Continuous smooth cold press machine

A cold press and smooth technology, applied in the field of cold presses, can solve the problems of practicability to be improved, poor continuity, inability to perform efficient gluing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

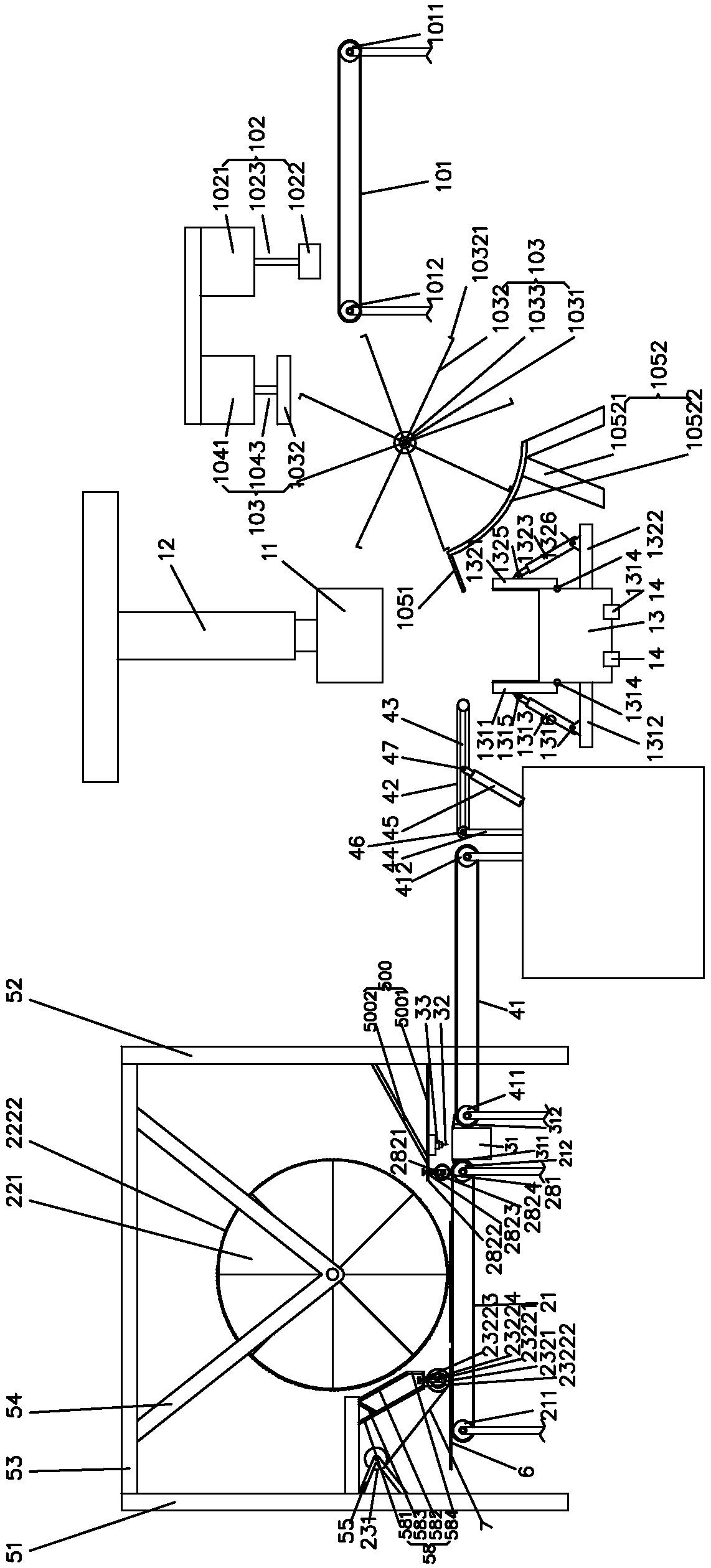

[0050] In order to further explain the technical solution of the present invention, specific embodiments are used to describe in detail below.

