Automatic lubrication mechanism for conveyor chain

A technology of automatic lubrication and conveying chain, which is used in conveyor objects, transportation and packaging, cleaning devices, etc., can solve the problems of difficult control of lubrication position and amount of lubricant, pollution of production environment, poor lubrication effect, etc., to achieve simple structure, avoid Pollution, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Hereinafter, the present invention will be described in detail with reference to the drawings.

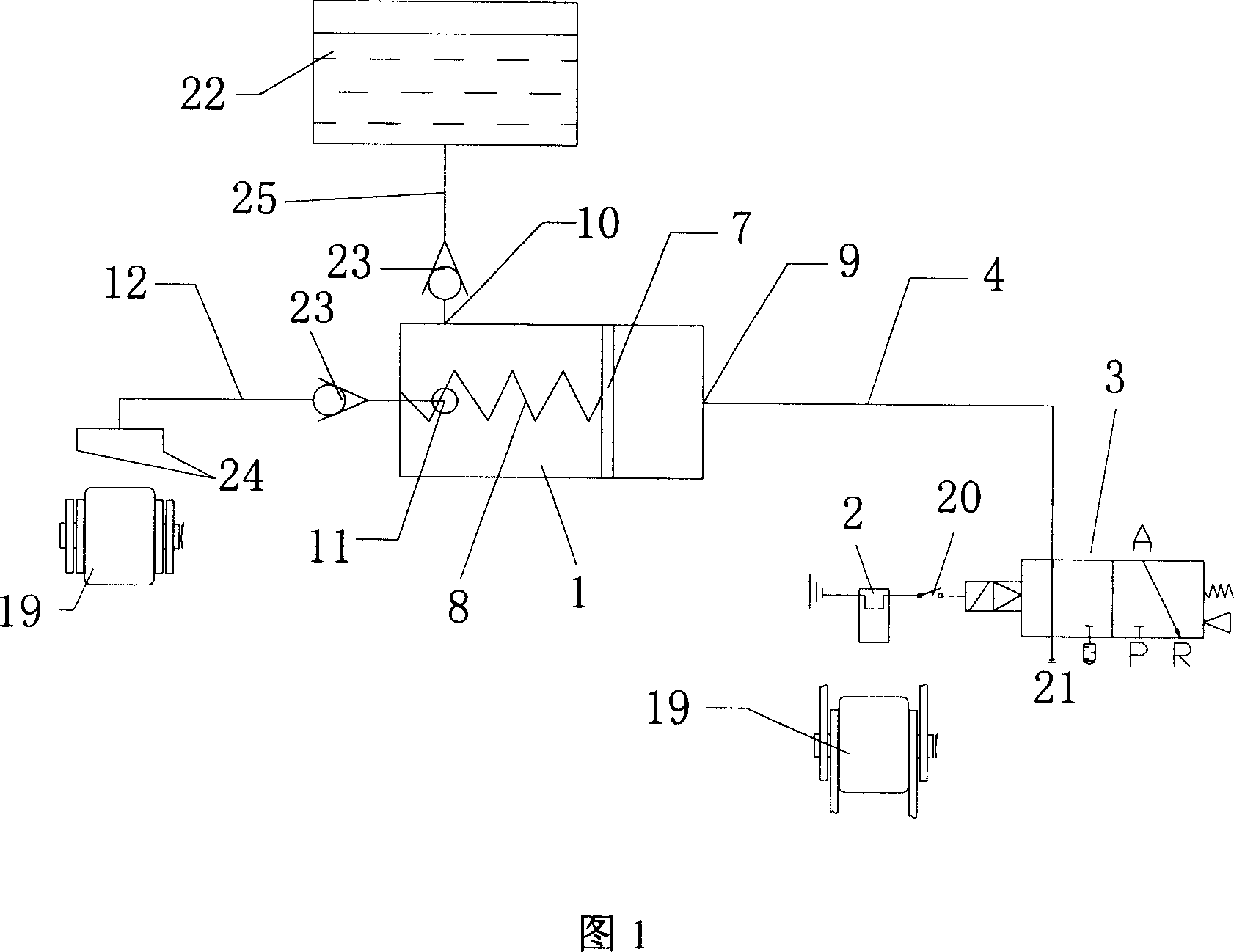

[0009] The automatic lubrication mechanism of the conveyor chain provided by the present invention includes a gas-liquid combined cylinder 1, a sensor 2, a solenoid valve 3, a gas path 4 and a pipeline 12, as shown in FIG.

