Power transmission device

A power transmission device and linkage technology, which is applied in the direction of gear lubrication/cooling, can solve the problems of slowing down speed, inability to effectively reduce stirring resistance, inability to obtain sufficient lubrication, etc., and achieve the effect of improving mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

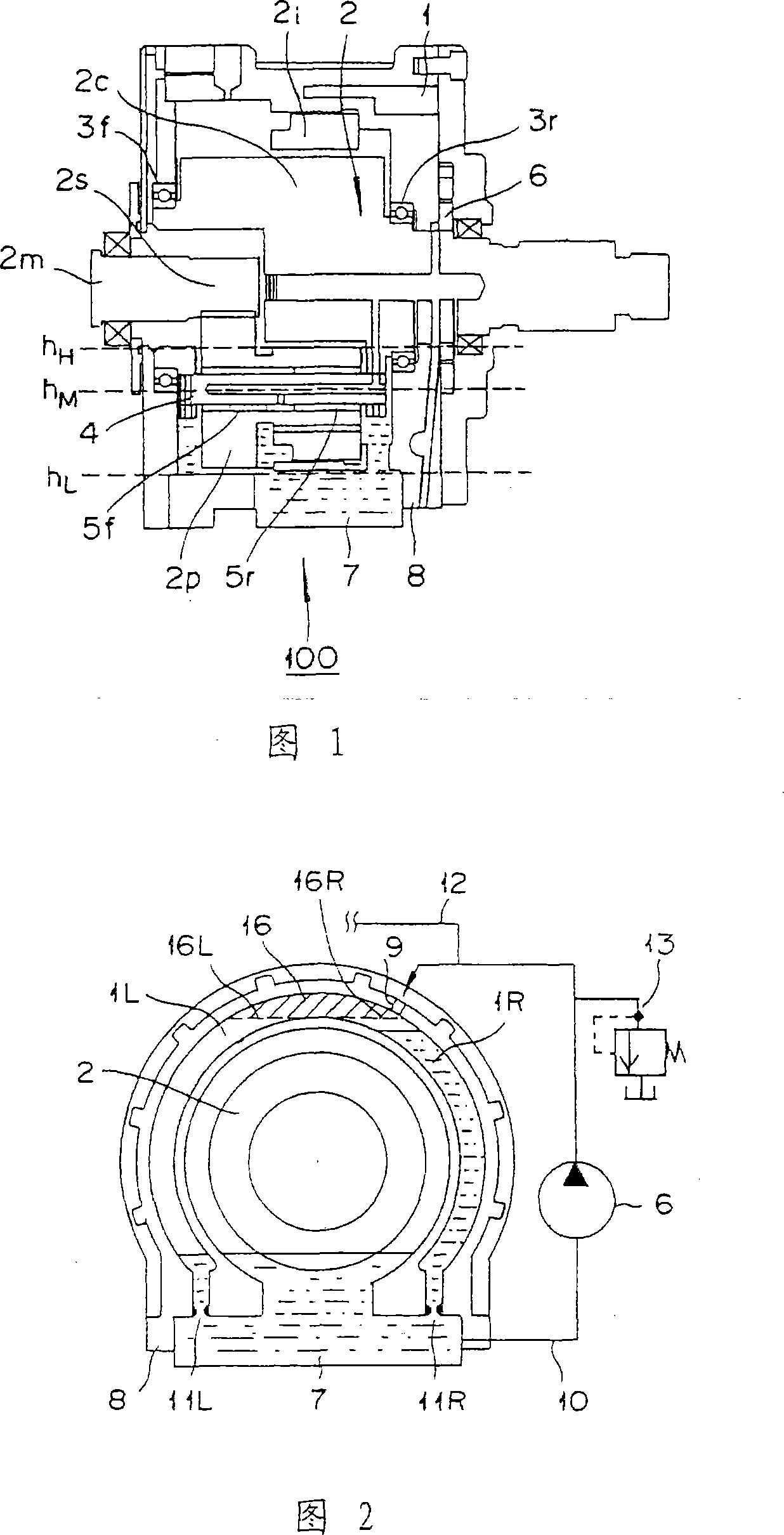

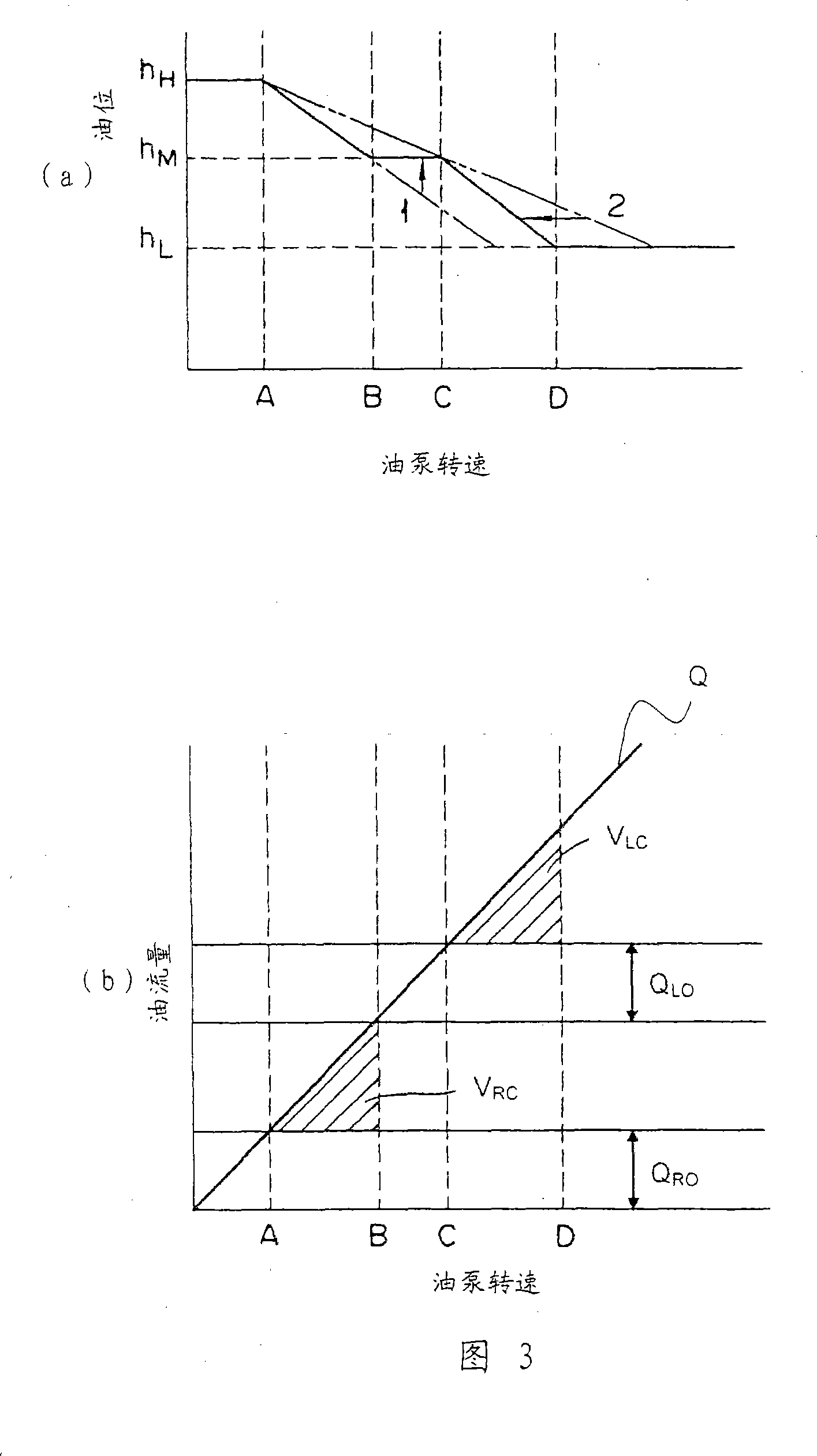

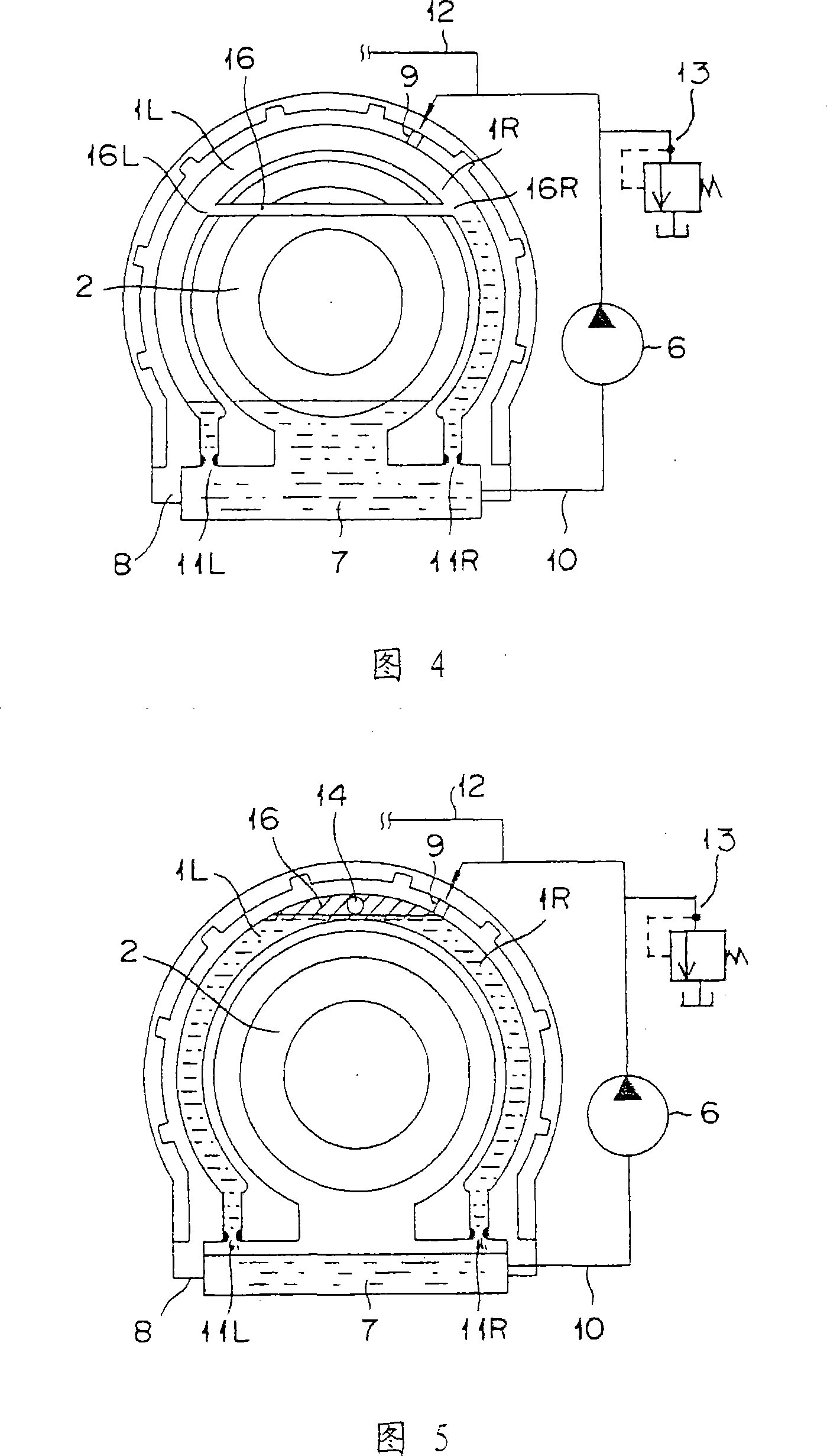

[0051] FIG. 1 is an axial cross-sectional view showing the outline of a power transmission device 100 according to a first embodiment, and FIG. 2 is an axial cross-sectional view of the power transmission device 100 . In addition, in this embodiment, oil has a lubricating effect and a cooling effect.

[0052] First, the outline of the power transmission device 100 of the present embodiment will be described.

[0053] The power transmission device 100 shown in FIG. 1 generally has: a casing 8, which can store oil; a gear mechanism 2, which is accommodated in the casing 8, and is linked with a driving source; an oil pump 6, which is linked with a driving source, and stores