Split bearing bush seat type sliding bearing tank

A sliding bearing, bearing seat type technology, applied in the direction of shaft and bearing, bearing components, bearing cooling, etc., can solve the problems of large volume and weight, large bending moment, and achieve the effect of simplifying structure, reducing weight and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

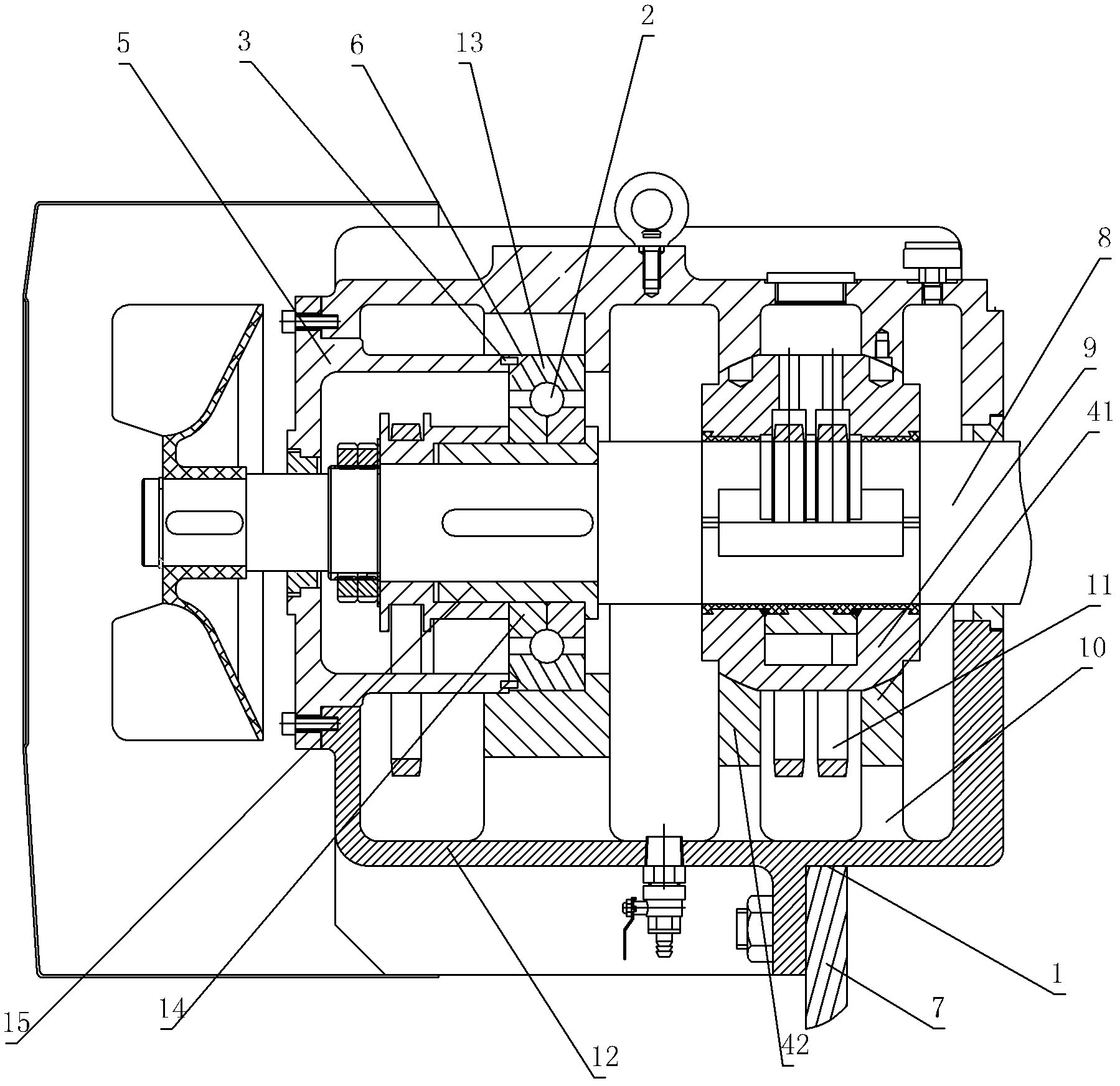

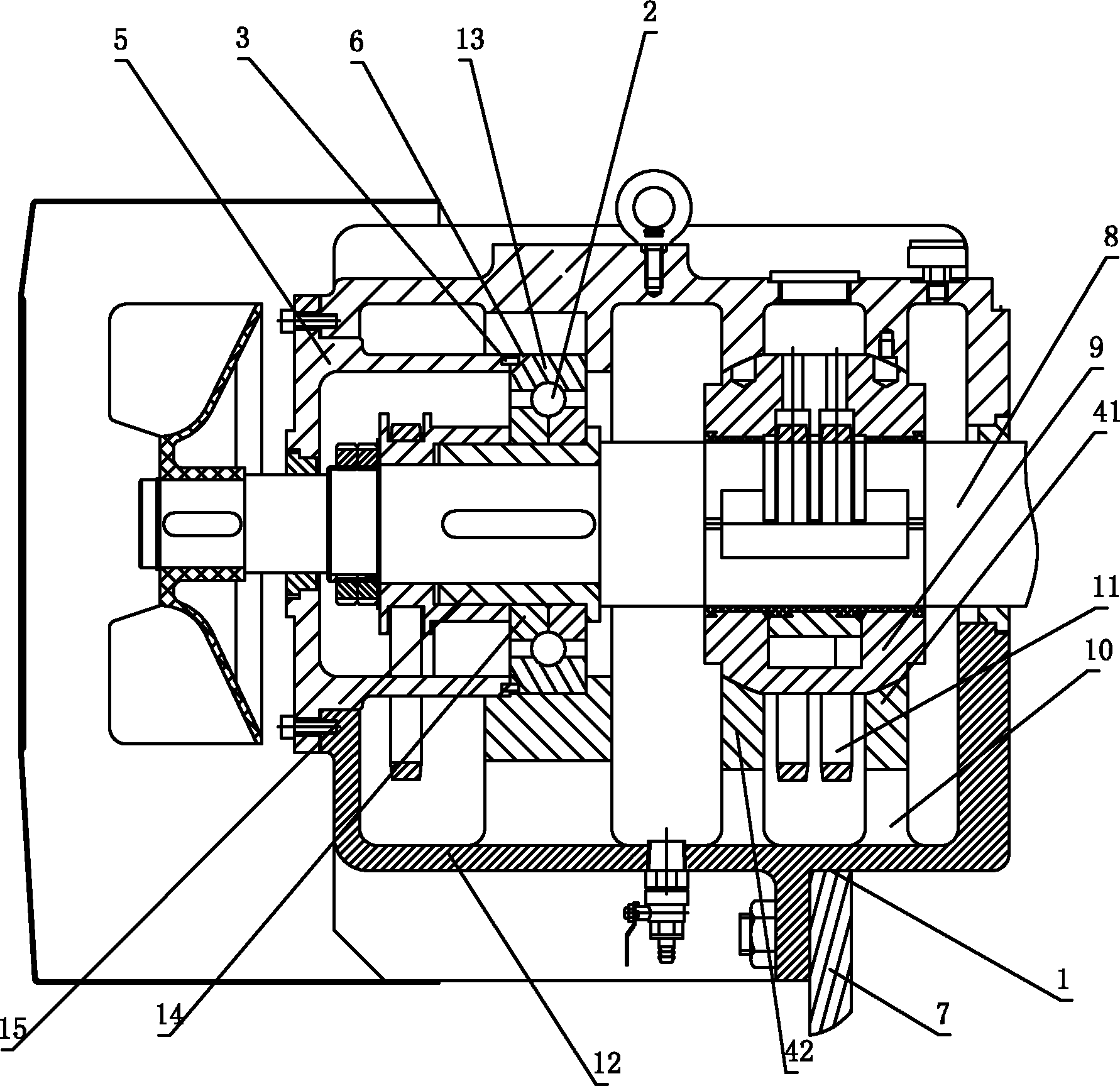

[0019] The split bearing pad seat type sliding bearing box of the present invention includes a box body 12 connected to the housing 7 of the pump, motor or gearbox, a sliding bearing assembly for supporting the shaft 8 and a single four-point contact set in the box body 12 Ball bearing 2 rolling bearing assembly; sliding bearing assembly includes bearing bush 9, oil ring 11, left bearing bush mounting seat 42 and right bearing bush mounting seat 41 symmetrically arranged outside the bearing bush; Below the bearing assembly; the oil ring 11 is arranged between the left bearing pad mounting seat 42 and the right bearing pad mounting seat 41; the left bearing pad mounting seat 42 and the right bearing pad mounting seat 41 are respectively provided with oil holes 10 communicating with the oil ring and the box. The bearing inner ring 14 of the single four-point contact ball bearing 2 and the shaft 8 are fixed through the shaft sleeve 15 and the key; the rear end cover 5 extends into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com