Bearing sleeve, gear case and rail vehicle

A technology of bearing sleeves and bearings, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of low lubrication efficiency and increase the difficulty of manufacturing gearboxes, and achieve the effect of improving lubrication efficiency and reducing manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

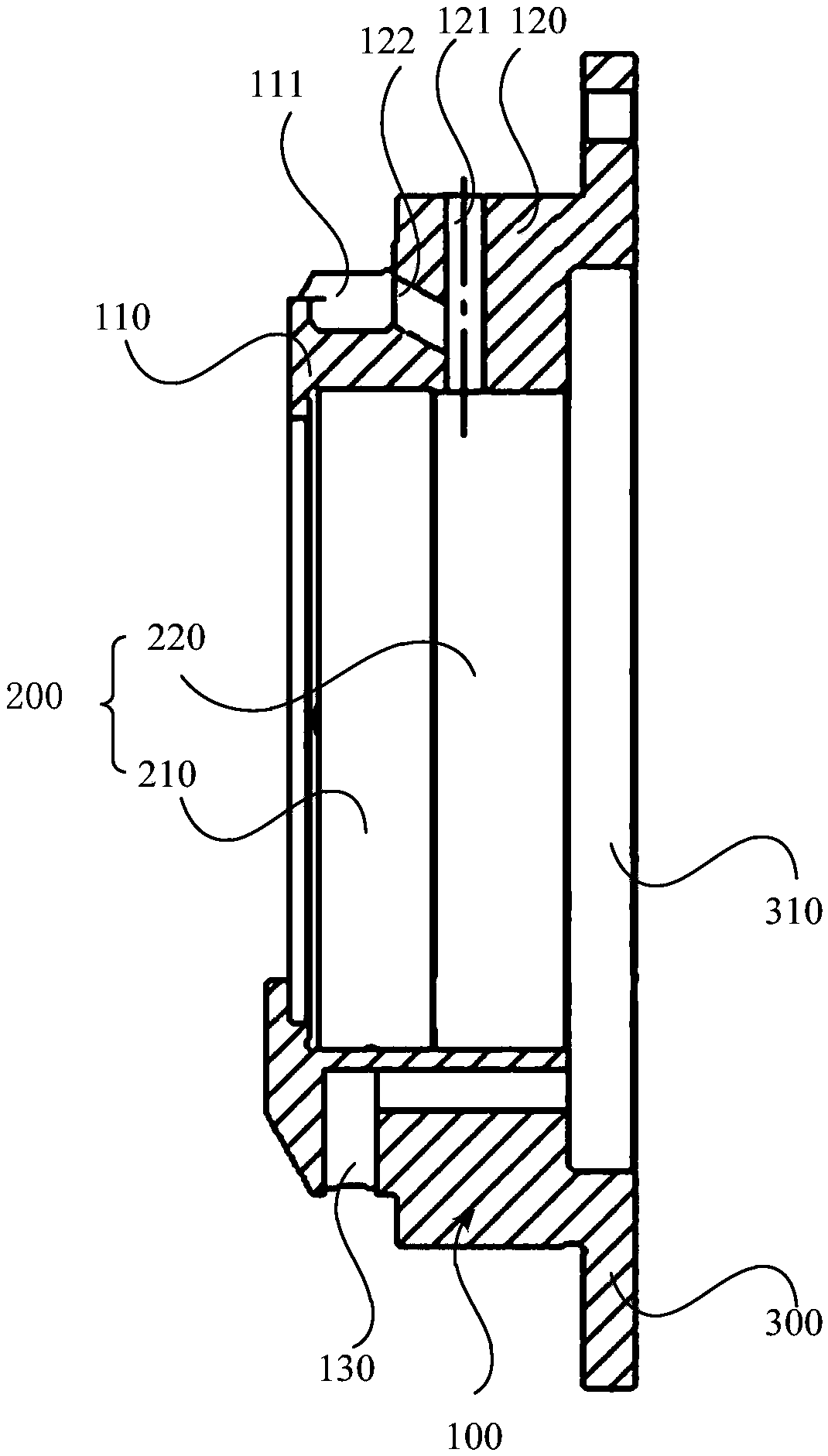

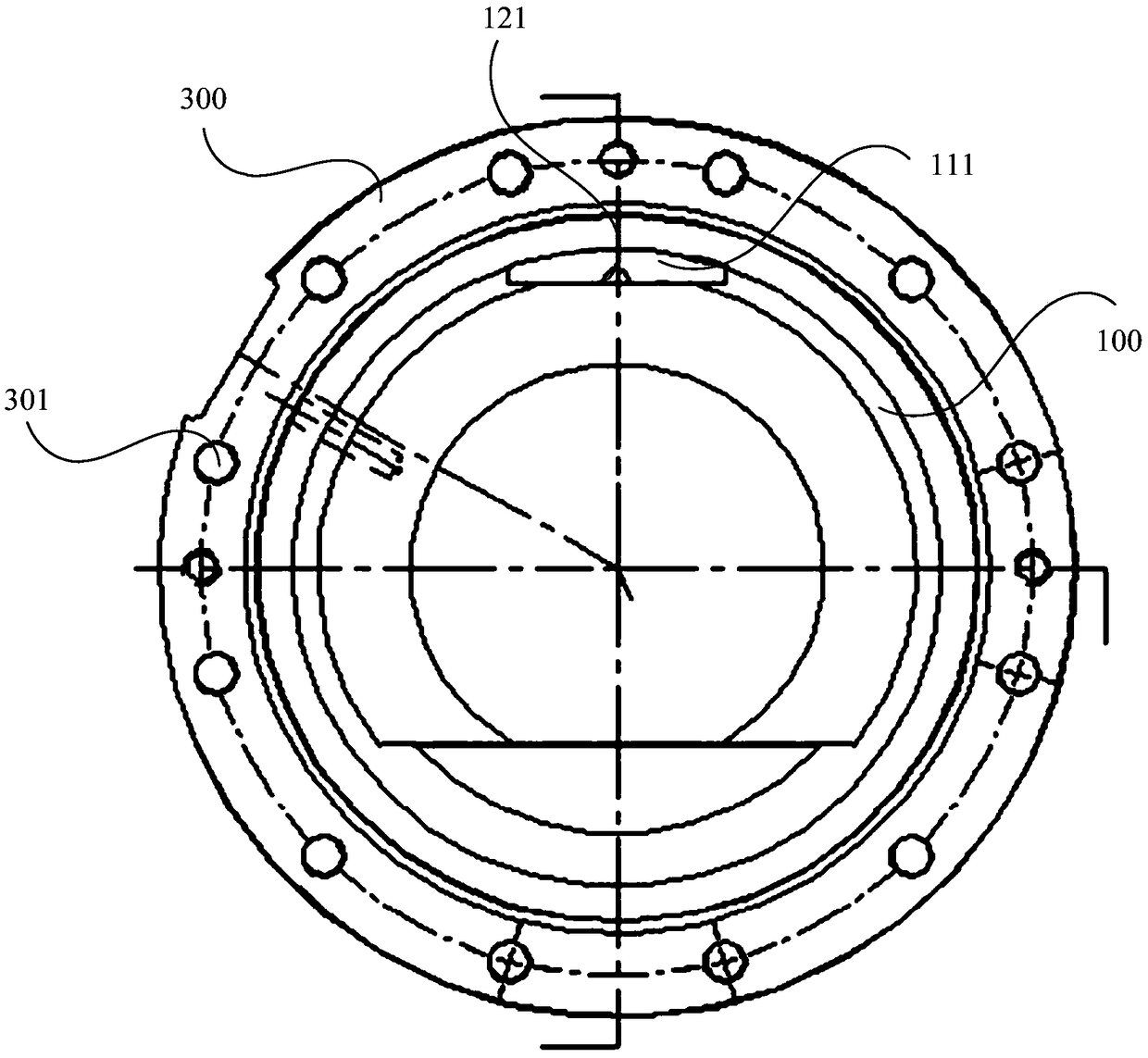

[0045] figure 1 A schematic structural diagram of a bearing sleeve provided by an embodiment of the present invention; figure 2 A cross-sectional view of the bearing sleeve at the position of the oil sump provided for an embodiment of the present invention; please refer to Figure 1-Figure 2 . This embodiment provides a bearing sleeve, which includes a cylindrical body 100. An installation space 200 for installing the bearing is formed inside the body 100 along the axial direction. The body 100 is also provided with an oil collecting groove 111 and an oil inlet hole 121. The oil collecting groove 111 is defined on the outer wall of the body 100 , and the oil collecting groove 111 is connected to the installation space 200 through the oil inlet hole 121 .

[0046] Optionally, the bearing sleeve of this embodiment is arranged inside the gear box of the rail vehicle for supporting the bearing and fixing the outer ring of the bearing. The bearing sleeve includes a body 100, an...

Embodiment 2

[0059] This embodiment provides a gear box, which includes a casing, and the bearing sleeve as described in the first embodiment above is arranged inside the casing.

