Printing head self-adaptive adjustment device and printer thereof

A self-adaptive adjustment and adjustment device technology, applied in power transmission devices, printing, transfer materials, etc., can solve problems such as the difficulty in adjusting the parallelism between the print head and the rubber roller, achieve stable locking, uniform pressure, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

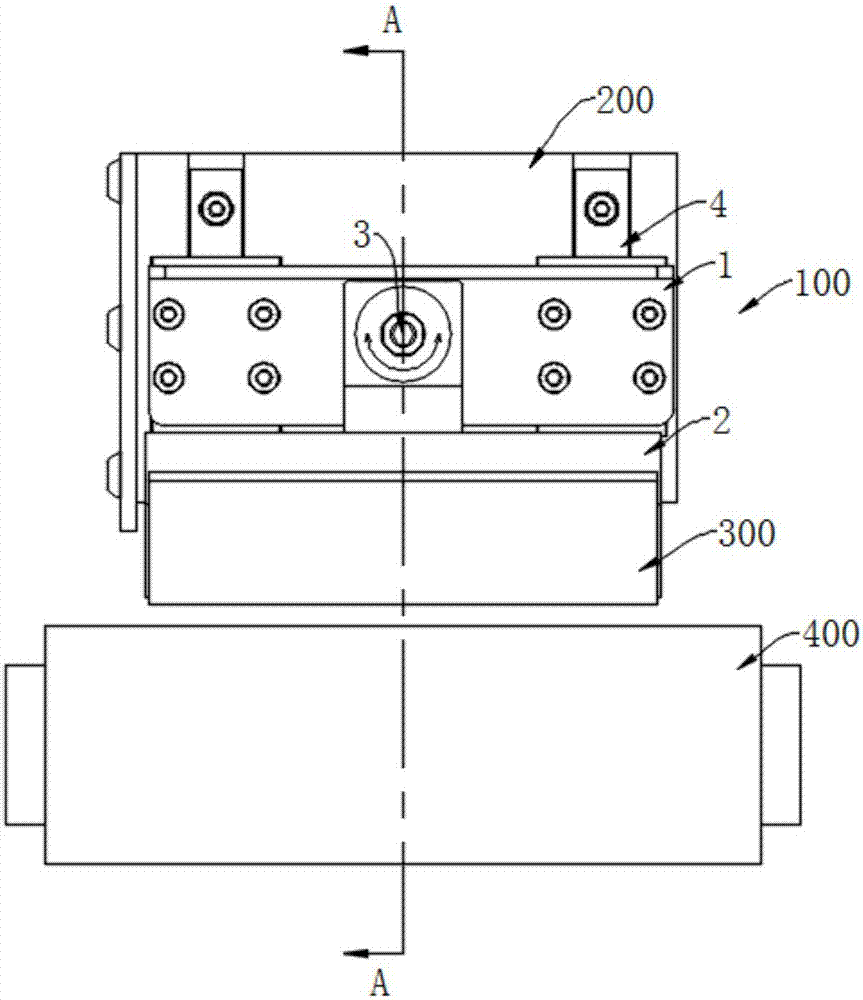

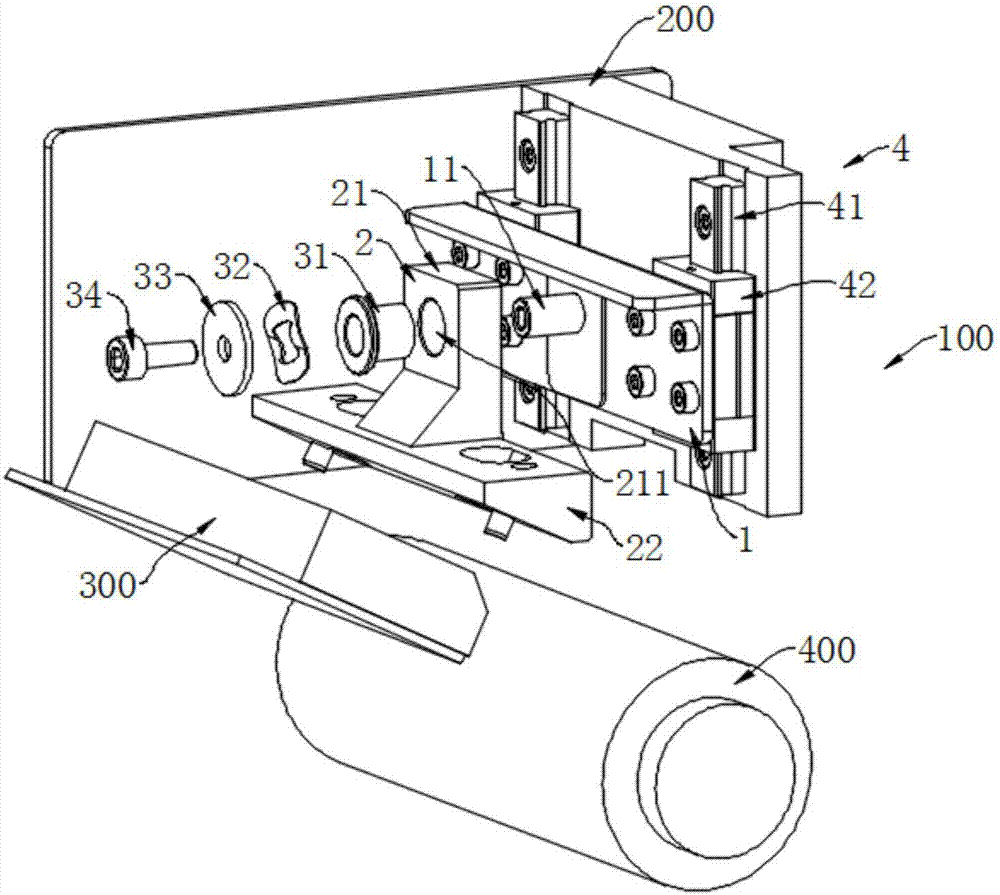

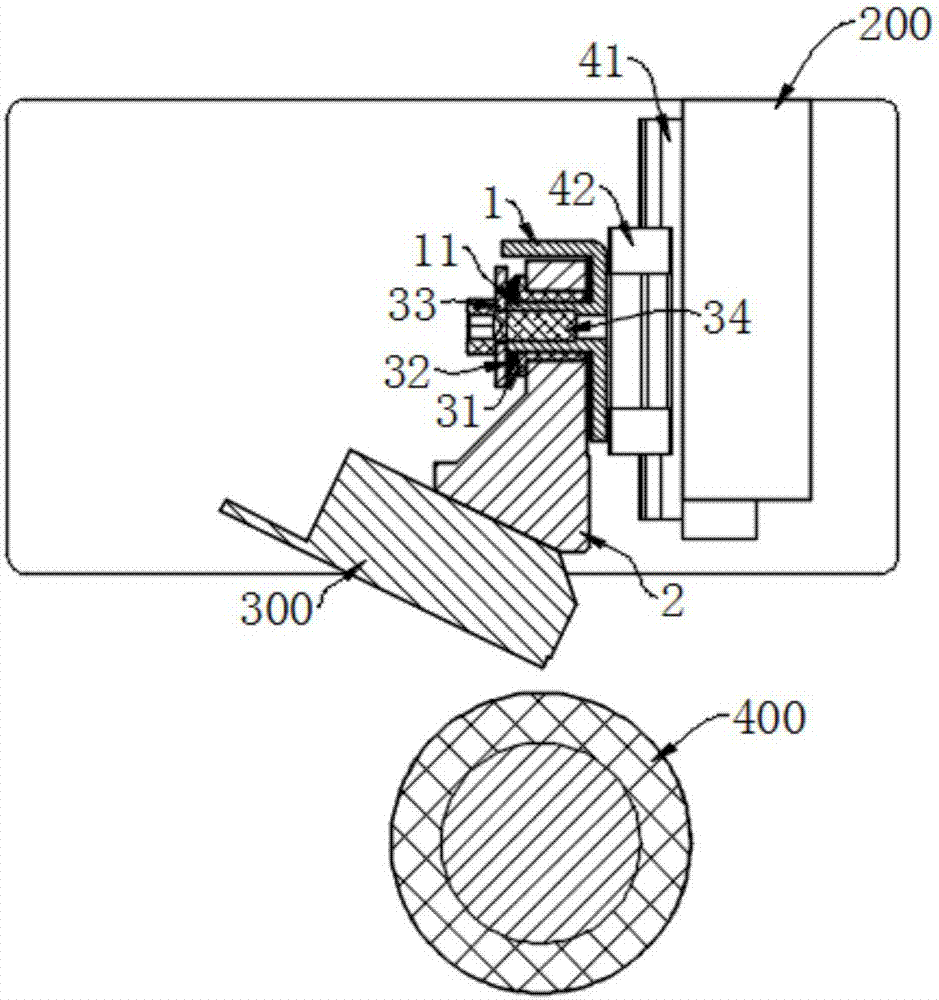

[0035] Reference Figure 1 to Figure 8 As shown, the background and concept of the present invention is: in the printing state, the print head 300 exerts a certain pressure on the rubber roller 400 so that the toner coating on the carbon belt is transferred to the recording medium. Therefore, when the print head 300 and the rubber roller 400 are arranged in parallel, the pressure of the print head 300 on the contact line with the rubber roller 400 is evenly distributed, which helps to improve the uniformity and consistency of the print marks. In the present invention, by designing the connecting assembly 3 and applying the print head 300 to apply a certain pressure to the rubber roller 400, a torque is generated in the case of unbalanced forces to make the connecting frame 2 rotate, thereby realizing adjustment. It has the advantages of automatic, adaptive, and real-time adjustment.

[0036] The adjusting device 100 includes a fixing frame 1, a connecting frame 2 and a connecting...

Embodiment 2

[0048] Reference Figure 1 to Figure 8 As shown, the printer uses the adjustment device 100 in Embodiment 1. The printer further includes a printer base 200, a print head 300, and a rubber roller 400. The adjustment device 100 is set on the printer base 200 via a fixed frame 1. Above, the print head 300 is fixed on the connecting frame 2, and in the printing state, the print head 300 and the rubber roller 400 are in line contact. The print head 300 can linearly reciprocate relative to the rubber roller 400. The recording medium passes through the gap between the print head 300 and the rubber roller 400. The print head 300 presses the carbon ribbon against the recording medium, and the toner on the carbon ribbon is heated. The coating transfer is printed on the recording medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com