Low toxicity and low fluorescence lubricant for drilling fluid and preparation method thereof

A lubricant and drilling fluid technology, applied in the field of lubricants, can solve the problems of insufficient lubricating performance, single variety of lubricants, and poor friction-reducing effect, so as to solve the problems of reduced performance, high lubricating efficiency and high use efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

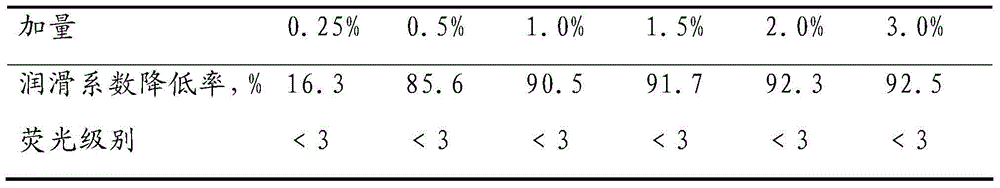

[0020] Example 1 A low-toxic, low-fluorescence, high-temperature-resistant, high-efficiency extreme-pressure lubricant for drilling fluid

[0021] (1) Raw material ratio

[0022] It is composed of the following components by weight fraction: 50% of base oil, 30% of emulsifier, 5% of penetrating agent, 5% of freezing point regulator, and 10% of extreme pressure agent.

[0023] (2) Preparation method

[0024] First add 50% industrial white oil to the reaction kettle, stir and heat up to 40-50°C, then add 20% Span-20 and 10% OP-7 for emulsification reaction, stir for 1 hour, then raise the temperature to 50°C -60°C, add 5% sodium alkyl sulfosuccinate and stir for 30 minutes, then add 10% chlorinated paraffin, continue stirring for 30 minutes, then stop heating, then add 5% poly-1,4 dioxanyl dimethylol The base alcohol is cooled while stirring, and poured out from the reaction kettle after being cooled to room temperature to obtain the low-toxicity, low-fluorescence, high-temper...

Embodiment 2

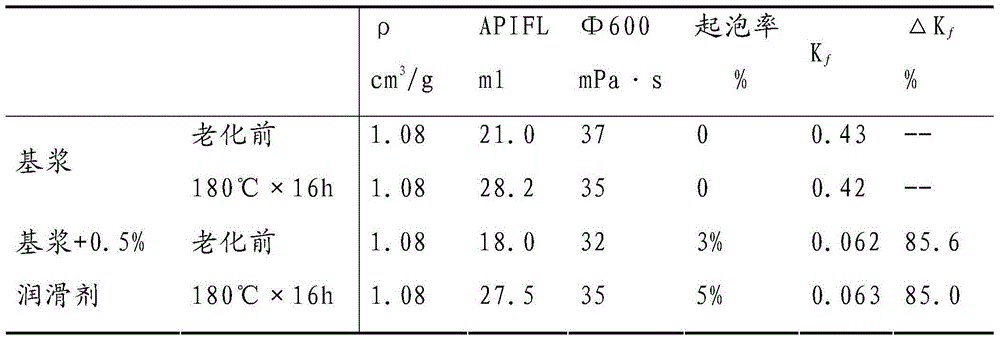

[0035] As shown in Table 2, the lubricant of Example 1 can withstand a high temperature of 180°C, has no adverse effect on the rheological properties and wall-building properties of the base slurry, and has almost no foaming. Example 2 A low-toxic, low-fluorescence, high-temperature-resistant, high-efficiency extreme-pressure lubricant for drilling fluid

[0036] (1) Raw material ratio

[0037] It consists of the following components by weight fraction: 60% of base oil, 25% of emulsifier, 5% of penetrating agent, 5% of freezing point regulator, and 5% of extreme pressure agent.

[0038] (2) Preparation method

[0039] First add 60% industrial white oil to the reaction kettle, stir, heat up to 40-50°C, then add 25% Span-80 for emulsification reaction, stir for 1 hour, raise the temperature to 50-60°C, add 5 After stirring for 30 minutes with % sulfated castor oil, add 5% 5-sulfurized olefin, stop heating after continuing to stir for 30 minutes, then add 5% poly-1,4-dioxanyl d...

Embodiment 3

[0042] Example 3 A low-toxicity, low-fluorescence, high-temperature-resistant, high-efficiency extreme-pressure lubricant for drilling fluid

[0043] (1) Raw material ratio

[0044] It consists of the following components by weight fraction: 70% of base oil, 20% of emulsifier, 3% of penetrating agent, 2% of freezing point regulator, and 5% of extreme pressure agent.

[0045] (2) Preparation method

[0046] First add 70% industrial white oil to the reaction kettle, stir, heat up to 40-50°C, then add 20% OP-10 for emulsification reaction, stir for 1 hour, raise the temperature to 50-60°C, add 3% Sodium alkyl sulfonate or secondary alkyl sulfonate was stirred for 30 minutes, then added 5% phosphate, continued stirring for 30 minutes, then stopped heating, then added 2% poly-1,4 dioxane dimethylol alcohol, while Cool while stirring, pour out from the reaction kettle after cooling to room temperature, and obtain the low-toxicity, low-fluorescence, high-temperature-resistant, high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com