Automatic waste recovery device with recognition and classification functions

A technology for identifying and sorting and recycling devices, which is applied in the direction of garbage collection, garbage bins, waste collection and transfer, etc. It can solve the problems of waste of resources, pollution of the environment, and inability to separate solids and liquids, and achieve easy recycling and cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

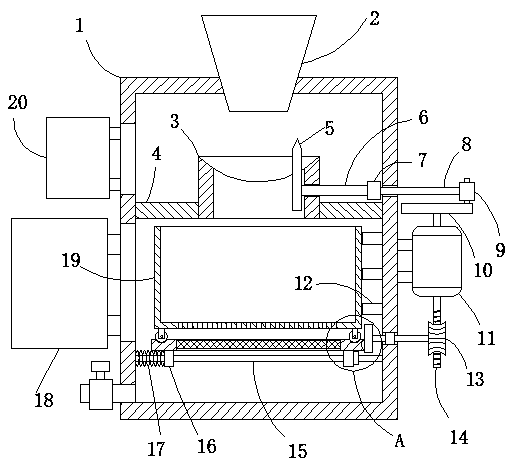

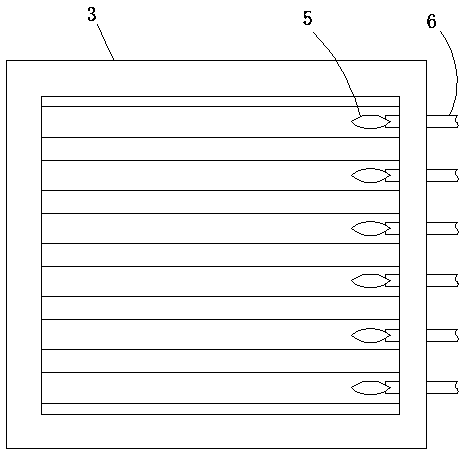

[0024] An automatic garbage recovery device for identification and classification, including a box body 1, a feed hopper 2 and a sensor assembly 26 arranged in the feed hopper 2, and the center of the upper end of the box body 1 passes through the installation opening and the side wall of the feed hopper 2 Fixedly connected, the sensor assembly 26 is fixedly connected with the right inner wall of the feed hopper 2, the left inner wall of the feed hopper 2 is provided with a T-shaped chute 21, and a sealing mechanism is connected inside the T-shaped chute 21, and the box body 1 The interior is fixedly connected with a horizontal plate 4, and the center of the horizontal plate 4 is fixedly connected with a rectangular block 3 through a rectangular through hole. The upper end of the rectangular block 3 is provided with an arc-shaped groove. A plurality of openings are opened between the openings, and the crushing blades 5 are connected to the plurality of openings through a transm...

Embodiment 2

[0026] Embodiment 2: the difference based on Embodiment 1 is;

[0027] The connection mechanism includes two rectangular sliding sleeves 16 that are slidably sleeved on the rectangular rod 15. The upper ends of the two rectangular sliding sleeves 16 are fixedly connected to the lower end of the placement plate 30. The rod wall of the rectangular rod 15 is slidably sleeved with a first Spring 17, one end of the first spring 17 is fixedly connected to one side of one of the rectangular sliding sleeves 16, the other end of the first spring 17 is fixedly connected to the inner wall of the left side of the box body 1, and the right side of the box body 1 is rotationally connected by a rolling bearing There is a rotating shaft, one end of the rotating shaft passes through the first rolling bearing and is fixedly connected with a turntable 28, one side of the turntable 28 is fixedly connected with a hemispherical bump 29, one side of the bump 29 is in contact with the right end of the...

Embodiment 3

[0029] Embodiment 3: the difference based on embodiment 1 is;

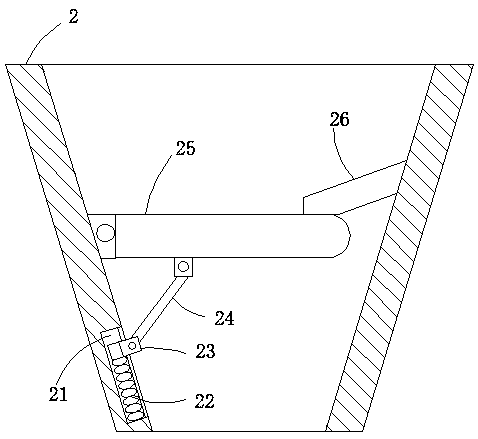

[0030] The sealing mechanism includes a sealing plate 25 arranged in the feed hopper 2, the left end of the sealing plate 25 is hinged with the left inner wall of the feed hopper 2 through a third hinge, and the upper right side of the sealing plate 25 is connected with the housing of the sensor assembly 26 Contact connection, the lower end of the sealing plate 25 is connected with the support rod 24 through the rotation of the pin, and the end of the support rod 24 away from the sealing plate 25 is connected with the T-shaped slider 23 through the rotating shaft, and the T-shaped slider 23 slides with the T-shaped chute 21 connection, the T-shaped chute 21 is provided with a second spring 22, one end of the second spring 22 is fixedly connected to one side of the T-shaped chute 21, and the other end of the second spring 22 is fixed to one side of the T-shaped slider 23 connect.

[0031] The present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com