Natural plant electroplating and finishing technique

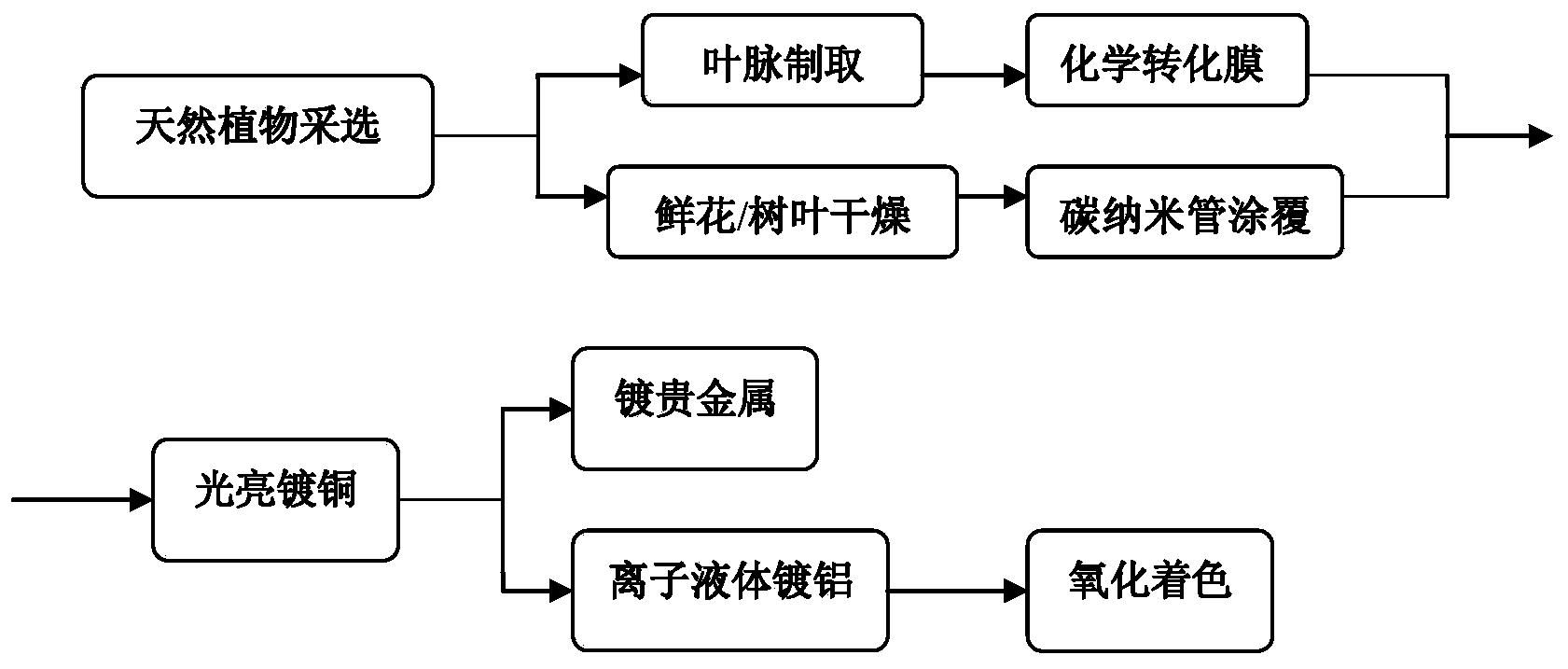

A technology of natural plants and process methods, which is applied to the electroplating and finishing of leaves and leaf veins, and can solve the problems of unsuitable natural plant substrates and harsh conditions for the flower field of plants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A natural plant electroplating fine decoration process method is realized through the following specific steps:

[0029] (1) Select intact and undamaged maple leaves with rich and strong veins that fall naturally in autumn;

[0030] (2) Immersed in a mass fraction of 4% NaOH and 3% Na 2 CO 3 Heat the mixed solution to 100°C and cook for 15 minutes, take it out and brush lightly with a brush to remove the mesophyll, soak in clean water, and absorb excess water with absorbent paper;

