Range hood unsusceptible to residing oil stain on filter device

The technology of a range hood and filter device is applied in the directions of removing oil fume, dispersing particle filtration, and increasing household heat, which can solve the problems of increasing the wind resistance of the fan, increasing the air volume of the fan, and reducing the residual oil pollution, and achieves the effect of expanding the area and improving the oil filter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

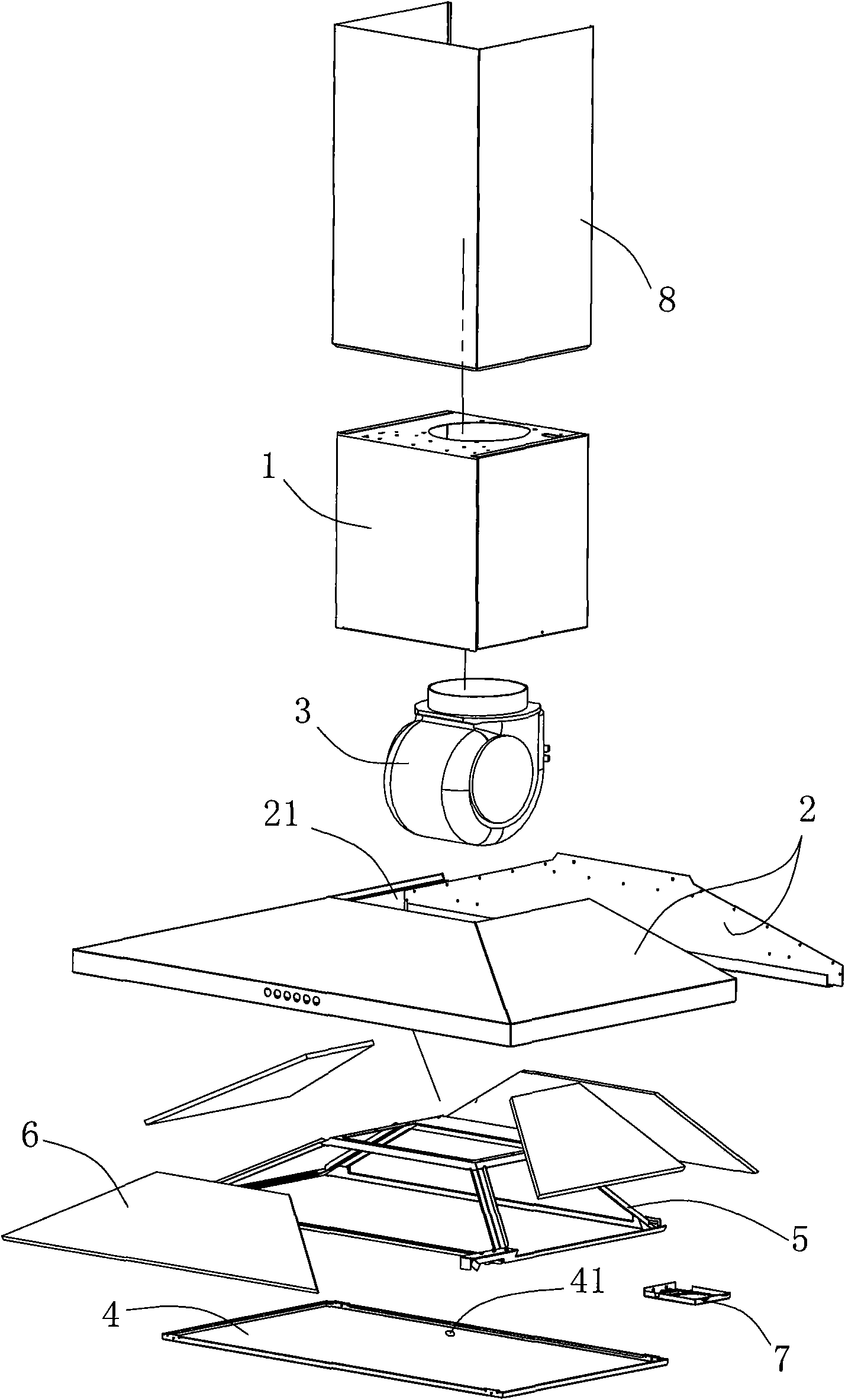

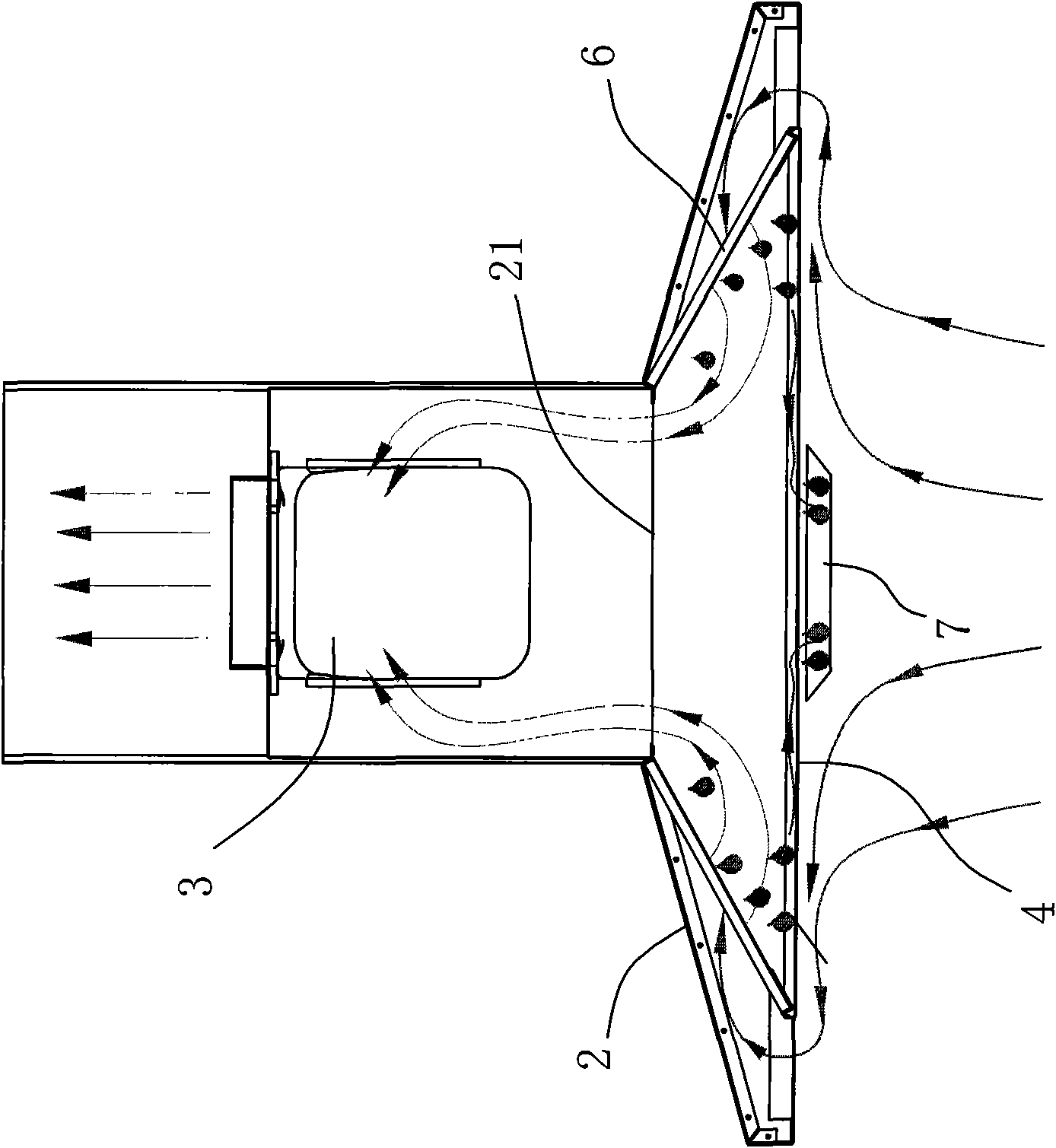

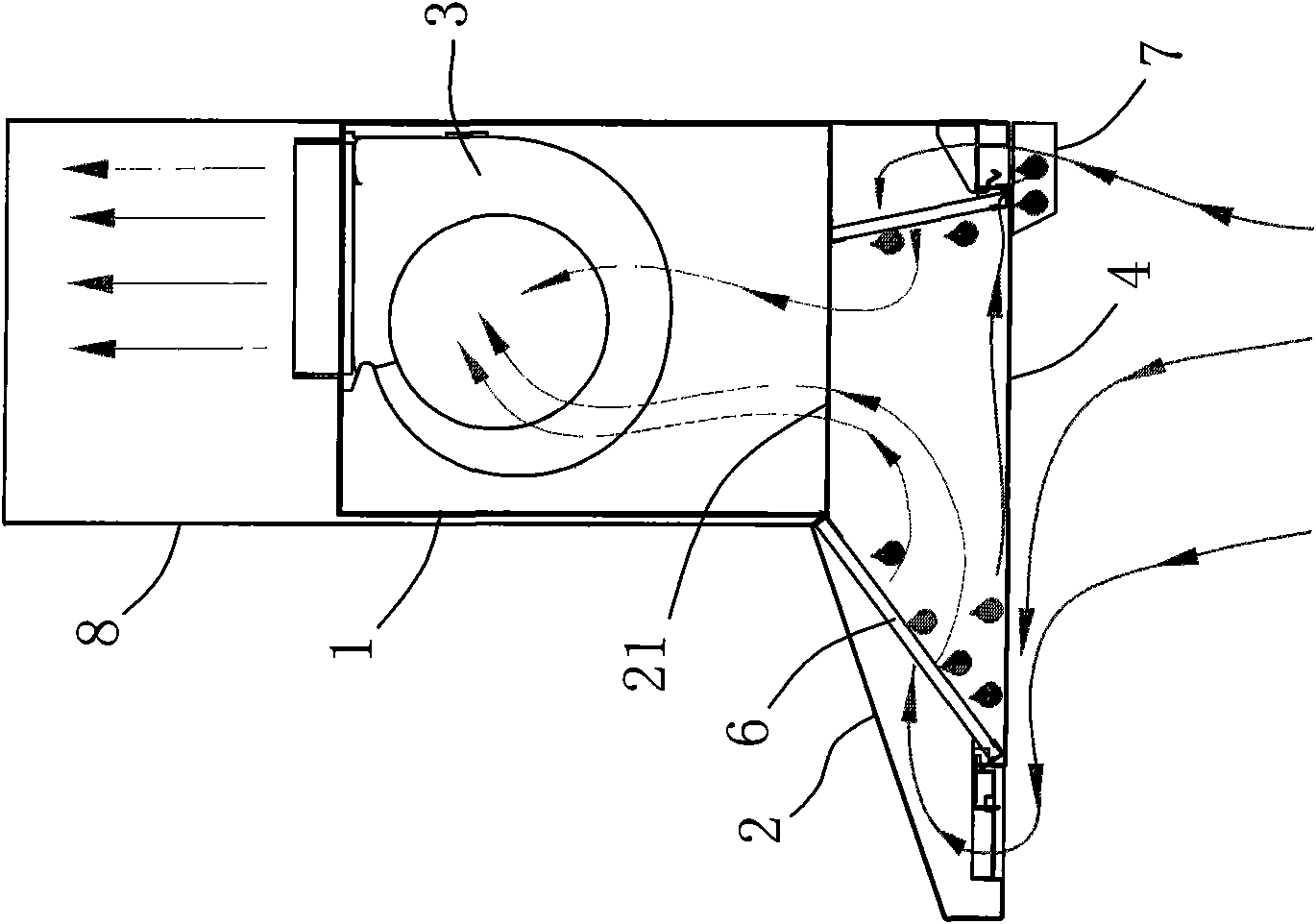