oil. The oil in the lower part 7 of the housing 8 is delivered under pressure to lubricate the gear mechanism 2 forcibly; the oil tank 1 stores a part of the oil delivered under pressure from the oil pump 6 .

[0054] The drive source is a motor not shown, and the gear mechanism 2 is connected to a motor shaf...

no. 2 approach

[0095] In the second embodiment, differences from the first embodiment will be described, and overlapping descriptions will be omitted.

[0096] FIG. 6 is an axially orthogonal cross-sectional view of the lubricating structure of this embodiment, and FIG. 7 is a diagram showing the relationship between the rotational speed of the gear mechanism and the oil level.

[0097] The lubricating structure and lubricating action of this embodiment will be described with reference to FIGS. 6 and 7 .

[0098] 6 shows an example in which the cross-sectional area of the second discharge port 11L at the lower end of the second oil tank 1L is smaller than the cross-sectional area of the first discharge port 11R at the lower end of the first oil tank 1R.

[0099] Thus, the second discharge flow rate Q RO Less than the first discharge flow Q LO , the oil accumulation speed of the second oil tank 1L is faster than the oil accumulation speed of the first oil tank 1R, after the oil pump spe...

no. 3 approach

[0112] In the third embodiment, differences from the first embodiment will be described, and overlapping descriptions will be omitted.

[0113] Fig. 10 is an axially orthogonal sectional view of the power transmission device according to the present embodiment.

[0114] Referring to FIG. 10 , the lubricating structure and lubricating action of this embodiment will be described.

[0115] FIG. 10 shows that in addition to the first discharge port 11R and the second discharge port 11L, a third row communicating with the housing lower part 7 is provided on the tank side wall above the bottom of the first fuel tank 1R and below the communication path 16. Exit 15 implementation. As in the first embodiment, after the supply of oil to the first oil tank 1R is started, if the lubricating oil is filled to the discharge port 15, the oil can also be discharged from the third discharge port 15 to the case lower part 7, and the case lower part can be further The oil level of 7 decreases s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com