Patents

Literature

79 results about "Railway brake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A railway brake is a type of brake used on the cars of railway trains to enable deceleration, control acceleration (downhill) or to keep them immobile when parked. While the basic principle is similar to that on road vehicle usage, operational features are more complex because of the need to control multiple linked carriages and to be effective on vehicles left without a prime mover. Clasp brakes are one type of brakes historically used on trains.

Railway braking and throttle guidance user interface

ActiveUS8509971B1Avoid interventionNeed for correctionArrangements for variable traffic instructionsDigital data processing detailsDisplay deviceEngineering

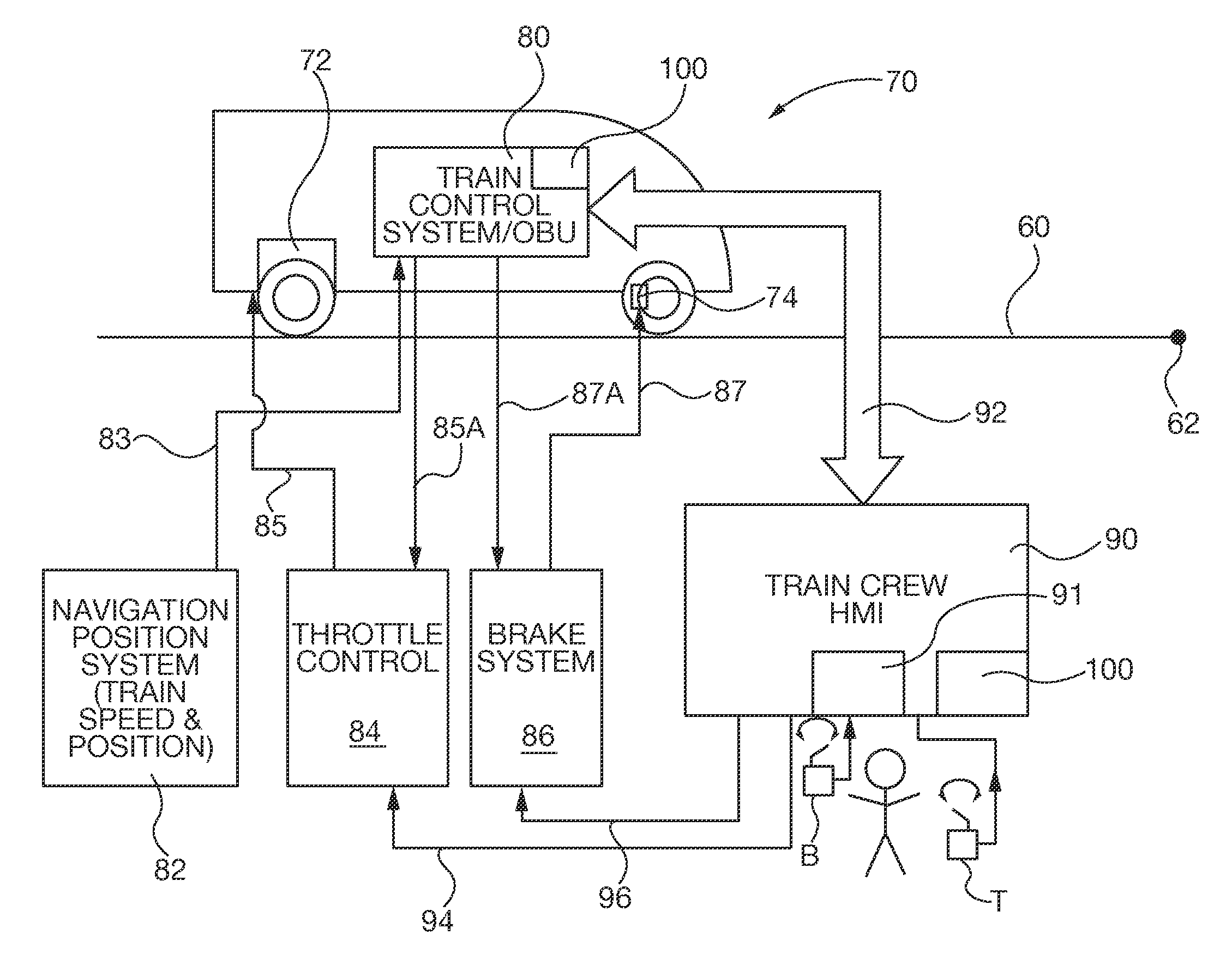

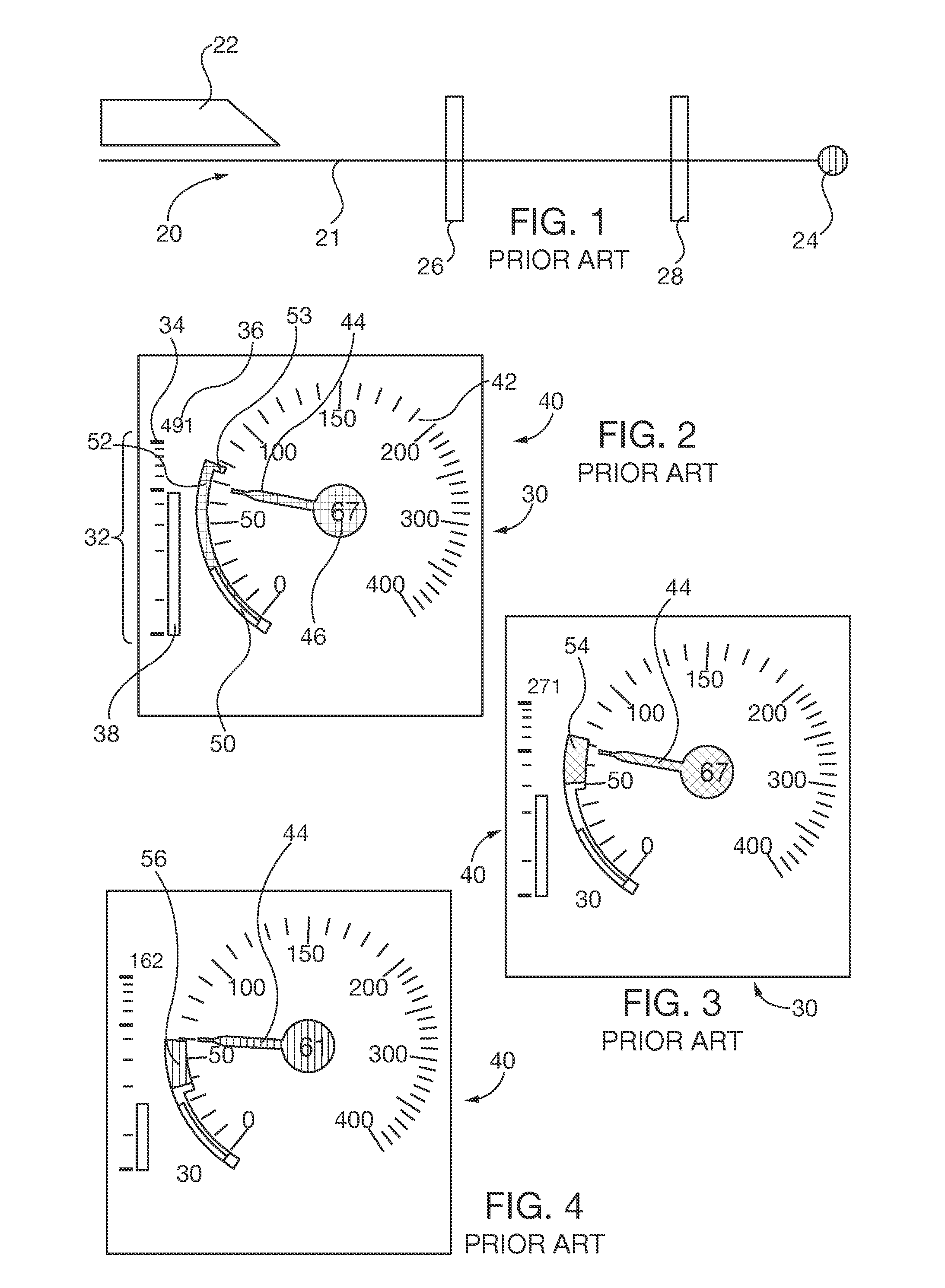

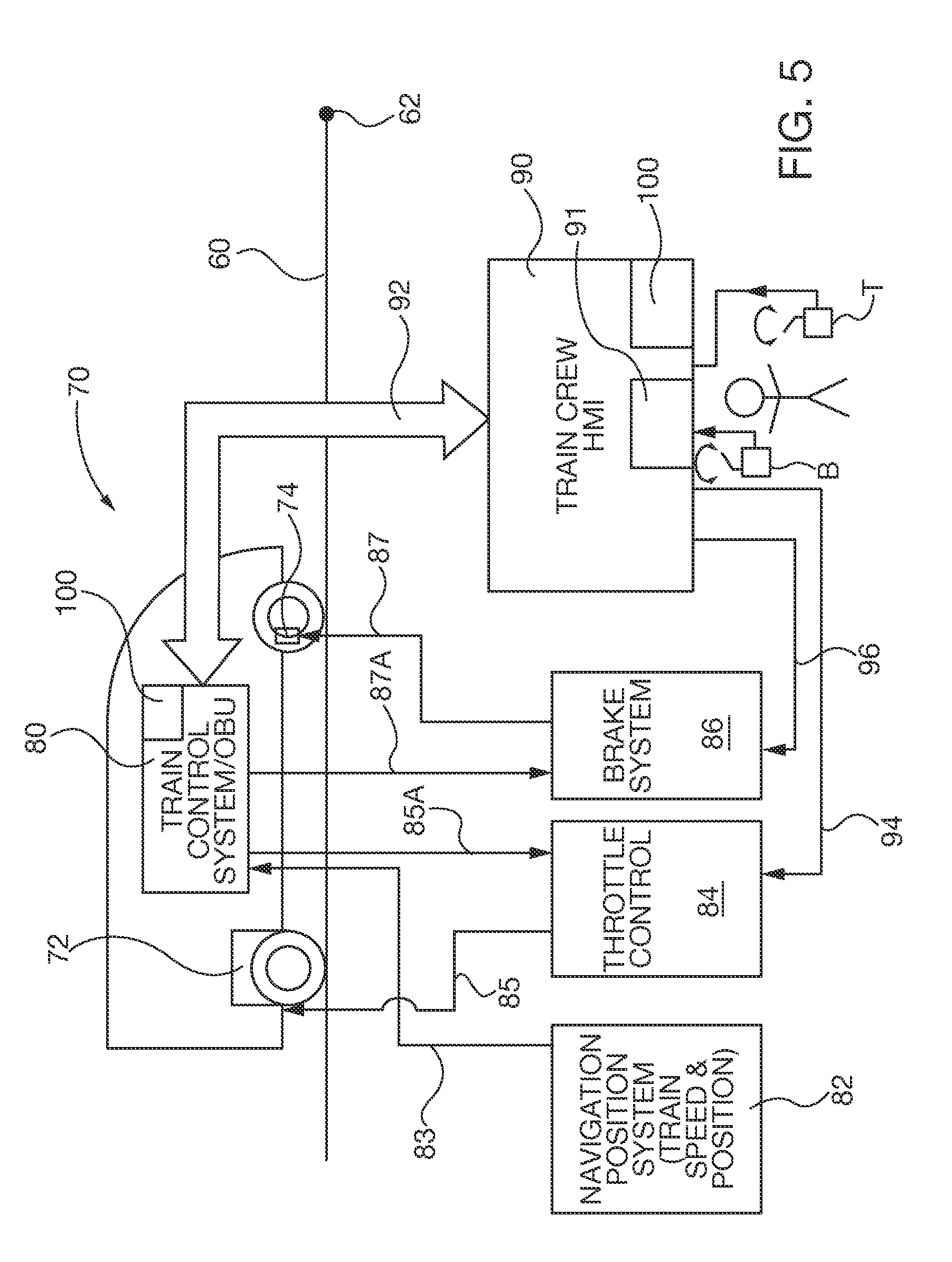

A user interface includes a visual display with suggested speed control throttle and / or brake settings display portion, a speedometer display portion and a distance to target guide portion. The display provides intuitive feedback information helpful for train operator decisions on how and when to change train speed control throttle and / or brake settings. In some embodiments of the present invention the interface suggests brake and / or throttle settings for reducing train speed. The distance to target guide portion includes an analog target display that grows in size as the train approaches a target point speed change or stop position. The speedometer includes analog speed scale, speed indicator needle and a suggested target speed indicator display portions.

Owner:SIEMENS MOBILITY INC

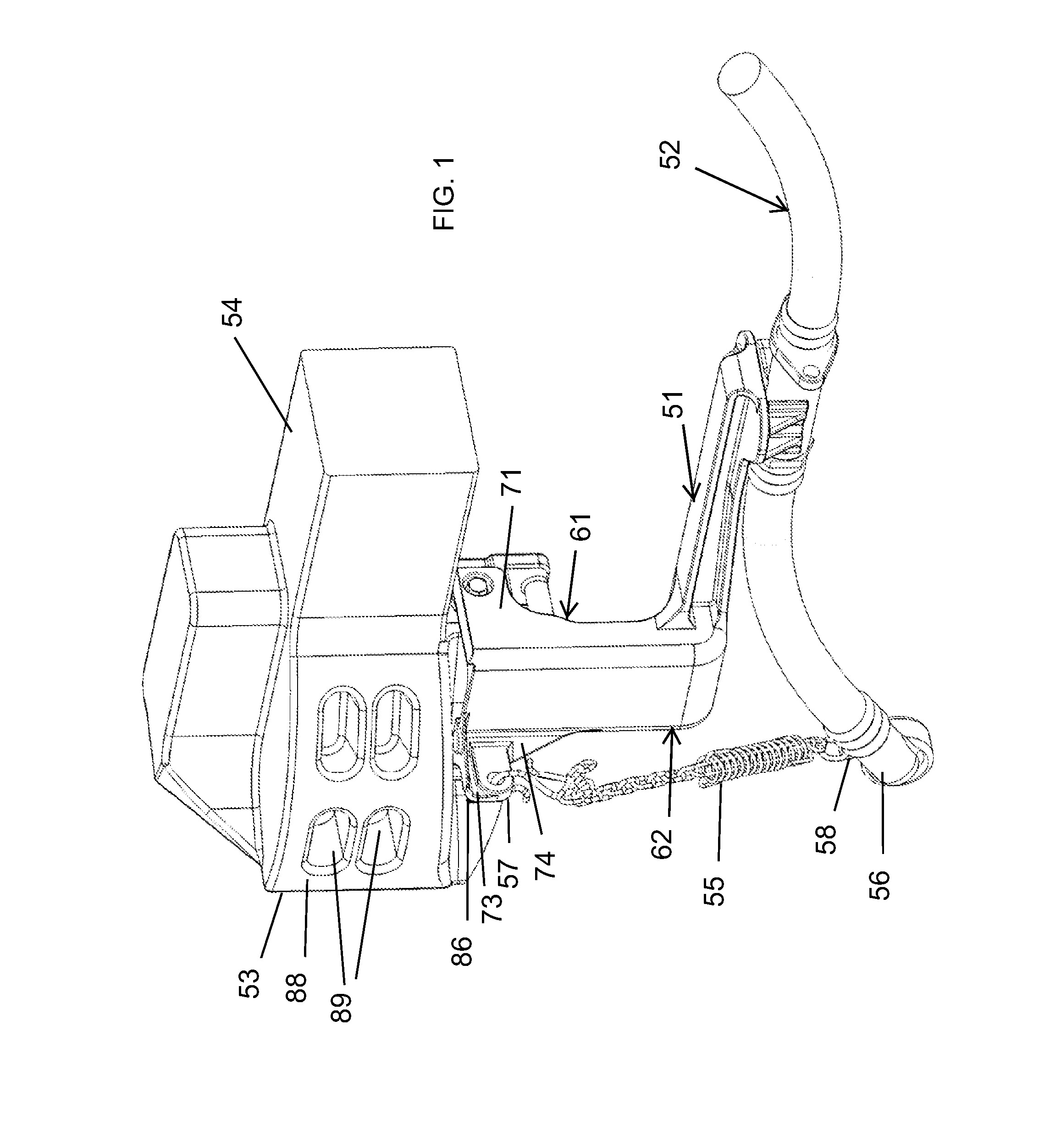

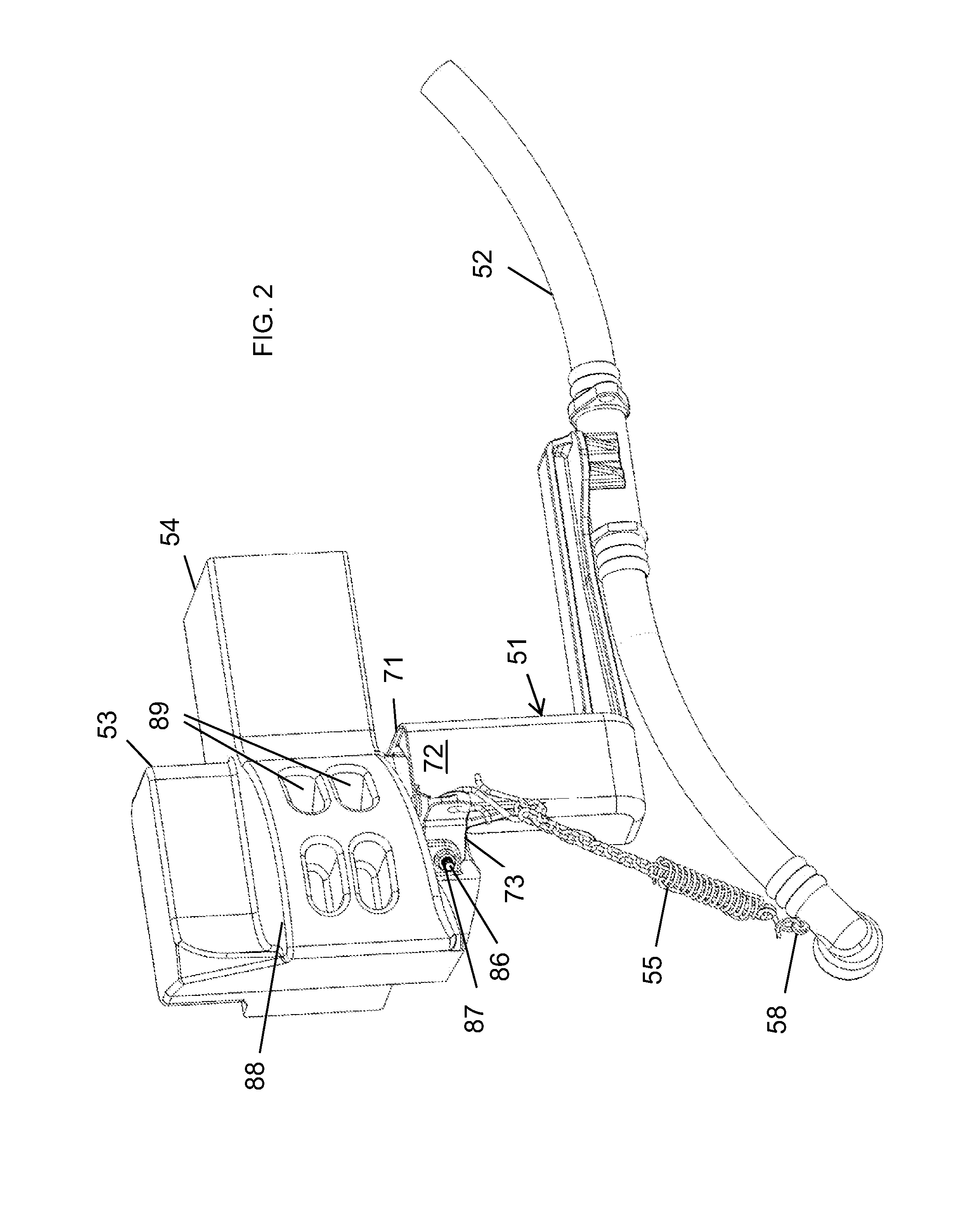

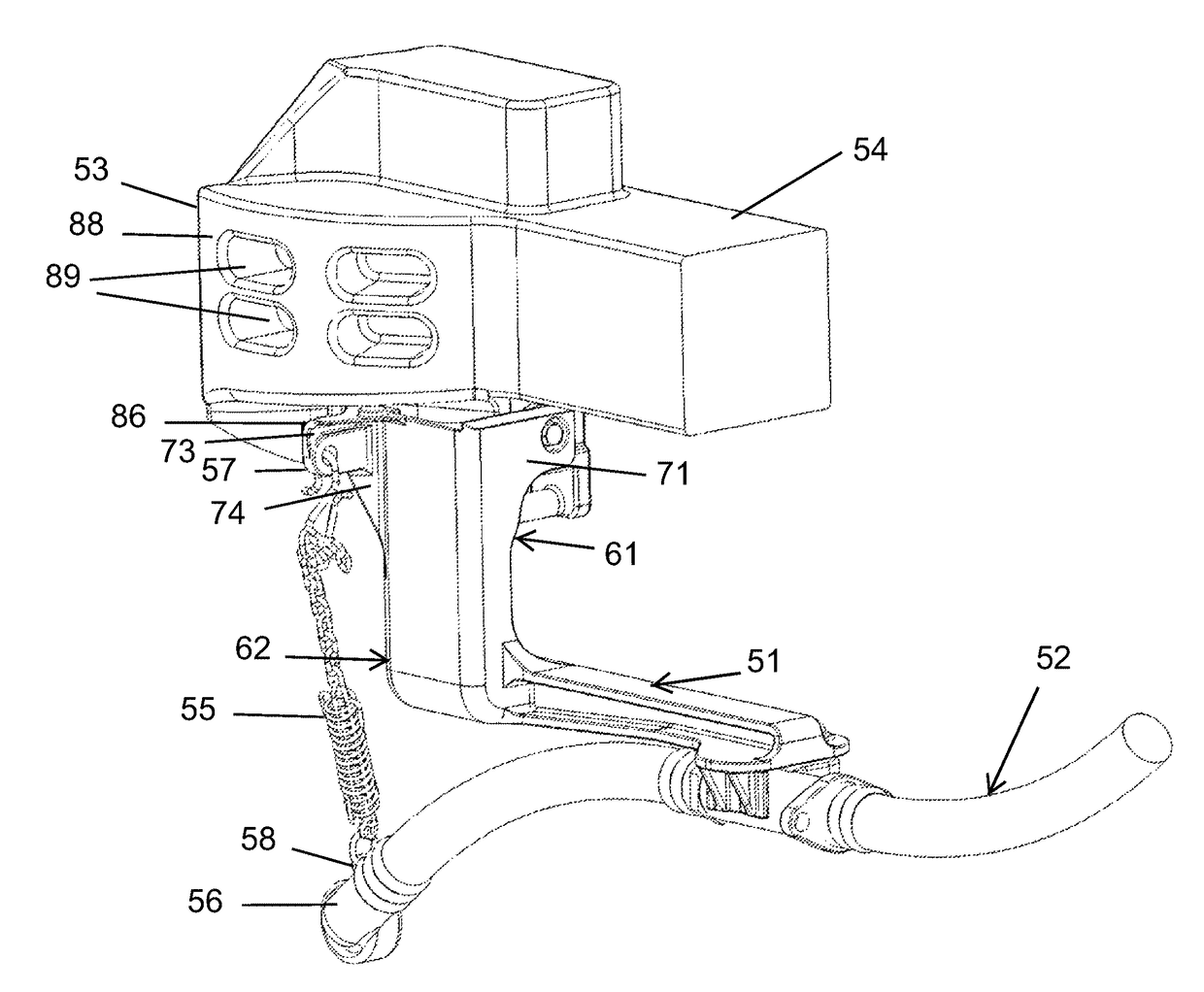

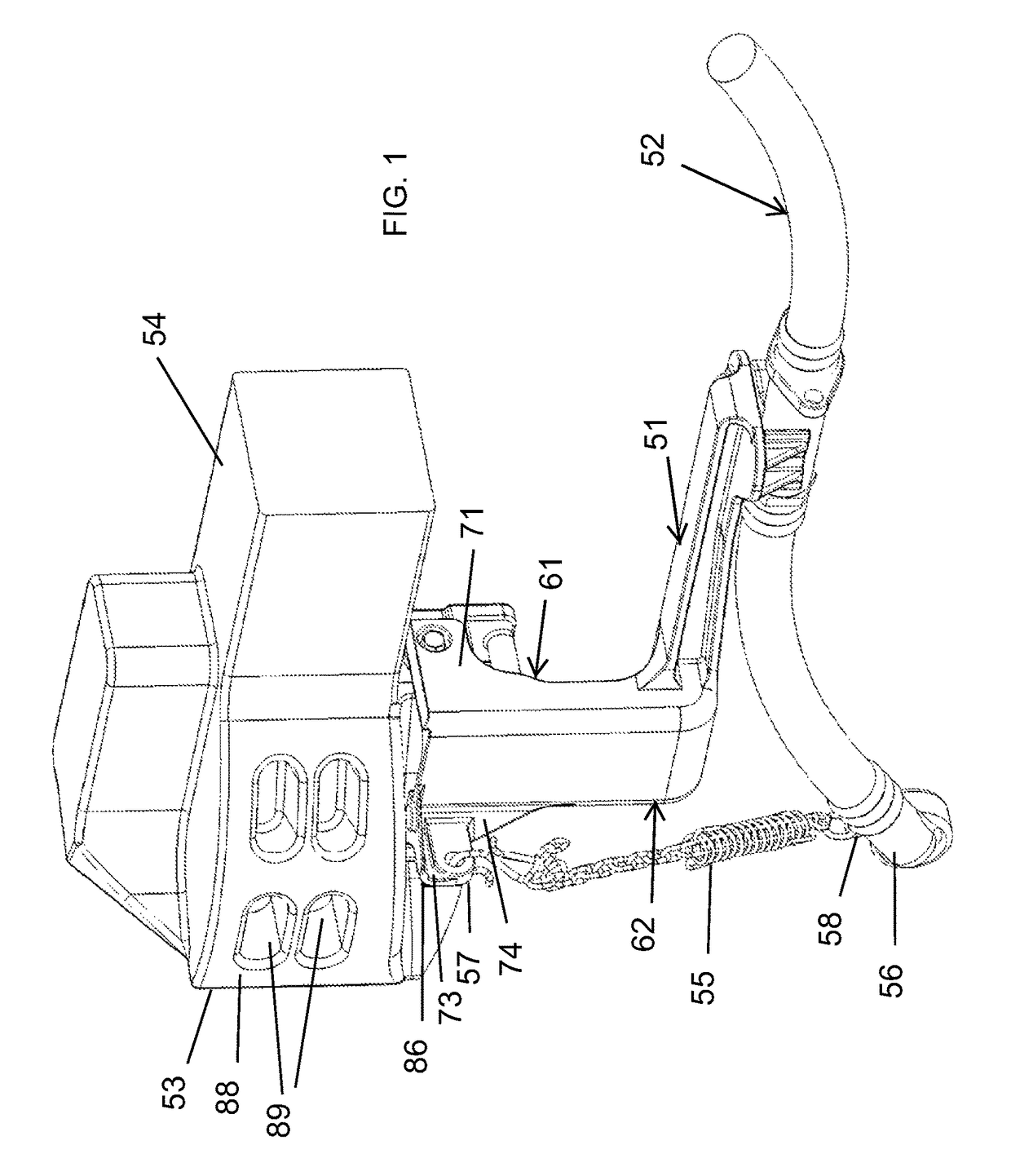

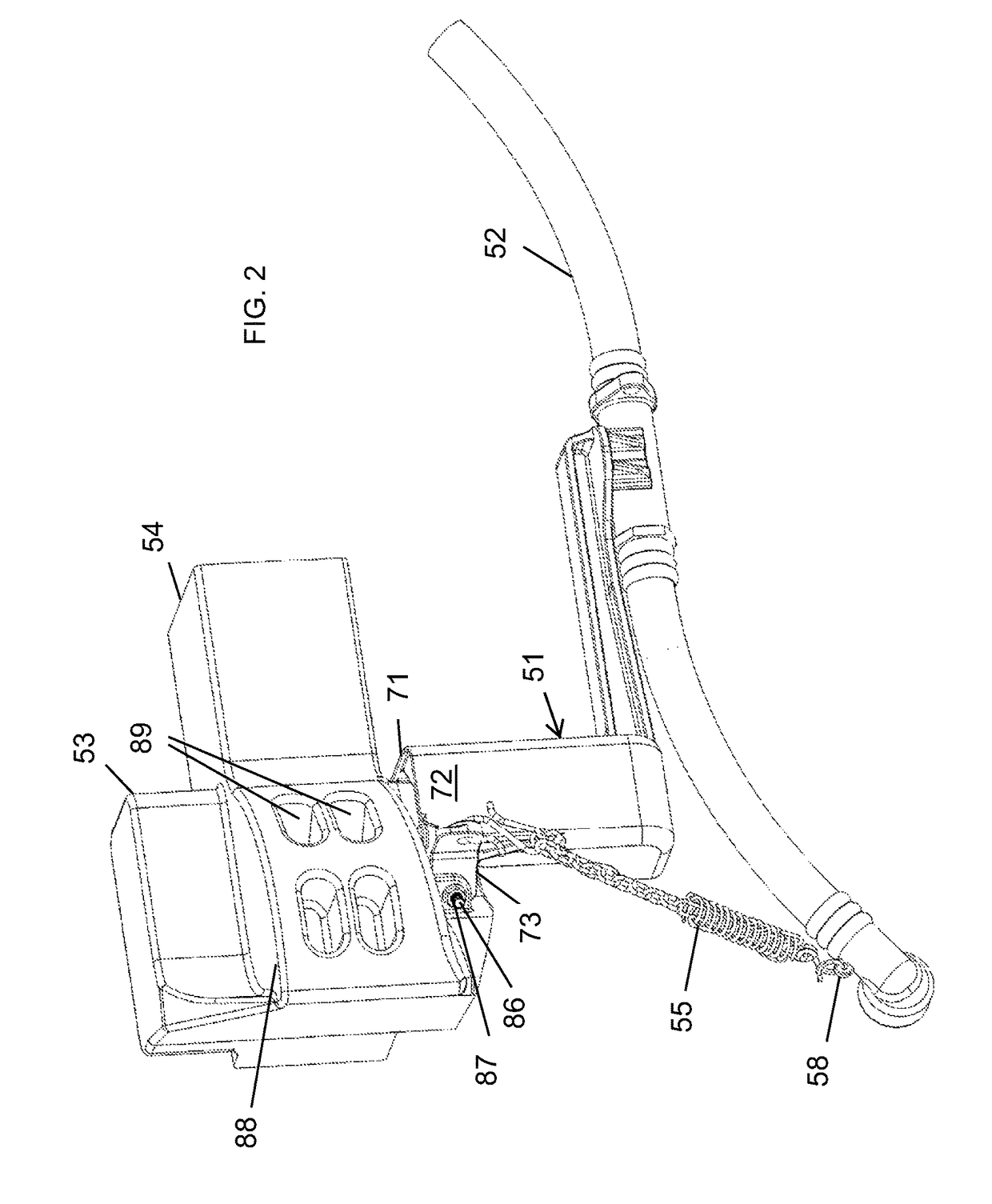

Air brake hose support bracket

ActiveUS20160123502A1Easy and faster and more installationSusceptibility to damageRailway hydrostatic brakesRailway hydrodynamic brakesEngineeringRailway brake

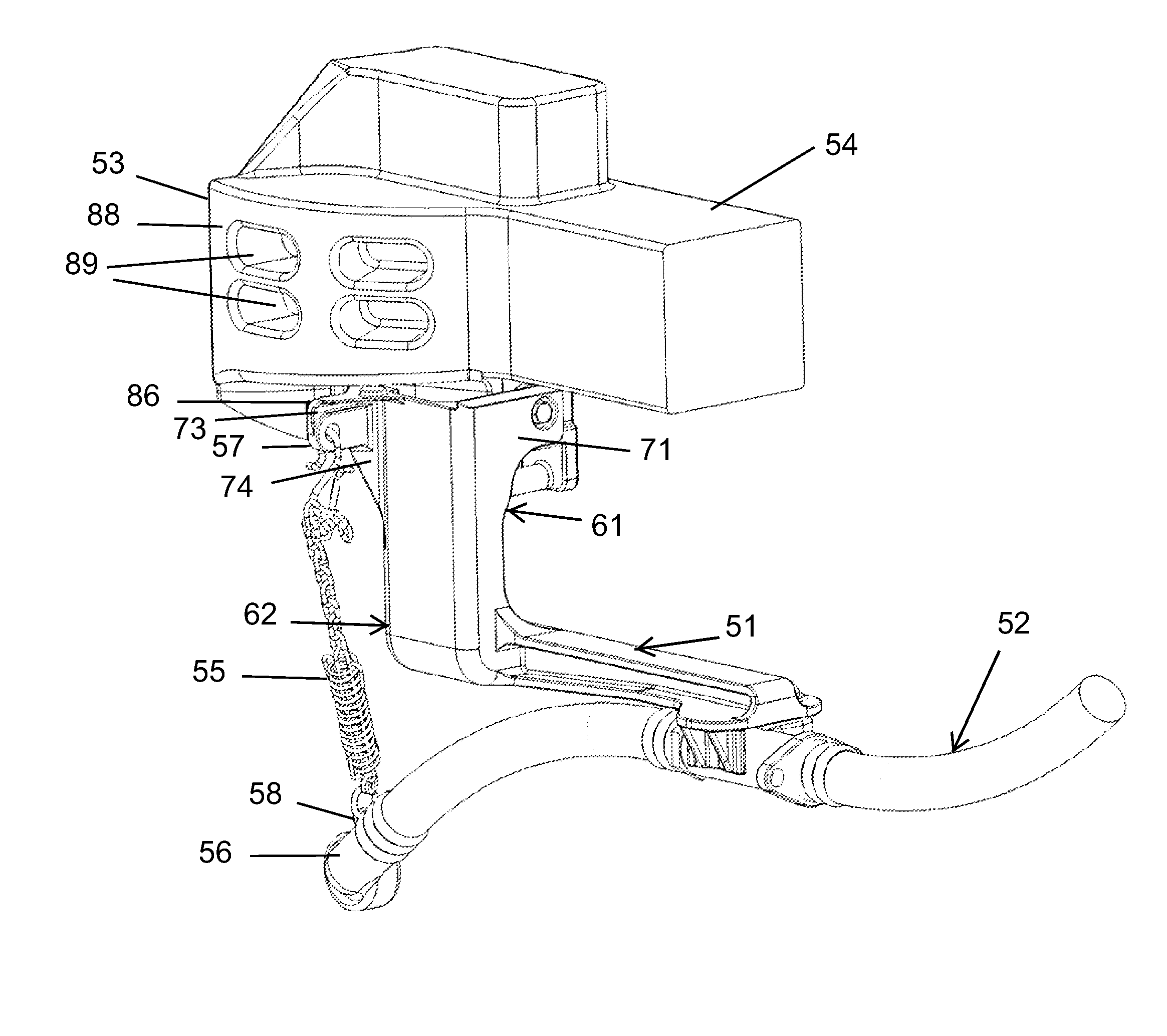

A railway car air brake hose support bracket has an upper portion with first and second attachment members, a lower portion and an air hose connector. The first attachment member enters into and engages a portion of an accessible compartment of an uncoupling mechanism housing below the coupler head, and the second attachment member is secured to an air brake hose support lug of the railway car coupler. The air brake hose connector engages an air brake hose assembly and suspends this hose assembly from the railway coupler at a predetermined distance above the rail bed. A method of installing the hose support bracket includes positioning the first and second attachment members, securing them in place, and attaching one or more railway brake hose units to the air hose connector, either before or after this positioning and securing of the upper portion of the bracket.