[0026] Such as Figure 1 ~ Figure 4 As shown, the range hood in this embodiment is not easy to leave oil stains on the filter device, including a fan body 1, a decorative shell 8 covering the outside of the body, and a smoke collecting hood 2 located directly below the body 1 and perpendicular to it. There is a fan volute 3, and the impeller and the motor driving the impeller are installed in the volute 3 (the impeller and the motor are not shown in the figure), and the smoke collecting hood 2 is provided with an air inlet 21 that is convenient for the oil fume to enter the inner cavity of the volute 3. The bottom of the air inlet 21 is provided with an oil deflector 4 with a predetermined distance from the end face of the air inlet of the fume collecting hood 2 , and an oil fume filter device in the shape of a small upper part and a larger bottom is arranged between the air inlet 21 and the oil guide plate 4 .

[0027] The oil fume filtering device includes a filter screen fr...

Embodiment 2

[0030] Such as Figure 5 As shown, the present embodiment is basically the same as the first embodiment, the only difference being that the oil fume filtering device is a frustum-shaped filter screen 8 with sufficient rigidity.

Embodiment

[0032] Such as Figure 6 As shown, the present embodiment is basically the same as the first embodiment, the only difference being that the oil fume filtering device is a combined filter screen in the shape of a sloping roof formed by butting two filter screens 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com