Wall coating roller brush

A roller brush and paint technology, which is applied in the direction of architecture and building construction, can solve the problems of brushing sagging and paint dripping easily, and achieve the effect of uniform brushing and not easy dripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

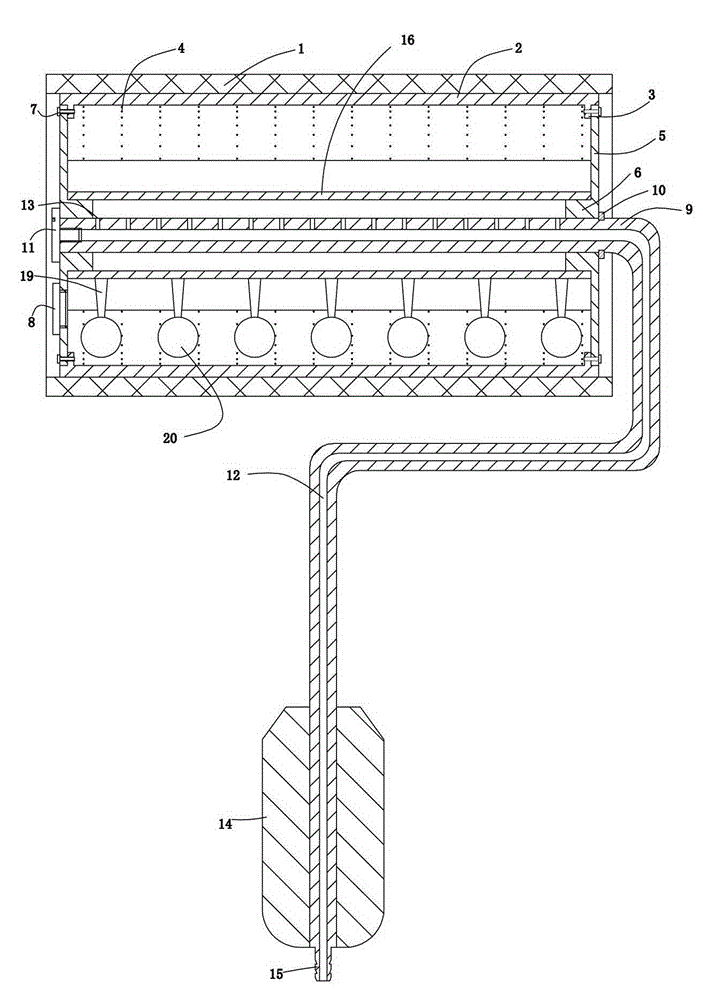

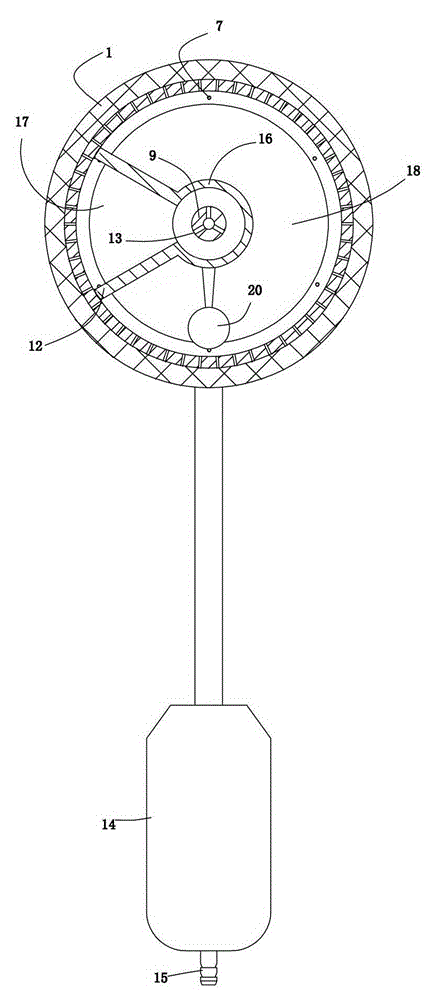

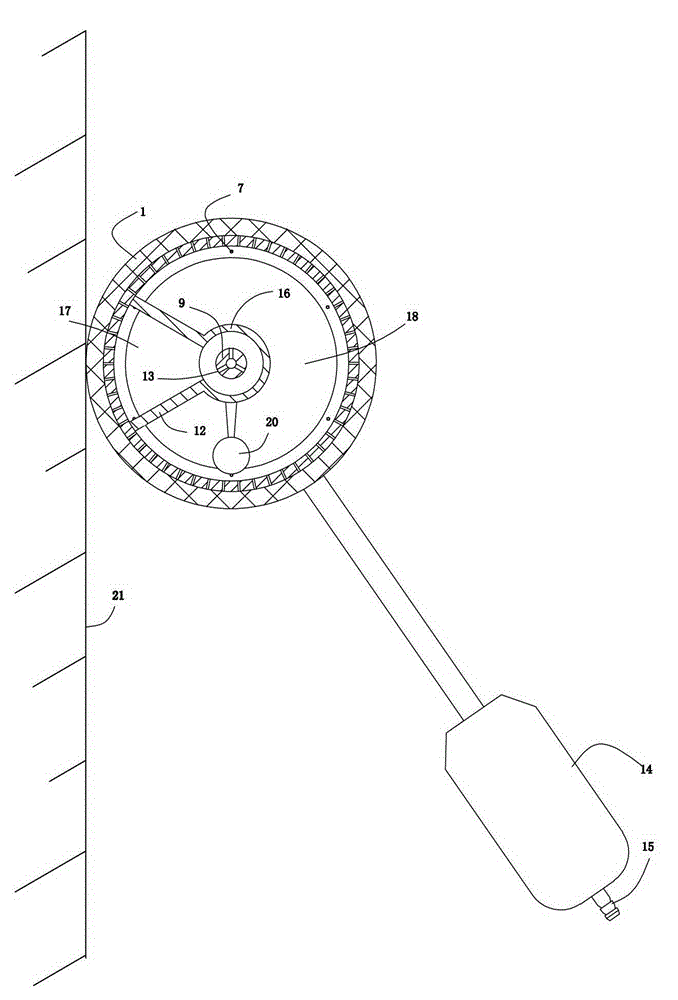

Embodiment 1

[0015] in the attached figure 1 , attached figure 2 In the shown embodiment 1, it includes a brush cylinder, a central shaft and a handle. The brush cylinder 1 is provided with a cylinder 2, the cylinder 2 is provided with a material storage cavity 18, and the two ends of the cylinder 2 inner wall are provided with belt mountings. The fixed ring 3 of the screw hole, the cylinder wall of the drum 2 is densely covered with through discharge holes 4, the outer side of the fixed ring 3 is provided with an end cover 5, the center of the end cover 5 is provided with a shaft hole, and the end surface of the end cover 5 Corresponding to the material storage cavity 18, there is a feed hole and a suitable feed hole cover 8. The central shaft 9 is a hollow shaft, and one end of the central shaft 9 is arranged in the shaft hole of the end cover 5. The central shaft 9 The end face on one side of the end cover 5 is provided with a limit screw 11, the central axis 9 is located on the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com