Small energy-saving paper brick machine

A paper brick machine, a small technology, applied in the direction of presses, paper product packaging, packaging items, etc., can solve the problems of inconvenient storage and transportation, shorten the service life of tools, and inaccurate packaging, and achieve convenient recycling and great application prospects. , Reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

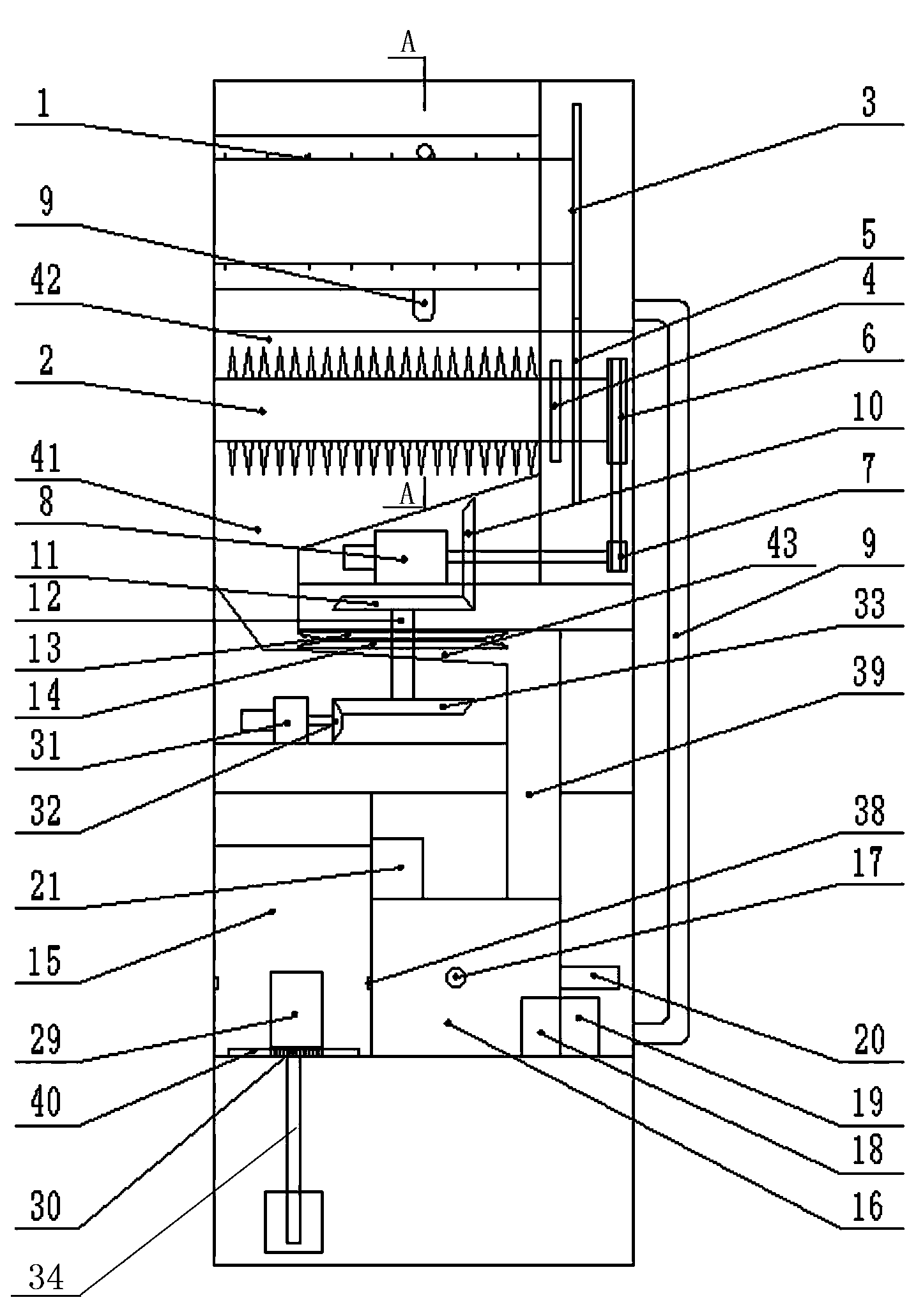