Owner:IRECO INC

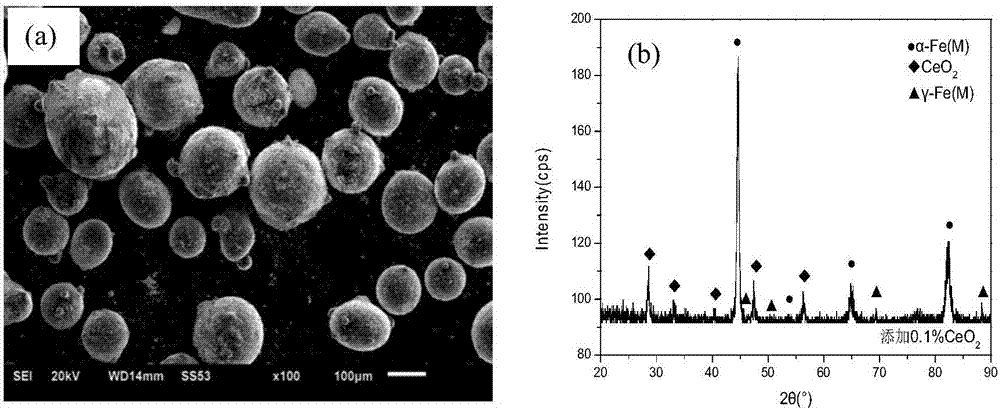

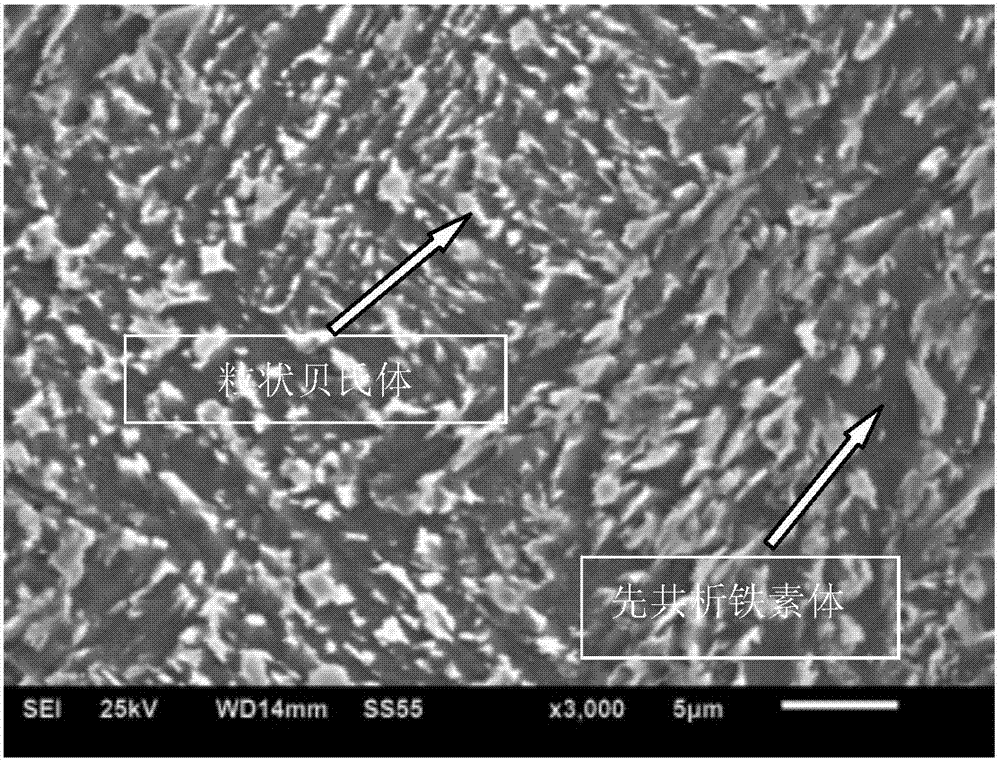

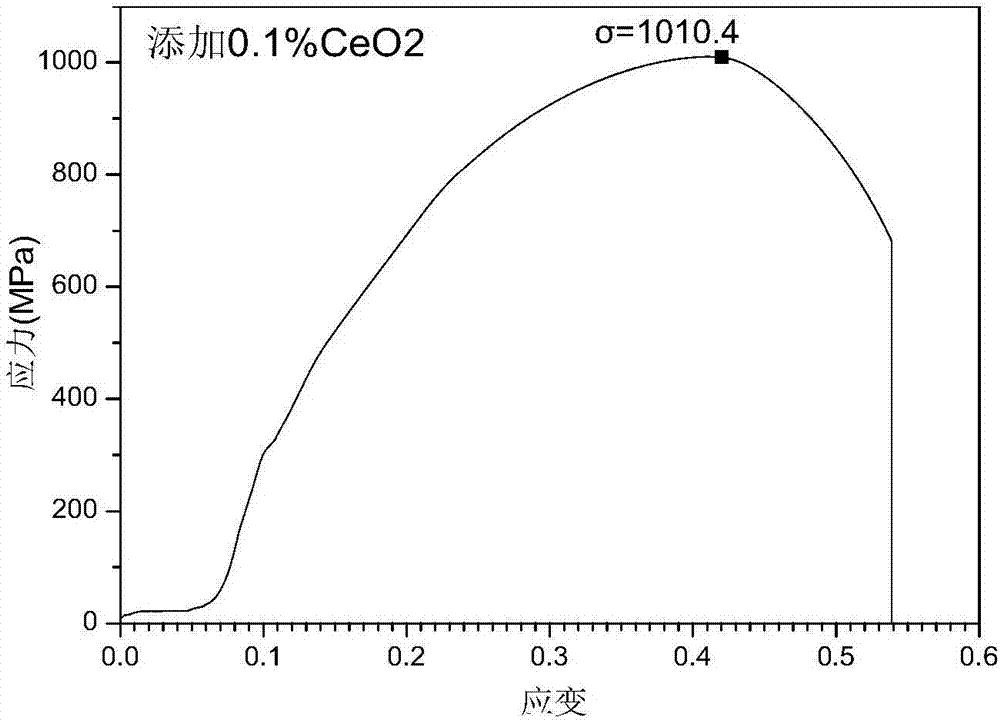

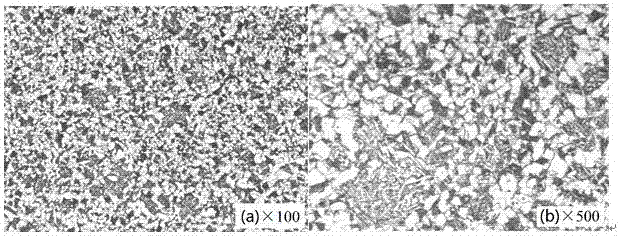

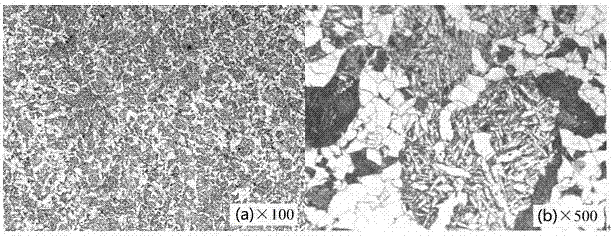

Method for preparing toughened 24 CrNiMo alloy steel through selective laser melting technology

ActiveCN107498054AImprove toughnessImprove mechanical propertiesAdditive manufacturing apparatusBraking discsMelting tankSelective laser melting

The invention relates to a method for preparing toughened 24 CrNiMo alloy steel through a selective laser melting technology. The method is characterized in that 24CrNiMo / CeO2 composite powder with a determined mass ratio and a uniform phase is prepared through mechanical ball-milling; and an alloy steel component is quickly formed layer by layer according to a predetermined selective laser melting path and process parameters. Through actions of refining crystalline grains, purifying a molten pool and the like in the laser molten pool through CeO2, samples which have small structures and are free of obvious defects such as cracks and pores are formed; and a selective laser melting process with large power, a great powder paving thickness and lower scanning speed is adopted, so that the forming rate is increased. A 24CrNiMo alloy steel component has room-temperature tensile strength of 10000 MPa level, and has ductility of 20-26%, so that strength and toughness of 24 CrNiMo alloy steel prepared by the selective laser melting technology are improved. The method is mainly applied to laser additive manufacturing of a 24 CrNiMo alloy steel high-speed railway brake disc.

Owner:NORTHEASTERN UNIV

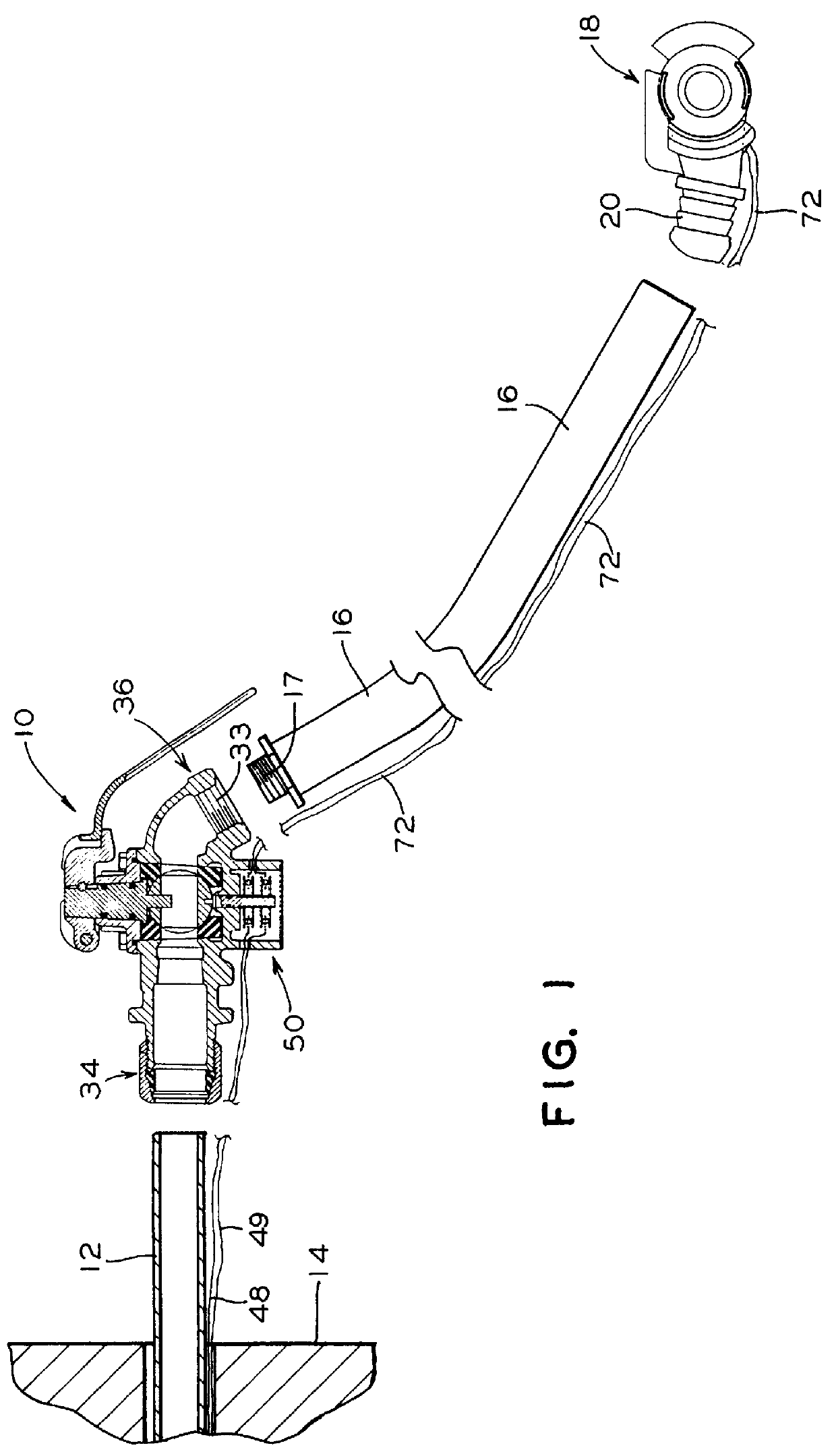

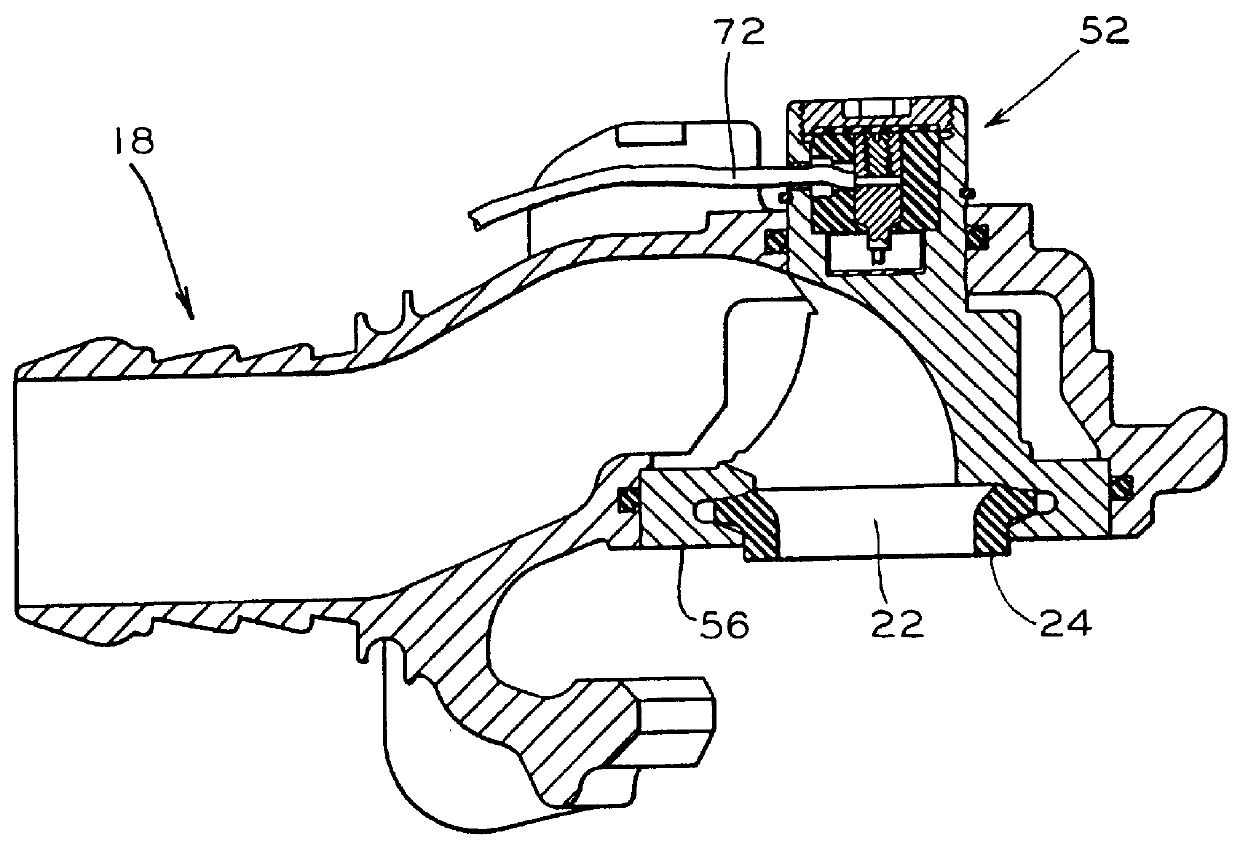

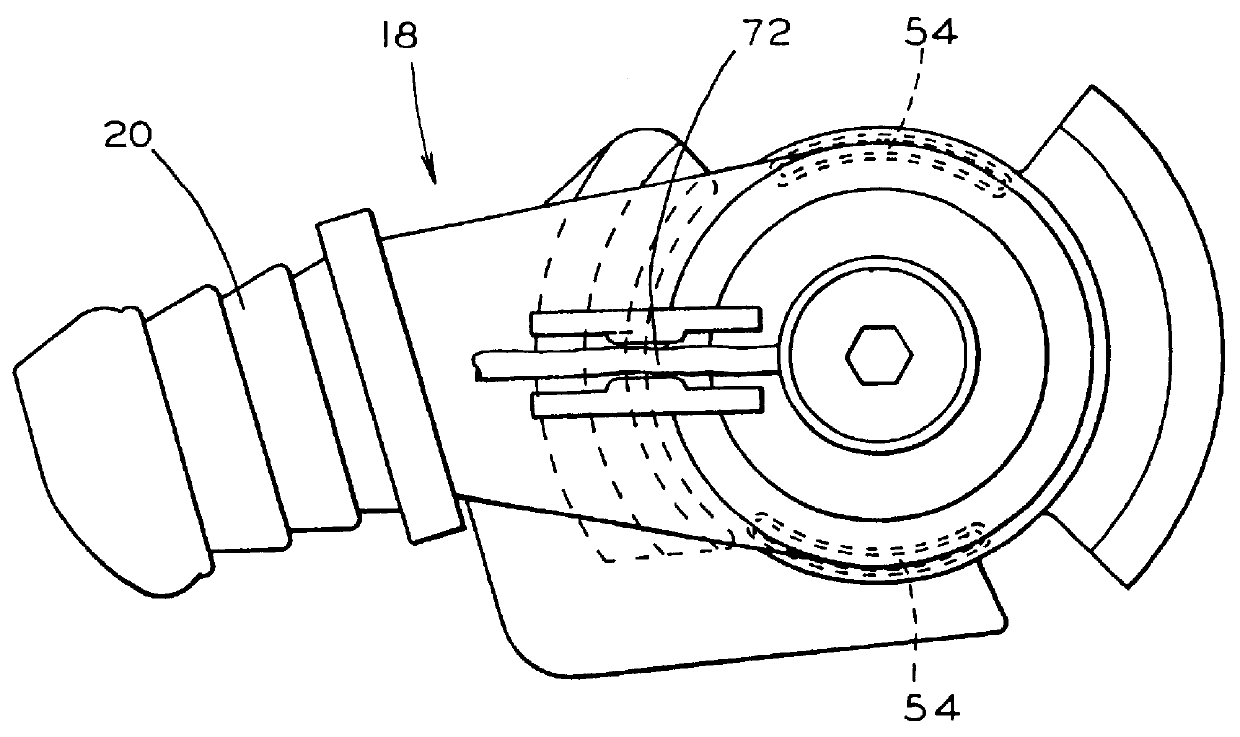

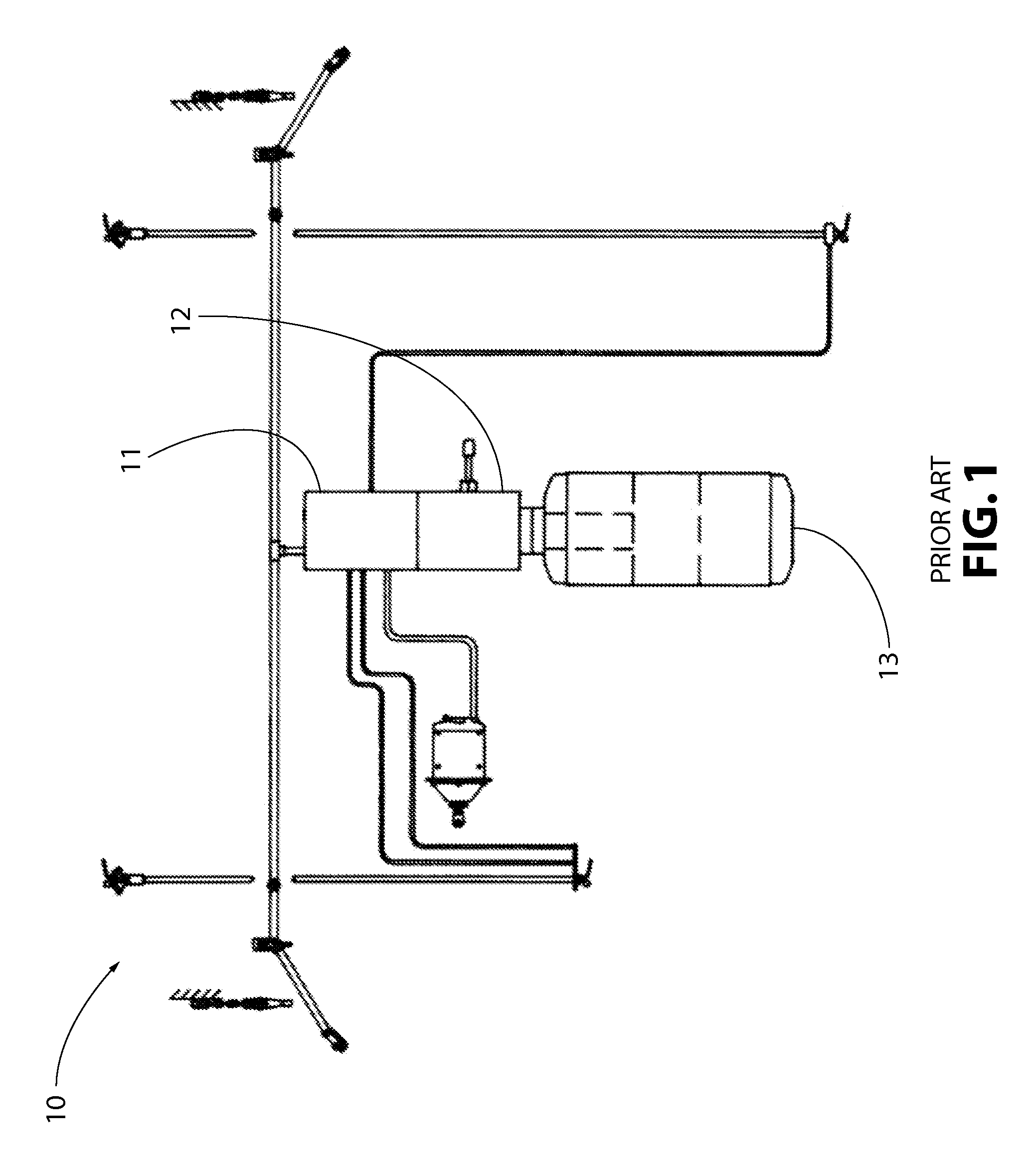

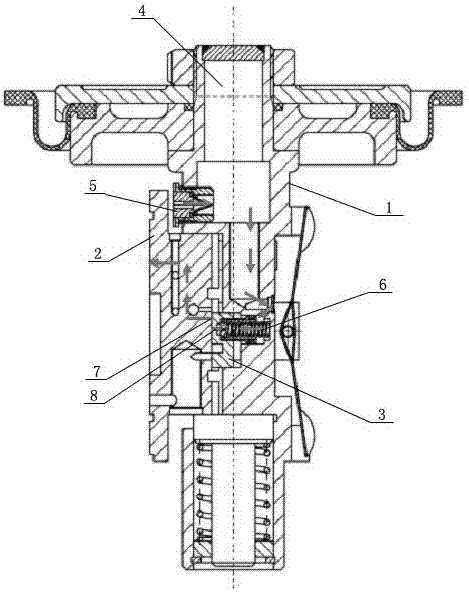

Shutoff valve assembly

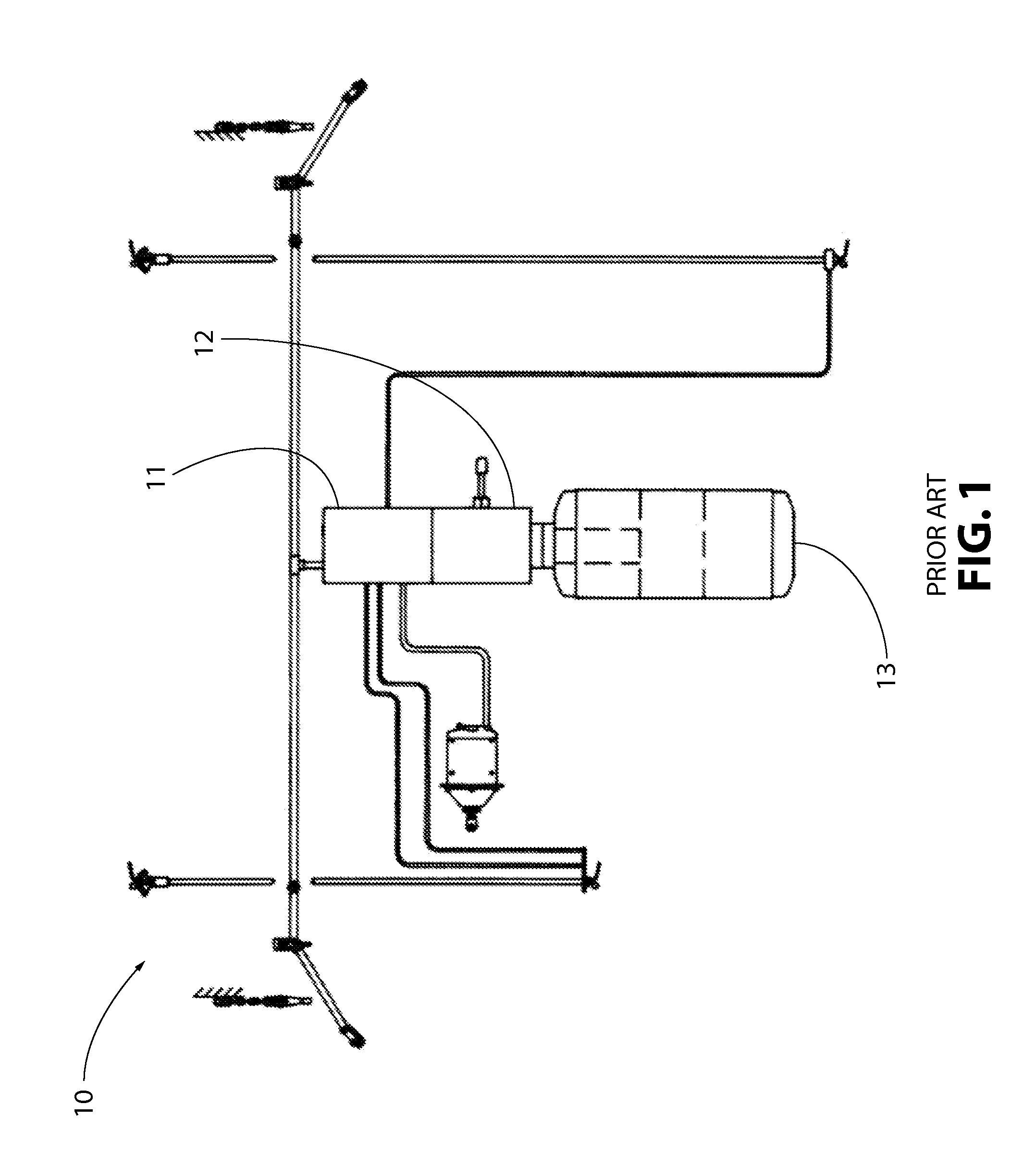

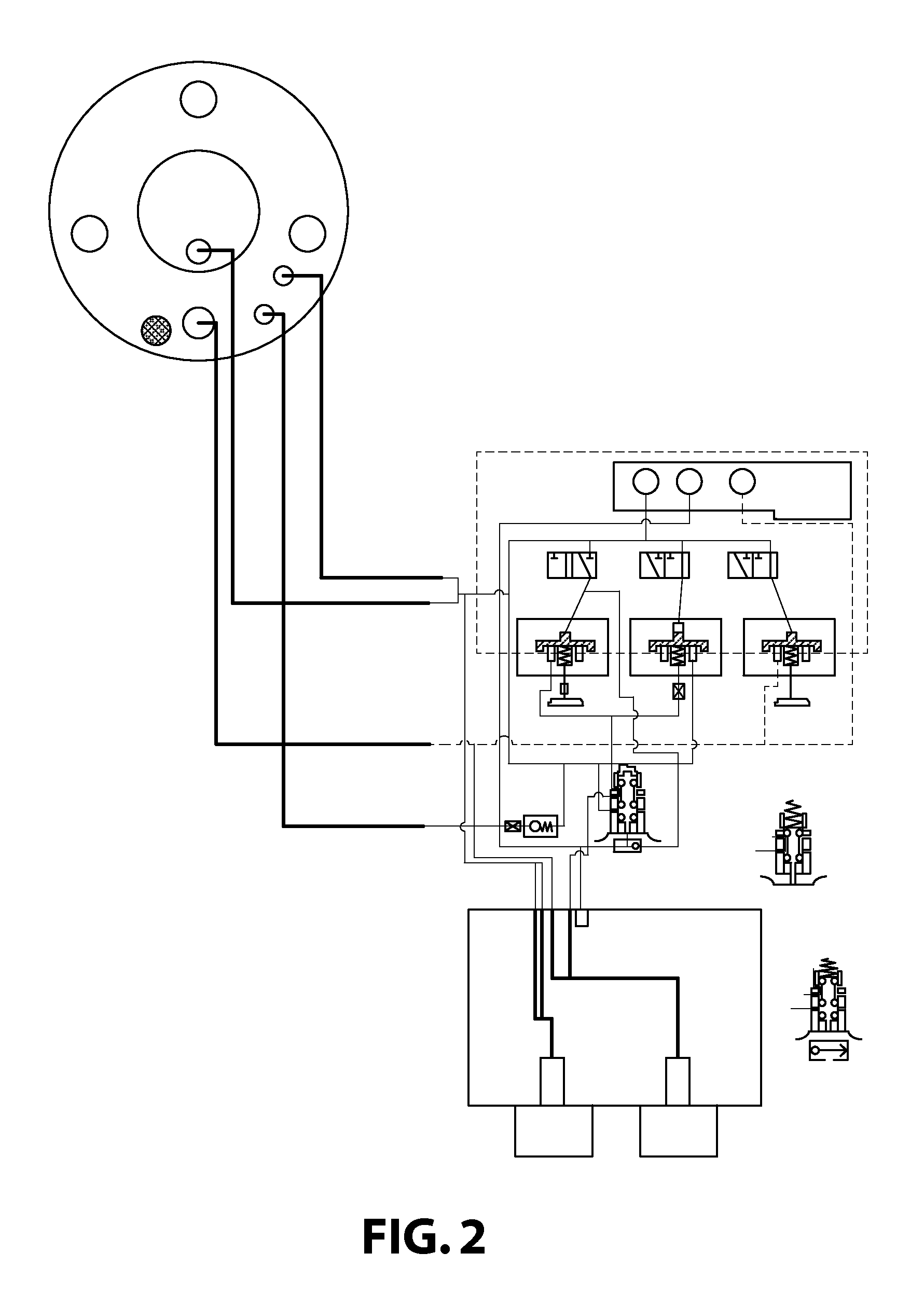

InactiveUS6039409AReduce in quantityBraking action transmissionRailway couplingsRailway brakeElectricity

A railroad brake line shutoff valve assembly for connecting a car mounted railway brake line to a brake line air hose. The assembly includes a shutoff valve with a stationary valve portion and a moveable valve portion. The stationary valve portion has a first fluid line attachment site and a second fluid line attachment site. Movement of the moveable valve portion to one position opens a flowpath through the valve between the first fluid line attachment site and the second fluid line attachment site. Movement of the moveable valve protion to another position closes the flowpath through the valve. The assembly includes a junction box having a first set of electric line attachment sites for connection of a set of car mounted electrical trainline conductors mounted on the railway vehicle and a second set of electric line attachment sites for connection of a set of electrical line end segments which terminate in a multiple contact electrical trainline connector. The junction box also has a third set of electric line of at least one of an electronic system or an electrical system located on the railway vehicle. Each member of the first set of electric line attachment sites is electrically connected to a corresponding member of the second set of electric line attachment sites and also to a corresponding member of the third set of electric line attachment sites.

