High-speed lower lubricating device for bearing ring

A lubricating device and high-speed bearing technology, which is applied in the field of bearing lubrication, can solve the problems of insufficient lubrication and cooling, insufficient lubrication and cooling, and affect the quality of equipment, so as to reduce frictional heat, achieve lubrication and cooling, and improve lubrication efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

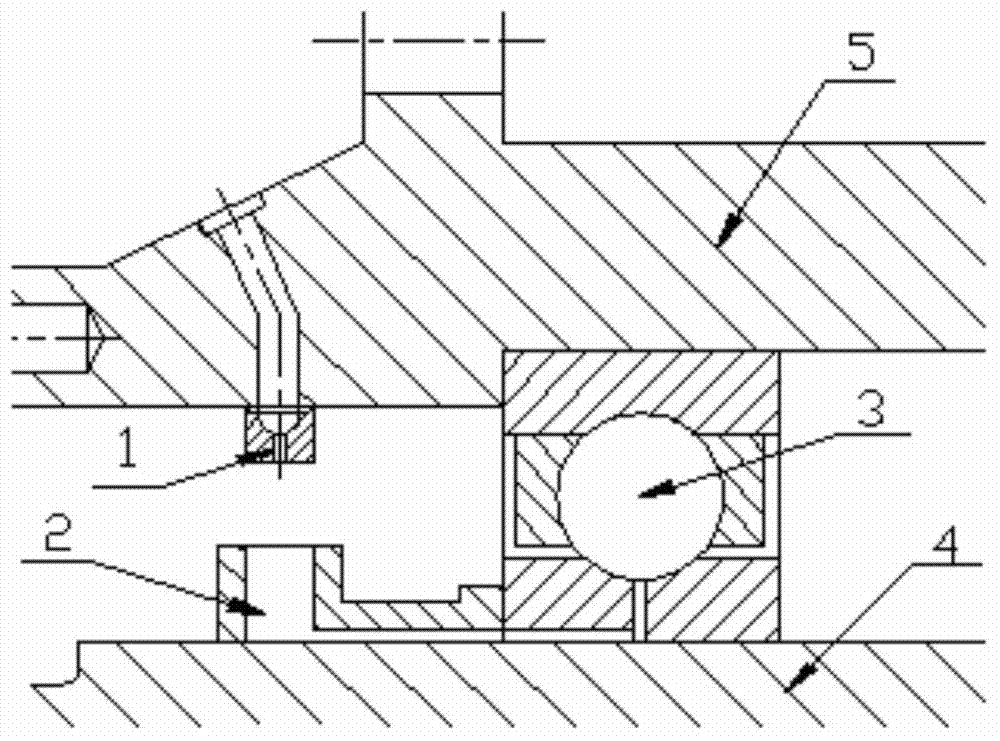

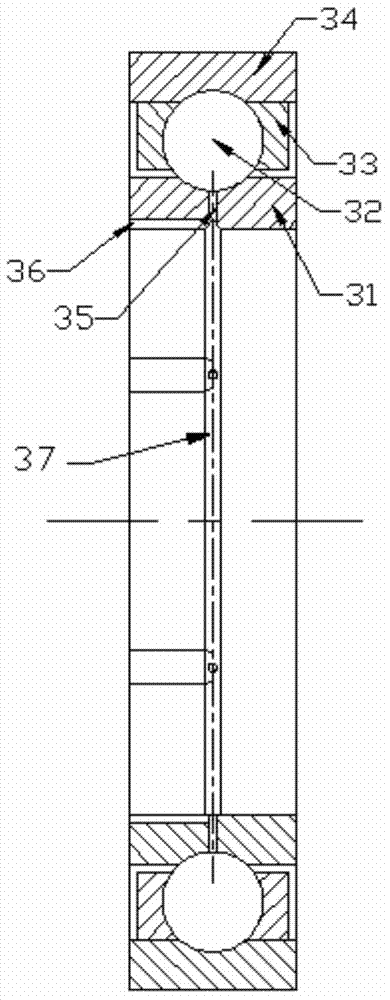

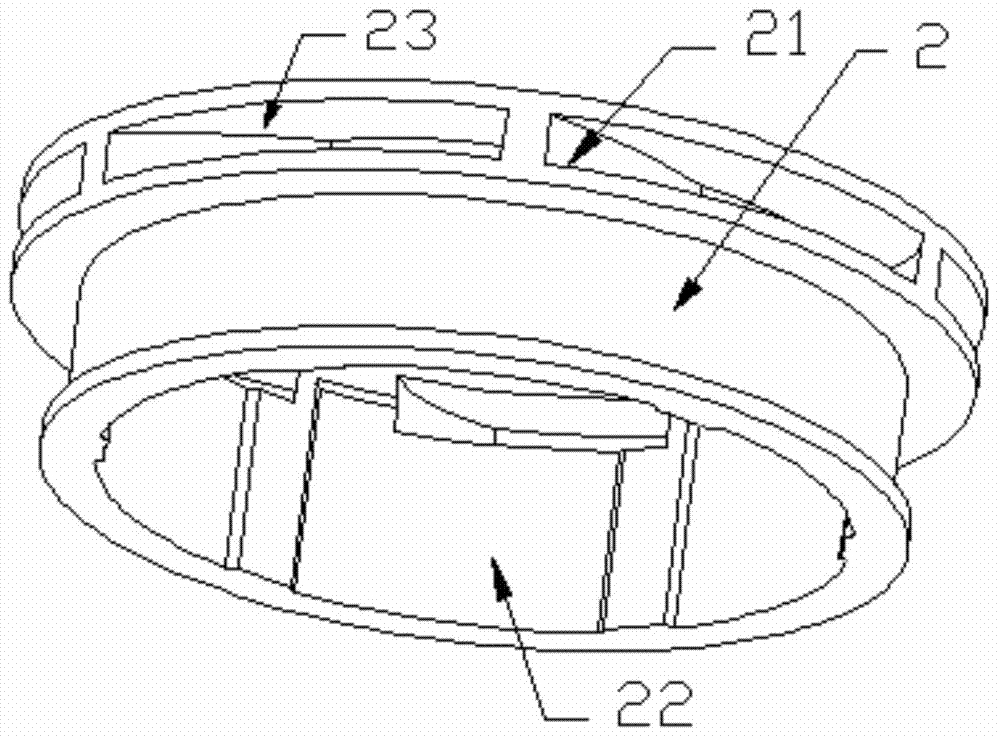

[0022] see Figure 1 to Figure 6 , the main shaft 4 is set in the shaft housing 5 through the bearing 3, and the bearing 3 adopts an under-ring lubrication device, which specifically includes an oil collection sleeve 2 that rotates synchronously with the inner ring of the bearing, and the oil collection sleeve 2 and the inner ring 31 of the bearing are coaxially fixed on the On the main shaft 4; the inner wall of the inner ring 31 of the bearing 3 is respectively provided with a lubricating oil groove 36 along the axial direction, and a radial oil hole 35 is arranged along the radial direction. One end of the radial oil hole 35 communicates with the lubricating oil groove 36, and the other end communicates with the The raceway of the inner ring 31 of the bearing; the oil collection sleeve 2 and the inner ring 31 of the bearing are coaxially fixed on the main shaft 4 through interference fit, and the oil collection sleeve 2 is divided into two parts along the axial direction, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com