartz sand.

[0015] Preferably, the lightweight heat insulating material is one or more of hollow vitrified microspheres, expanded perlite, expanded vermiculite, aluminum silicate wool, and sepiolite.

[0016] The cement is prepared by stirring and uniformly mixing the above components in a mixer.

Embodiment 2

[0018] An improved anti-cracking cement, including the following components in parts by mass: 50 parts of Portland cement, 43 parts of quartz sand, 1 part of water-repellent agent, 11 parts of dispersible rubber powder, 3 parts of nylon fiber, and 2 parts of glass fiber parts, 5 parts of polyethylene rubber powder, 3 parts of elastic latex, 4 parts of aluminum silicate cotton, 39 parts of water, wherein, 70 mesh quartz sand accounts for 37% of described quartz sand.

[0019] The cement is prepared by stirring and uniformly mixing the above components in a mixer.

Embodiment 3

[0021] An improved anti-cracking cement, including the following components in parts by mass: Portland cement 51 parts, quartz sand 41 parts, water-repellent agent 2 parts, dispersible rubber powder 11 parts, nylon fiber 4 parts, glass fiber 2 parts part, 6 parts of polyethylene rubber powder, 8 parts of elastic latex, 5 parts of sepiolite, 34 parts of water, wherein, 50 mesh quartz sand accounts for 39% of described quartz sand.

[0022] The cement is prepared by stirring and uniformly mixing the above components in a mixer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com