Owner:WESTINGHOUSE AIR BRAKE CO

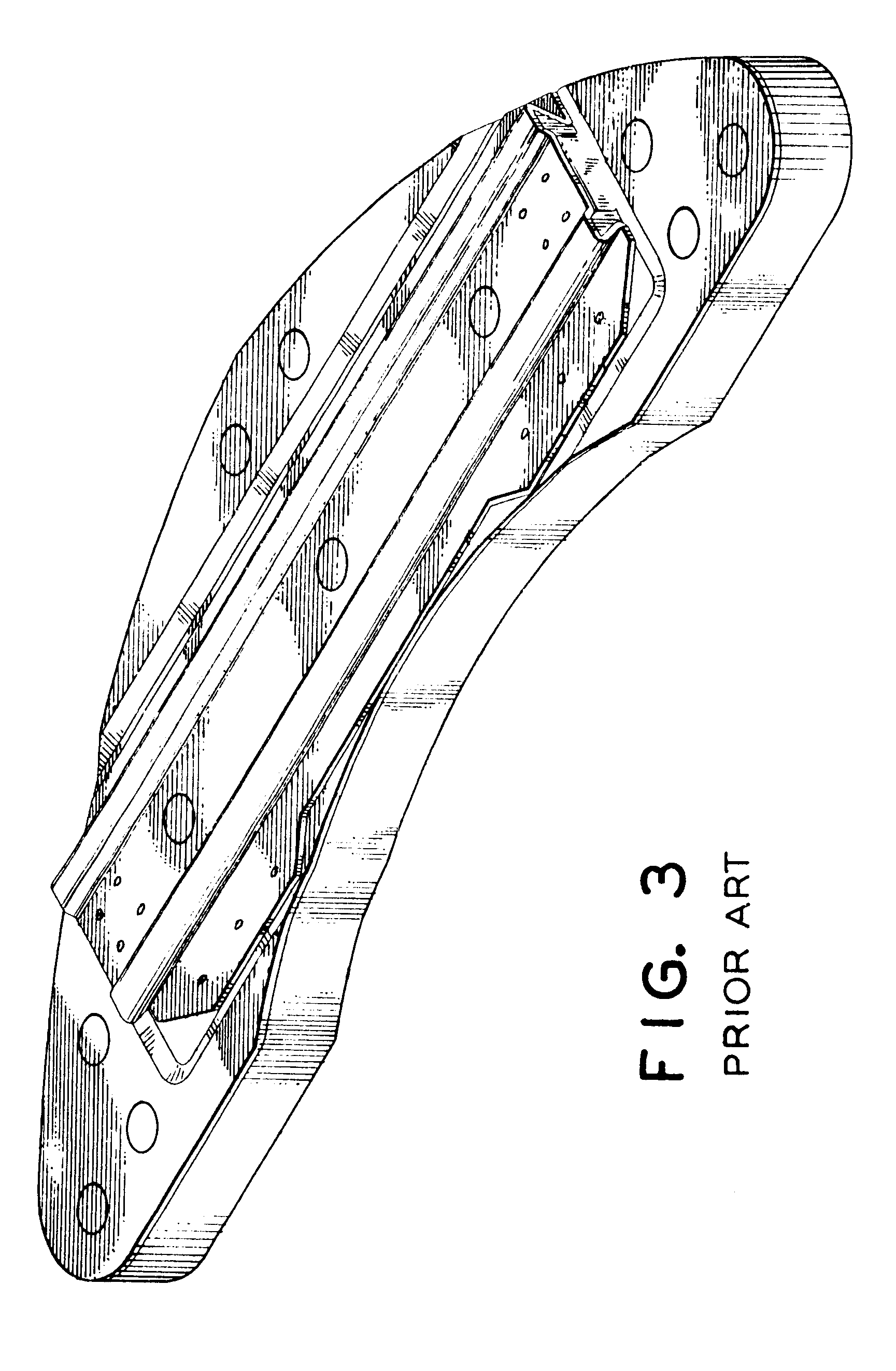

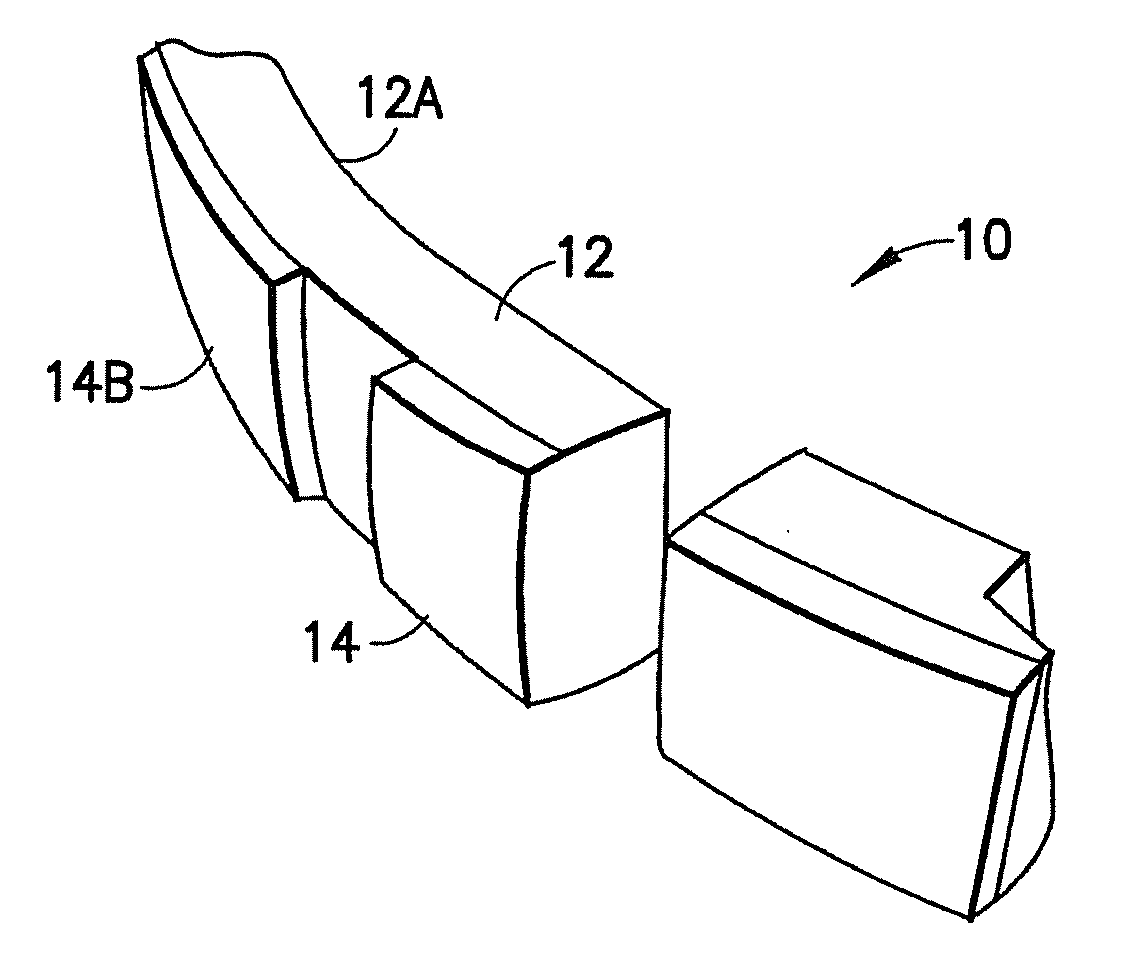

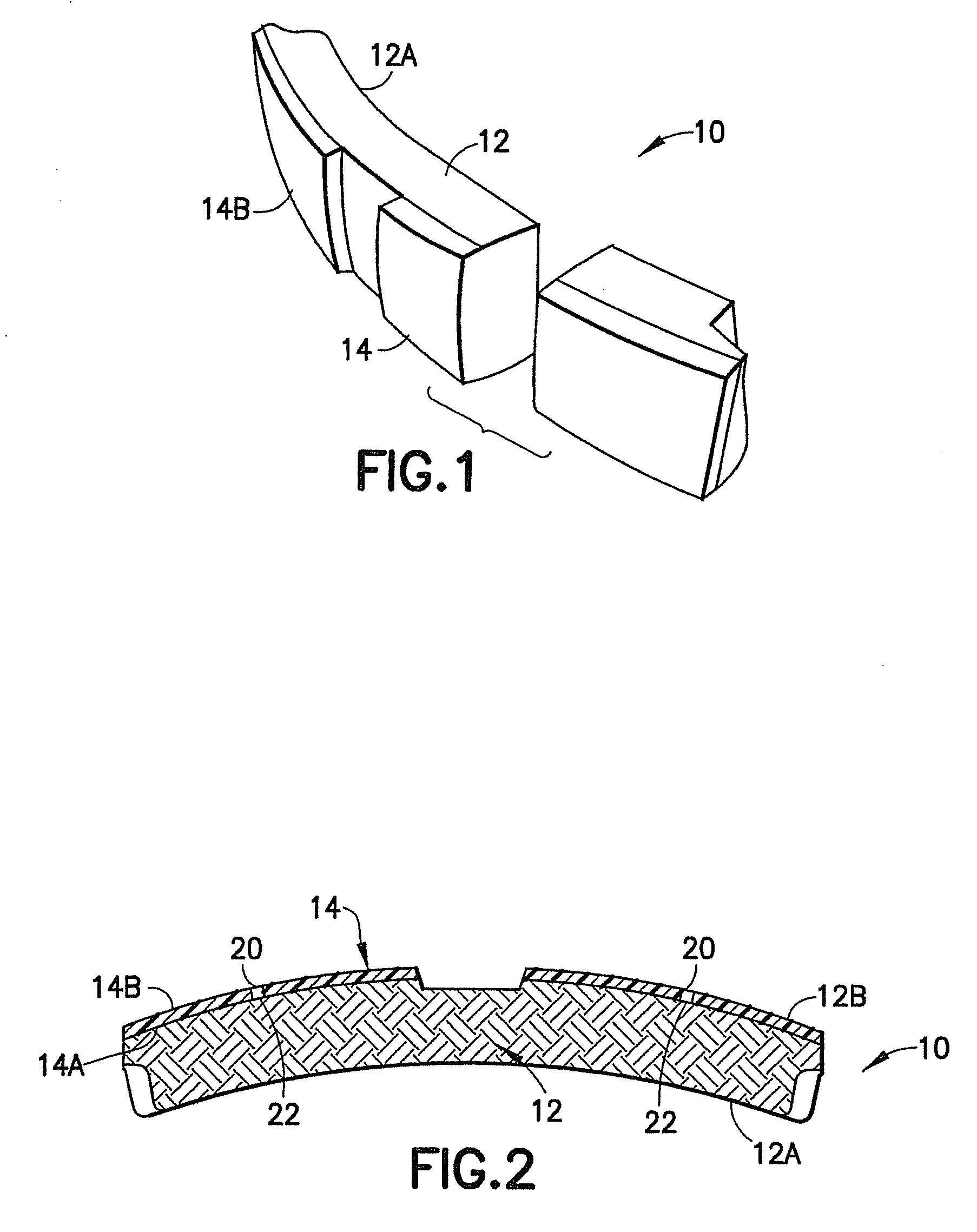

Polymer based backing plates for railway brake shoes and disc pads

InactiveUS20020053492A1Extended service lifeEasy to manufactureBraking membersFriction liningEngineeringPolymer

A lightweight backing plate for use with at least one of a railway brake shoe and a disc brake pad. Such lightweight backing plate being formed from a predetermined polymeric material selected from a group consisting of unsaturated polyester, polyphenylene sulfide, glass epoxy, phenolic polymers and various combinations thereof.

Owner:WESTINGHOUSE AIR BRAKE CO

Railway brake beam material XWQ470E and machining method

ActiveCN107058865ASatisfy the use effectAvoid surface crackingProcess efficiency improvementElectric furnaceNiobiumRare earth

The invention discloses a railway brake beam material XWQ470E and a machining method. The material comprises the following components: 0.12-0.20 of C, 0.25-0.35 of Si, 1.20-1.50 of Mn, P not more than 0.020, S not more than 0.010, 0.20-0.30 of Cr, 0.30-0.55 of Ni, Mo not more than 0.20, 0.08-0.14 of V, 0.015-0.035 of Al, 0.015-0.030 of Nb, and 0.001-0.03 of Ce; in a continuous casting and straightening procedure, the straightening temperature of a continuous-cast blank is controlled within 930-950 DEG C; the normalization temperature is 920+-20 DEG C; the continuous-cast blank is insulated by 40 minutes, and then, is cooled by air; and the tempering temperature is 480+-30 DEG C. The material is prepared through hot cutting, drawing and shaping by brand new component design and production process, and is excellent in manufacturability and stable in quality. In the component design process, such alloy elements as nickel, niobium, vanadium and rare earth are added, so that the overall toughness, the welding performance and the wear resistance of the material are improved, and the excellent application effect is achieved.

