Low-aliquation high-speed steel roll and the preparing method

A high-speed steel and roll technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of reducing the mechanical properties and wear resistance of rolls, loose rolls, etc., and achieve good bonding, reduced hardness drop, and production technology. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

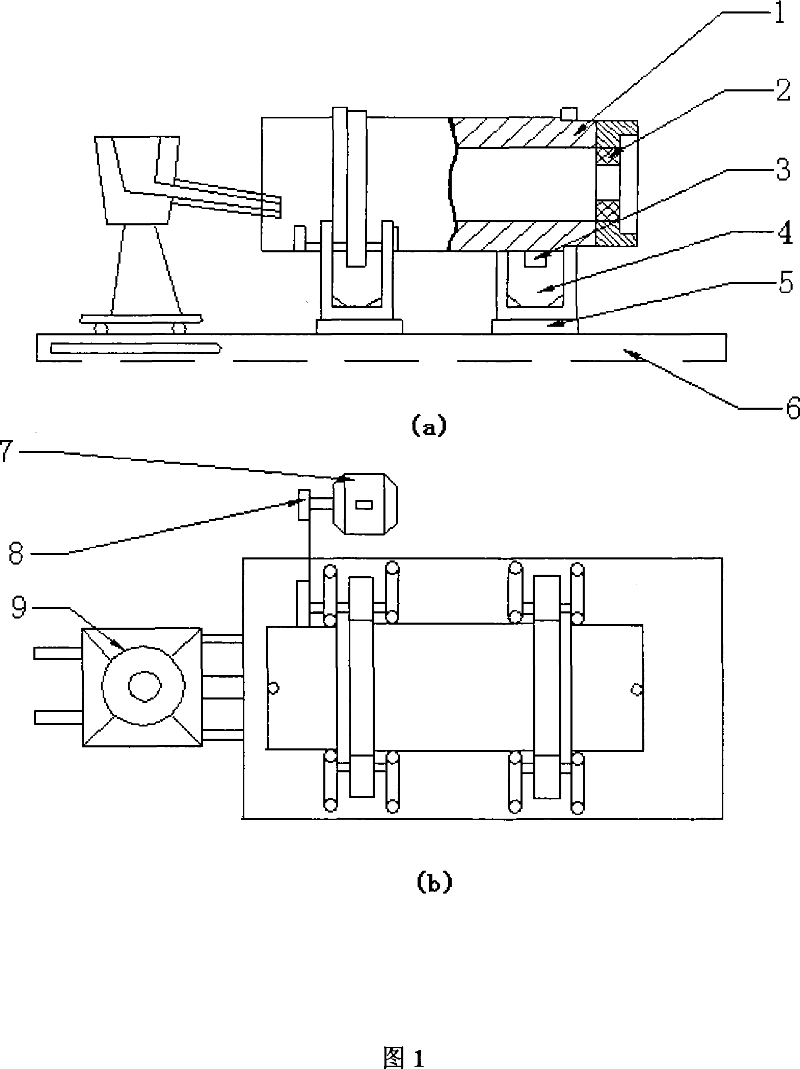

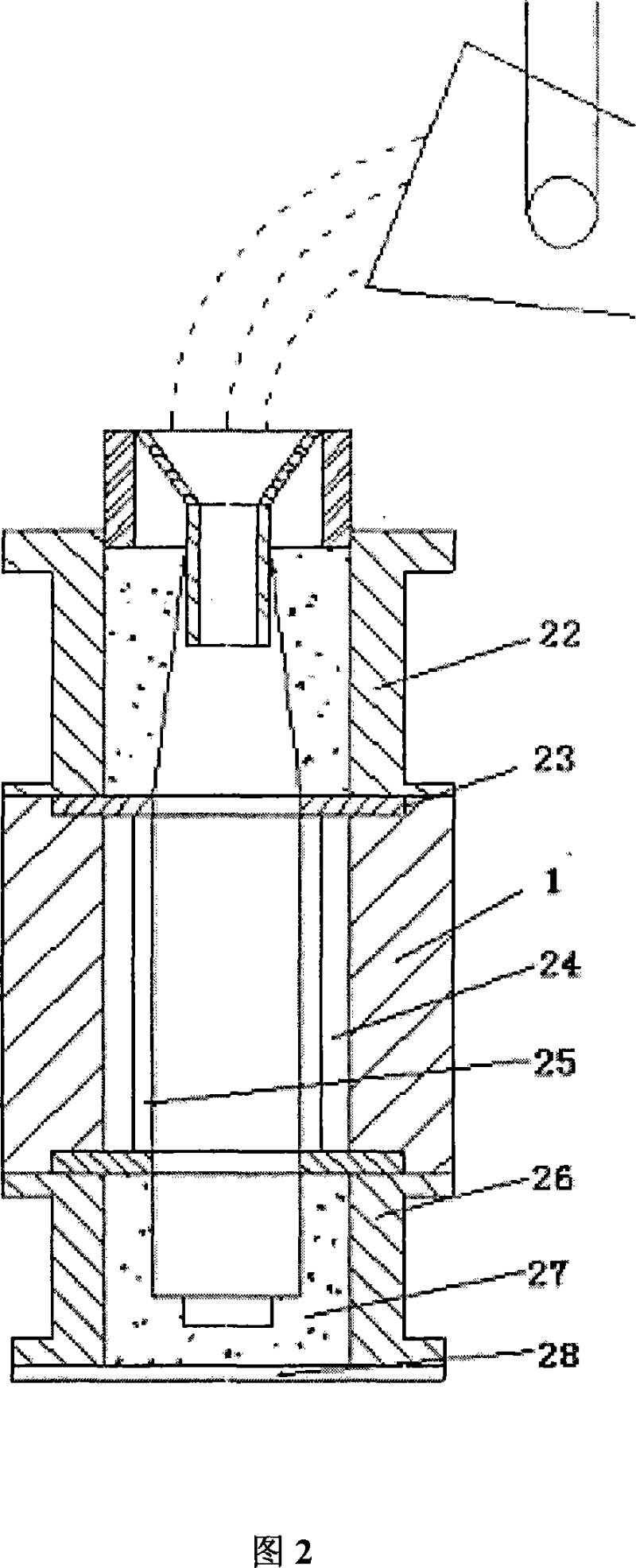

[0040] The high-speed steel roll of this embodiment is cast by a horizontal centrifuge. The outer diameter of the roll body is 650 mm, the thickness of the roll body is 60 mm, the length of the roll body is 800 mm, and the total length of the roll is 2760 mm. The outer layer of high-speed steel is melted in a 1500 kg intermediate frequency induction furnace, and the inner layer of ductile iron is melted in a 5000 kg intermediate frequency induction furnace. The preparation process steps are:

[0041] (1) The smelting process of high-carbon high-speed steel molten steel for rollers is as follows:

[0042] ①Heat and melt ordinary steel scrap, pig iron, ferrochrome, ferromolybdenum, ferrotungsten and metal nickel plate, add ferrosilicon and ferromanganese after molten steel is melted, and add ferrovanadium before it is released from the furnace;

[0043] ② After adjusting the composition before the furnace, the temperature of the molten steel is raised to 1583°C, adding 0.18% of ...

Embodiment 2

[0056] The high-speed steel roll of this embodiment is cast by a horizontal centrifuge. The outer diameter of the roll body is 500 mm, the thickness of the roll body is 55 mm, the length of the roll body is 650 mm, and the total length of the roll is 2510 mm. The outer layer of high-speed steel is melted in an intermediate frequency induction furnace with a capacity of 1000 kg, and the inner layer of ductile iron is melted in an intermediate frequency induction furnace with a capacity of 5000 kg. The preparation process steps are:

[0057] (1) The smelting process of high-carbon high-speed steel molten steel for rollers is as follows:

[0058] ① Mix and heat ordinary steel scrap, recarburizer, ferrochrome, ferromolybdenum, ferrotungsten and metal nickel plate, add ferrosilicon and ferromanganese after molten steel is melted, and add ferrovanadium before it is released from the furnace;

[0059] ② After adjusting the composition before the furnace, the temperature of the molten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com