[0060] Optionally, a bearing sleeve is provided inside the gearbox of this embodiment for supporting the bearing and fixing the outer ring of the bearing. The bearing sleeve includes a body, and the body is cylindrical as a whole. An installation space for installing bearings is formed in the axial direction inside it, and the two ends of the installation space pass through the body, so that the two ends of the body form openings. The body is also provided with an oil collecting groove and an oil inlet hole, wherein the oil collecting groove is set on the outer wall of the body, and the oil collecting groove is connected to the installation space through the oil inlet hole, so that the lubricating oil in the gearbox can be stored in the oil collecting groove and passed through The oil inlet hole connected with ...

Embodiment 3

[0064] This embodiment provides a rail vehicle, including the gear box as described in the second embodiment above.

[0065] Optionally, the gear box of the rail vehicle in this embodiment is provided with a bearing sleeve for supporting the bearing and fixing the outer ring of the bearing. The bearing sleeve includes a body, and the body is cylindrical as a whole. An installation space for installing bearings is formed in the axial direction inside it, and the two ends of the installation space pass through the body, so that the two ends of the body form openings. The body is also provided with an oil collecting groove and an oil inlet hole, wherein the oil collecting groove is set on the outer wall of the body, and the oil collecting groove is connected to the installation space through the oil inlet hole, so that the lubricating oil in the gearbox can be stored in the oil collecting groove and passed through The oil inlet hole connected with the oil sump sends lubricating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com