Owner:SHANDONG XIWANG SPECIAL STEEL

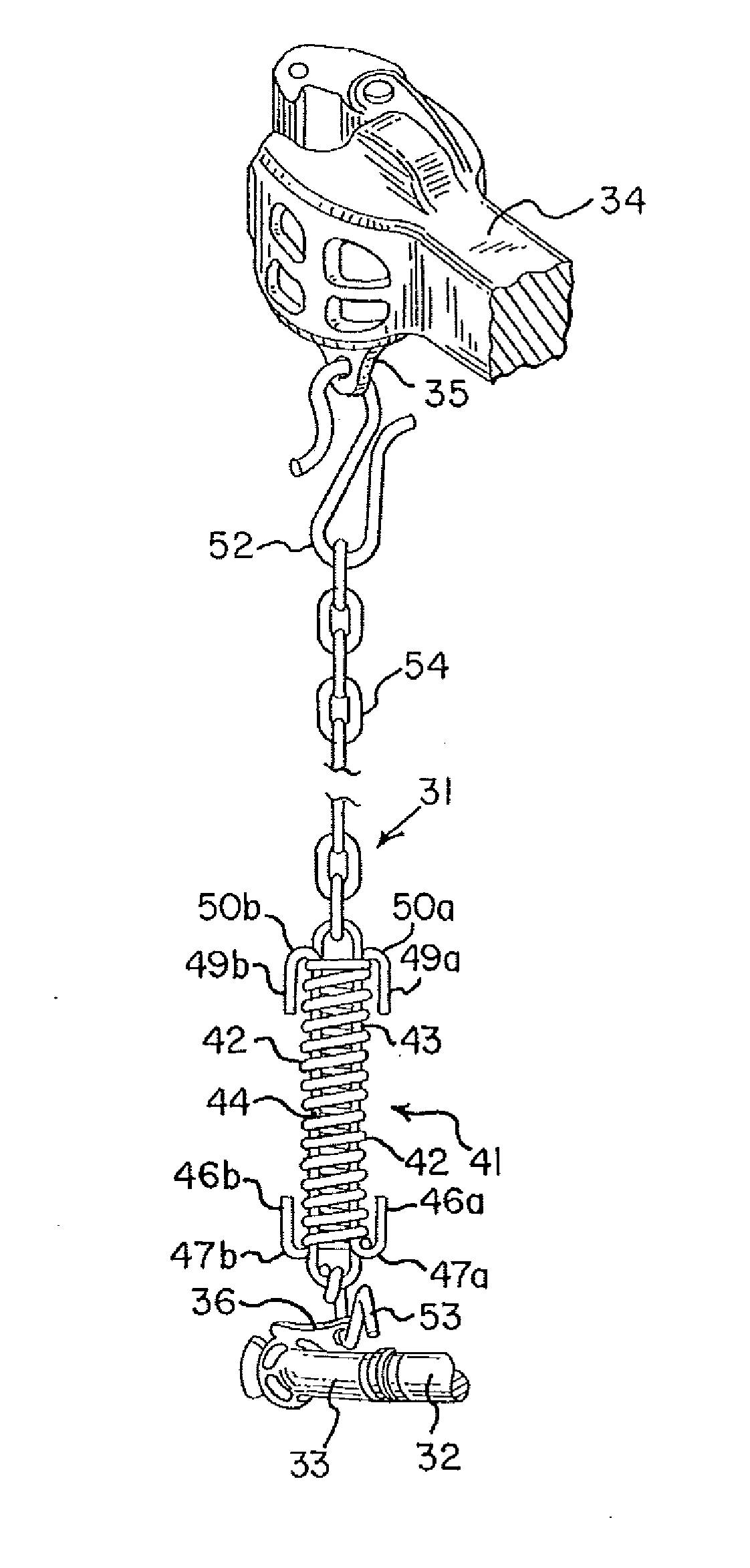

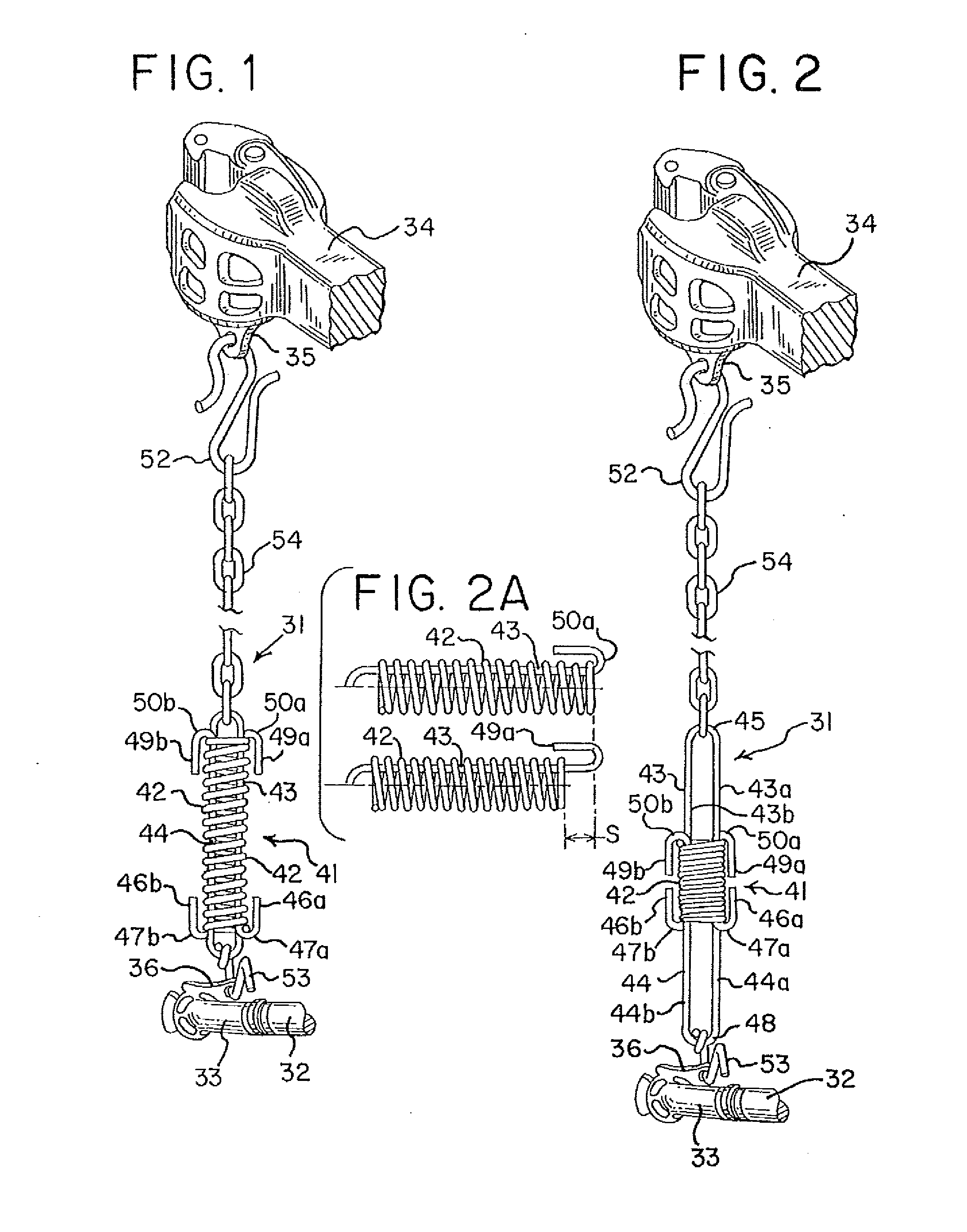

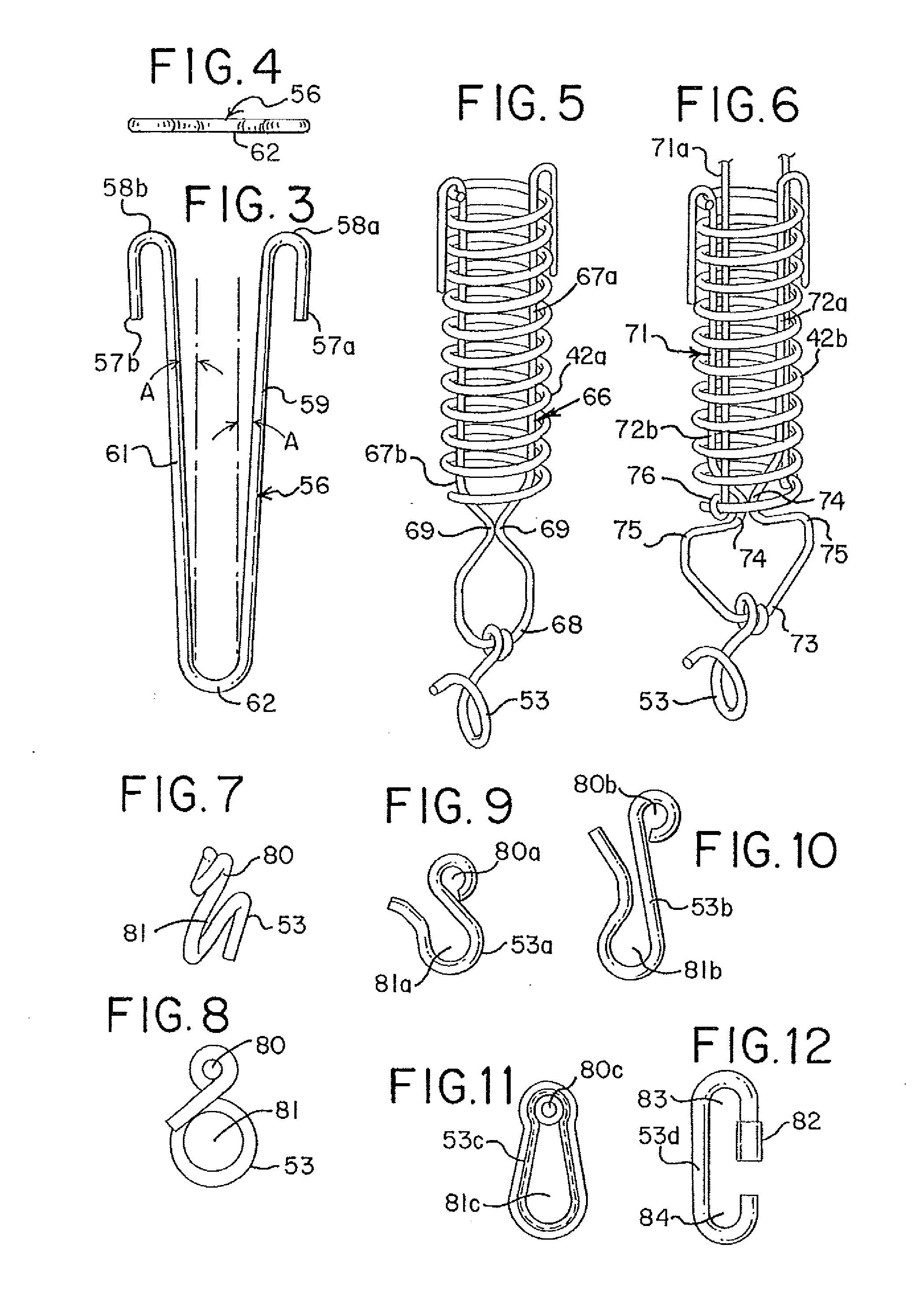

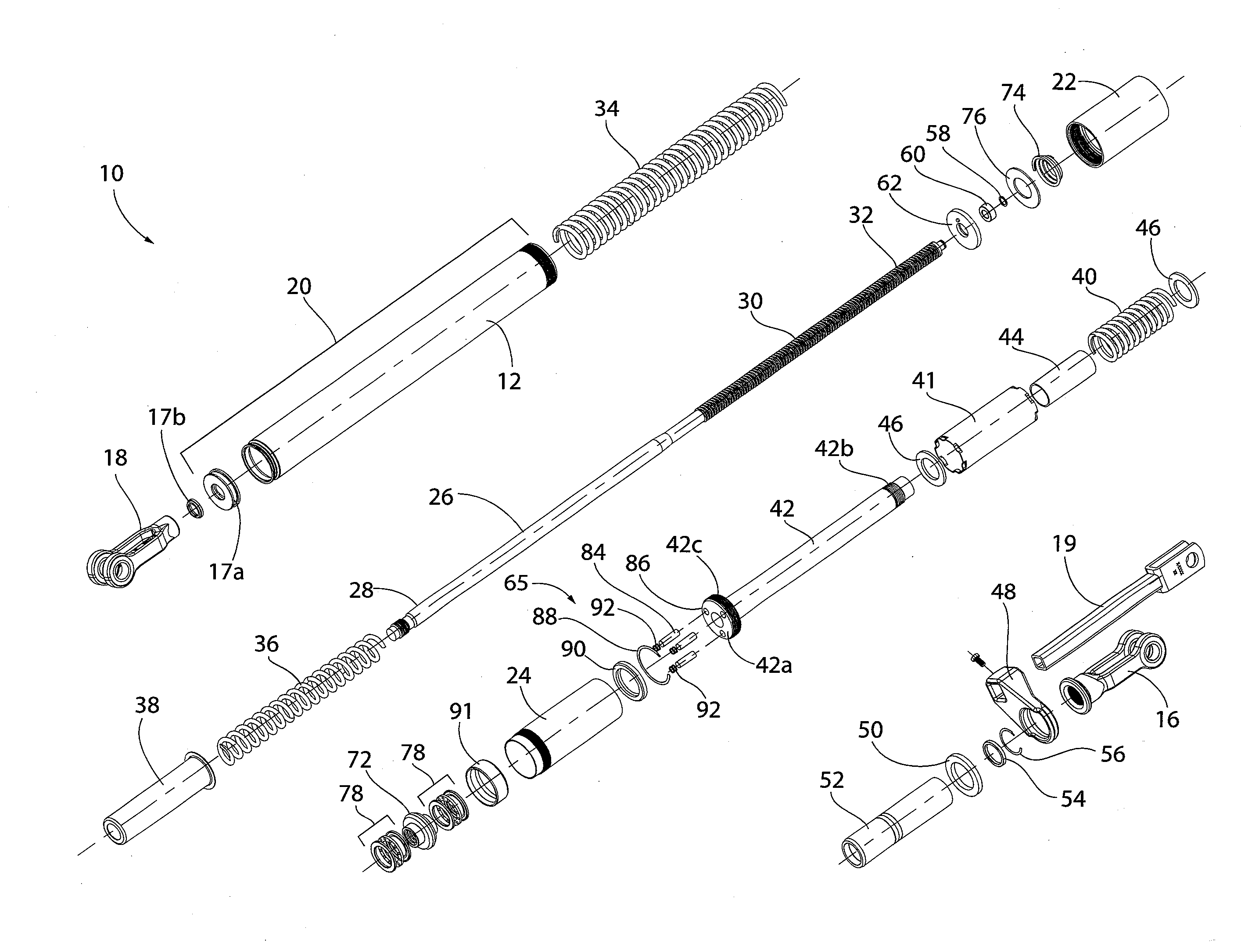

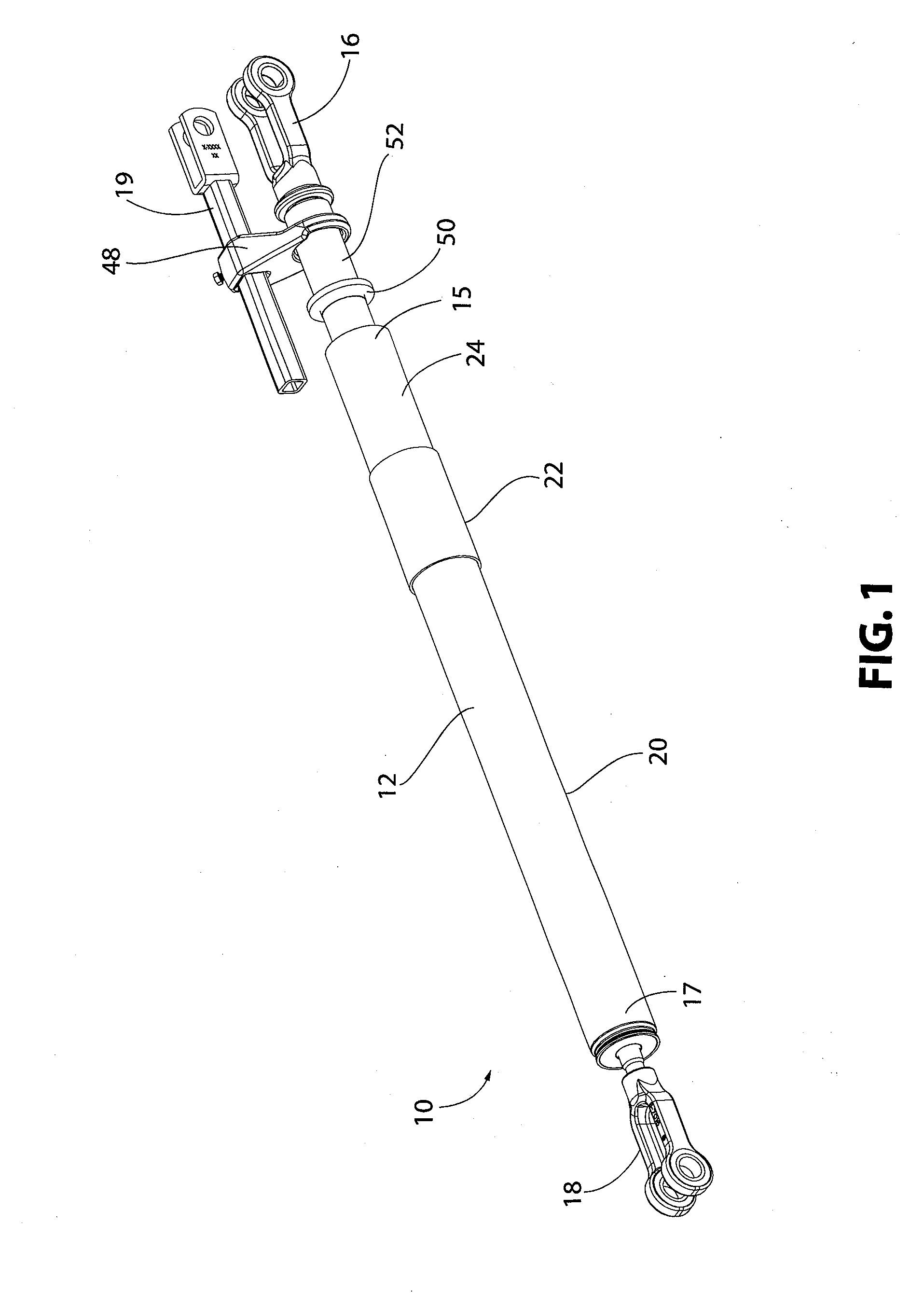

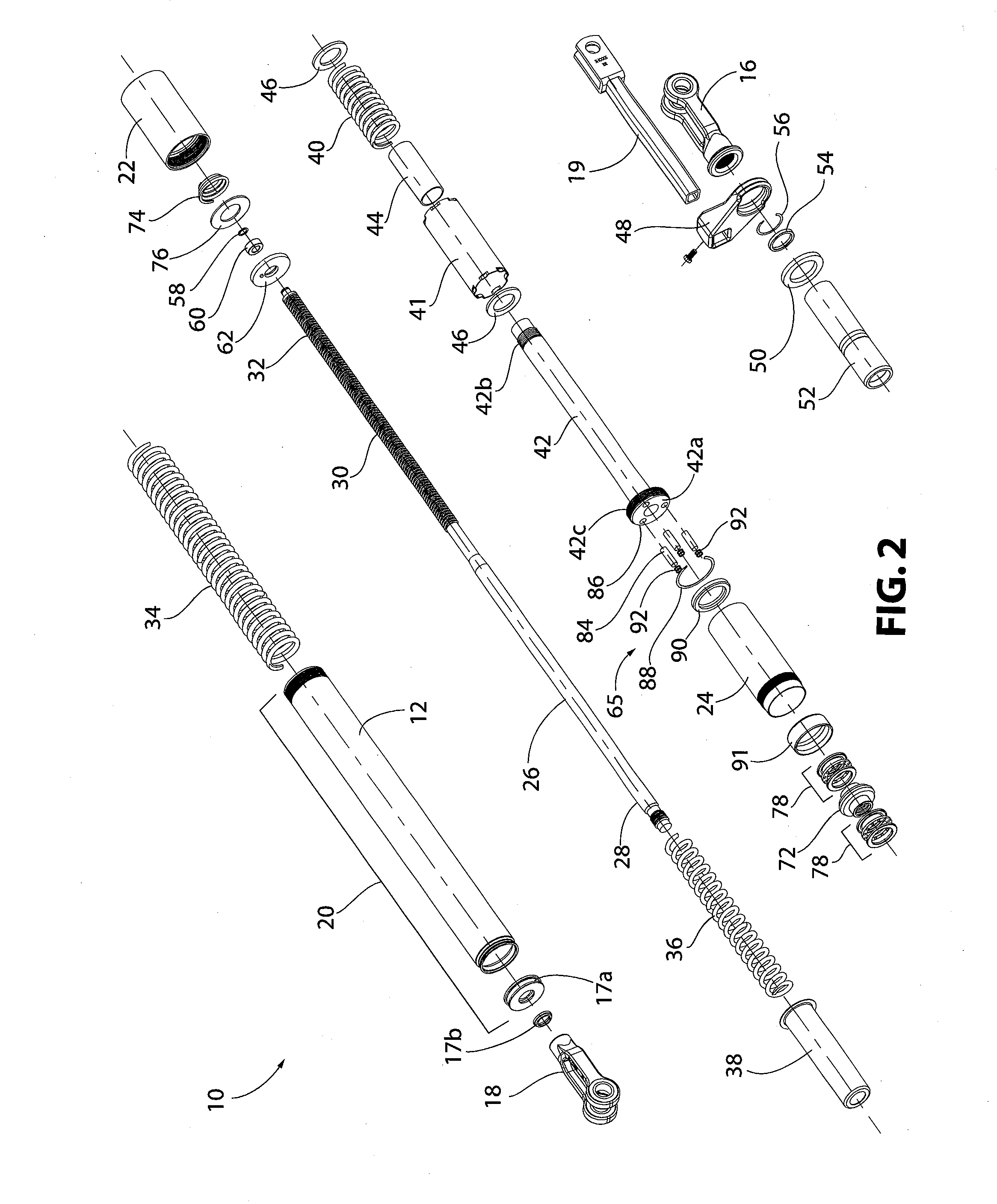

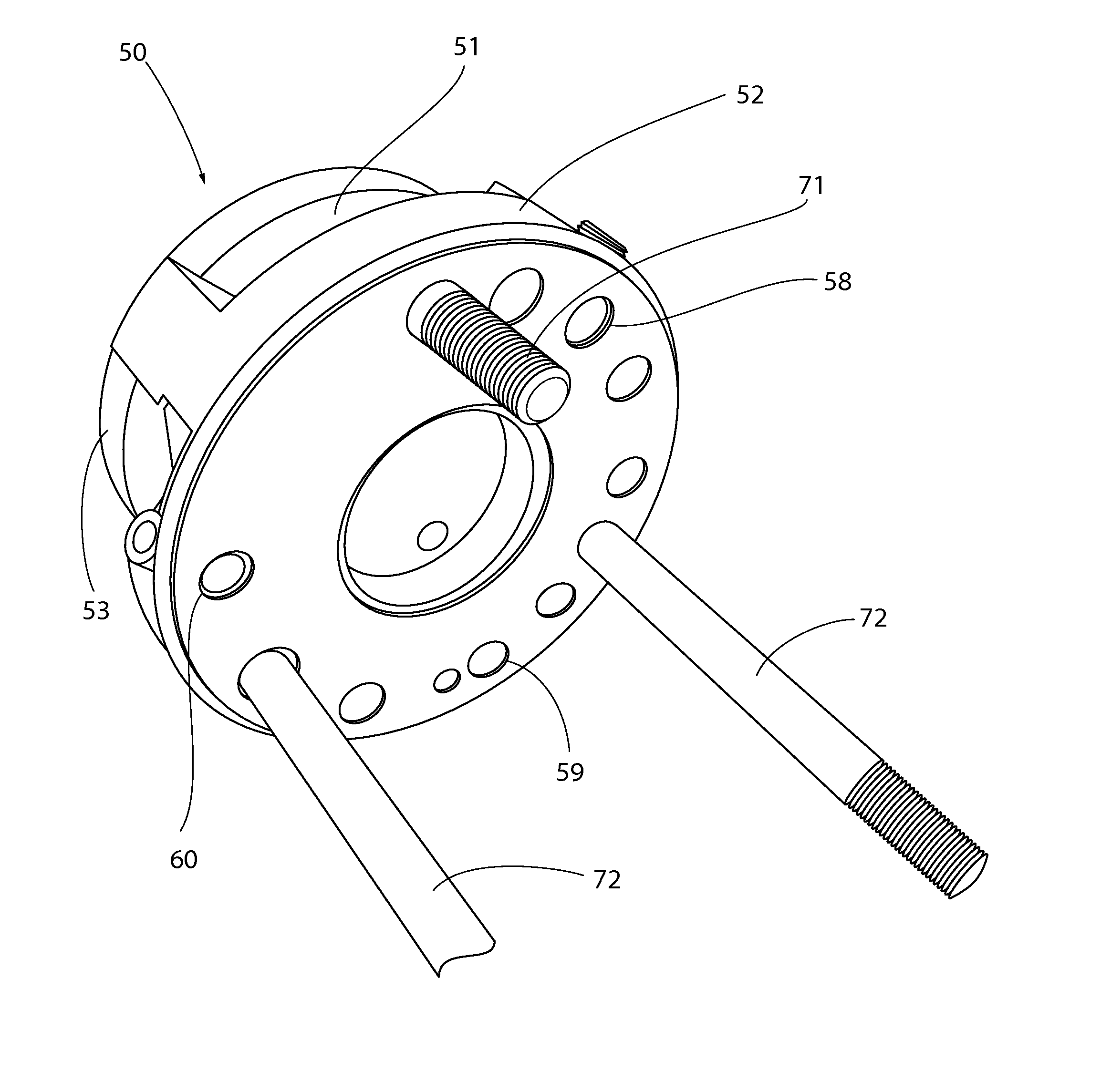

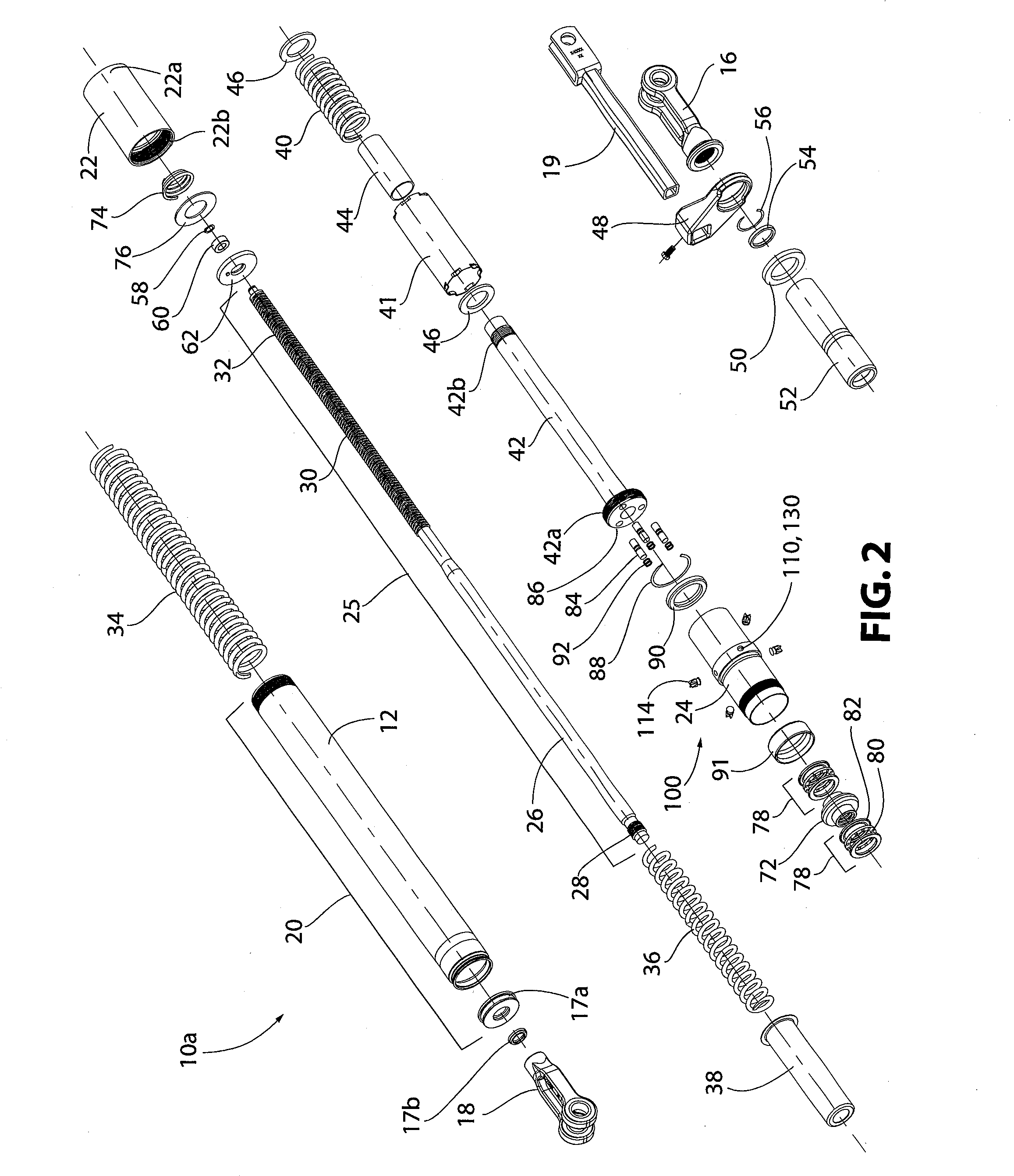

Spring-style air brake hose support

ActiveUS20150158479A1Reasonable degree of flexibilityElongation of the length of the support assemblyPipe supportsPipe elementsHose supportRailway brake

A spring-style railway hose support has a retraction-biased extension unit of a longitudinally compressible spring and a pair of oppositely directed internal wireforms within the longitudinally compressible spring. The internal wireforms engage respective ends of the longitudinally compressible spring, and a closed end of each is configured to allow it to project beyond a respective end of the longitudinally compressible spring. The retraction-biased extension unit is adapted to be directly or indirectly connected to a railway brake hose and to a railway car component that is positioned above the hose on a railway car.

Owner:IRECO INC

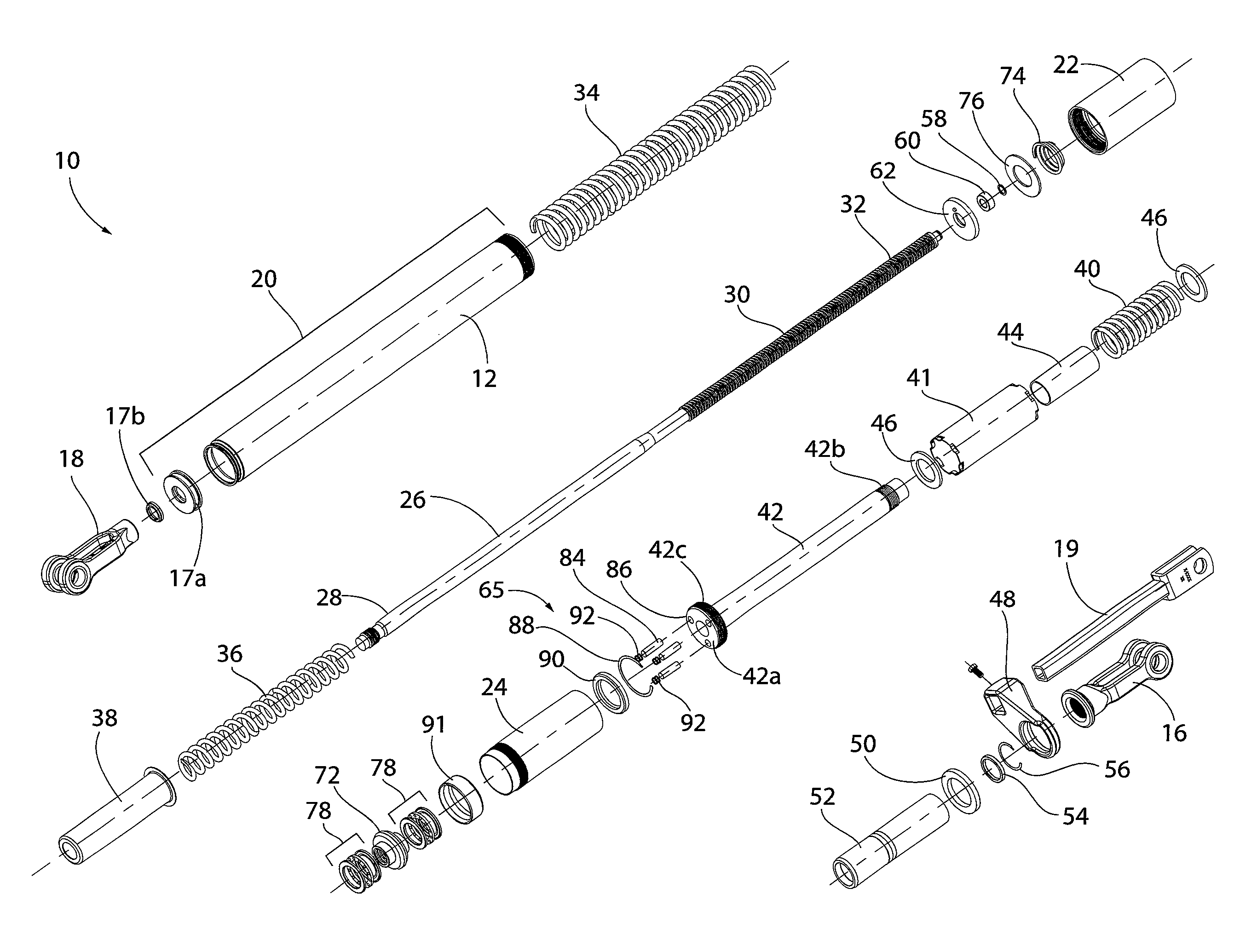

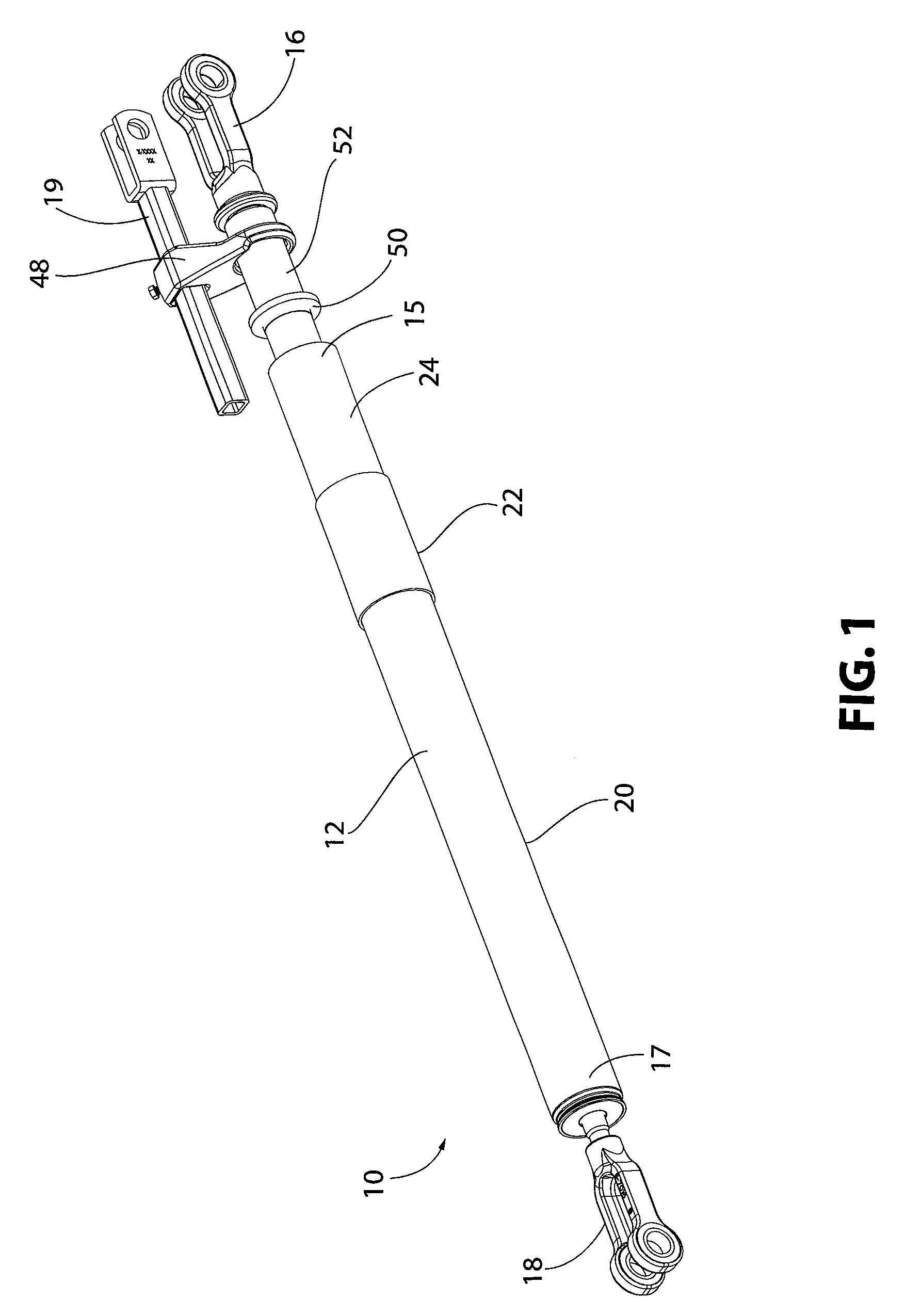

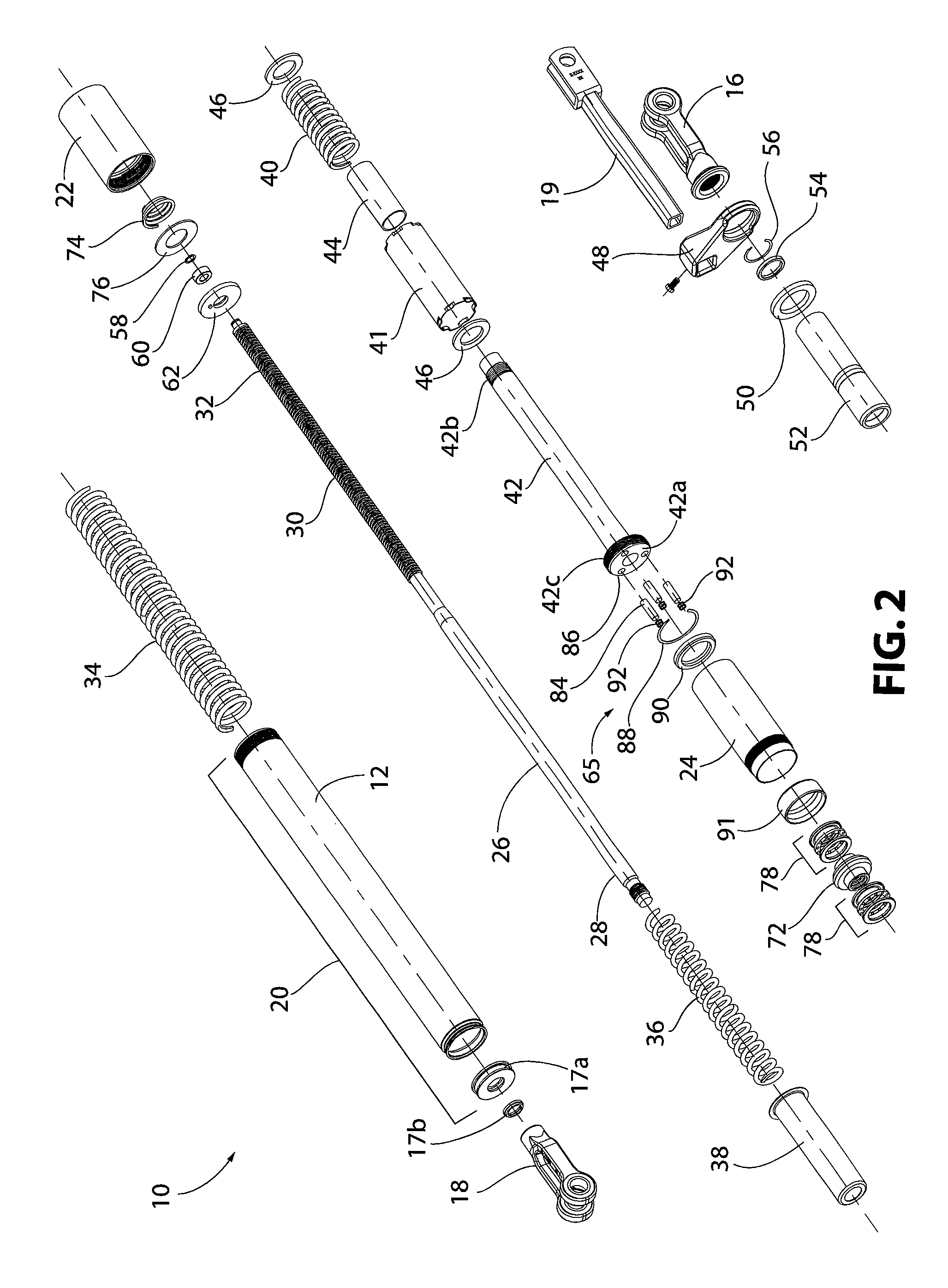

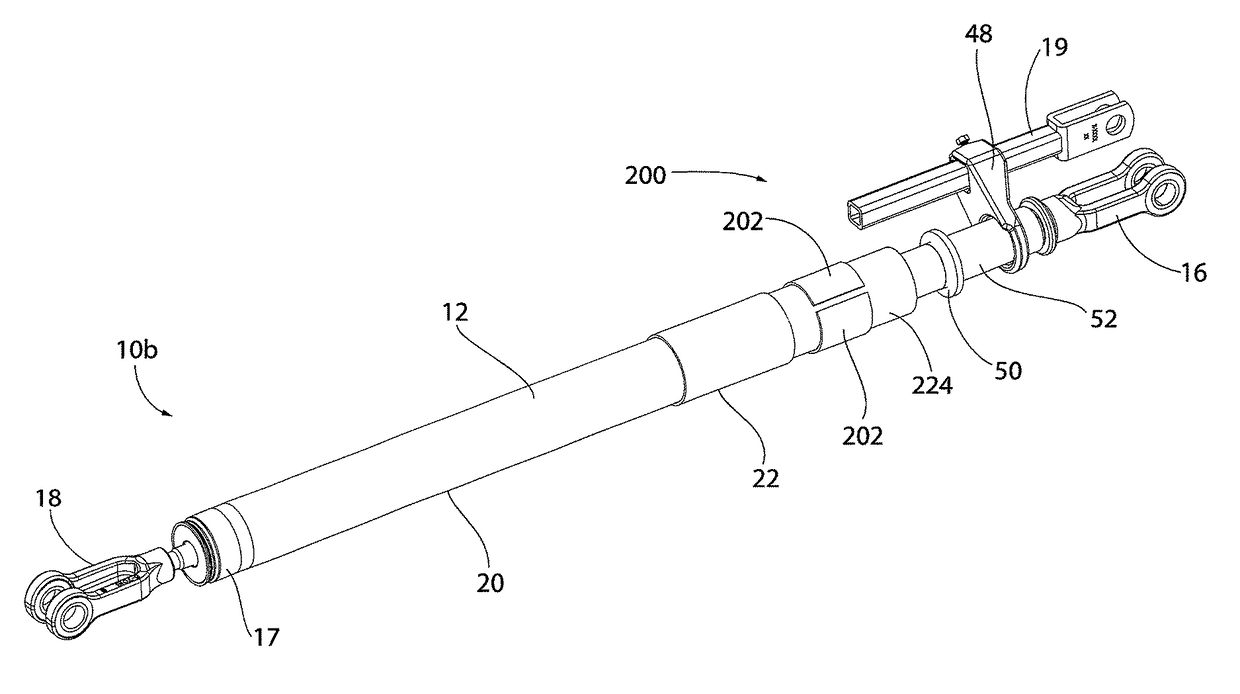

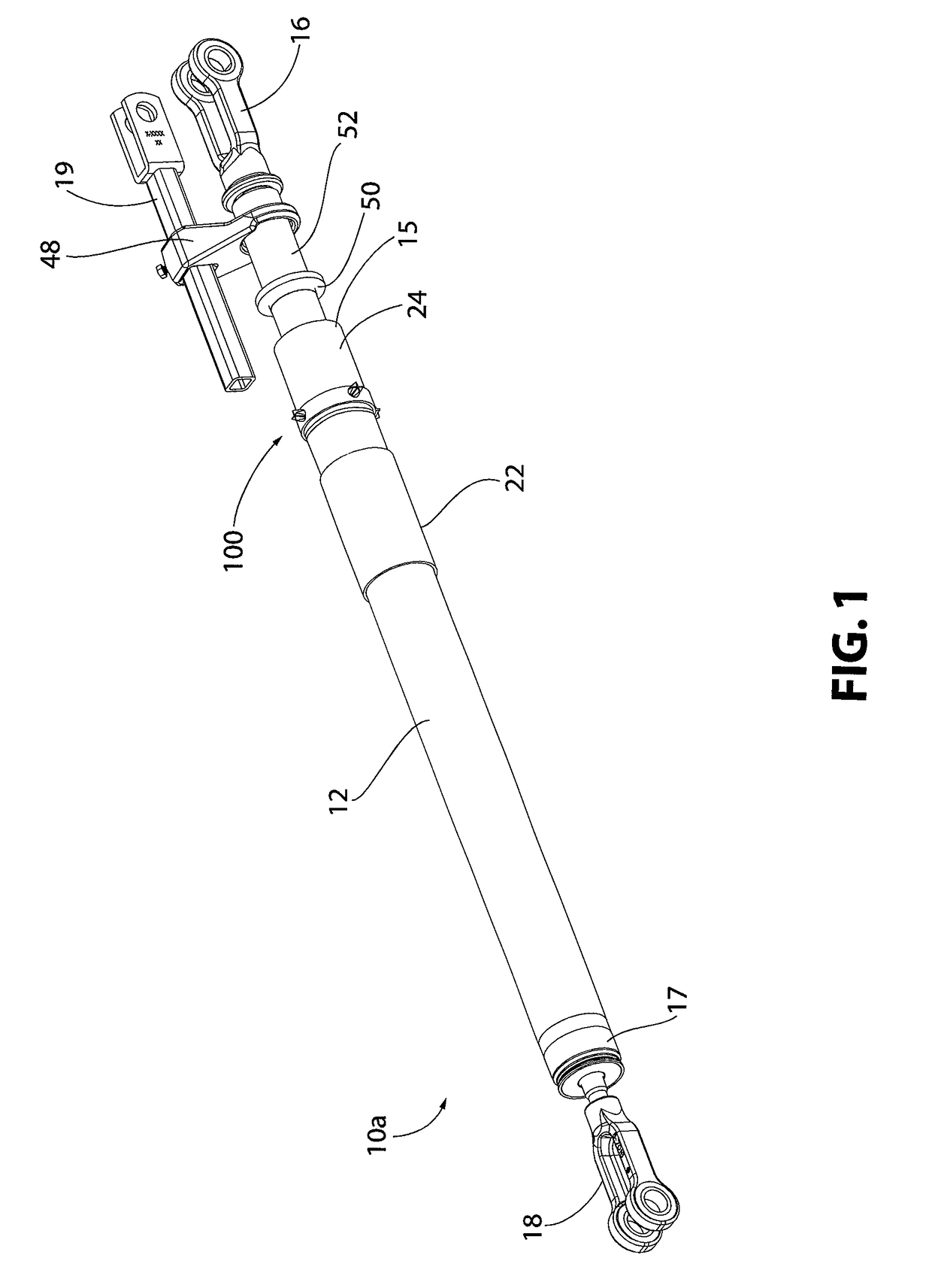

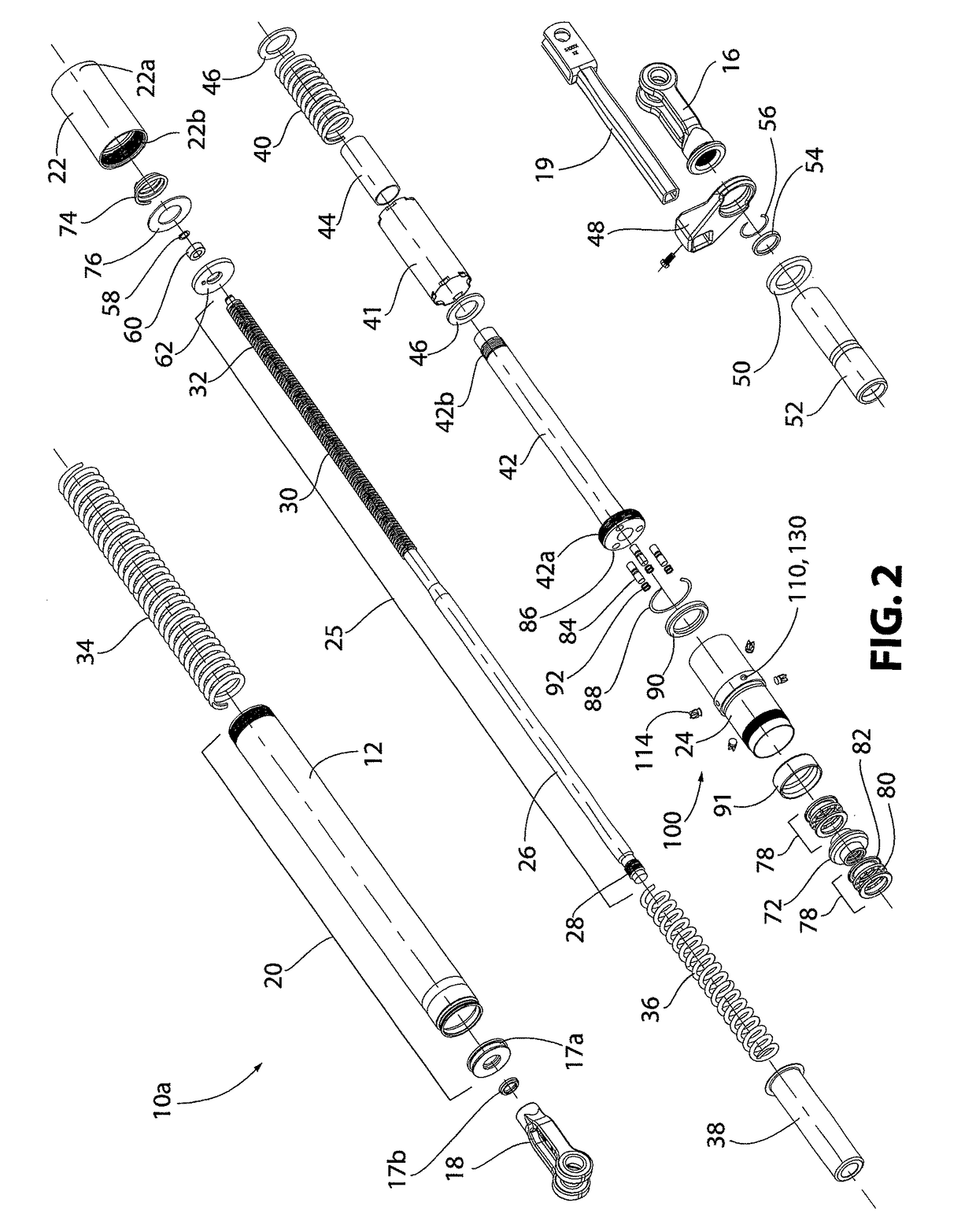

Slack adjuster contaminant mitigation device

ActiveUS20150001016A1Reduce exposureAvoid enteringEngine sealsBrake wear compensation mechanismEngineeringRailway brake

A contaminant mitigation device for use with a slack adjuster for a railway brake rigging to protect the critical operating area of the slack adjuster. The critical operating area of a slack adjuster includes the components that are configured to operate together to adjust the brake rigging. The slack adjuster includes at least a main housing portion, a cone nut housing portion enclosing the critical operating area of the slack adjuster, and an overtravel housing portion. The contaminant mitigation device includes a sealing system configured for cooperating with at least one of the main housing portion, cone nut housing portion, and overtravel housing portion to seal the critical operating area against entrance of fluid and / or contaminants therein and / or to at least reduce the exposure of this area to fluid and / or contaminants. The contaminant mitigation device can also include a drainage system associated therewith.

