Radial oil collecting ring and under-ring oil supply lubricating device and method

An oil scavenger, oil supply technology, applied in bearing components, shafts and bearings, bearing cooling, etc., can solve the problems of low bearing lubrication efficiency and poor cooling effect, and achieve the effect of improving lubrication and cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

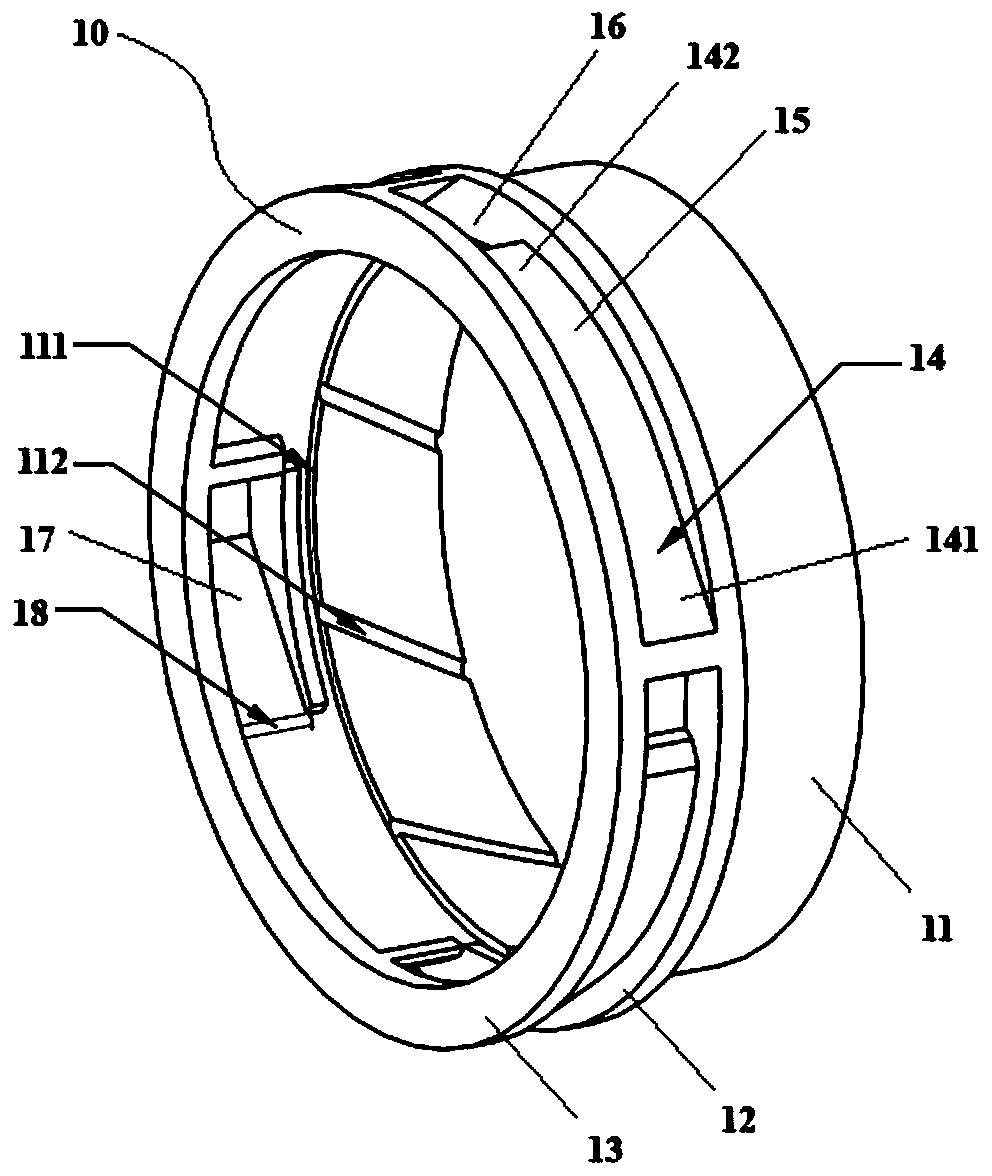

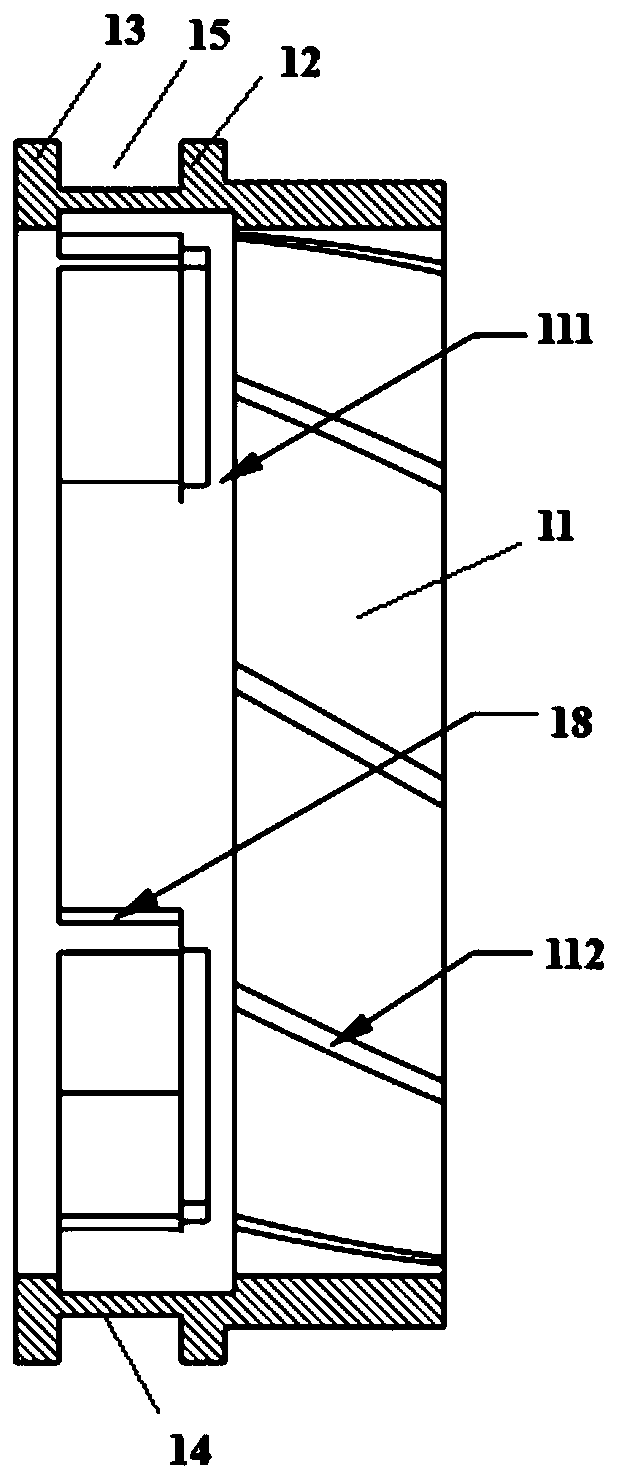

[0042] Such as figure 1 , figure 2 and image 3As shown, this embodiment provides a radial oil collector, including integrally formed: a cylindrical wall 11, a first annular retaining wall located at the end of the cylindrical wall 11 and coaxial with the cylindrical wall 11 12. The second annular retaining wall 13 parallel to the first annular retaining wall 12 and a plurality of oil collector vanes 14 connected between the first annular retaining wall 12 and the second annular retaining wall 13; the first annular retaining wall 12 and the plane where the second annular retaining wall 13 is located are all perpendicular to the central axis of the cylindrical wall 11, and the first annular retaining wall 12, the second annular retaining wall 13 and the oil collecting vanes 14 jointly form an oil collecting groove 15; One end of the oil collecting blade 14 corresponding to the oil groove 15 is the blade tip 141, and the other end is the blade root 142; The oil collection in...

