Simple foamed aluminum silencer

A muffler, foam aluminum technology, applied in the direction of sound-producing equipment, instruments, etc., can solve the problems of endangering human health, short service life, environmental pollution, etc., and achieve the effect of improving muffler performance, high strength, and strong sound absorption ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

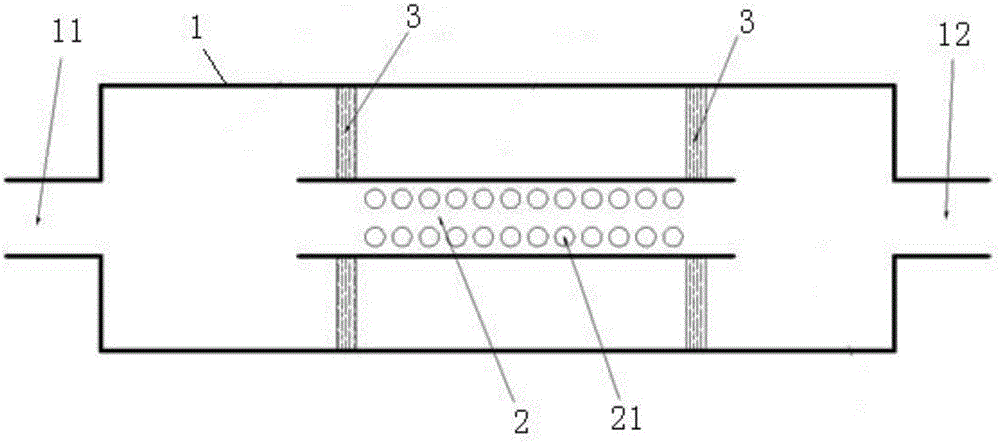

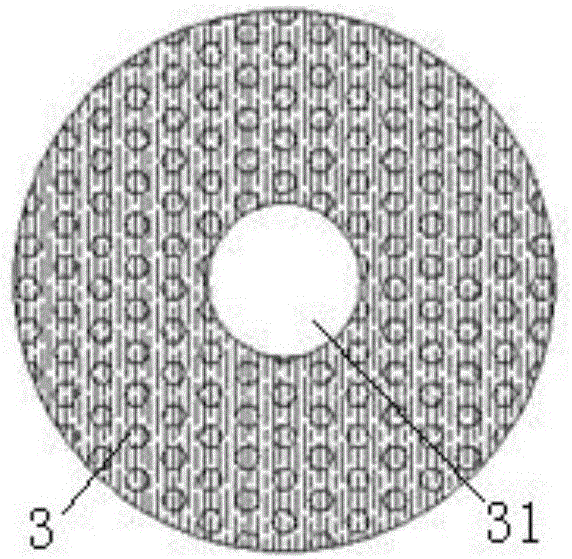

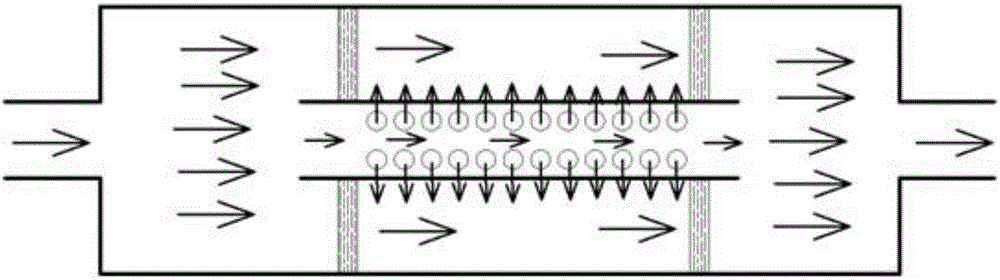

[0019] refer to Figure 1 to Figure 4 , this embodiment provides a simple foam aluminum muffler, including a hollow cylindrical shell 1, one end of the cylindrical shell 1 is provided with a muffler inlet 11, the other end is provided with a muffler outlet 12, the cylindrical shell 1 is a steel shell, the muffler inlet 11 and The muffler outlet 12 is a circular hole structure coaxial with the cylindrical shell 1. The cylindrical shell 1 is provided with a perforated pipe 2 and two foamed aluminum plates 3. The closed-cell foamed aluminum material prepared by the melt foaming method is made, and the closed-cell foamed aluminum material is perforated to form a connected channel in the foamed aluminum disc. The two foamed aluminum plates 3 are both perpendicular to the axis of the cylindrical shell 1. And the two foamed aluminum plates 3 are closed and fixed with the inner wall of the cylindrical shell 1, the perforated tube 2 is coaxially arranged with the cylindrical shell 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com