Owner:WABTEC HLDG CORP

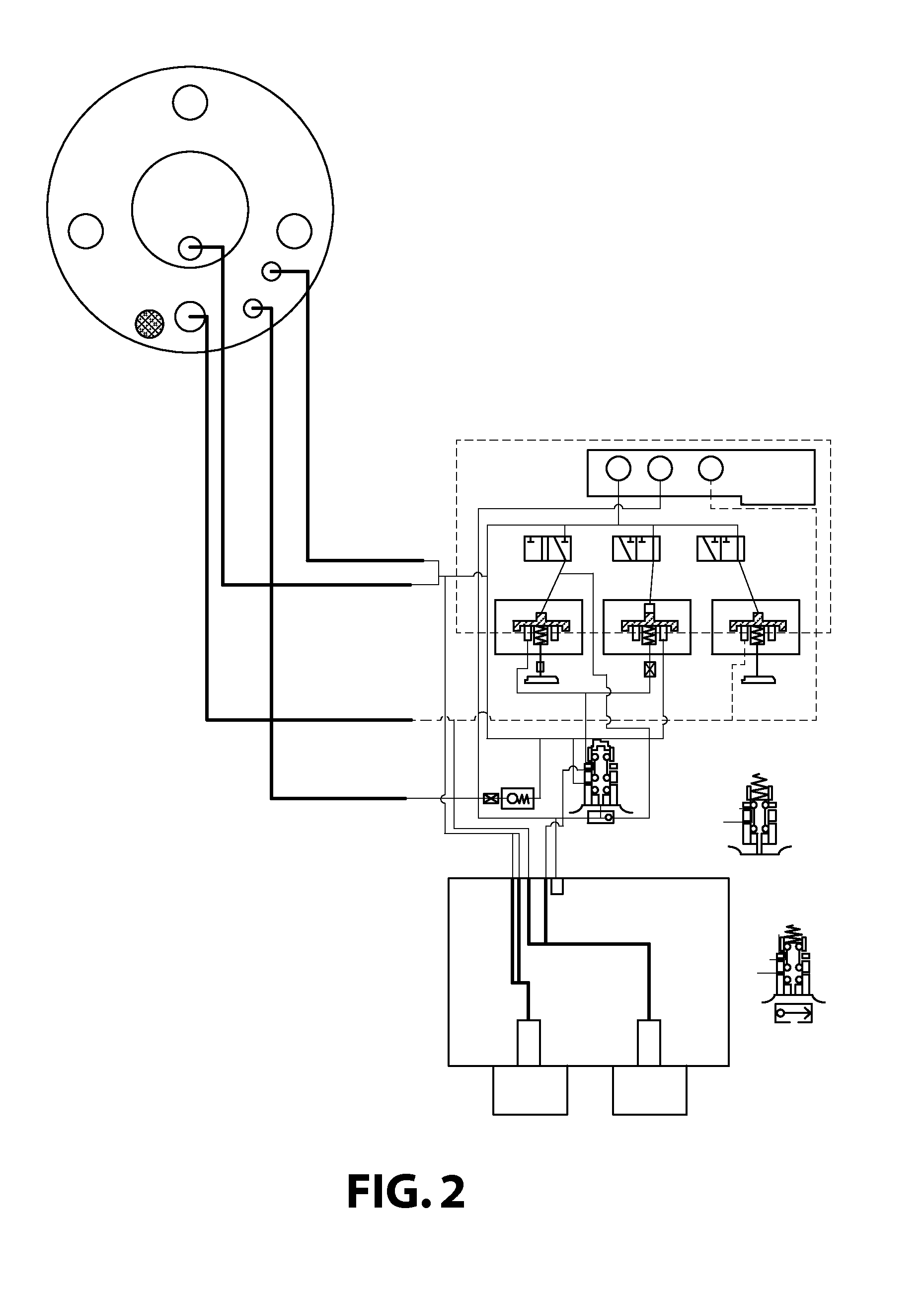

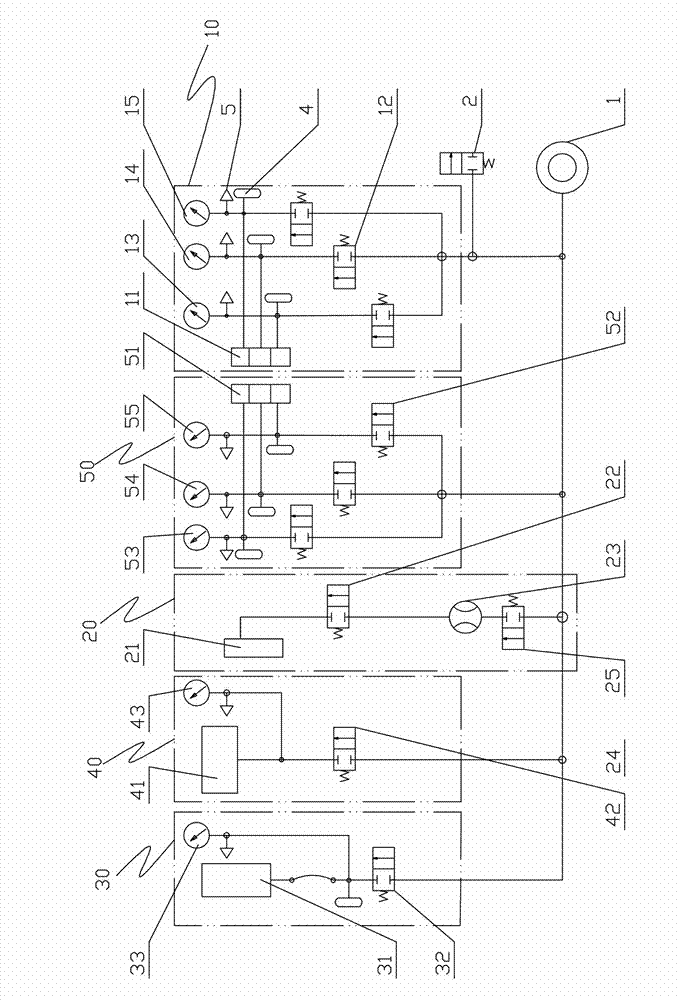

ECP/Triple Valve Transition Plate

ActiveUS20140049037A1Effective applicationAdjustable jointsPipe elementsMechanical engineeringRailway brake

A transition plate connects an electronic manifold to a pipe mounting bracket of a railway brake system and includes a body having a manifold portion that defines a face configured to engage the manifold and a pipe bracket portion that defines a face configured to engage the pipe mounting bracket; ports defined in the manifold face that are configured to align and communicate with ports in the face of the manifold; ports defined in the pipe bracket face that are configured to align and communicate with ports in the face of the pipe mounting bracket; and a plurality of air passages extending through the body for connecting the plurality of ports defined in the manifold face with the plurality of ports defined in the pipe bracket face. The transition plate establishes a pneumatic interface between the electronic manifold and the pipe mounting bracket.

Owner:WABTEC HLDG CORP

Slack adjuster contaminant sump, drain, and overload relief

ActiveUS20150075924A1Reduce exposureAvoid accumulationBrake wear compensation mechanismSlack adjustersEngineeringRailway brake

A drainage system for use with a slack adjuster for a railway brake rigging. The drainage system allows fluid and other contaminants to drain from the slack adjuster to prevent the fluid and contaminants from accumulating within the slack adjuster, contacting an operating area of the slack adjuster, and interfering with the operation of the slack adjuster. The slack adjuster includes a main housing portion, a cone nut housing portion enclosing a critical operating area of the slack adjuster, and an overtravel housing portion. The drainage system includes at least one aperture extending through a sidewall portion of the overtravel housing portion. The at least one aperture is configured to allow fluid and / or contaminants to drain there through to reduce exposure of the critical operating area to fluid and / or contaminants. A plug and / or patch can be provided to sealingly and / or removably engage the at least one aperture.

Owner:WABTEC HLDG CORP

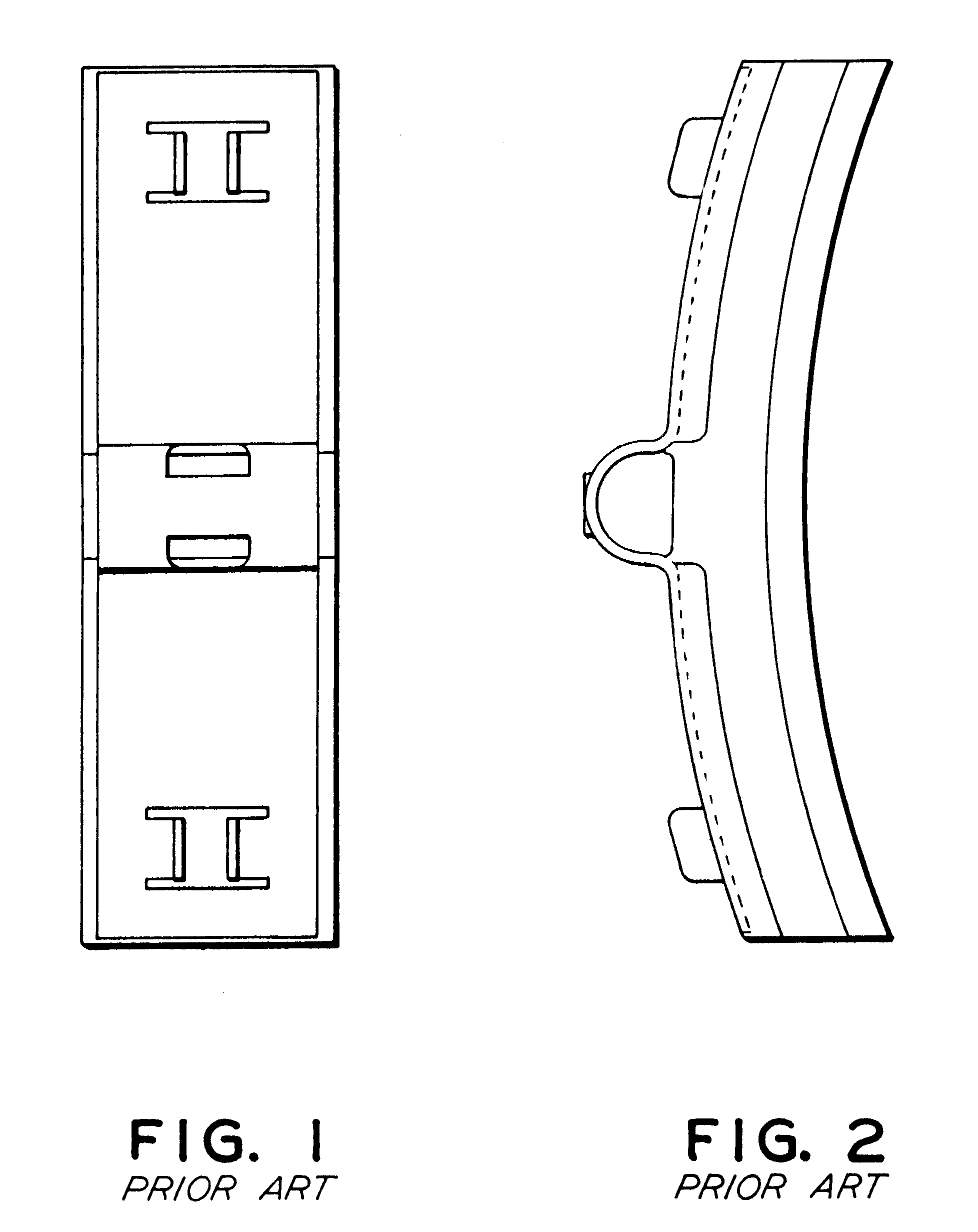

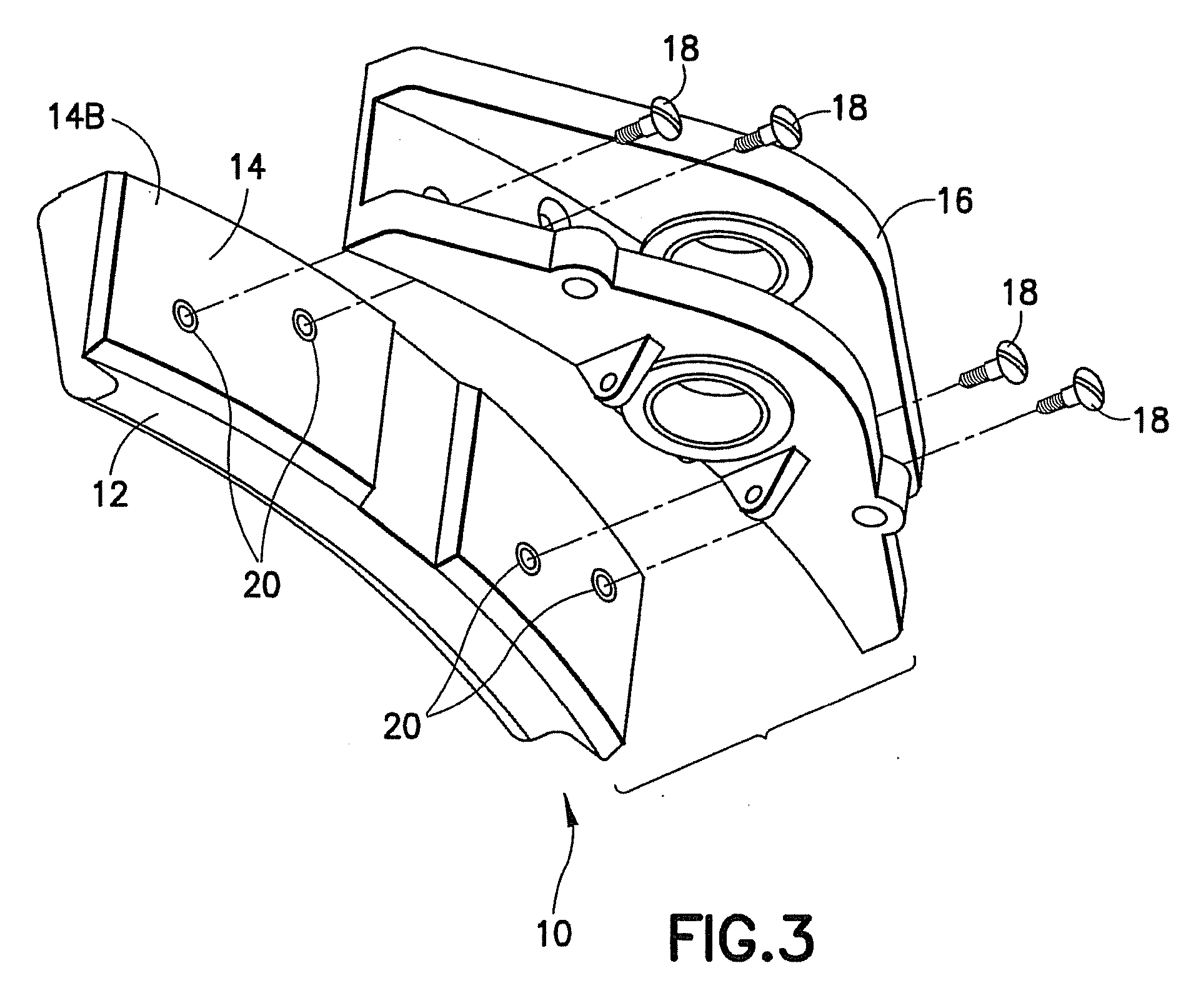

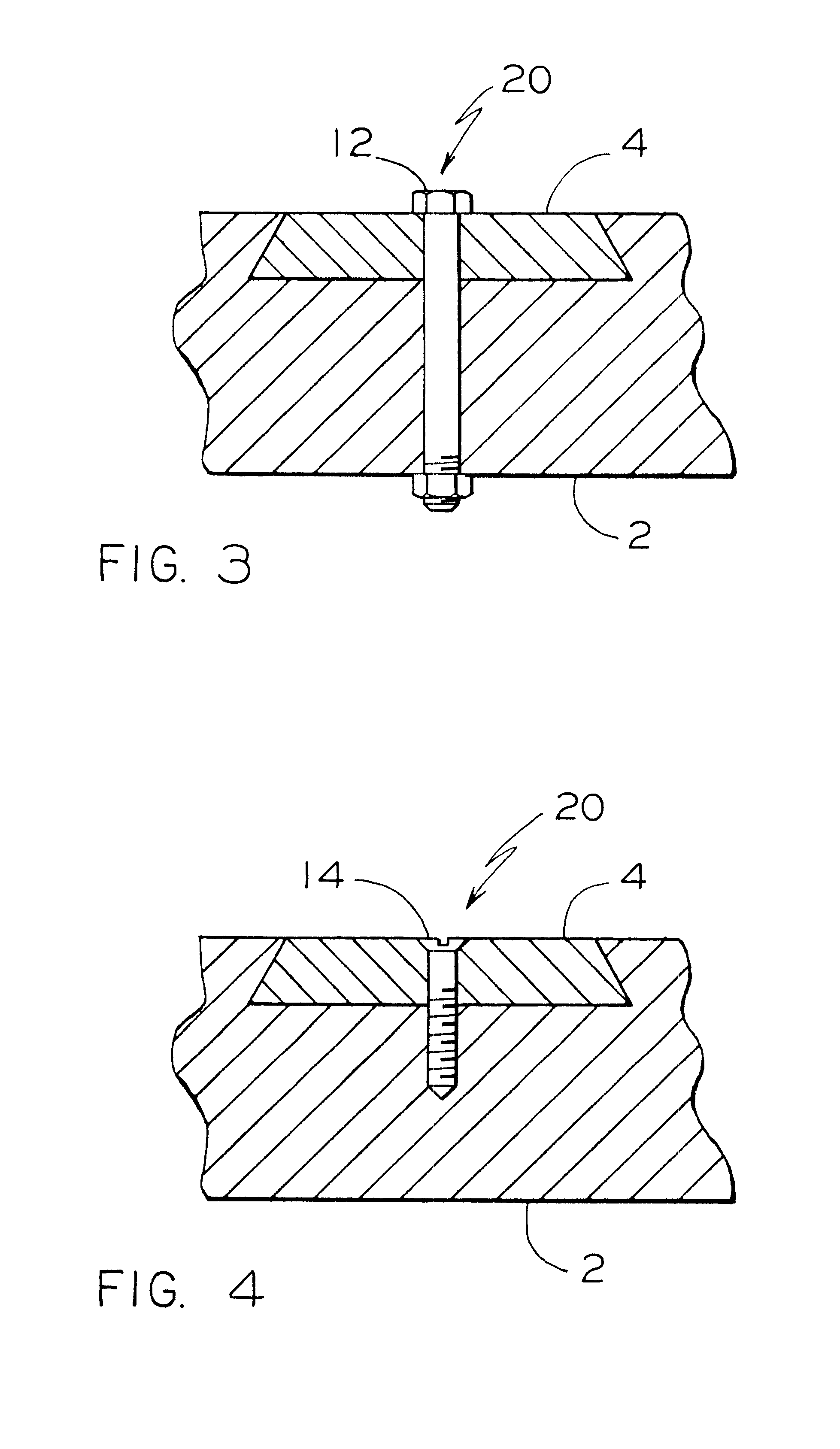

Railway brake shoe backing plate with improved mounting alignment feature

A brake shoe for a railway vehicle having a three-piece backing plate formed of a longitudinal main plate portion having a front surface to which a friction material is attached, and an end-plate portion attached to each end of the longitudinal main plate portion. Each of the end plate portions having, a pair of wall members extending generally perpendicularly therefrom adapted to engage not only the edge surface of a the main plate portion but also the edge surfaces of the brakehead to which the three-piece backing plate is attached.

Owner:RFPC HLDG CORP

Air brake hose support bracket

ActiveUS9625060B2Easy and faster and more installationSusceptibility to damageRailway hydrostatic brakesPipe supportsEngineeringRailway brake

A railway car air brake hose support bracket has an upper portion with first and second attachment members, a lower portion and an air hose connector. The first attachment member enters into and engages a portion of an accessible compartment of an uncoupling mechanism housing below the coupler head, and the second attachment member is secured to an air brake hose support lug of the railway car coupler. The air brake hose connector engages an air brake hose assembly and suspends this hose assembly from the railway coupler at a predetermined distance above the rail bed. A method of installing the hose support bracket includes positioning the first and second attachment members, securing them in place, and attaching one or more railway brake hose units to the air hose connector, either before or after this positioning and securing of the upper portion of the bracket.

Owner:IRECO INC

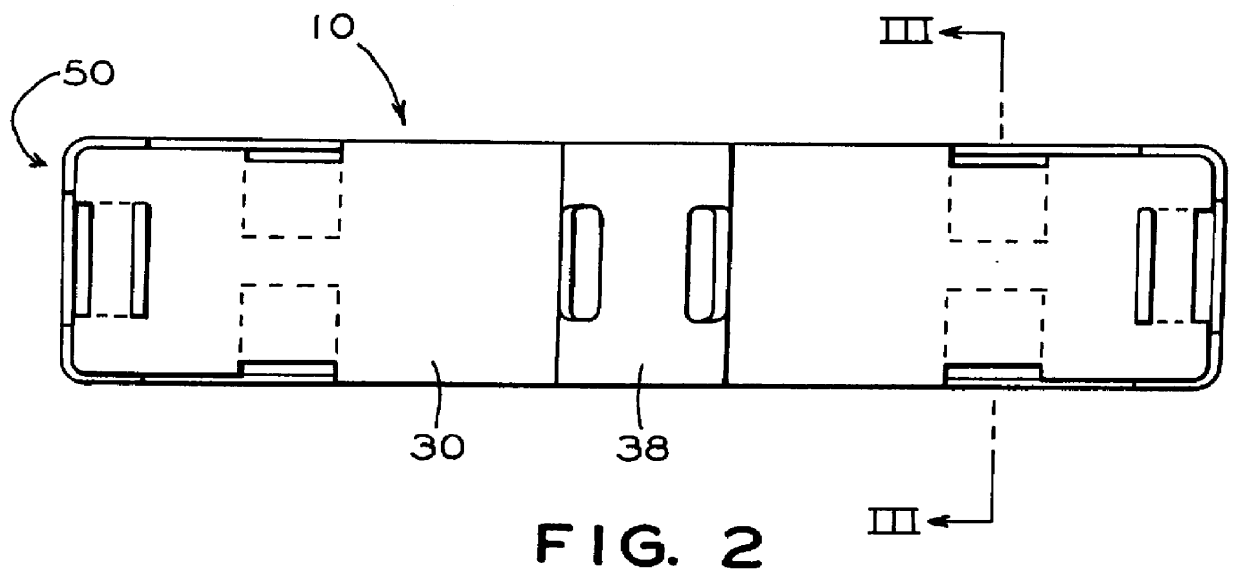

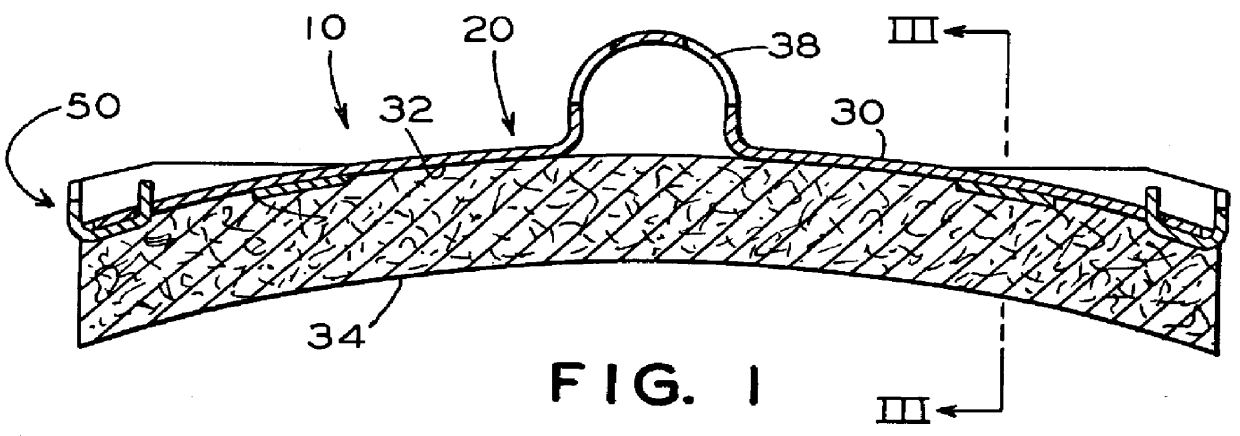

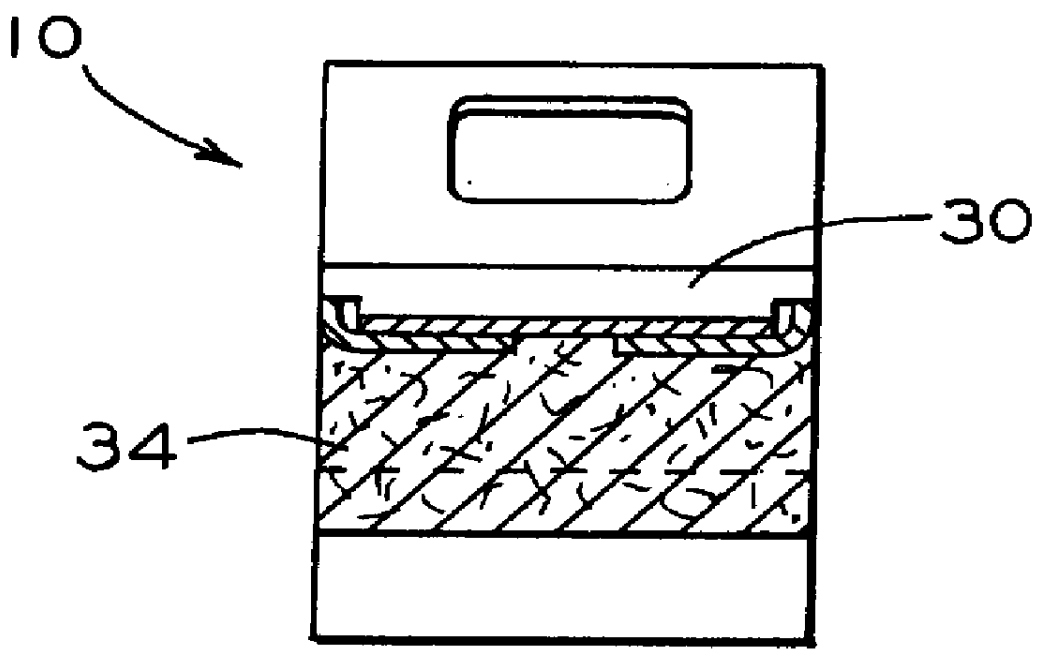

Polymer based backing plates for railway brake shoes and disc pads

InactiveUS6474452B2Extended service lifeEasy to manufactureBraking membersFriction liningEngineeringBrake pad

A lightweight backing plate for use with at least one of a railway brake shoe and a disc brake pad. Such lightweight backing plate being formed from a predetermined polymeric material selected from a group consisting of unsaturated polyester, polyphenylene sulfide, glass epoxy, phenolic polymers and various combinations thereof.

Owner:WESTINGHOUSE AIR BRAKE CO

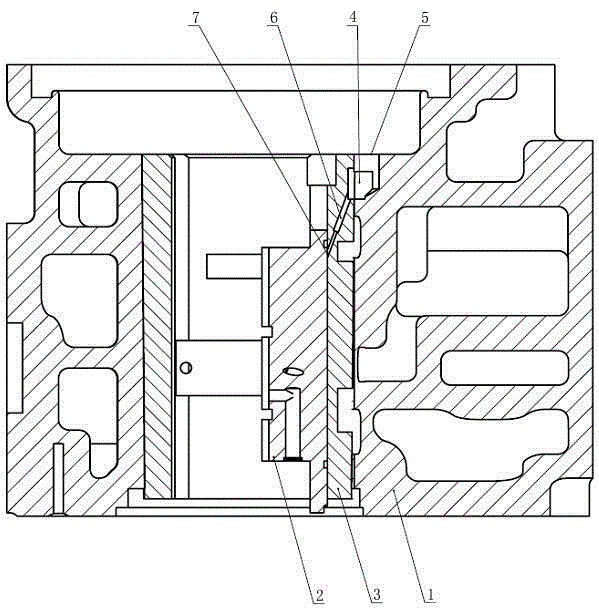

Railway brake valve with self-lubricating function

ActiveCN102878313AExtension of timeGuaranteed lubrication effectSlide valveWorking environmentProduct processing

The invention discloses a railway brake valve with a self-lubricating function. The railway brake valve comprises a main valve body, a slide valve and a slide valve sleeve which is arranged between the main valve body and the slide valve, wherein an oil storage chamber and an oil filling port which is communicated with the oil storage chamber are arranged on the main valve body, the oil storage chamber is communicated with an oil line which is arranged on the slide valve sleeve, and an oil outlet of the oil line is formed in a non-working area of the working area of the slide valve sleeve. The oil storage chamber is arranged on the main valve body, lubricating oil in the oil storage chamber passes through the oil path in the slide valve sleeve and the oil outlet to reach the working surface for generating an oil film, the slide valve moves up and down at the oil outlet during the operation, so that automatic lubricating is formed on a slide valve surface, a slide valve pair can be enabled to be effectively lubricated, accordingly, the existence time of the oil film is prolonged, the sliding wear is reduced, the working environment of the slide valve pair is improved, and the service live of the slide valve pair is prolonged. The railway brake valve is ingenious in structure, has an obvious effect, and is easy for new product processing and old product reproduction, and the existing railway brake valve is slightly changed.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