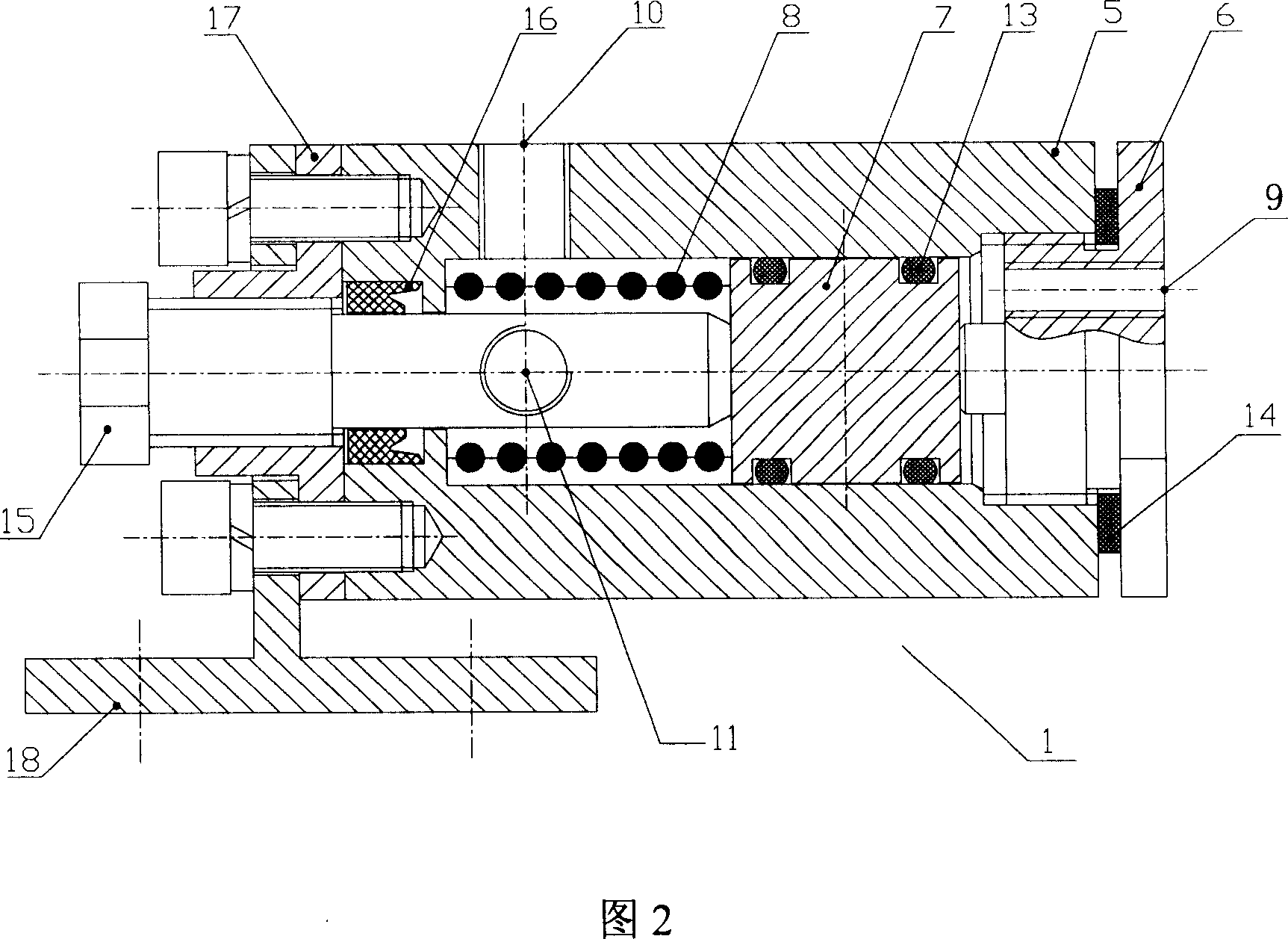

[0010] Among them, as shown in FIG. 2, the gas-liquid combined cylinder 1 includes a cylinder block 5, a cylinder head 6, a piston 7 and a return member 8. The cylinder head 6 includes a vent 9. Preferably, a sealing member 14 is assembled around the vent hole 9 of the cylinder head 6 for sealing the inflation cavity of the cylinder. The sealing element 14 can be various well-known sealing elements, such as an oil seal apron, a rubber flat gasket, an O-ring seal, etc., preferably an oil seal apron. The cylinder body 5 includes an oil inlet hole 10 and an oil outlet hole 11 communicating with the inner cavity of the cylinder where the return member 8 is assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com