Environmentally-friendly low-dust and low-noise novel brake pad for high-speed railway and preparation method thereof

An environmentally friendly, brake pad technology, applied in the direction of process efficiency improvement, additive manufacturing, mechanical equipment, etc., can solve the problems of brake pad braking performance decline, poor noise reduction effect of brake pads, and inability to meet performance requirements, etc. Achieving good heat dissipation, tight bonding, and preventing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

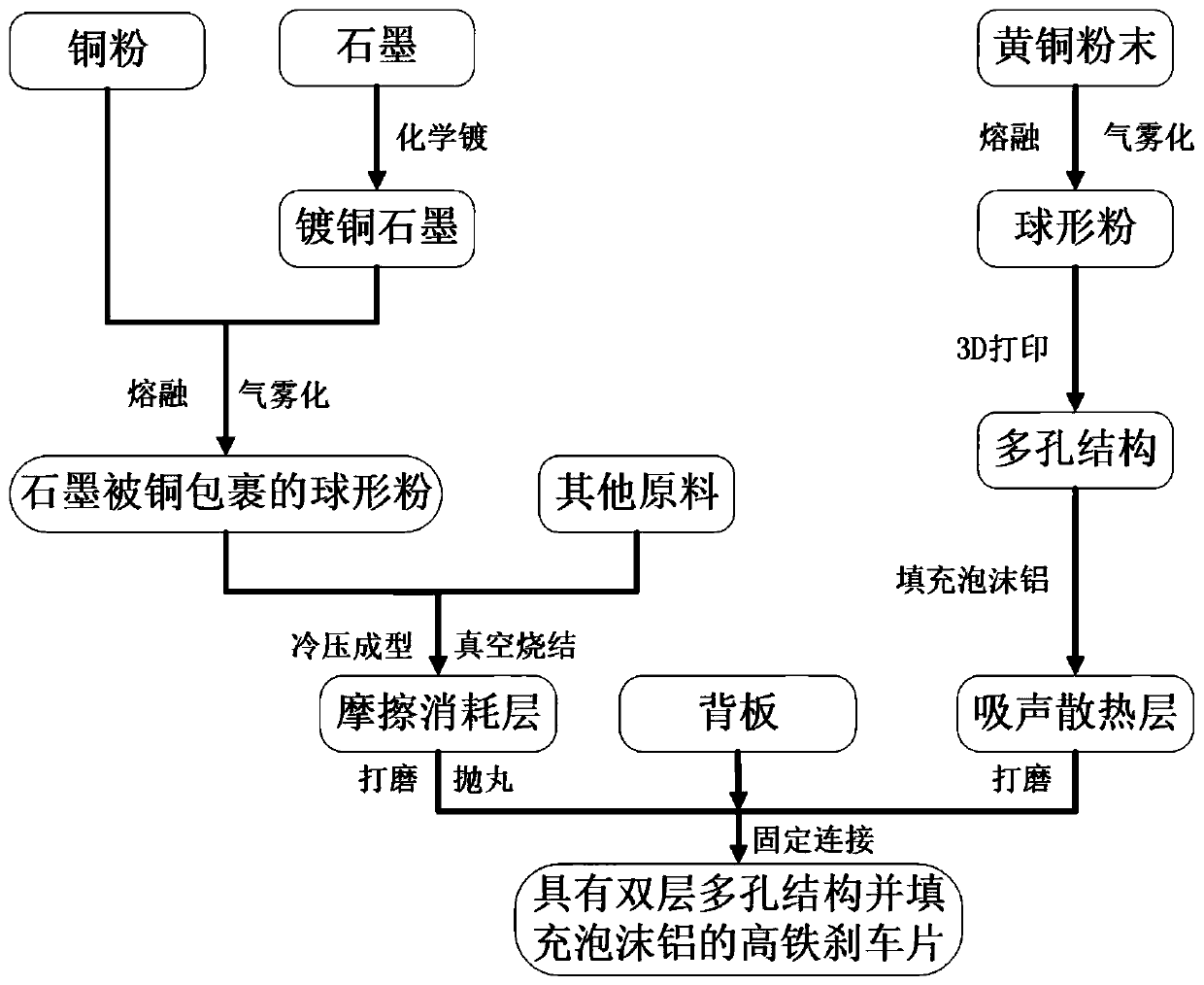

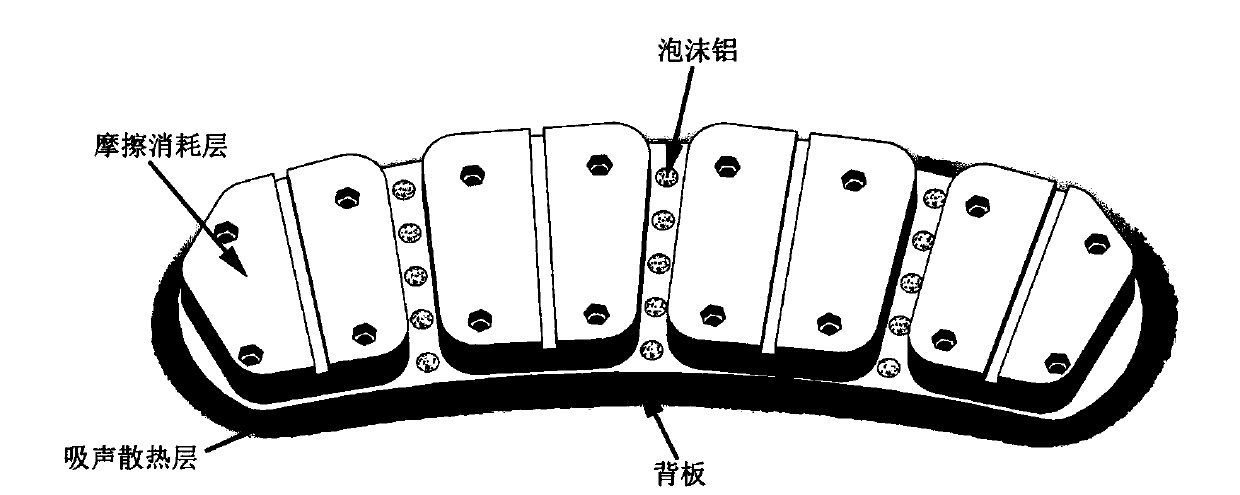

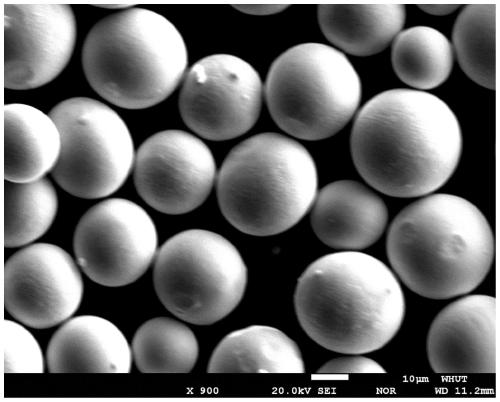

[0056] An environmentally friendly, dusty and low-noise new high-speed rail brake pad, including a back plate, a frictional consumption layer, and a sound-absorbing and heat-dissipating layer, wherein the components and mass percentages of the frictional consumption layer are: copper 34%, iron 4%, titanium Silicon carbon 3%, manganese 4%, molybdenum disulfide 3%, silicon carbide 6%, aluminum oxide 3%, chromium carbide 4%, zirconia 5%, copper-graphite composite spherical powder 29%, barium sulfate 5% The sound-absorbing and heat-dissipating layer includes a H62 copper alloy substrate and foamed aluminum, wherein the H62 copper alloy substrate has a porous structure, and the foamed aluminum is located in the pores of the H62 copper alloy substrate.

[0057] The preparation steps of the above-mentioned new high-speed rail brake pad that is environmentally friendly, dusty and low-noise are as follows:

[0058] 1. Preparation of copper-coated graphite:

[0059] (1) Keep the graphi...

Embodiment 2