Railway brake shoe

Owner:RFPC HLDG CORP

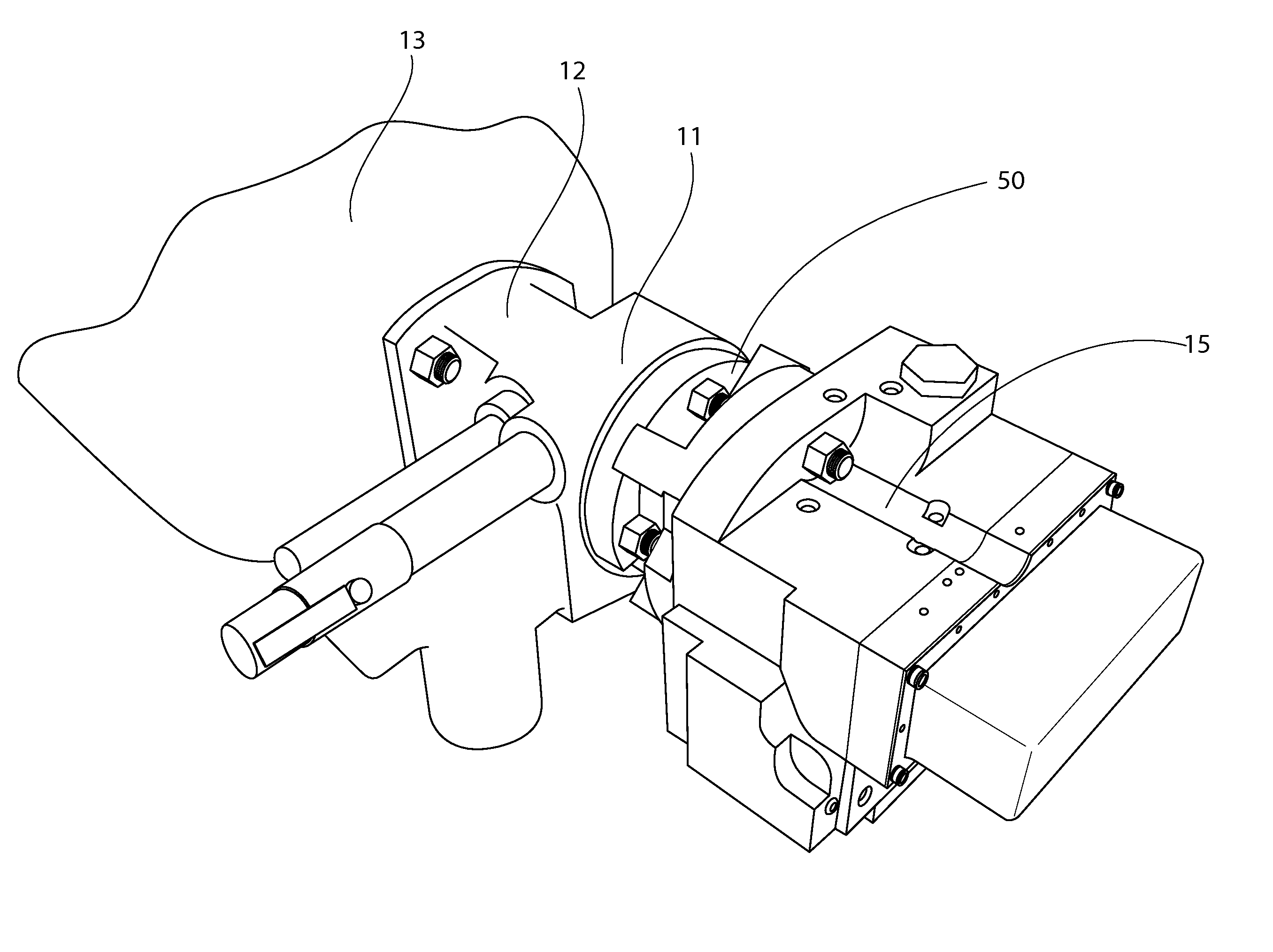

Lubricating Insert for Railroad Brake Head Assembly

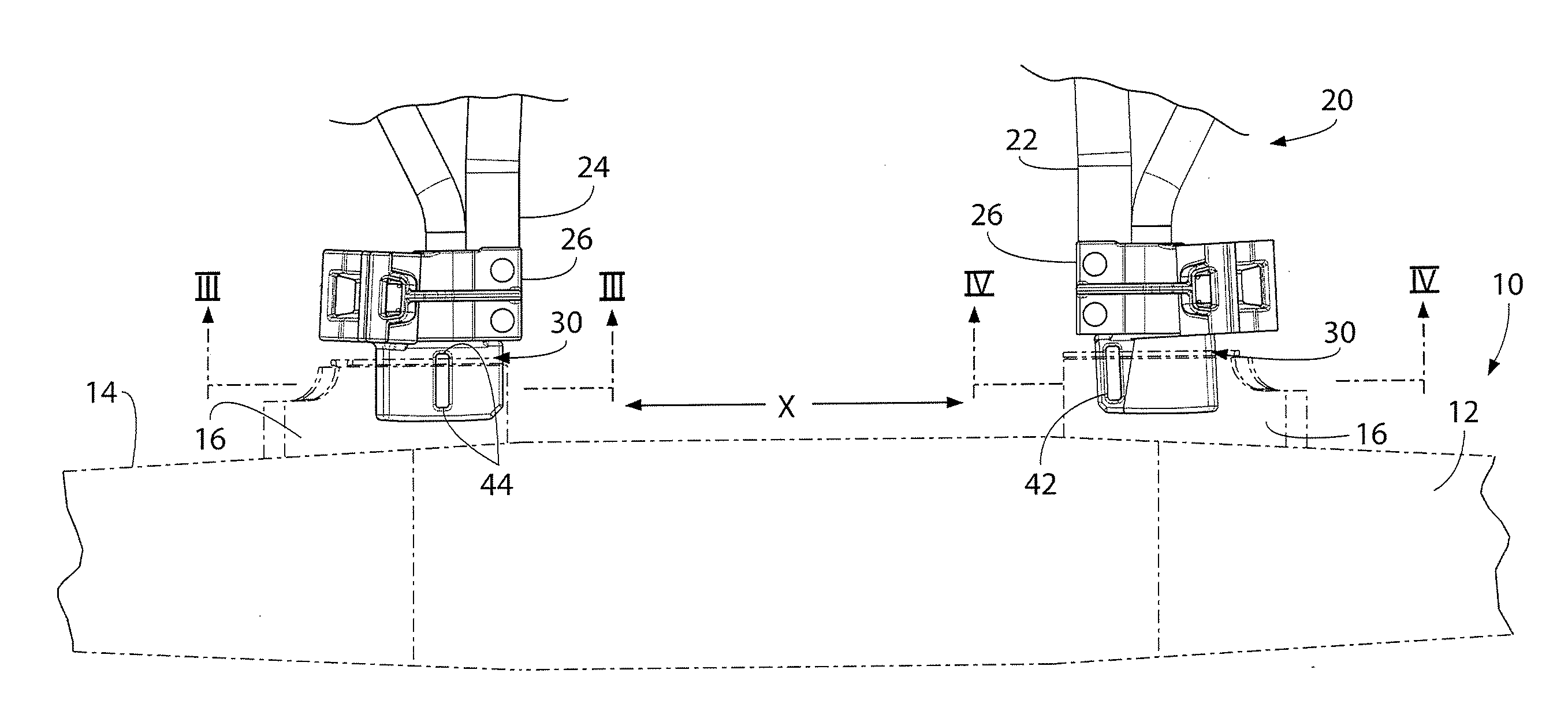

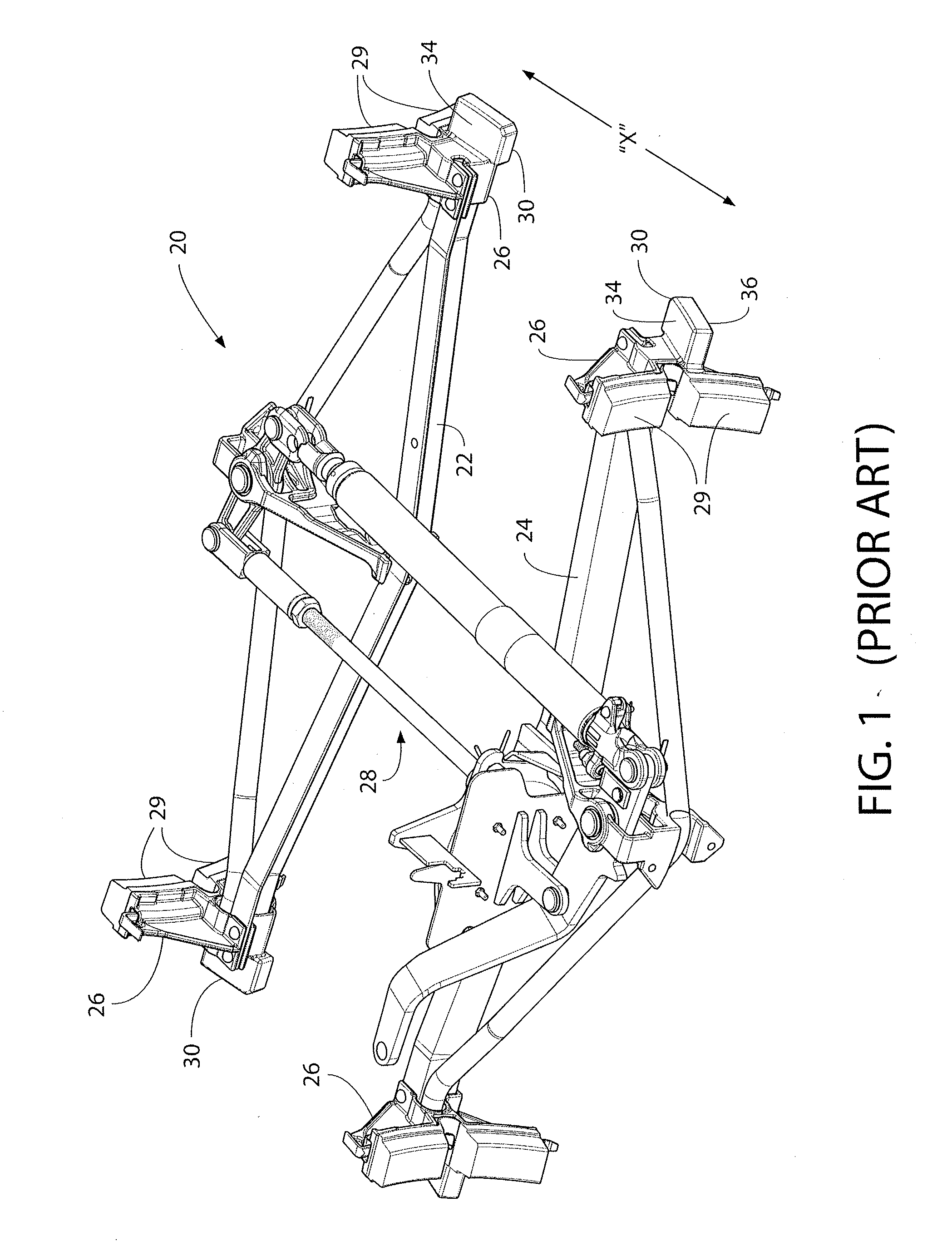

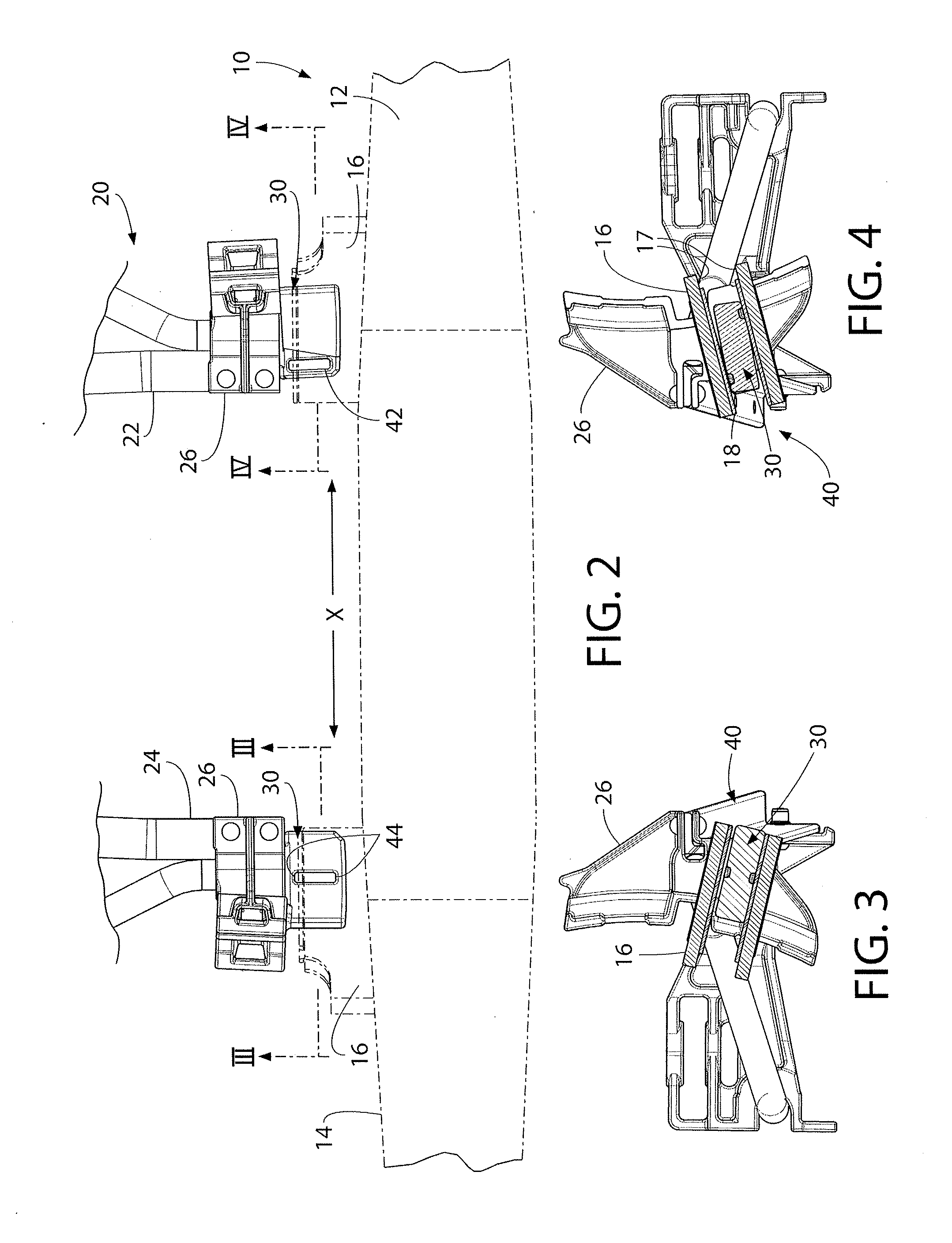

ActiveUS20120261218A1Economically manufacturedRail brake actuationMetal working apparatusReciprocating motionTruck

A lubricating arrangement for an end guide of a railcar truck mounted brake rigging includes at least one elongated groove provided in the at least one surface of the end guide in open communication therewith, the elongated groove having a length thereof disposed generally transverse to a direction of the sliding reciprocal movement of the end guide. A lubricating member is secured within the at least one elongated groove, the lubricating member has a thickness portion thereof protruding, a predetermined height at initial installation, above the at least one surface of the end guide. The predetermined height of the protruding thickness portion is reduced during the reciprocal movement of the end guide within the channel or pocket so that material removed from the predetermined height during the reciprocal movement substantially resurfaces the at least one surface of the end guide.

Owner:WABTEC HLDG CORP

Slack adjuster contaminant mitigation device

ActiveUS9540021B2Reduce exposureAvoid enteringBrake wear compensation mechanismSlack adjustersEngineeringRailway brake

Owner:WABTEC HLDG CORP

Vacuum detection method and device for abraded surface leakage of slide valves of railway brake

InactiveCN102853975AIncrease volumeLow detection sensitivityMeasurement of fluid loss/gain rateEngineeringTest procedures

The invention relates to a vacuum detection method for abraded surfaces of slide valves of railway brake. The vacuum detection method for abraded surfaces of slide valves of the railway brake includes the steps of firstly, detecting leakage of the slide valves; secondly, detecting leakage of valve sleeves; thirdly, detecting fitting test leakage; and fourthly, detecting backflow hole flux. A vacuum detection device for abraded surfaces of slide valves of the railway brake is used to detect airtightness of abraded surfaces of the slide valves, the slide valve sleeves and the like according to the principle of vacuum absorption, performances of the abraded surfaces of the slide valves can be reflected quickly, simply and accurately, test procedures are simplified, pass percentage of one-time assembly is increased, production efficiency is improved, and product quality is improved.

Owner:沈阳西屋制动科技有限公司

Railway Vehicle Brake Shoe

InactiveUS20070151817A1Reliable mechanical attachmentReduce noiseBraking elementsFriction liningVehicle brakeSecondary layer

A railway brake shoe including a first layer constructed of a composition friction material and a second layer constructed of a resilient composition material. The second layer is joined to the first layer. The second layer is adapted to receive at least one mechanical fastener therein to removably secure the brake shoe to a brake head. The resilient material of the second layer is capable of applying a circumferentially compressive force to the at least one mechanical fastener and prevent breakage of the composition friction material at the attachment location and / or enlargement of the attachment apertures due to vibration and lateral impacts.

Owner:RFPC HLDG CORP

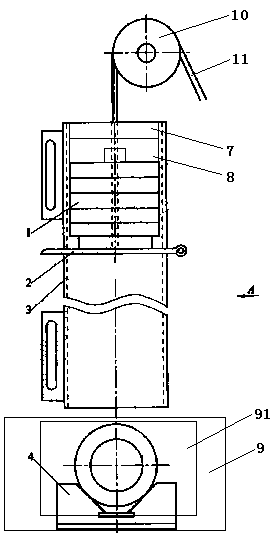

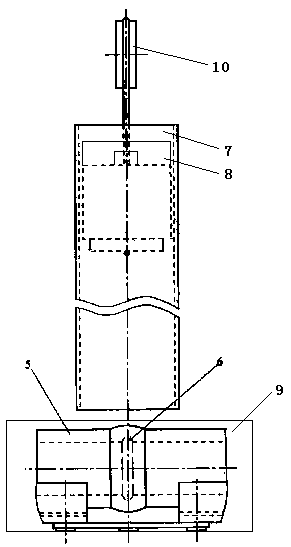

Test device for impact performance of railway brake hose

PendingCN108254269AImprove impact performanceImprove securityMaterial strength using single impulsive forceElectromagnetRailway brake

The invention discloses a test device for impact performance of a railway brake hose, and the test device comprises a power mechanism, an electromagnet, and a test base. The electromagnet is lifted and lowered by the power mechanism. A counter weight is arranged below the electromagnet, the weight counter is adsorbed at the bottom of the electromagnet when the electromagnet is energized, the testbase is disposed under the weight counter, and the base is provided with a groove for placing the railway brake hose. The railway brake hose is horizontally placed in the groove, and the upper sursurface of the railway brake hose is protruded outside the groove. In impact performance tests, firstly, an insertion piece is inserted into the railway brake hose, then the railway brake hose is horizontally placed in the groove on the base, the power mechanism is used to raise the electromagnet and the weight counter to a set height position, the electromagnet is de-energized, the weight counter falls, and the weight counter hammers the expanded convex portion of the hose. The impact performance of the hose can be evaluated by hammering the hose with the weight counter and observing whether thehose is deformed or damaged. The device is simple and convenient to operate, and the weight counter falls due to de-energizing of the electromagnet, so that the safety is improved.

Owner:NANJING ORIENTLEADER TECH CO LTD

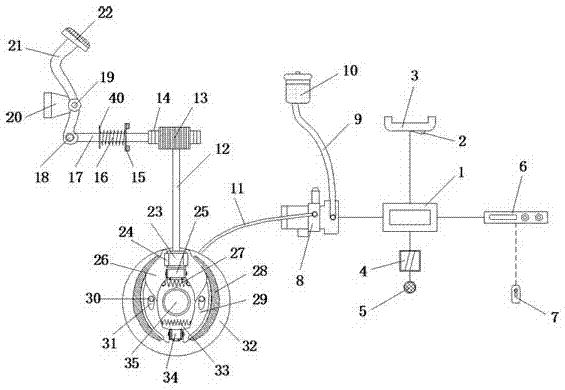

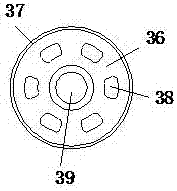

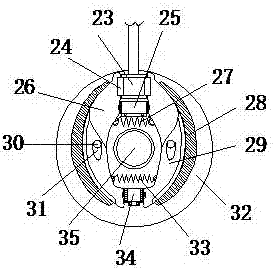

Remote-control braking device of learner-driven vehicle

InactiveCN106965784AReduce heatAvoid damageBraking action transmissionFoot actuated initiationsRemote controlControl signal

The invention discloses a remote control braking device for a coach, which comprises a brake crank, a mounting base plate, a brake shoe block, a brake disc, a brake controller and a brake switch. 1. For the brake shoes on both sides of the right side, the upper ends of the two brake shoes are uniformly provided with installation blocks. The inner sides of the two installation blocks are rollingly connected with the outer wall of the cam column through the rolling column, and are fixed on the installation base plate under the cam column. There is a double-head brake oil cylinder, the telescopic heads on both sides of the double-head brake oil cylinder are in conflict with the installation grooves on the inside of the installation block, and the outer walls of the two brake shoe blocks are covered with friction plates. A brake drum that cooperates with the friction plate for braking is arranged on the moving disc; the signal output end of the brake controller is connected with the driving end of the hydraulic actuator. The invention has a reasonable structural design, can adopt multiple modes of braking, is convenient and fast for remote control braking, and is compatible with dual functions of pedaling and remote control.

