Lubricating grease composition for gears of electric shovel and preparation method thereof

A technology of gear grease and composition, applied in the field of grease, can solve the problems of large environmental temperature difference, scouring by rain and snow, many dust impurities, etc., and achieve the effects of prolonging the grease changing period, saving energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

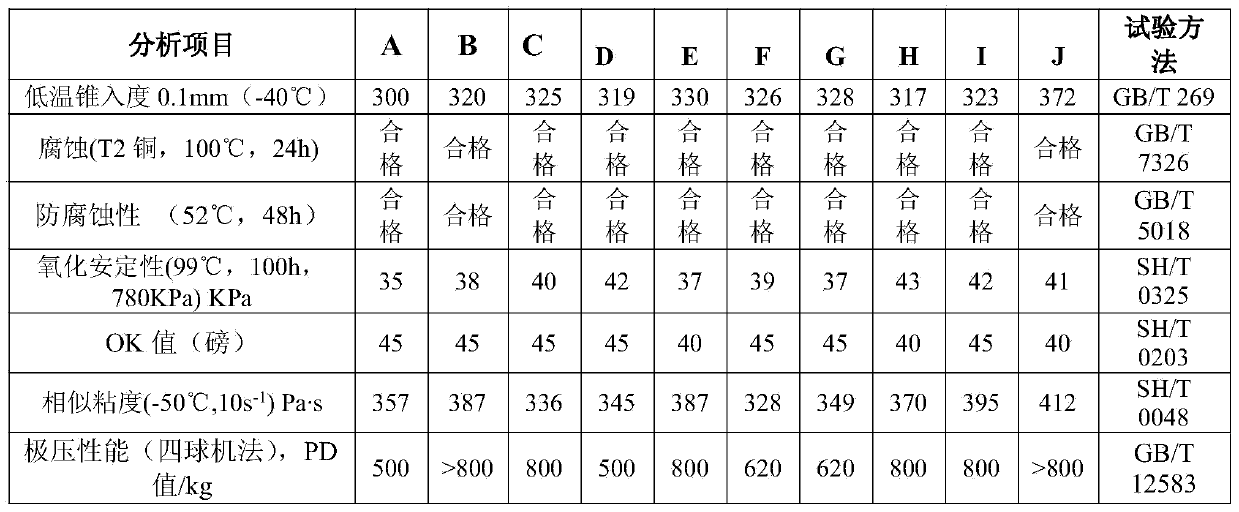

Examples

Embodiment 1

[0030] Base oil: 73.7%;

[0031] Thickener: 18.1%;

[0032] Additives: 8.2%;

[0033] Quality Total: 100%

[0034] Wherein the thickener is:

[0035] 12-Hydroxystearic acid: 14.1%

[0036] Adipic acid: 1.3%

[0037] Salicylic Acid: 2.7%

[0038] The additives are:

[0039] Polyacrylic acid: 3.8%;

[0040] Extreme pressure agent (molybdenum disulfide, graphite, A): 1.9%;

[0041] Rust inhibitor (sorbitol monooleate): 1.0%;

[0042] Repair agent (nano-silver powder and nano-zinc oxide): 1.0%;

[0043] Antioxidant (phenothiazine): 0.5%;

[0044] Add 14.1% 12-hydroxystearic acid, 2.7% salicylic acid and 3.8% polyacrylic acid to 73.7% base oil by mass, mix and heat to 60-90°C , add lithium hydroxide monohydrate saponification composite of 1.3% adipic acid in parts by mass for 1.5-2 hours; heat up to 185-190°C in 2 hours, keep the temperature constant for 1.5 hours; continue to heat up to 220-240°C, and then naturally Cool down to below 120°C, add extreme pressure agen...

Embodiment 2

[0046] Base oil: 50%;

[0047] Thickener: 25%;

[0048] Additives: 25%;

[0049] Quality Total: 100%

[0050] Wherein the thickener is:

[0051] 12-Hydroxystearic acid: 20.3%

[0052] Adipic acid: 1.3%

[0053] Salicylic Acid: 3.4%

[0054] The additives are:

[0055] Polyacrylic acid: 8.0%;

[0056] Extreme pressure agent (molybdenum disulfide, graphite, A): 5.0%;

[0057] Rust inhibitor (sorbitol monooleate): 5.0%;

[0058] Repair agent (nano-silver powder and nano-zinc oxide): 5.0%;

[0059] Antioxidant (phenothiazine): 2.0%.

[0060] Add 20.3% 12-hydroxystearic acid, 3.4% salicylic acid and 8.0% polyacrylic acid to 50% base oil, mix and heat to 60-90°C , add lithium hydroxide monohydrate saponification composite of 1.3% adipic acid in parts by mass for 1.5-2 hours; heat up to 185-190°C in 2 hours, keep the temperature constant for 1.5 hours; continue to heat up to 220-240°C, and then naturally Cool down to below 120°C, add extreme pressure agents (molybdenum di...

Embodiment 3

[0062] Base oil: 84%;

[0063] Thickener: 8%;

[0064] Additives: 8%;

[0065] Quality Total: 100%

[0066] Wherein the thickener is:

[0067] 12-Hydroxystearic acid: 5.9%

[0068] Adipic acid: 0.6%

[0069] Salicylic Acid: 1.5%

[0070] The additives are:

[0071] Polyacrylic acid: 3.0%;

[0072] Extreme pressure agent (molybdenum disulfide, graphite, A): 1.0%;

[0073] Rust inhibitor (sorbitol monooleate): 1.0%;

[0074] Repair agent (nano-silver powder and nano-zinc oxide): 1.0%;

[0075] Antioxidant (phenothiazine): 2.0%.

[0076] Add 5.9% 12-hydroxystearic acid, 1.5% salicylic acid and 3.0% polyacrylic acid to 84% base oil by mass, mix and heat to 60-90°C , add the lithium hydroxide monohydrate saponification compound that the mass fraction is 0.6% adipic acid 1.5~2 hours; Take 2 hours to heat up to 185~190 ℃, this temperature is kept at a constant temperature for 1.5 hours; Continue to heat up to 220~240 ℃, and then naturally Cool down to below 120°C, add e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com