[0082] An environmentally friendly, dusty and low-noise new high-speed rail brake pad, including a back plate, a frictional consumption layer, and a sound-absorbing and heat-dissipating layer. The components and mass percentages of the frictional consumption layer are: copper 36%, iron 4.2%, titanium Silicon carbon 3.6%, manganese 3.5%, molybdenum disulfide 2%, silicon carbide 6%, aluminum oxide 2.4%, chromium carbide 2%, zirconia 2.3%, copper-graphite composite spherical powder 35%, barium sulfate 3% The sound-absorbing and heat-dissipating layer includes a H62 copper alloy substrate and foamed aluminum, wherein the H62 copper alloy substrate has a porous structure, and the foamed aluminum is located in the pores of the H62 copper alloy substrate.

[0083] The preparation steps of the above-mentioned new high-speed rail brake pad that is environmentally friendly, dusty and low-noise are as follows:

[0084] 1. Preparation of copper-coated graphite:

[0085] (1) Insulate grap...

Embodiment 3

[0108] An environmentally friendly, dusty and low-noise new high-speed rail brake pad, including a back plate, a frictional consumption layer, and a sound-absorbing and heat-dissipating layer, wherein the components and mass percentages of the frictional consumption layer are: copper 39%, iron 5%, titanium Silicon carbon 3.2%, manganese 3.8%, molybdenum disulfide 2.2%, silicon carbide 7%, aluminum oxide 2.5%, chromium carbide 2.5%, zirconia 2.8%, copper-graphite composite spherical powder 30%, barium sulfate 2% The sound-absorbing and heat-dissipating layer includes a H62 copper alloy substrate and foamed aluminum, wherein the H62 copper alloy substrate has a porous structure, and the foamed aluminum is located in the pores of the H62 copper alloy substrate.

[0109] The preparation steps of the above-mentioned new high-speed rail brake pad that is environmentally friendly, dusty and low-noise are as follows:

[0110] 1. Preparation of copper-coated graphite:

[0111] (1) Kee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com