Owner:刘莹莹

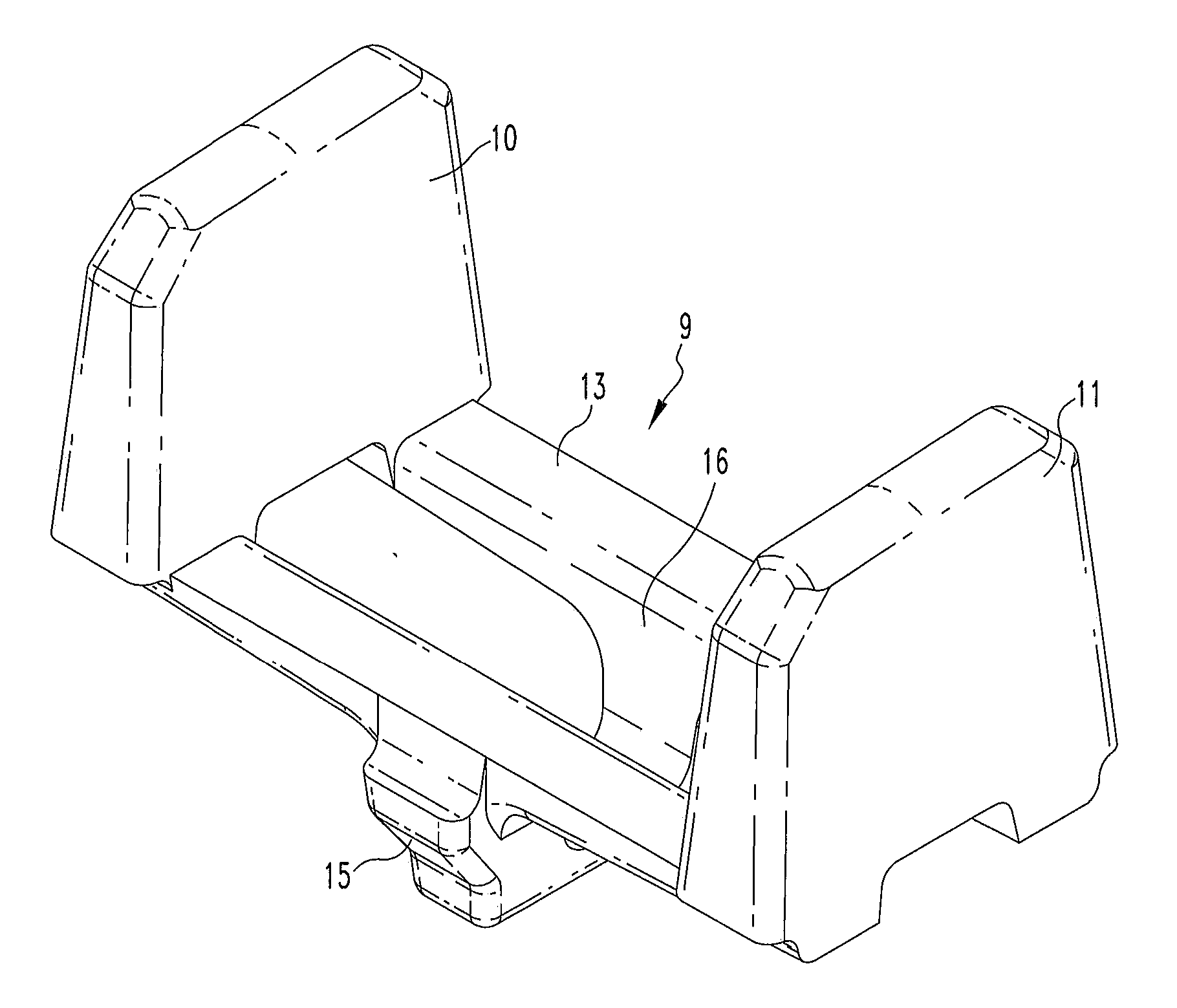

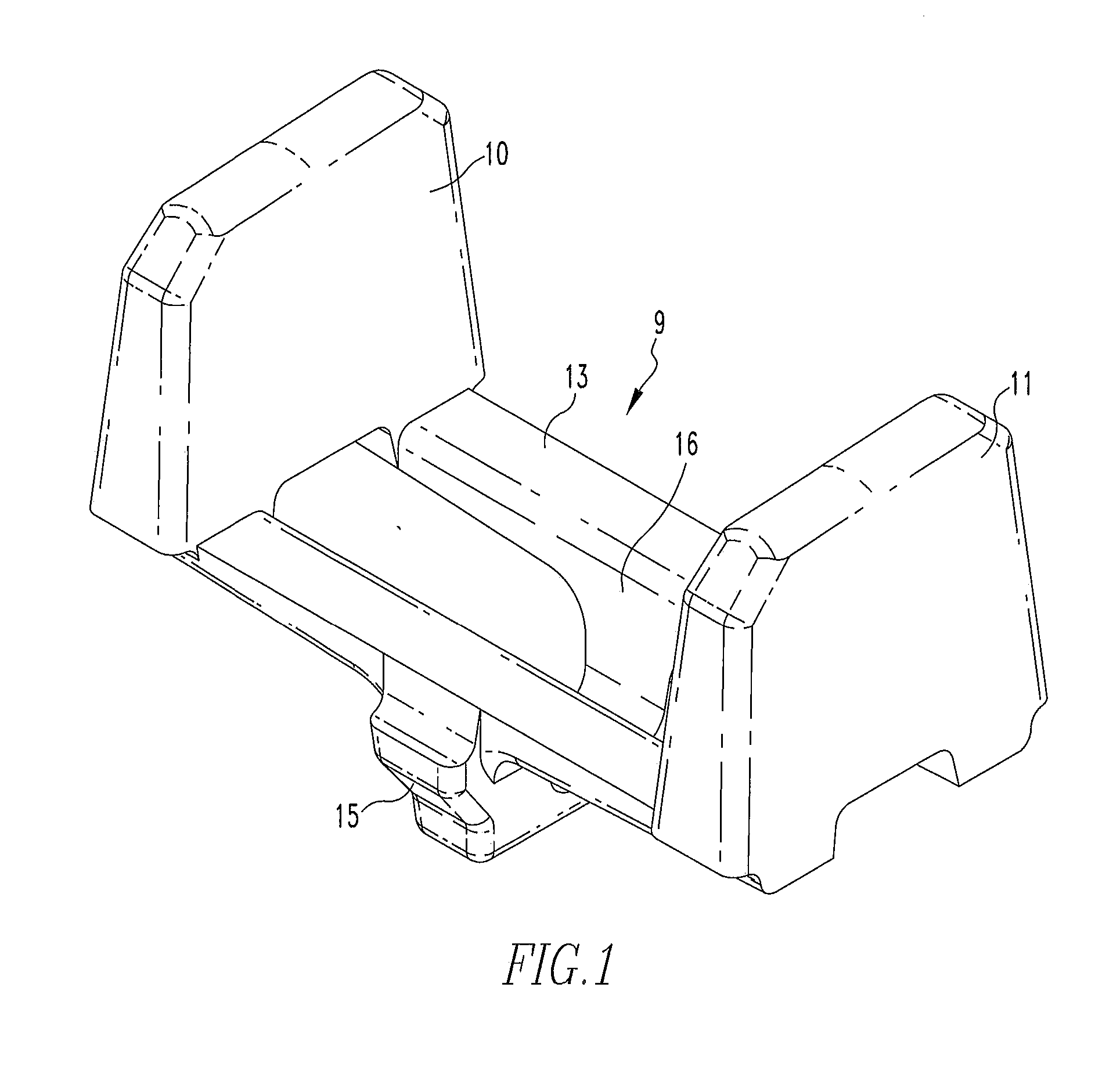

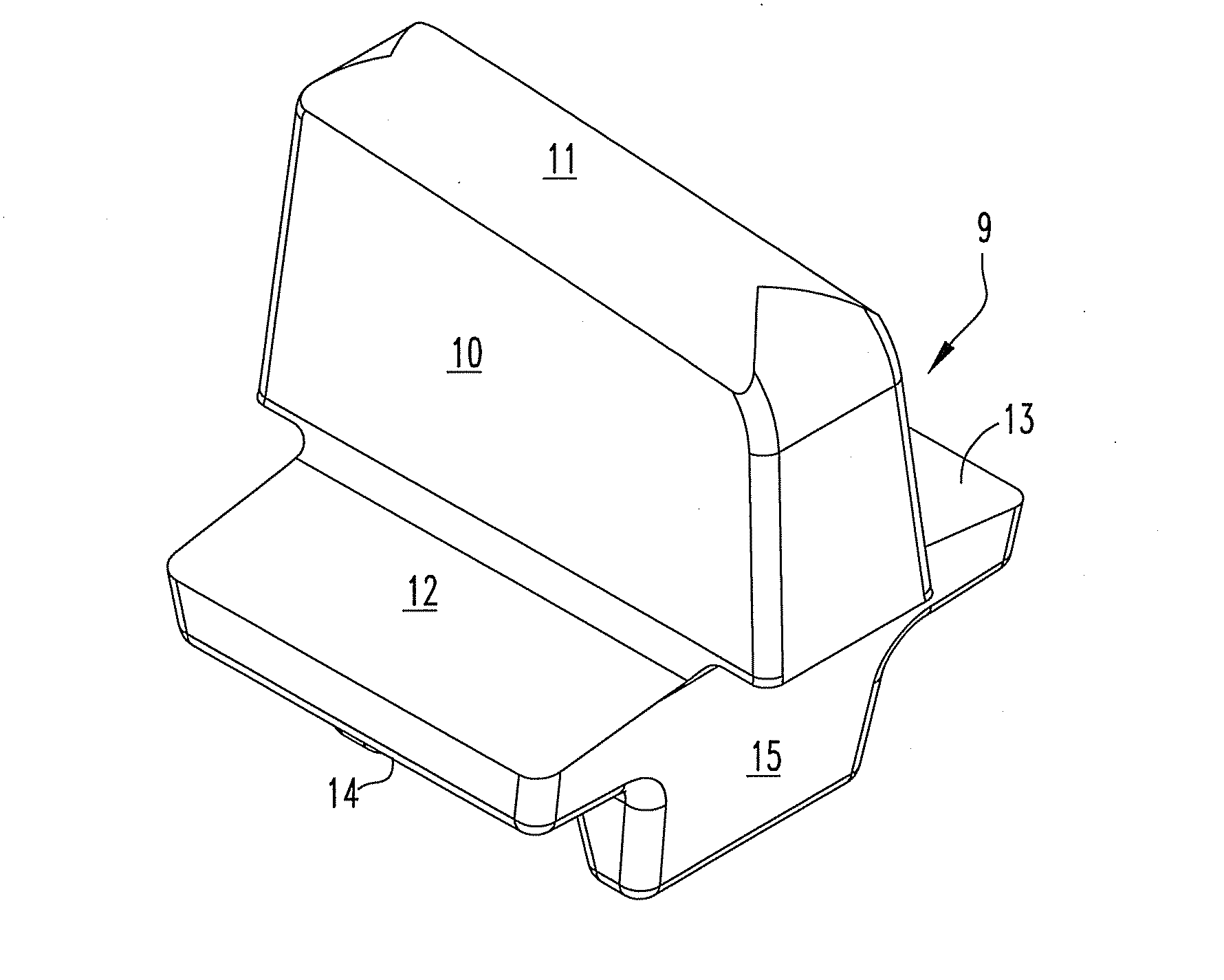

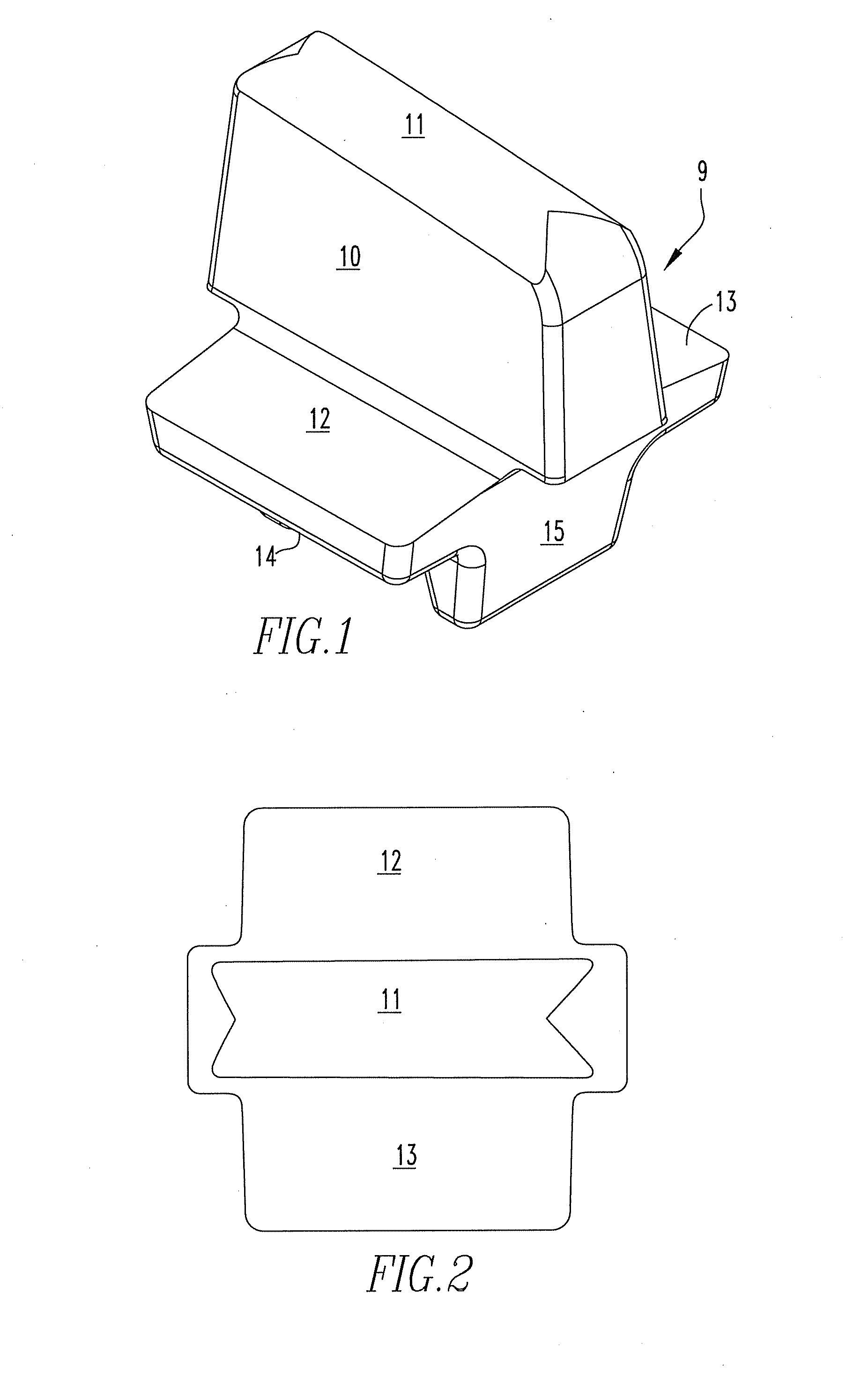

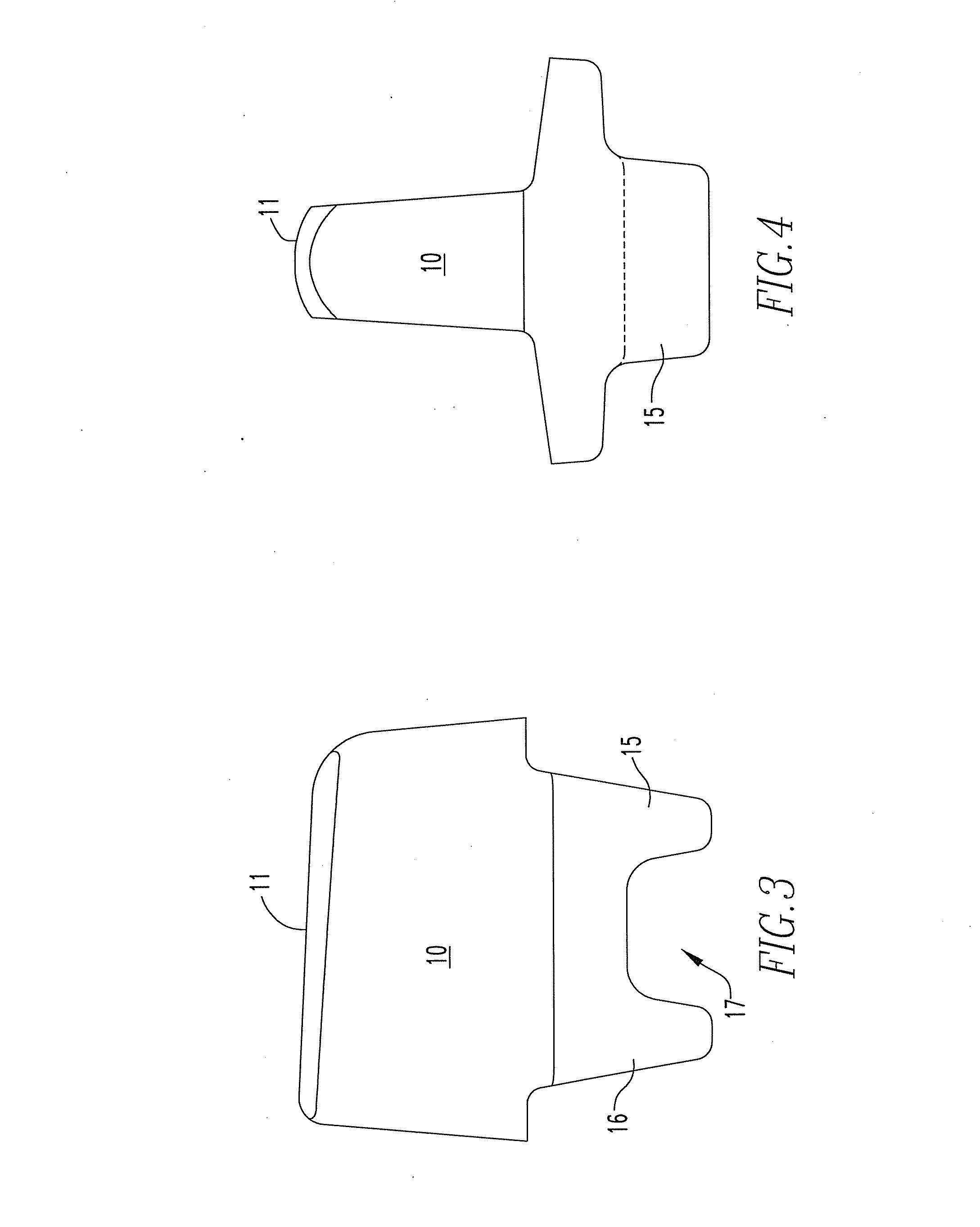

Railway brake shoe

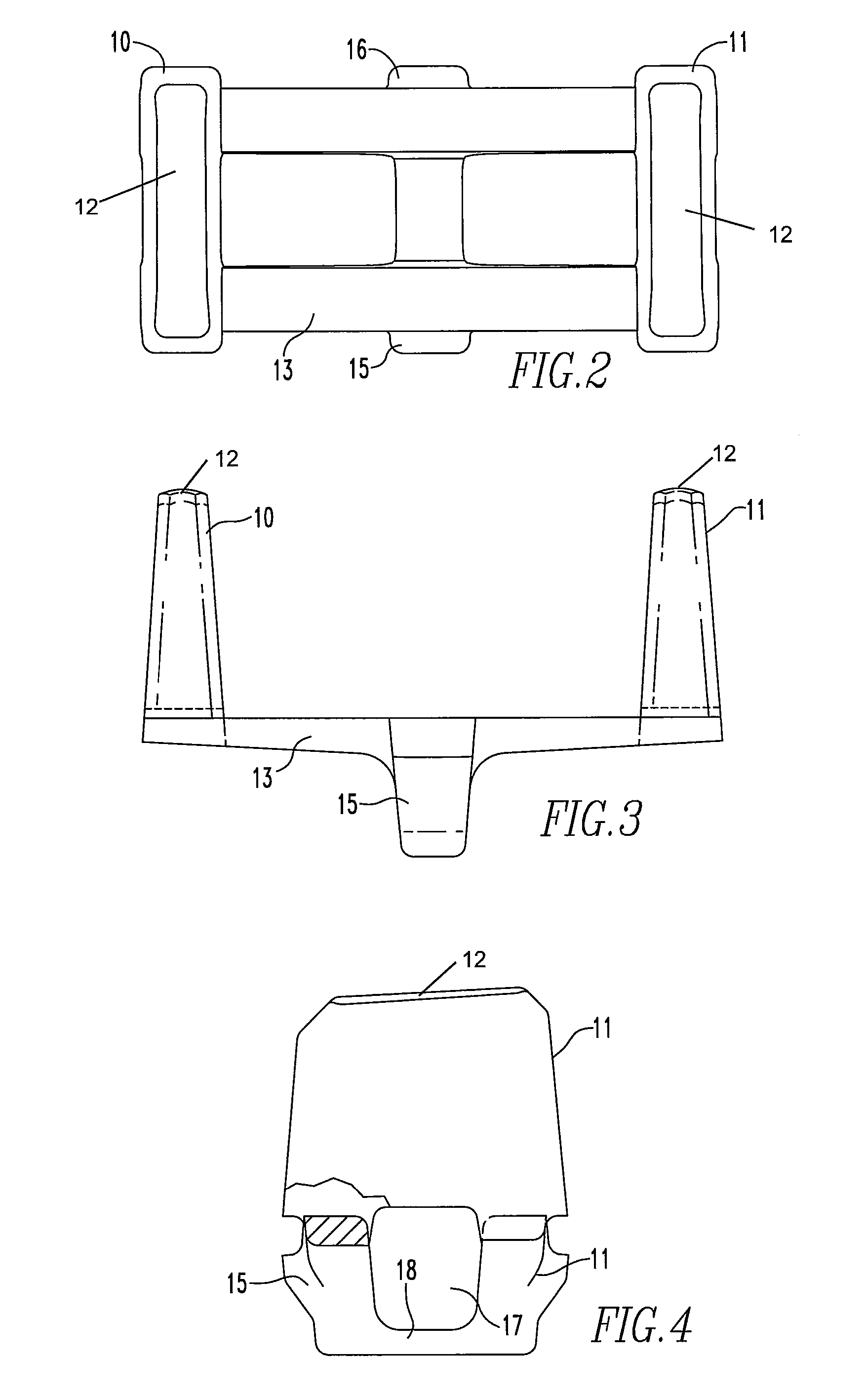

A brake shoe without a metal backing has a metal insert (9) comprising a main body (10), two wing-like extensions (12 / 13) integral with, on opposite sides of and extending away from the main body having back faces adjacent to the back surface of the brake shoe, two generally parallel radially extending flanges (15 / 16) integral with the main body and / or the wing-like extensions. The parallel extension defines a keyway (17), wherein when the brake shoe is emplaced on the brake head, the keyway extends through an opening provided in the brake head.

Owner:RFPC HLDG CORP

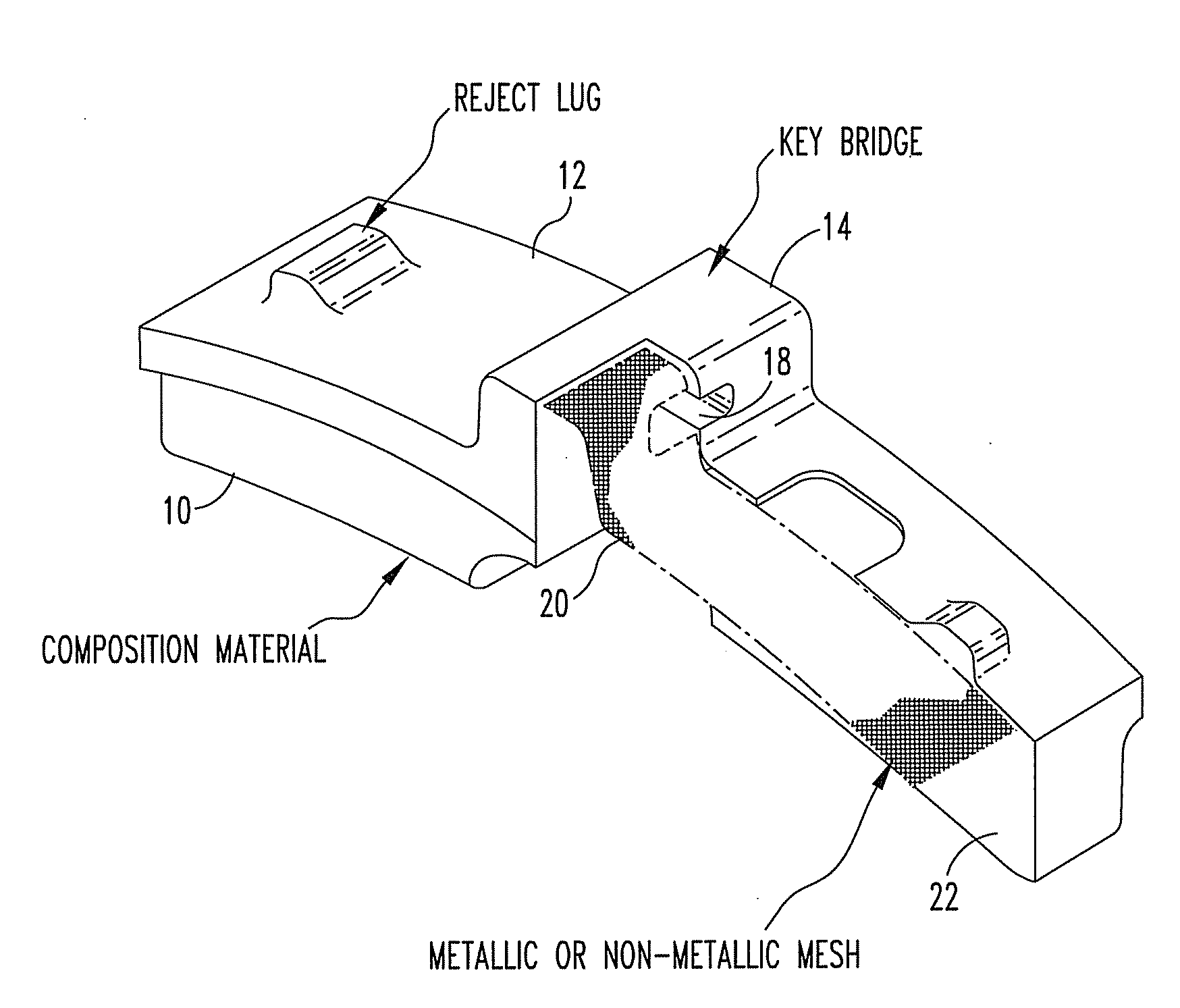

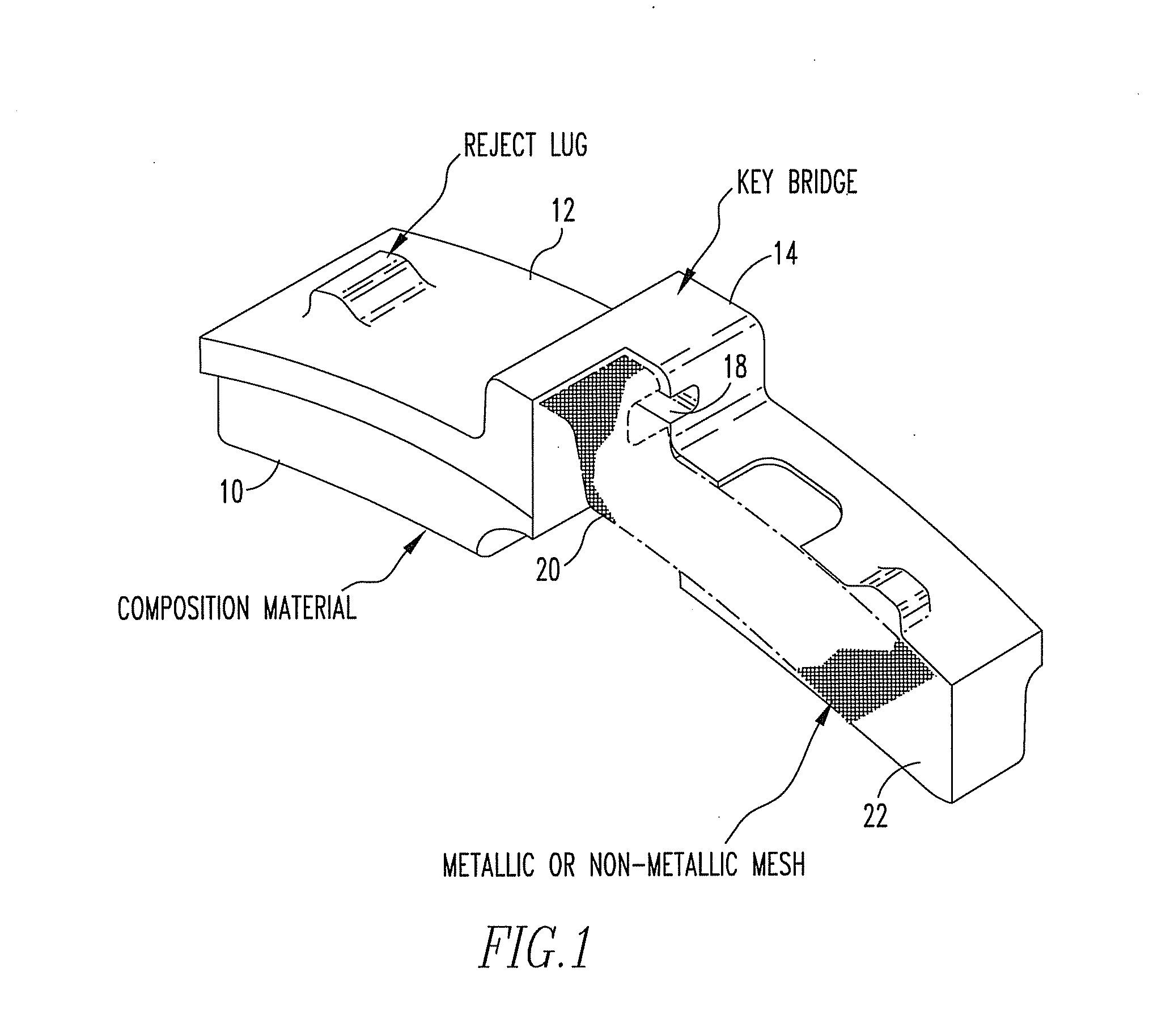

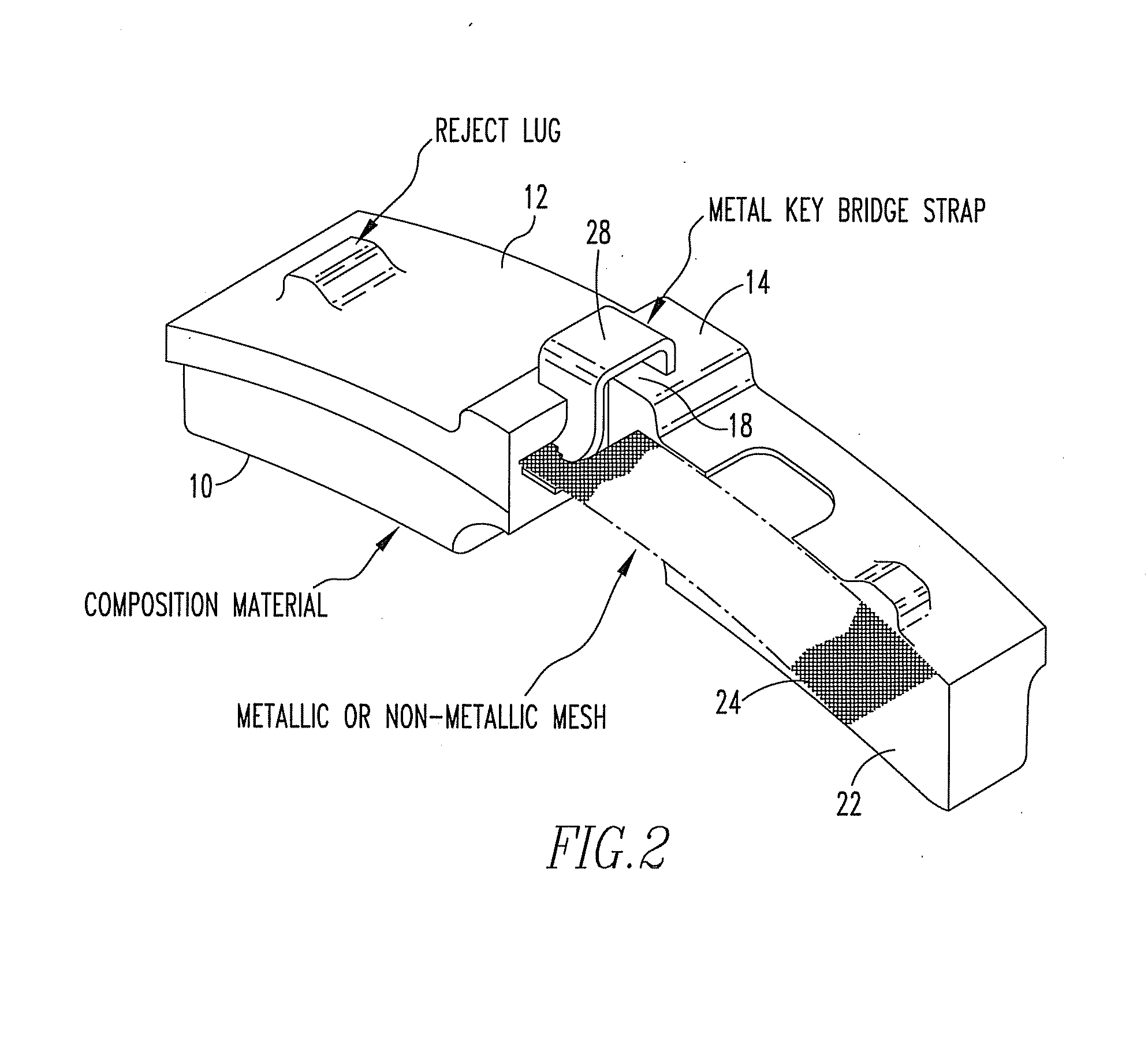

Plateless Railway Brake Shoe

A brake shoe formed of friction material for use without a metal backing plate. The brake shoe is defined by a friction surface for bearing upon a wheel tread and an opposed back surface for being placed in contact with and secured to a brake head. The brake shoe has a reinforcing mesh defining a plurality of interstices positioned along the back surface of the brake shoe embedded in a molded friction material that is reinforced with a plurality of fibers. A keyway is at least partially formed of the molded fiber reinforced friction material extending away from the back surface of the brake shoe.

Owner:RFPC HLDG CORP

ECP/triple valve transition plate

A transition plate connects an electronic manifold to a pipe mounting bracket of a railway brake system and includes a body having a manifold portion that defines a face configured to engage the manifold and a pipe bracket portion that defines a face configured to engage the pipe mounting bracket; ports defined in the manifold face that are configured to align and communicate with ports in the face of the manifold; ports defined in the pipe bracket face that are configured to align and communicate with ports in the face of the pipe mounting bracket; and a plurality of air passages extending through the body for connecting the plurality of ports defined in the manifold face with the plurality of ports defined in the pipe bracket face. The transition plate establishes a pneumatic interface between the electronic manifold and the pipe mounting bracket.

Owner:WABTEC HLDG CORP

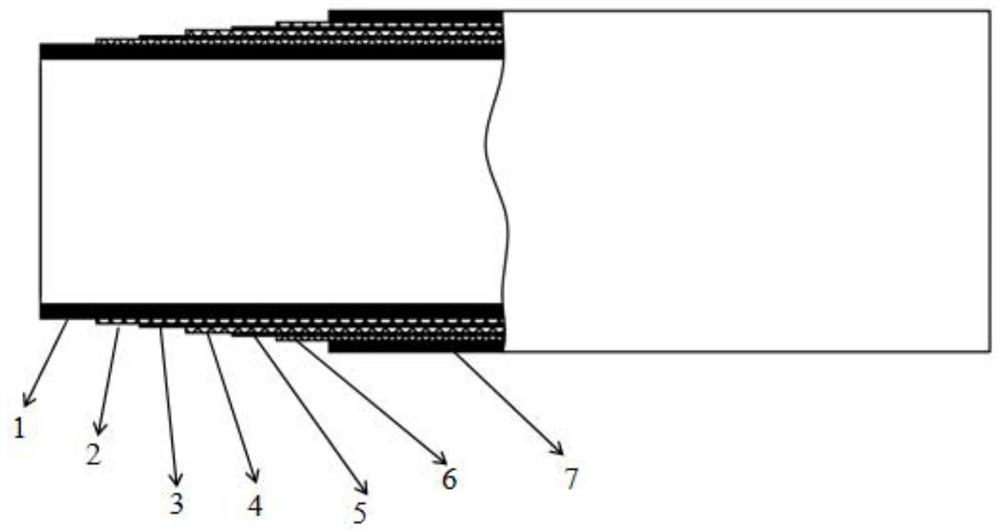

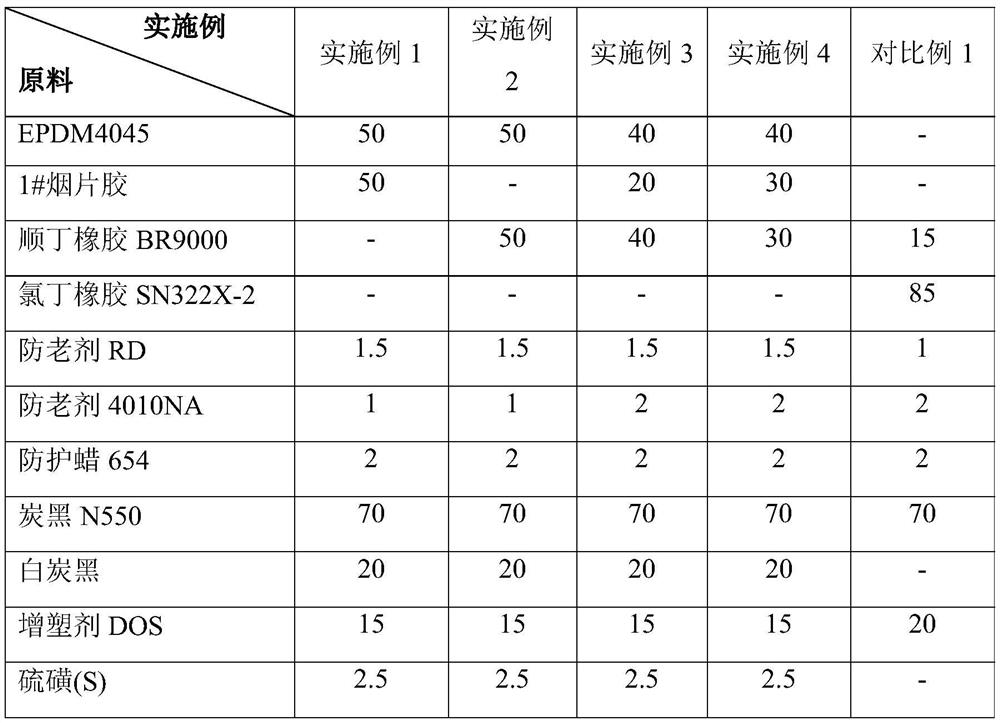

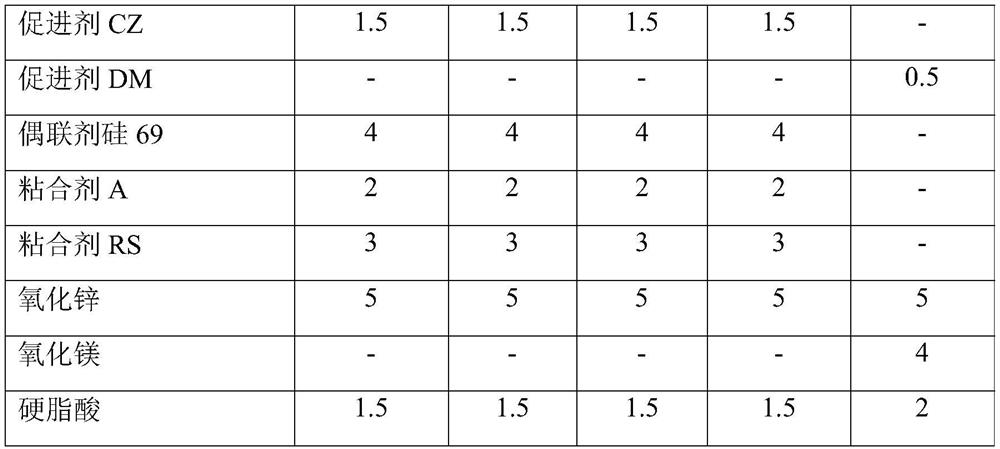

Environment-friendly, low-cost and high-performance railway brake pipe

ActiveCN113372656ALow costHigh strengthSynthetic resin layered productsPiping arrangementsRubber materialPolyester

The invention discloses a rubber material for preparing an inner rubber layer, an outer rubber layer or middle rubber sheets of a railway brake pipe. The rubber material comprises the following raw materials in parts by weight: 100 parts of a base material, 3-5.5 parts of an anti-aging agent, 60-120 parts of carbon black, 10-30 parts of white carbon black, 5 parts of zinc oxide, 1.5-2 parts of stearic acid, 5-20 parts of a plasticizer, 3-5 parts of a coupling agent, 5-8 parts of an adhesive, 2-5 parts of sulfur and 1-2 parts of an accelerant. The base material is one or more of ethylene propylene diene monomer, natural rubber, butadiene rubber and nitrile rubber. The invention further discloses a railway brake pipe which sequentially comprises an inner rubber layer and an outer rubber layer from inside to outside, three braid layers are arranged on each of the inner rubber layer and the outer rubber layer, and a middle rubber layer is arranged between every two adjacent braid layers. The inner rubber layer, the middle rubber layers and the outer rubber layer are all made of the rubber material in an extrusion mode, and the braid layers are formed by weaving polyester threads. The normal-temperature stiffness, low-temperature flexibility, bursting strength, weather resistance and aging resistance of the railway brake pipe are superior to those of a chloroprene rubber hose.

Owner:NANJING ORIENTLEADER TECH CO LTD

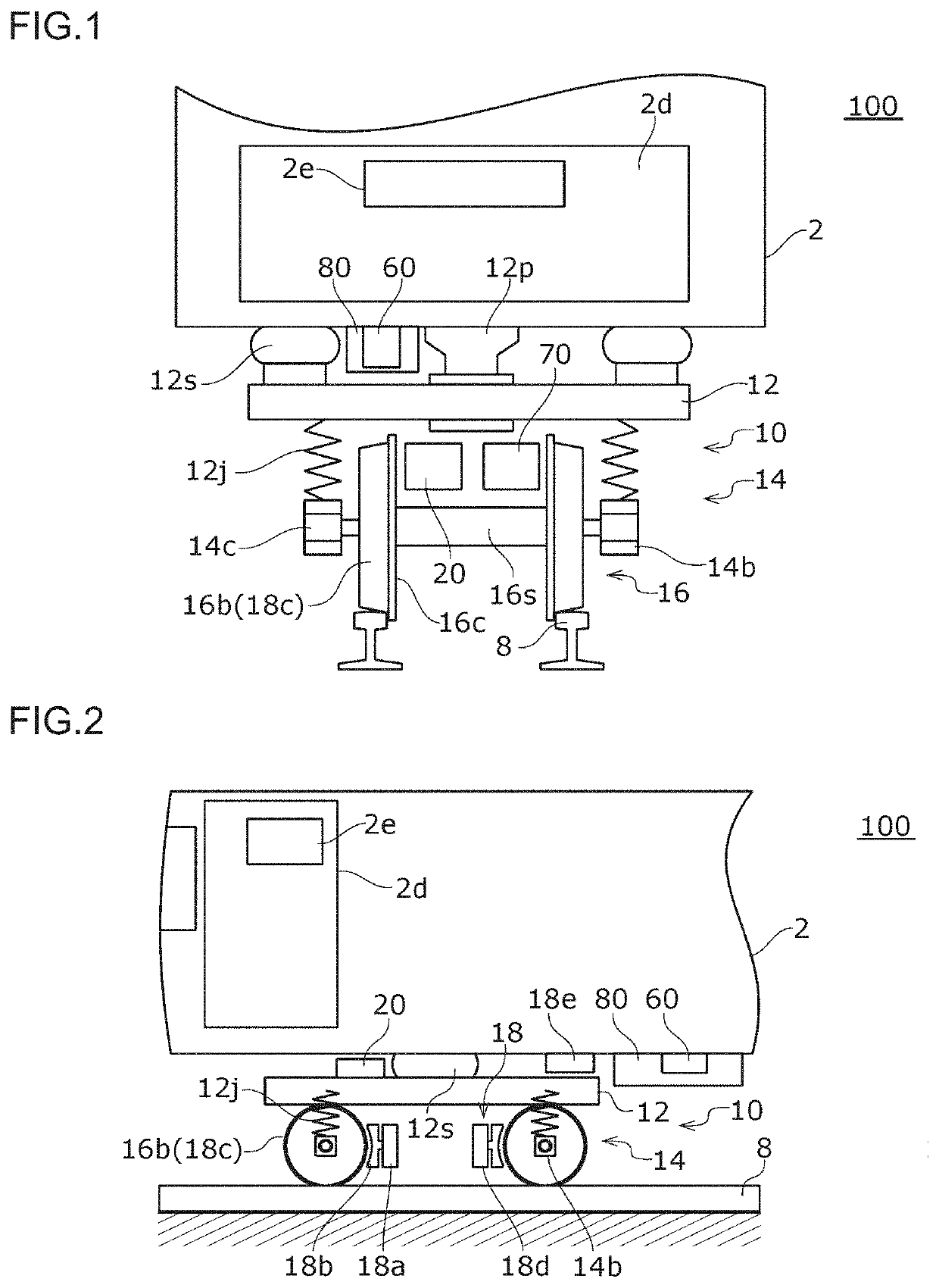

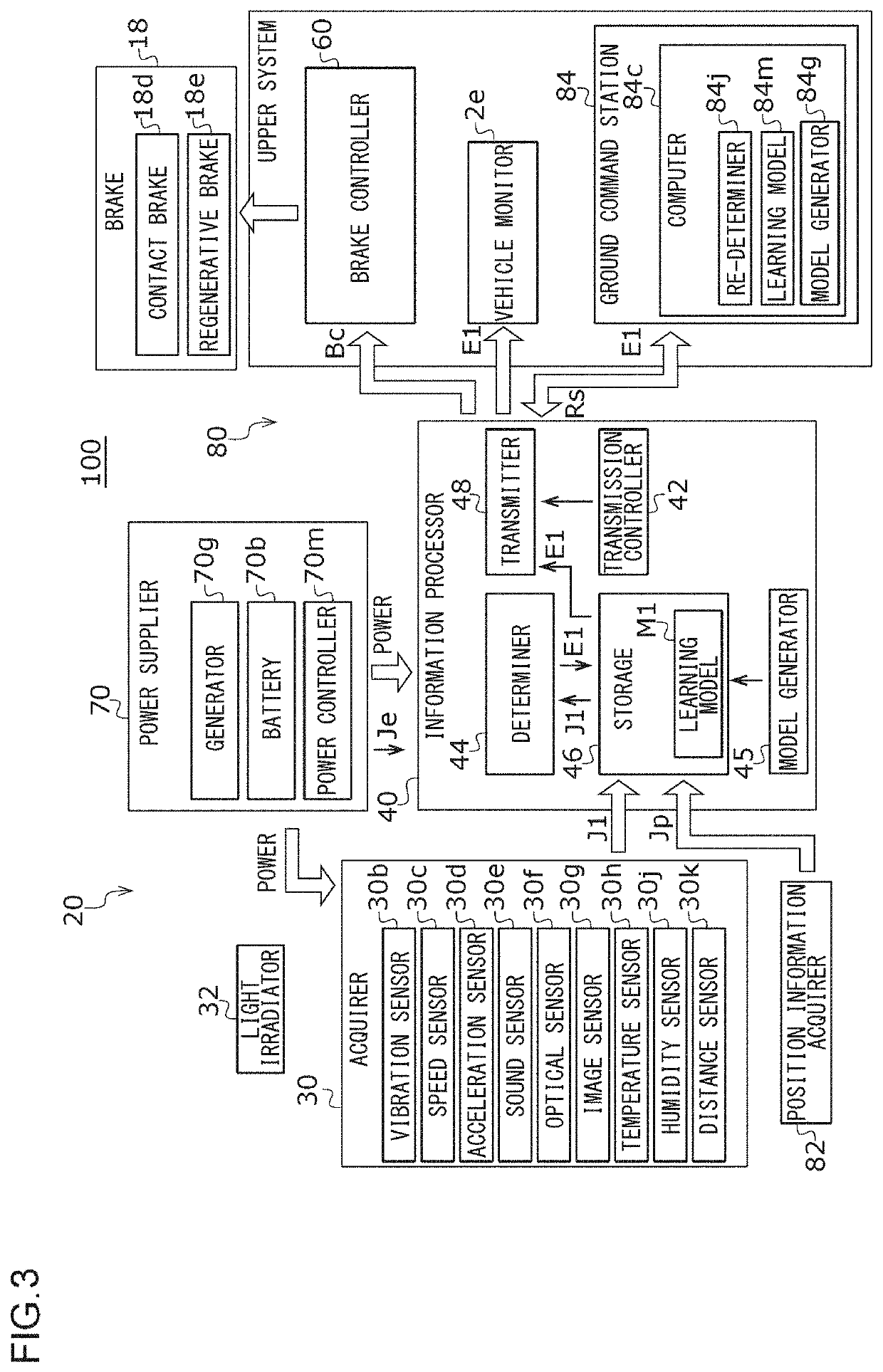

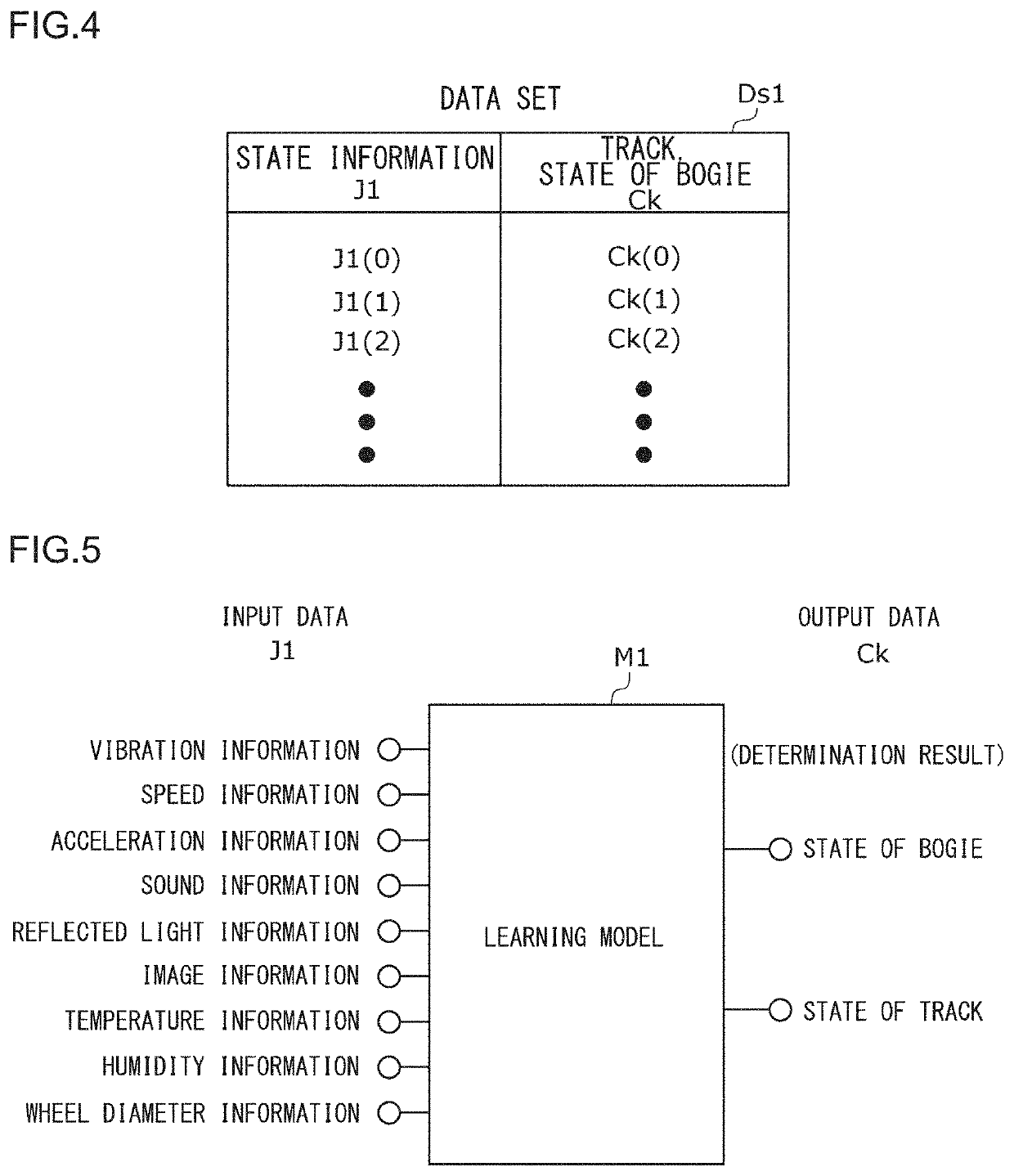

Railway condition monitoring device, railway vehicle bogie, railway vehicle, railway brake control device

PendingUS20210078619A1Improve versatilitySignalling indicators on vehicleRoute devices for controlling vehiclesBogieCondition monitoring

A railway condition monitoring device includes an acquirer structured to be attached to a railway vehicle bogie and acquire state information on one or more state of vibration, speed, acceleration, sound, reflected light, image, temperature, humidity, and a wheel diameter, a determiner structured to be attached to a bogie, perform a determination of a state of a track on which the bogie travels or a state of the bogie based on the state information acquired by the acquirer, and provide the determination result, a transmitter structured to be attached to the bogie and transmit the determination result to an outside of the bogie, and a power supplier structured to be attached to the bogie and supply power to the acquirer and the transmitter.

