Coal ash drying device

A drying device and fly ash technology, applied in the direction of drying gas arrangement, heating device, non-progressive dryer, etc., can solve the problems of unbalanced and backward comprehensive utilization work, and achieve the effect of good drying effect and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

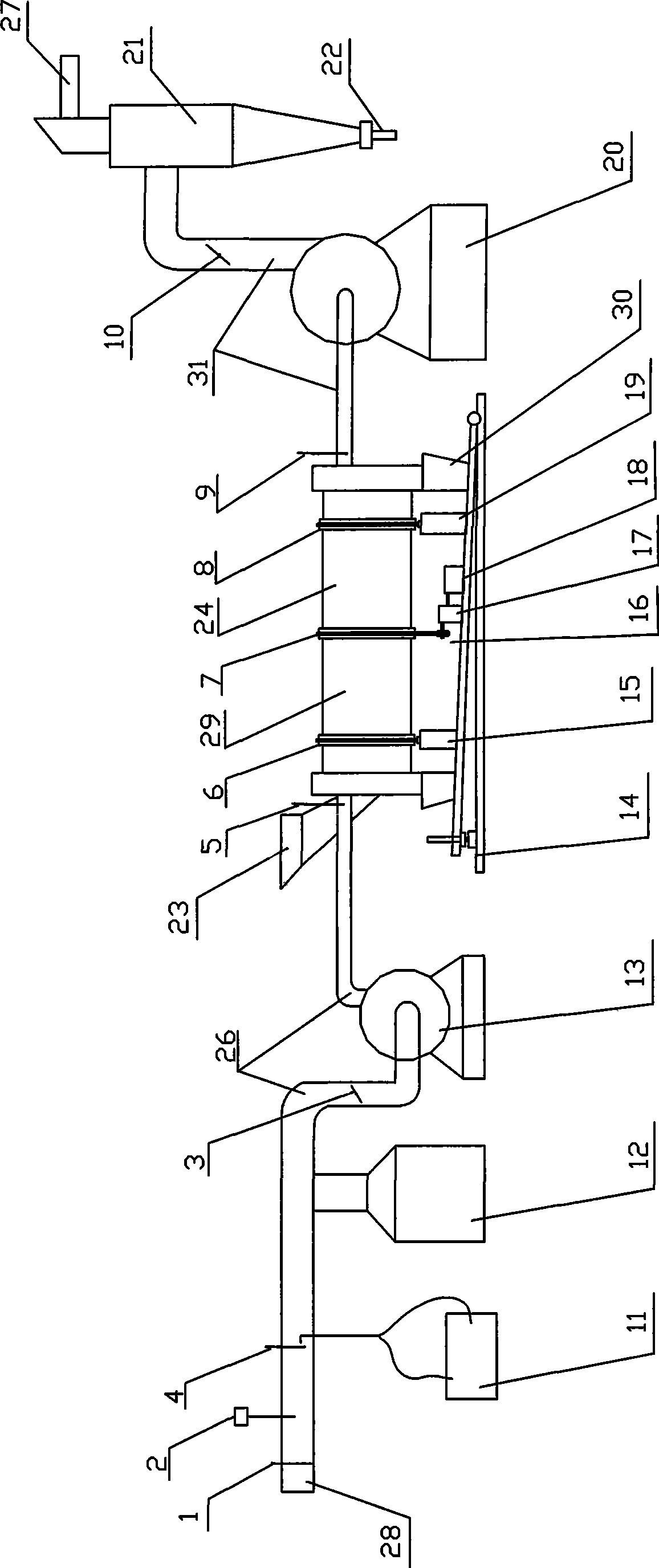

[0011] The present invention will be further described below using the embodiments shown in the accompanying drawings.

[0012] Referring to the figure, the fly ash drying device of the present invention has a drum dryer 24, the hot flue gas inlet of the drum dryer 24 communicates with the heating pipeline 26, and the hot flue gas inlet 28 of the heating pipeline 26 is provided with The damper 1 is provided with a blower 13 on the heat supply pipeline 26, a butterfly valve 3 is provided on the heat supply pipeline 26 at the front end of the air inlet of the blower 13, and a guide valve 3 is provided on the material delivery pipeline 31 connected to the outlet of the drum dryer 24. The fan 20 is provided with a cyclone separator 21 at the end of the material delivery pipeline 31 , and a butterfly valve 10 is provided on the material delivery pipeline 31 between the induced draft fan 20 and the cyclone separator 21 . The auxiliary heating furnace 12 is connected to the heating p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com