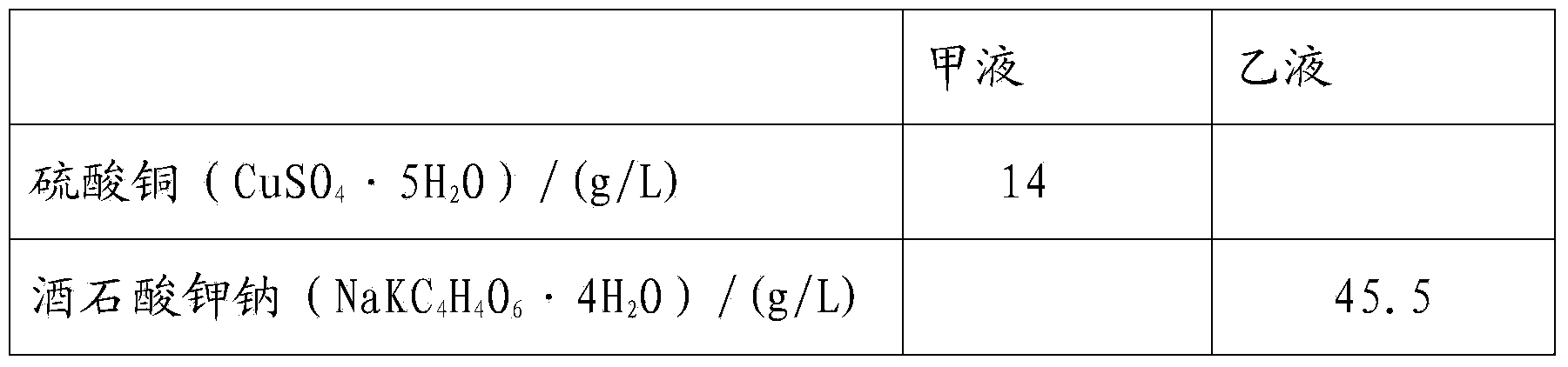

[0031] (3) Then soak the leaf veins in the sensitizing solution for 3 minutes, rinse it in clear water for a few times, then immerse it in the activation solution for 3 minutes, then rinse it in the clear water for a few times, and immerse it in 10% formaldehyde solution for a few times, then Immerse in the pre-prepared electroless copper plating solution, perform electroless copper plating at room temperature, and electroplate for 15-20 minutes;

[0032] (4) After taking out the leaf vei...

Embodiment 2

[0041] A natural plant electroplating fine decoration process method is realized through the following specific steps:

[0042] (1) Take an appropriate amount of clove leaves with smooth surface and beautiful shape;

[0043] (2) Wrap it with soft paper, embed it in a color-changing silica gel specimen bottle, keep it sealed and protected from light at room temperature for 8 days, and then take it out;

[0044] (3) Immerse it in carbon nanotube powder and two-component polyester resin with 20% styrene added to the total mass, and after it is completely coated, bake it in a vacuum drying oven at 60°C for 40 minutes;

[0045] (4) After taking it out, put it into the acidic sulfate bright copper plating solution, and adjust the current density to 6.0A / dm 2 , keep at room temperature, electroplating for 15-20 minutes, take it out and dry it with absorbent paper;