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

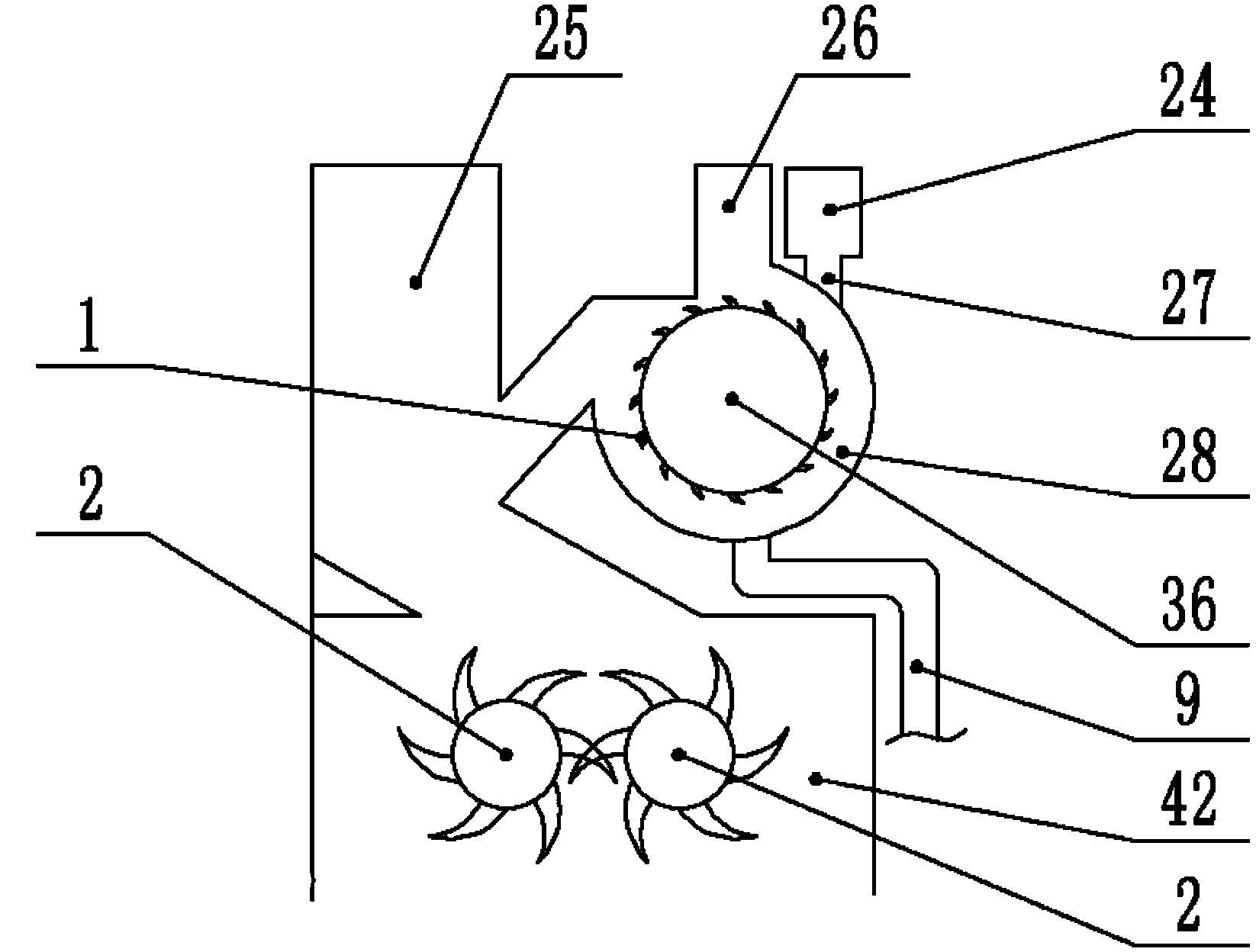

[0019] A small energy-saving paper brick machine, including a shell, such as figure 1 As shown, the top of the housing is provided with a desiccant paper inlet 25, a damp paper inlet 26 and a desiccant bottle 24. The desiccant formula in the desiccant bottle 24 is: the weight ratio of calcium oxide, manganese oxide, and phosphate rock powder 55-65%: 15-20%: 15-20%.