Embodiment 2

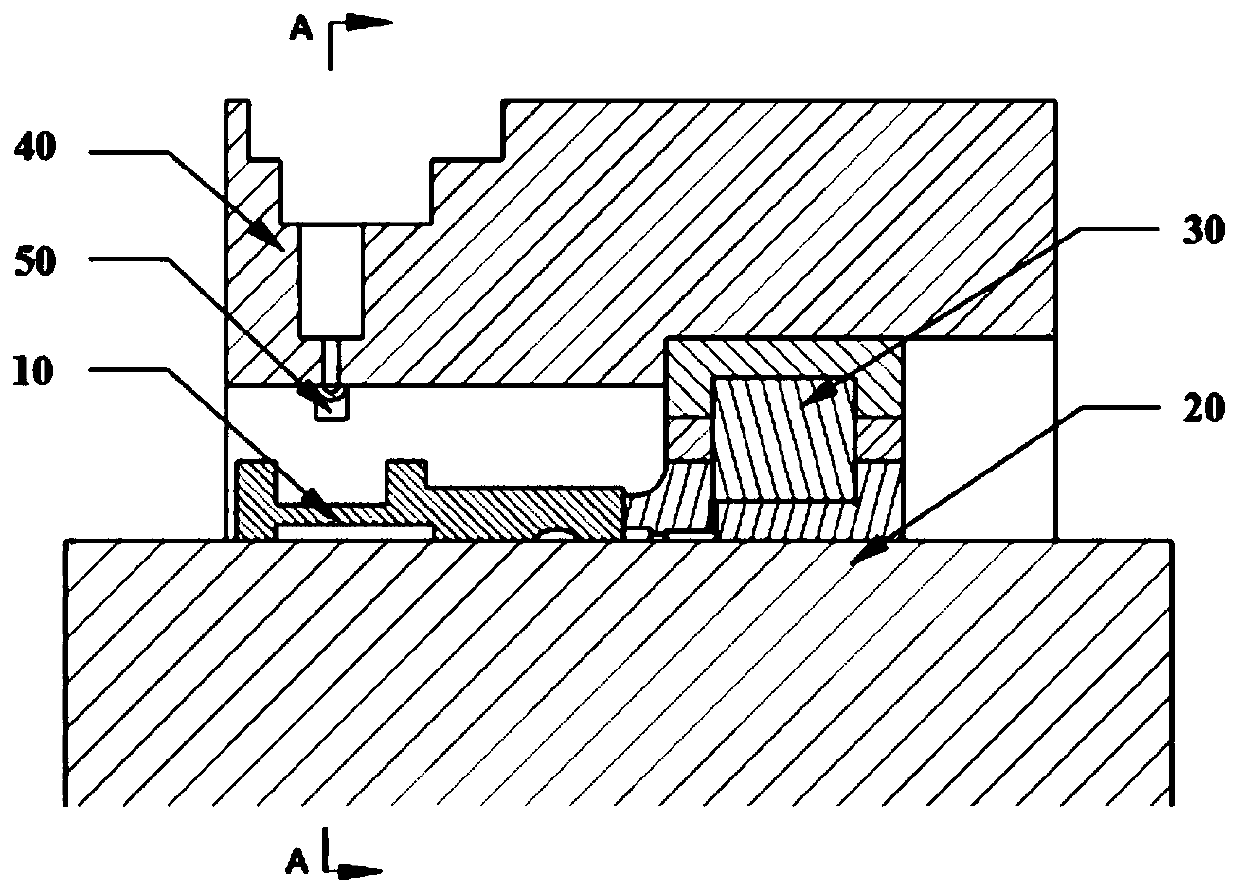

[0049] Such as Figure 3 to Figure 6 As shown, this embodiment provides an oil supply lubrication device under the ring, including the radial oil collector ring 10 in Embodiment 1, and also includes: a main shaft 20, a bearing 30 sleeved outside the main shaft 20, and a bearing 30 sleeved outside the bearing 30. The bearing seat 40 and the oil supply nozzle 50 arranged on the bearing seat 40 and connected to the oil supply passage; the oil supply nozzle 50 penetrates into the bearing seat 40 and aligns with the oil collection groove 15; the radial oil collection ring 10 is set on the main shaft 20 And it can rotate synchronously with the main shaft 20 , and one end provided with the oil delivery chute 112 is in close contact with the bearing 30 .

[0050] The bearing 30 includes a bearing inner ring 31 in contact with the main shaft 20 , a bearing outer ring 32 , and rolling elements 34 held by a cage 33 and provided between the bearing inner ring 31 and the bearing outer ring...

Embodiment 3

[0054] This embodiment provides a lubricating method for oil supply under the ring, which is realized by using the device in Embodiment 2, and specifically includes the following steps:

[0055] The lubricating oil jet sprayed from the oil supply nozzle is sprayed to the oil collecting groove of the radial oil collecting ring through the air field in the bearing cavity. The lubricating oil in the oil collection channel of the oil collection ring flows along the inner surface of the oil collection vane, flows through the blade protrusion on the oil collection vane, and then enters the front oil collection ring groove;

[0056] The blade protrusions on the oil collection vane can prevent the lubricating oil entering the front oil collection ring groove from being thrown out of the oil collection channel, and the lubricating oil in the front oil collection ring groove is transported to the rear oil collection ring groove along the oil delivery chute Inside, due to the oblique lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com