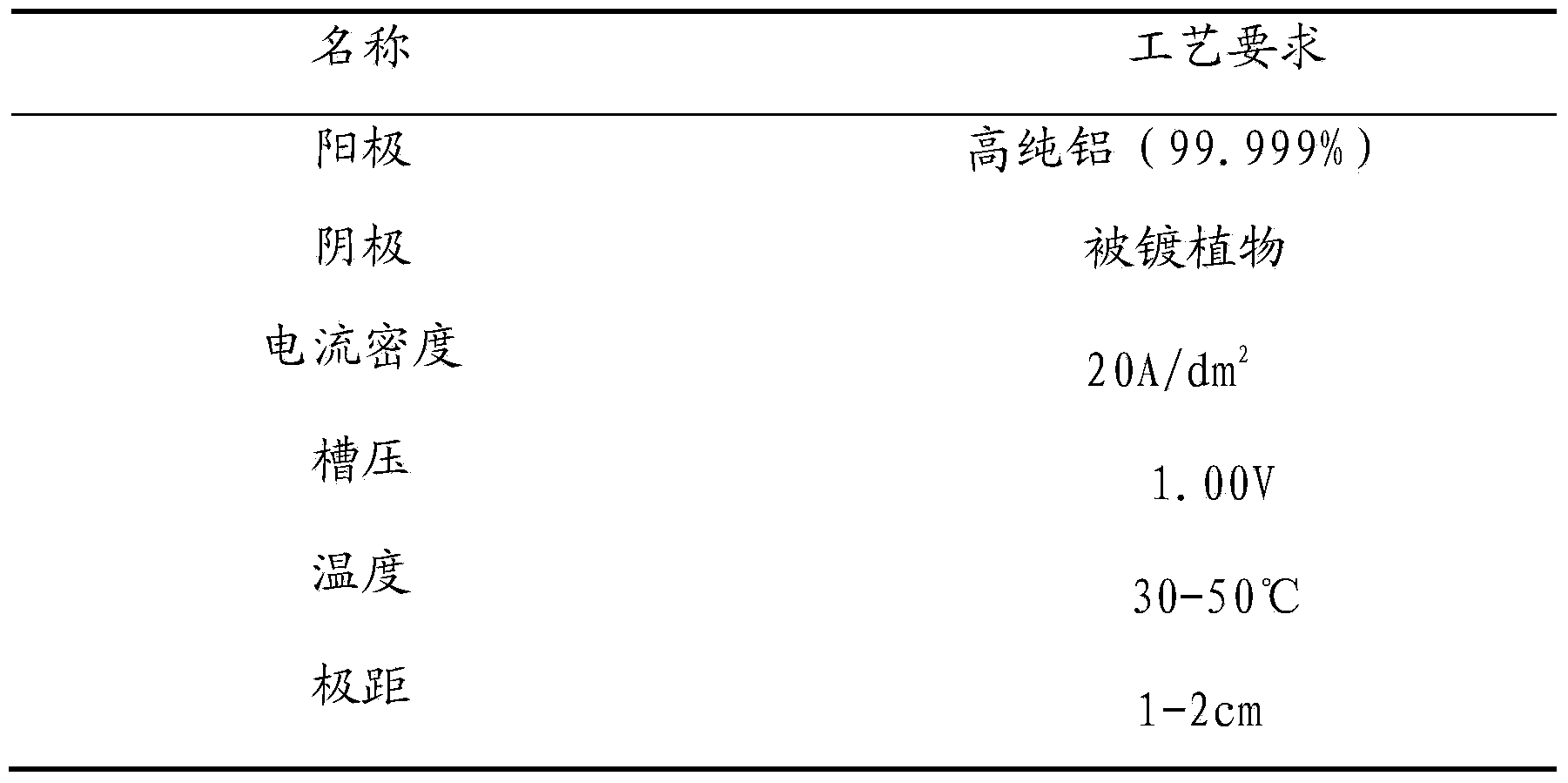

[0046] (5) Dry 1-butyl-3-methylimidazolium chloride ([BMIM]Cl) in a vacuum oven at 60°C with P2O5 as a desiccant for ...

Embodiment 3

[0049] A natural plant electroplating fine decoration process method is realized through the following specific steps:

[0050] (1) Select roses with a moderate number of petals and strong petal hardness;

[0051] (2) Wrap it with soft paper, keep it as it is, embed it in the specimen bottle with color-changing silica gel, seal it, place it at room temperature in the dark for 8 days, and take it out;

[0052] (3) Immerse it in the mixture of carbon nanotube powder and two-component polyester resin with 20% styrene added to the total mass, and after it is completely coated, bake it in a vacuum drying oven at 60°C for 40 minutes;

[0053] (4) After taking it out, put it into the acidic sulfate bright copper plating solution, adjust the current density to 6.0A / dm2, keep it at room temperature, electroplate for 15-20 minutes, take it out and dry it with absorbent paper;

[0054] (5) Put 1-butyl-3 methylimidazolium chloride ([BMIM]Cl) in a vacuum oven at 60°C with P 2 o 5 Dry fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com