Corrugated paper printing and drying equipment

A technology for printing drying and corrugated paper, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc. It can solve the problems of inconsistent printing effect, effect distortion, and poor printing color overlap, and achieve good drying effect and easy maintenance. The effect of convenience and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

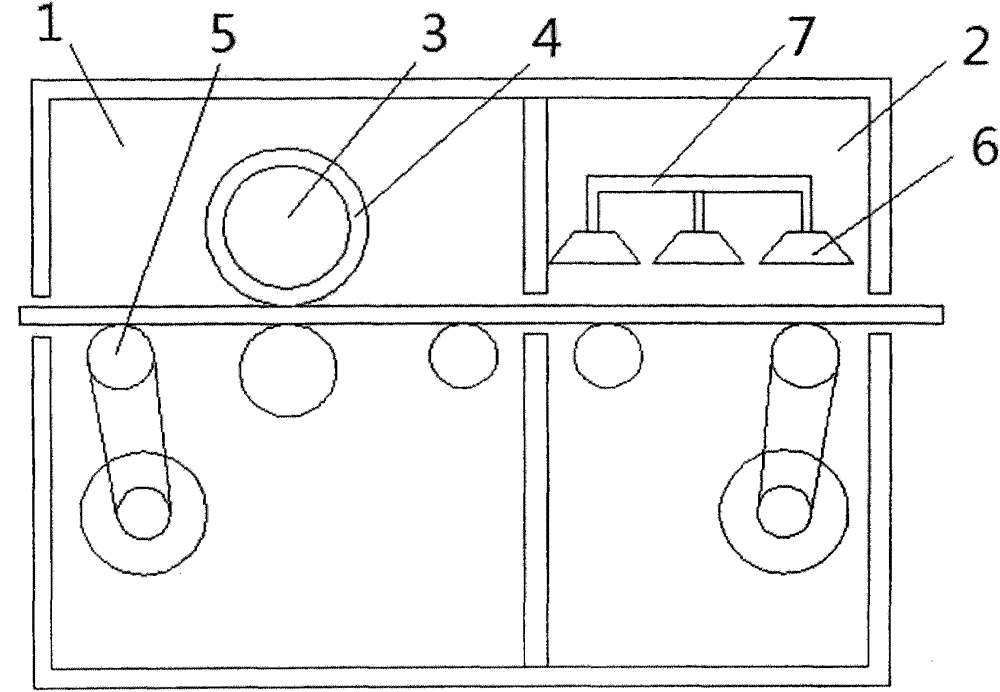

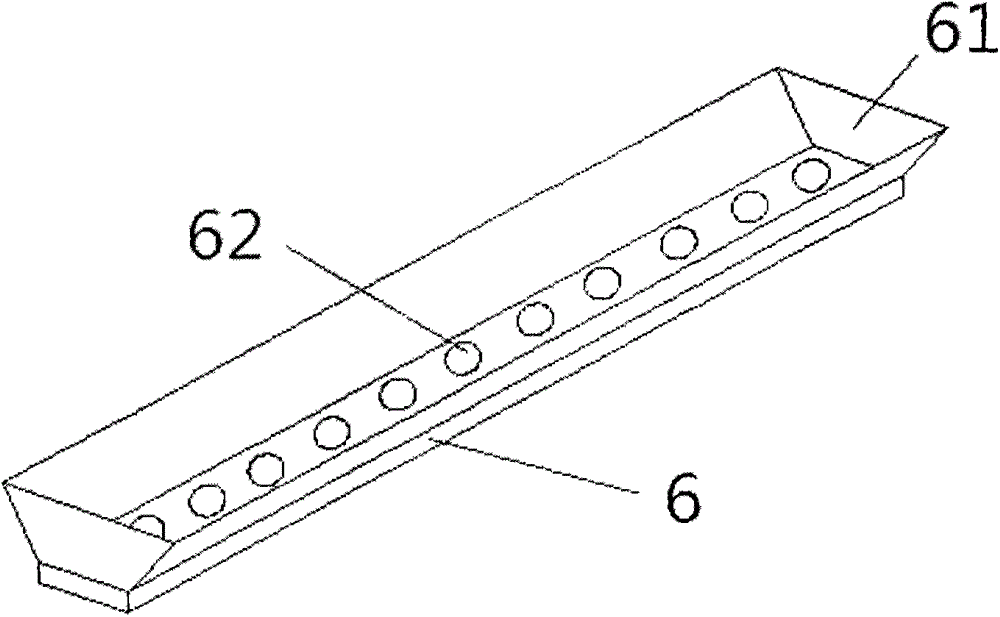

[0010] Figure 1-2 As shown, a corrugated paper printing and drying equipment includes a printing room 1 and a drying room 2. The printing room 1 is provided with a printing roller 3 and a printing plate 4 arranged on the surface of the roller 3; A number of drying lamp groups 6 are provided, and the drying lamp groups 6 are connected by brackets 7; the drying lamp group 6 includes a lampshade 61, and a number of drying lamps 62 are uniformly arranged in the lampshade 61; the printing room 1 and A conveying device 5 is provided in the drying chamber 2 .

[0011] The above is only a preferred embodiment of the present invention, and is not intended to limit the present invention. Although the present invention has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com