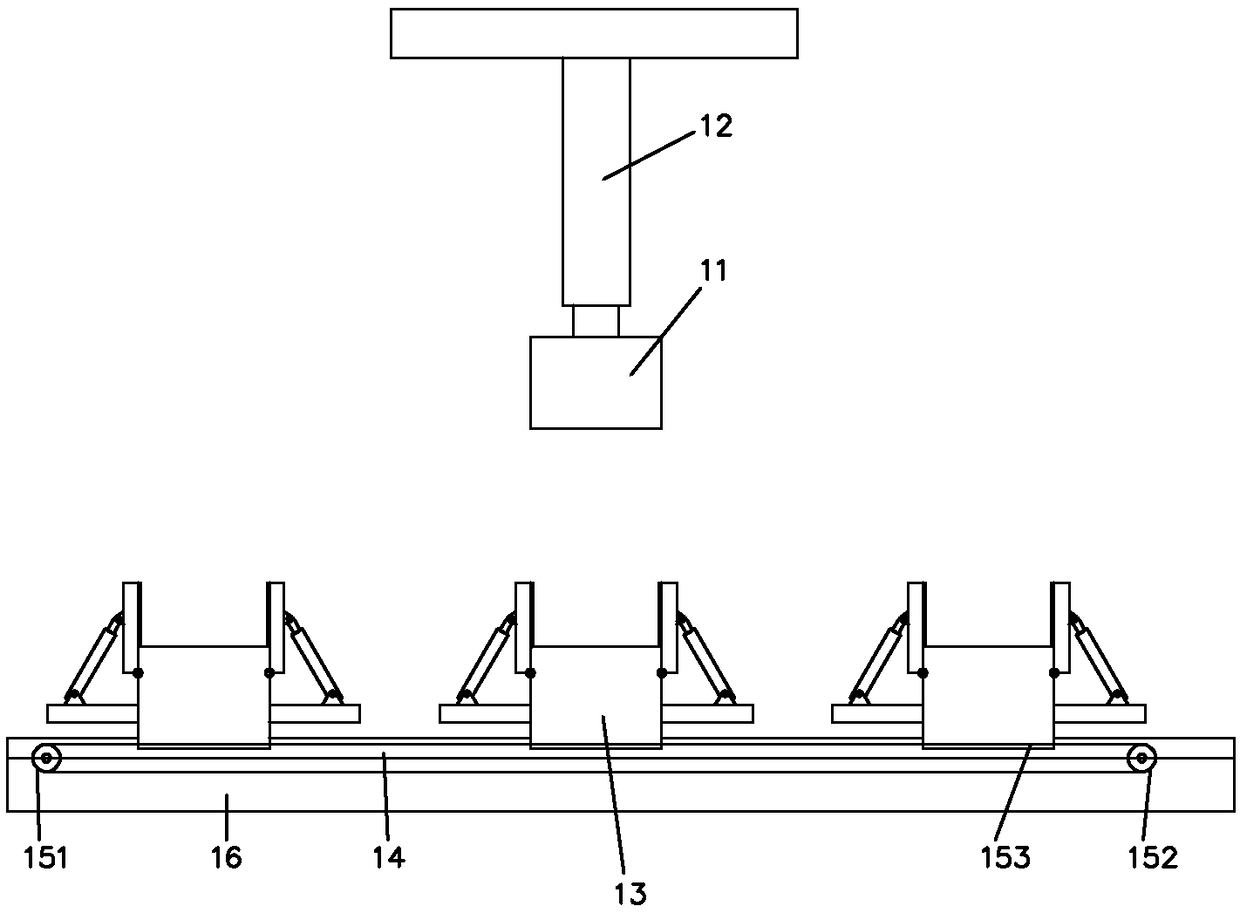

[0051] A continuous and smooth cold press of the present invention, such as Figure 1-5 As shown, it includes the cold press forming production line 1, the glue brushing production line 2 that supplies the cold press forming production line 1 with brushing template blocks, and the supply production line for the cold forming production line 1 to transport the partition and the uppermost template blank 6 Section 10; Preferably, the present invention also includes a general controller for controlling the cold forming production line section 1, the glue brushing production line section 2, and the glue brushing production line section 2; preferably, the cold forming production line section 1 is in the glue brushing production line section 2 and the supply production line segment 10, and the extension directions of the glue-brushing production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com