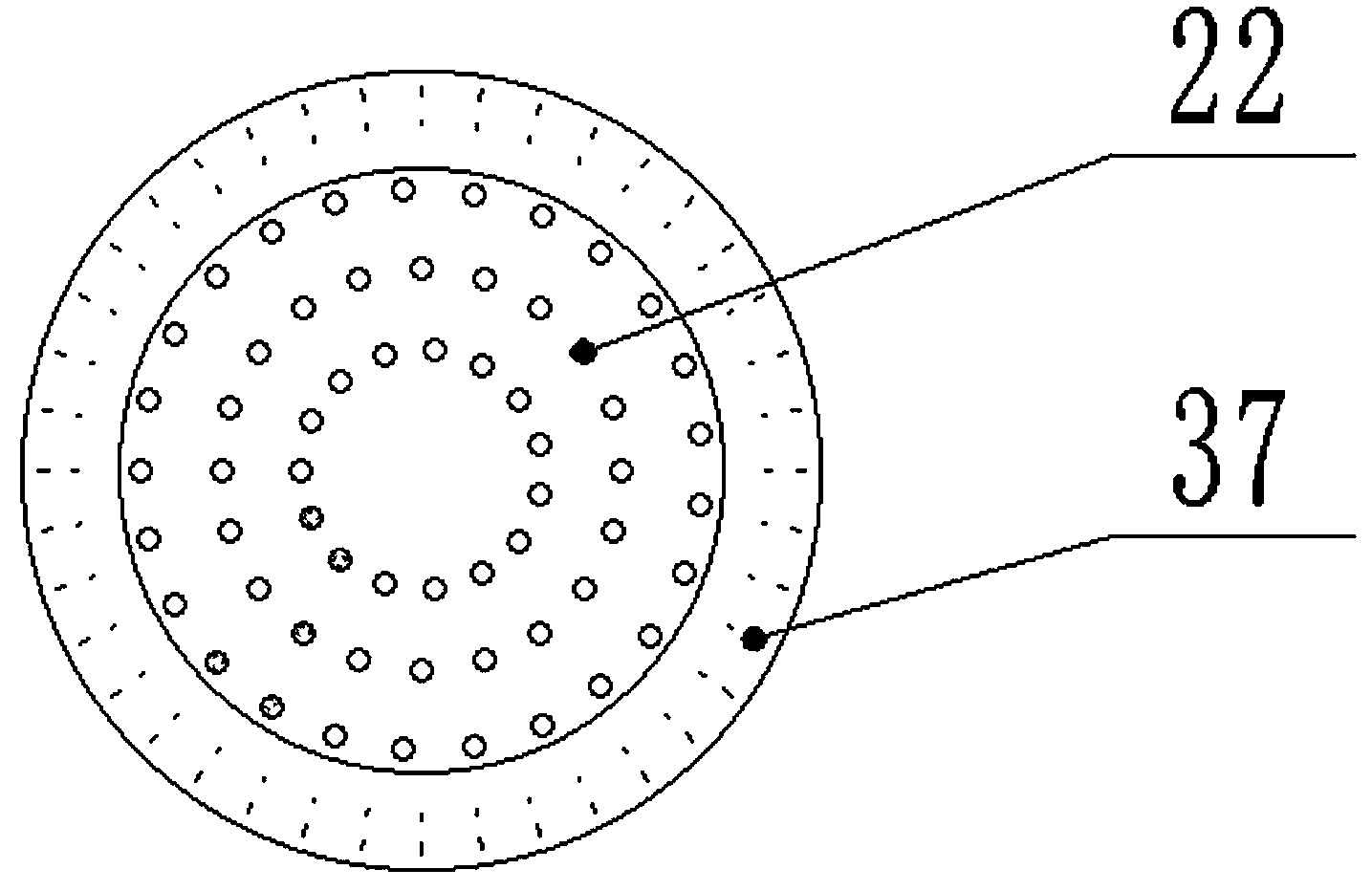

[0020] The drying paper inlet 26 communicates with the drying chamber 28 below it, and the drying medicine bottle 24 communicates with the drying chamber 28 below it through the medicine nozzle 27, and the drying chamber 28 is equipped with a super slow Drying roller 36, the surface of the ultra-slow drying roller 36 is covered with barbs 1 for paper feeding, the drying paper inlet 25 and the paper outlet of the drying chamber 28 are connected with the coarse crushing machine bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com