Owner:NABLESCO CORP

Slack adjuster contaminant sump, drain, and overload relief

ActiveUS9676401B2Reduce exposureAvoid accumulationBrake wear compensation mechanismSlack adjustersEngineeringRailway brake

Owner:WABTEC HLDG CORP

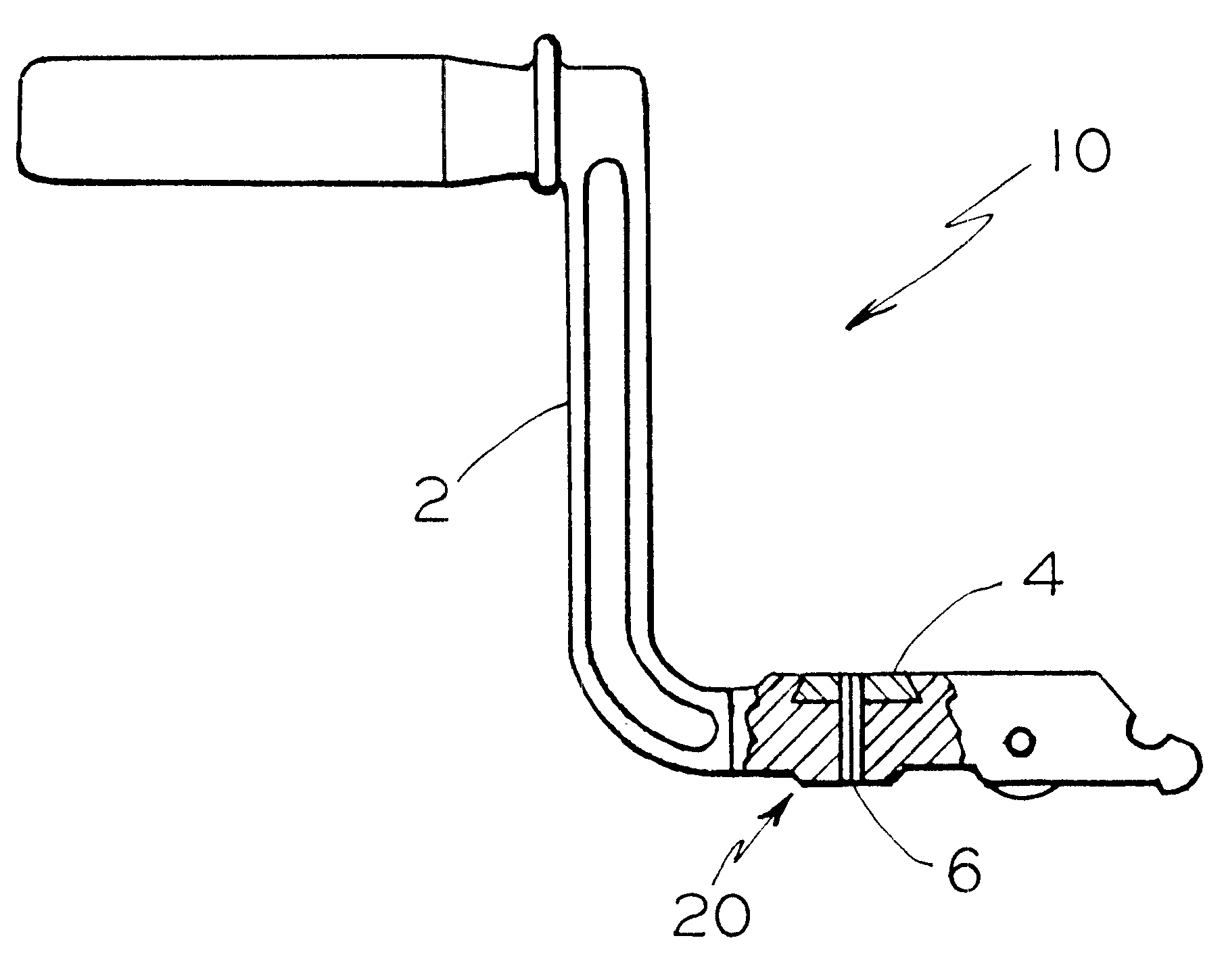

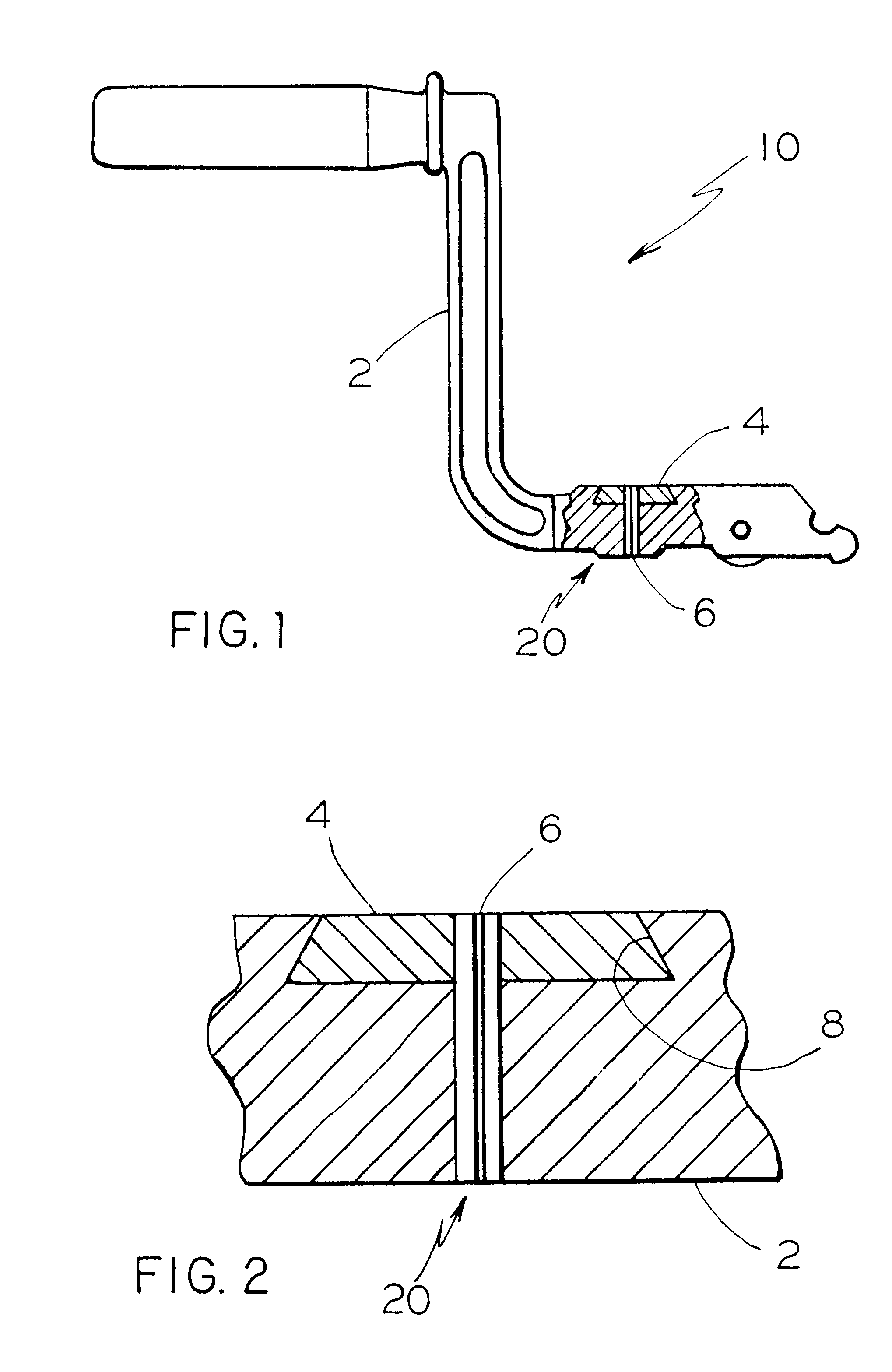

Locomotive brake valve handle with wear pad

InactiveUS6408713B1Easy to replaceControlling membersMechanical apparatusMechanical engineeringBraking system

The present invention provides a brake valve handle assembly for use in a brake valve of a railway braking system. The handle assembly comprises a handle for manually adjusting such brake valve to various positions and having a cavity with a predetermined shape and a predetermined width formed in the handle at least adjacent a top surface thereof that is disposed adjacent a slot formed in a housing of such brake valve. The handle assembly further includes a wear pad mounted in the cavity of the handle and a means for securing the wear pad to the handle.

Owner:WESTINGHOUSE AIR BRAKE TECH CORP +1

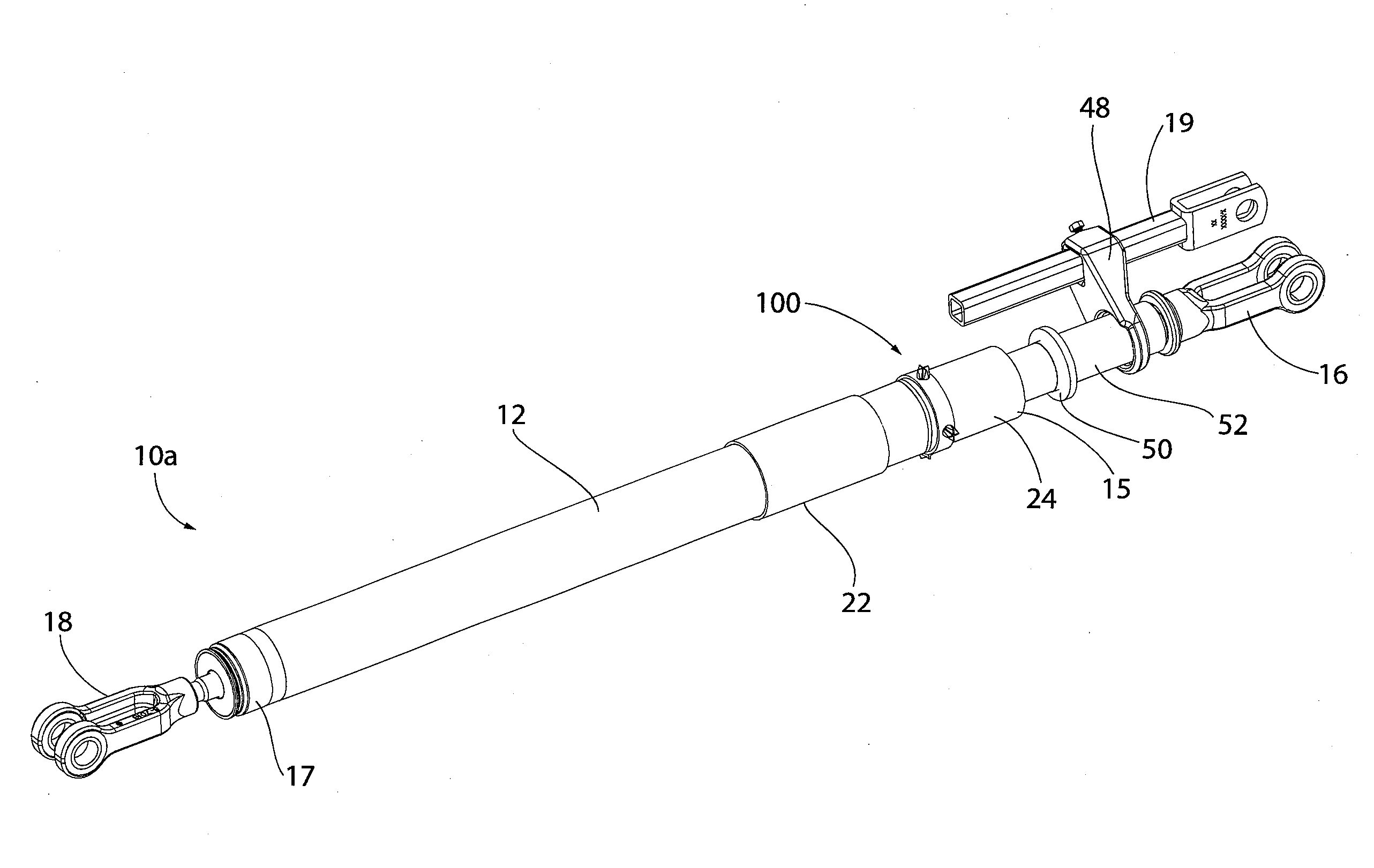

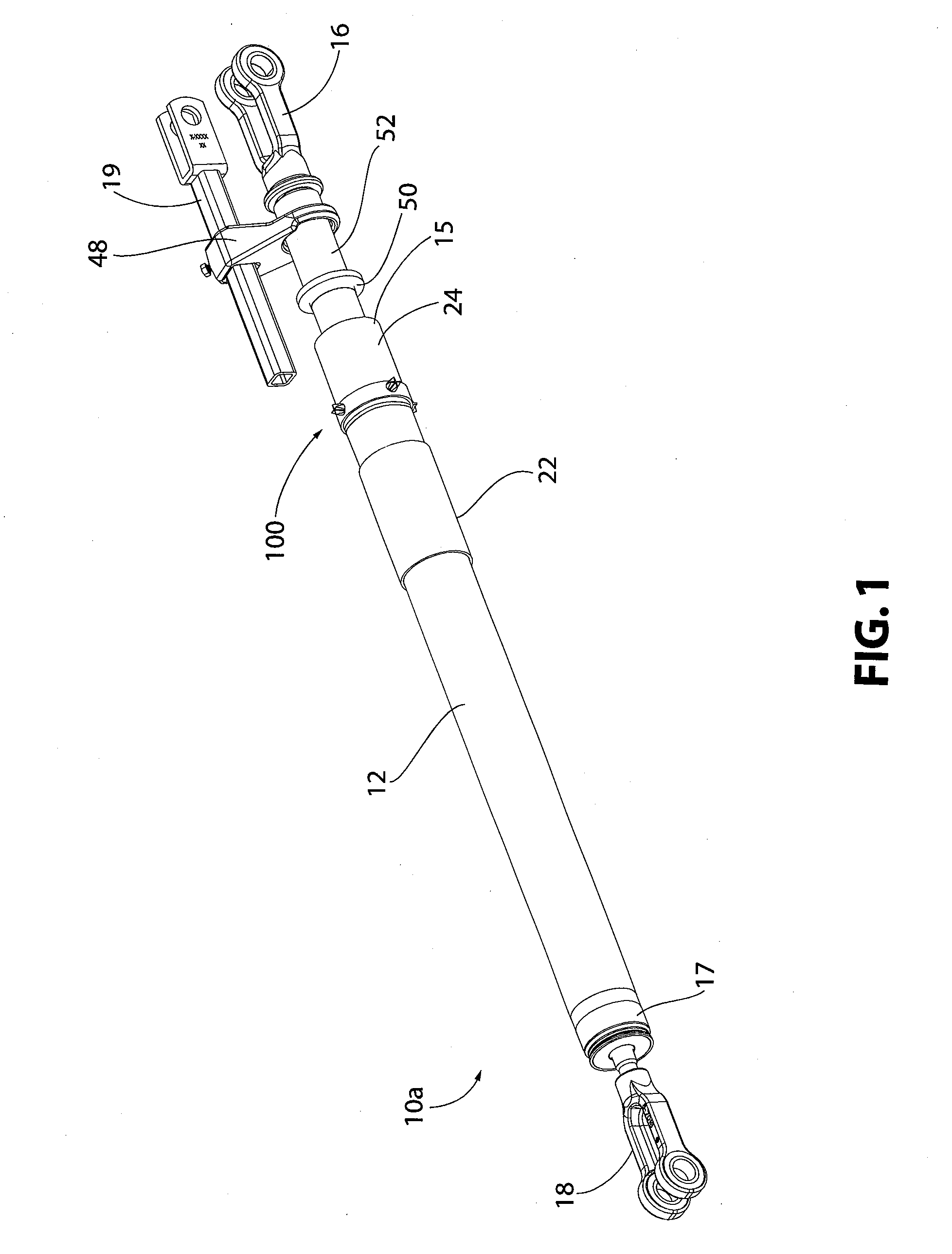

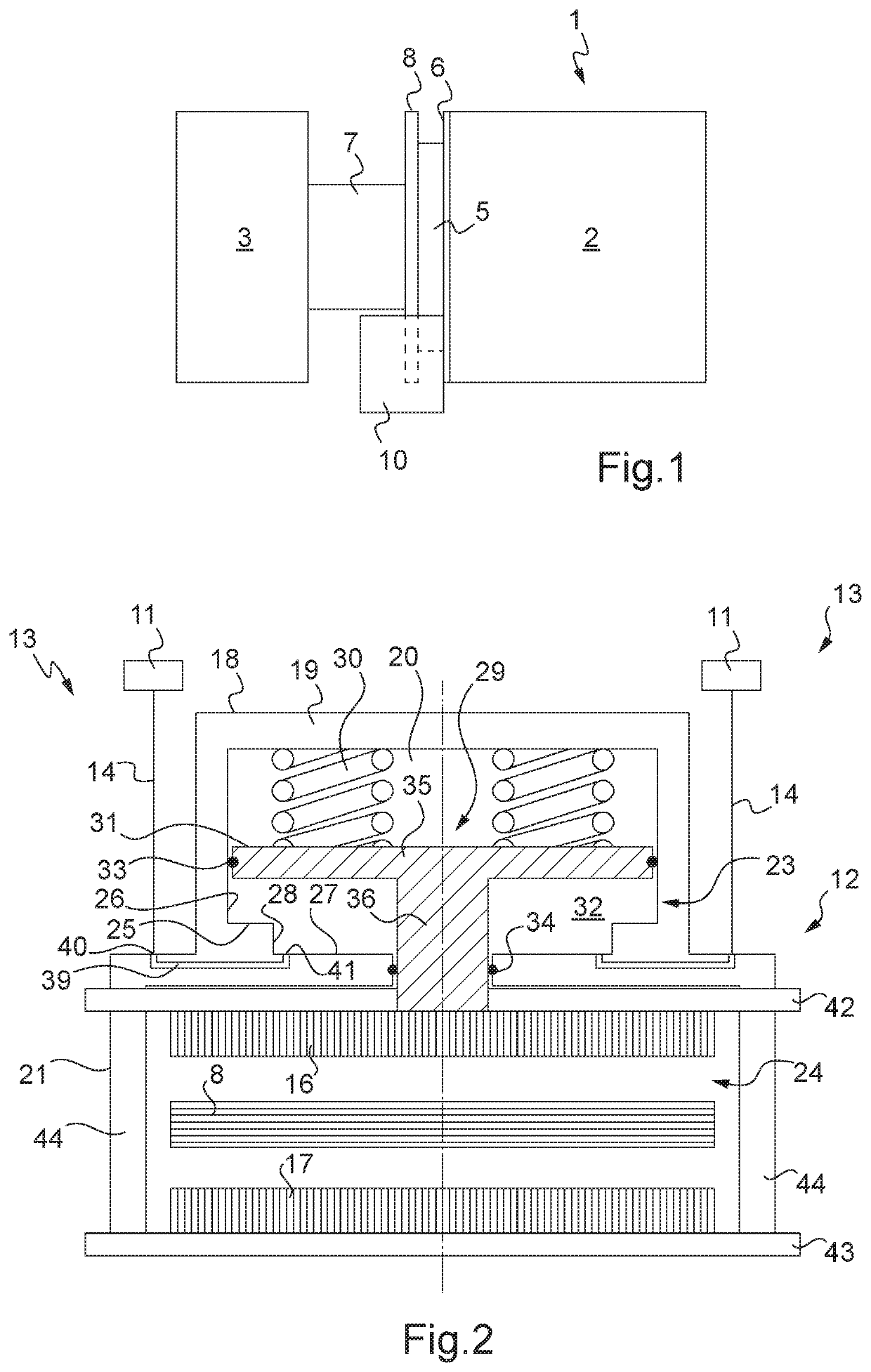

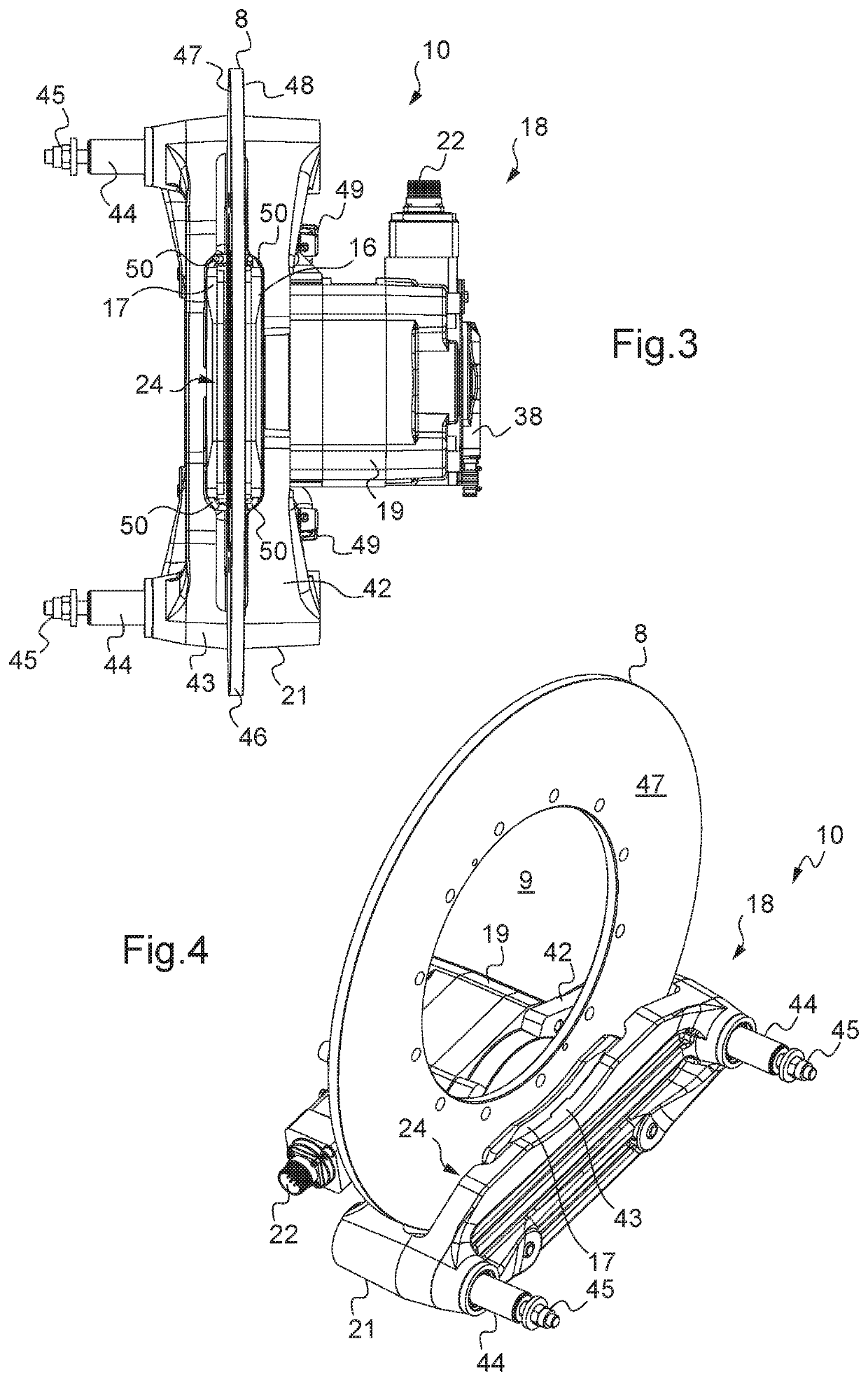

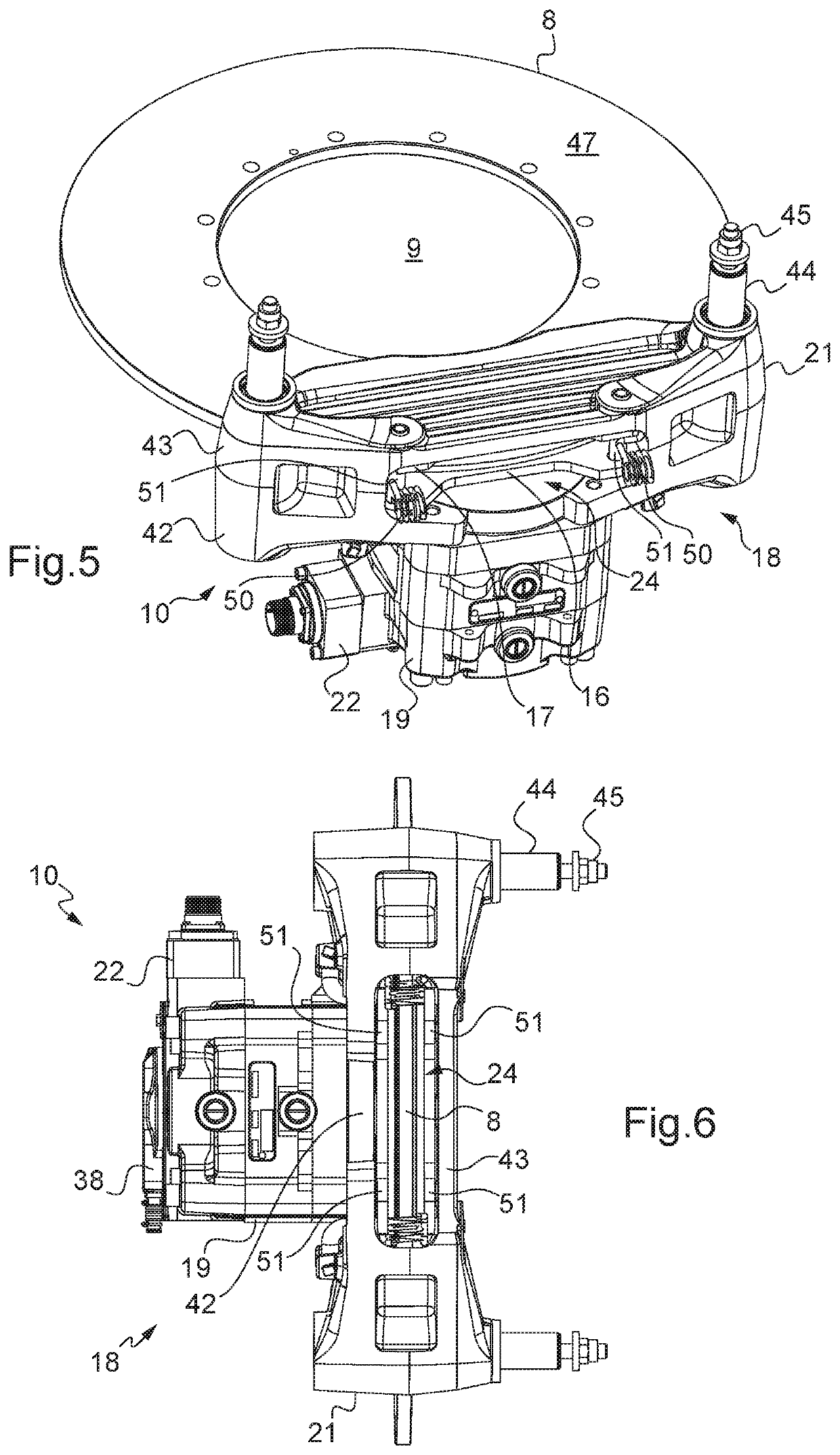

Railway brake system for a railway vehicle

ActiveUS11260886B2Easy mounting/dismantlingGood performance in term of safety and useAxially engaging brakesBraking action transmissionActuatorControl theory

Owner:FAIVELEY TRANSPORT AMIENS

Vice-driving lubricating structure of sliding valve of railway brake valve with automatic switching action

PendingCN107101011AMinor changesReduce fuel consumptionSlide valveValve housingsEngineeringPiston rod

The invention discloses a vice-driving lubricating structure of a sliding valve of a railway brake valve with automatic switching action. The vice-driving lubricating structure of the sliding valve of the railway brake valve with the automatic switching action comprises a main piston rod, a sliding valve and a graduating valve. An oil storage cavity is arranged in the main piston rod. A one-way valve assembly is arranged on the main piston rod. The oil storage cavity communicates with an oil outlet through an oil-way pipe, wherein the oil outlet is arranged at the non-working area of the working surface on the graduating valve. An oil inlet is arranged at the non-working area of the working surface of the sliding valve. The oil outlet of the graduating valve and the oil inlet of the sliding valve are not be communicated during an air inflation position and a pressure maintaining position in the cycle of motion of the railway brake valve, wherein the air inflation position and the pressure maintaining position occupy most of the time, while in the process of braking of the railway brake valve, the oil outlet of the graduating valve is instantly communicated with the oil inlet of the sliding valve, and the rest traveling all be closed. In this way, just as an automatic switch is arranged at the oil outlet of the graduating valve and the oil inlet of the sliding valve, the oil consumption of lubricating oil in the oil storage can be reduced greatly, and the existing time of a vice oil slick of the sliding valve and the vice service life of the sliding valve are prolonged remarkably.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com