Self-lubrication device for conveying production line

An automatic lubrication and production line technology, applied in cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of contaminated conveyor chains, unreasonable installation positions of dry lubricating devices, and inability to remove them well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

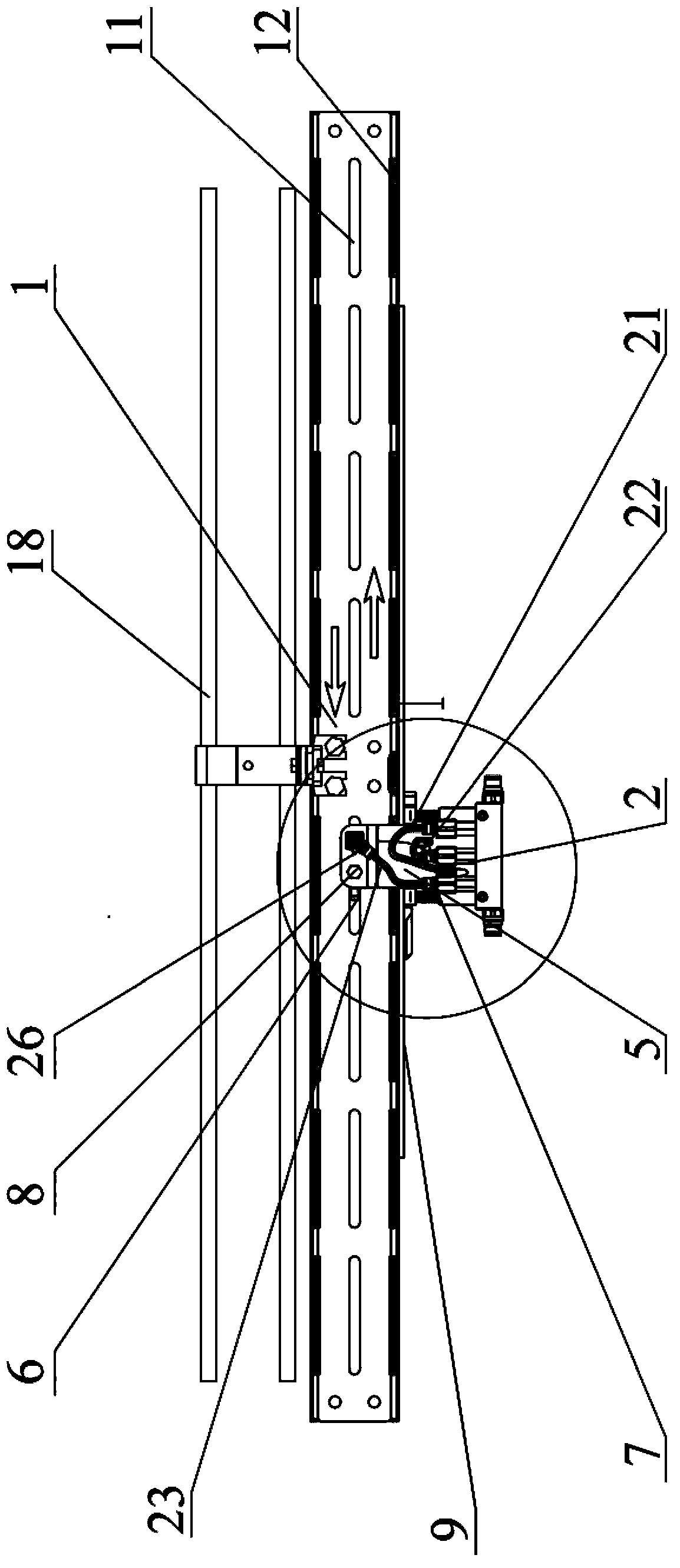

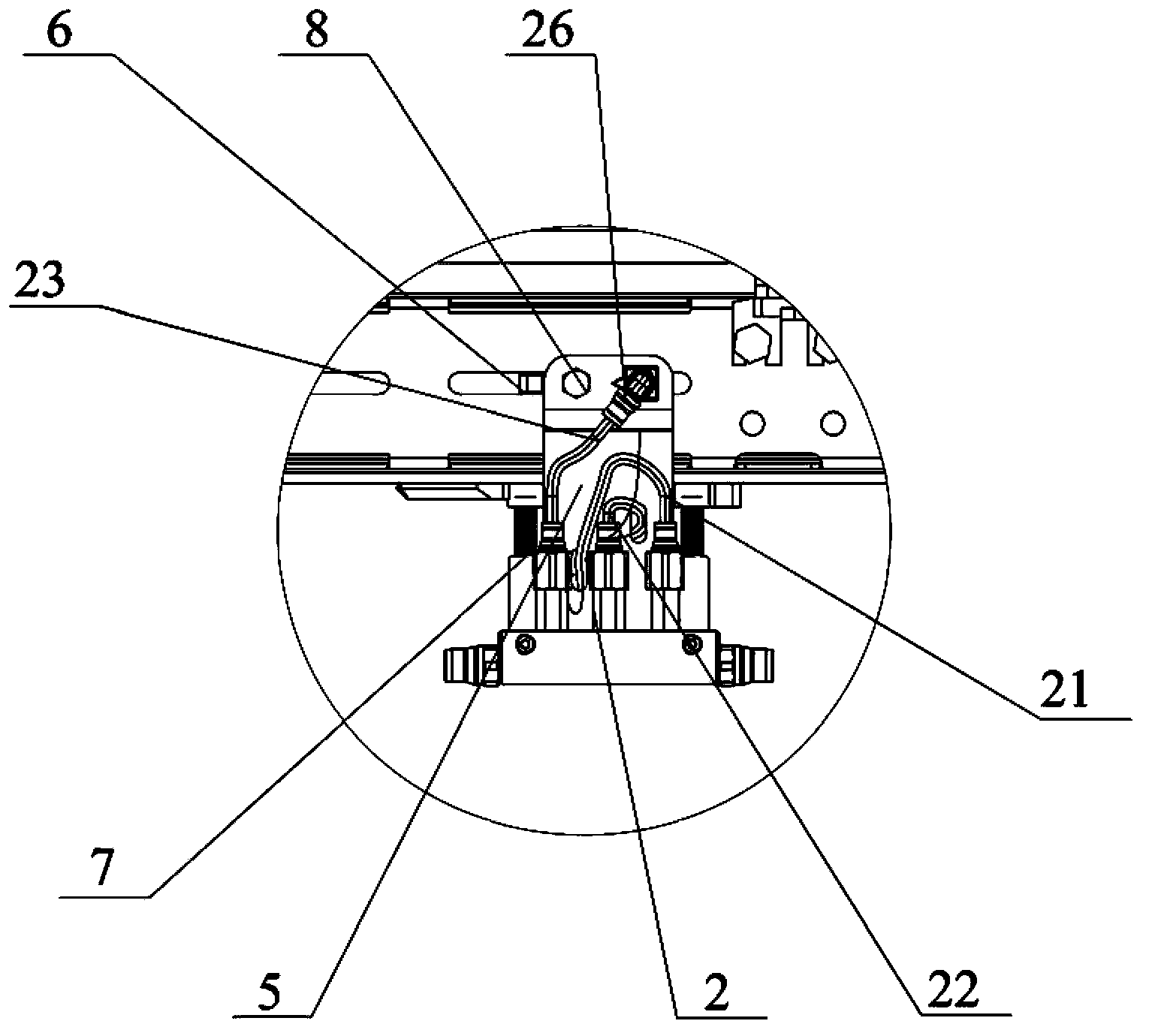

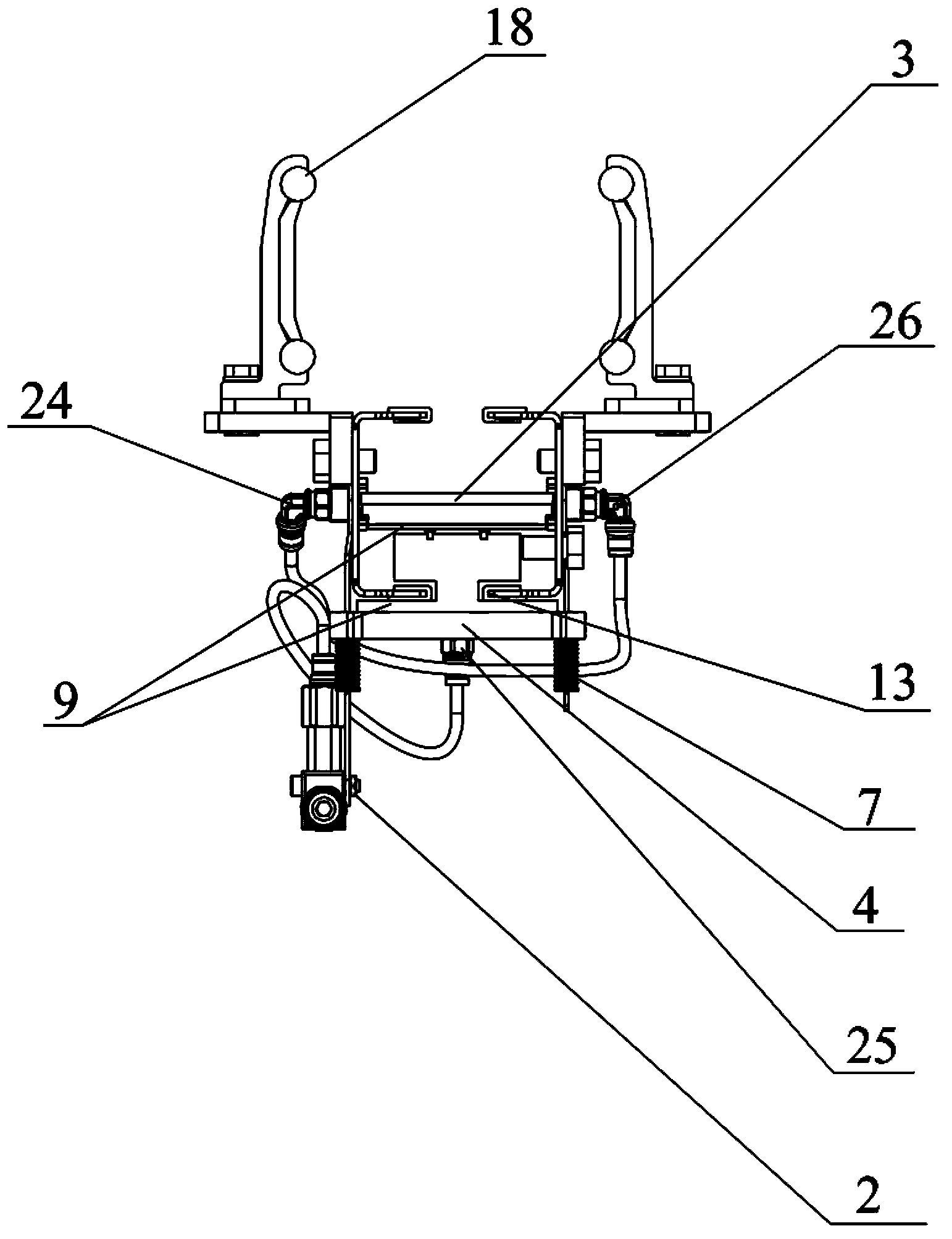

[0065] The present invention will be described in detail below in conjunction with the accompanying drawings, and the related embodiments are described in the form of description. Therefore, all terms are only for better description and illustration, and should not be construed as any limitation to the present invention.

[0066] The main content of the present invention is to provide an automatic lubricating device for the conveying production line. The lubricating device can be directly installed and fixed on the existing frame of the production line to perform single-sided or Double-sided as well as single or multi-point lubrication. The lubricating device includes a lubricant supply mechanism, a lubricating mechanism and a fixing mechanism; among them, according to requirements, the lubricating mechanism can use a separate top lubricating mechanism or a bottom lubricating mechanism to realize single-sided lubrication of the conveyor chain; preferably, a combined setting can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com