Engine oil processing system

An engine oil and processing system technology, applied to engine components, machines/engines, engine lubrication, etc., can solve the problems of difficult to accurately control the fuel injection angle, reduce the oil life cycle, increase engine wear and other problems, and improve fuel utilization. rate, increase engine life, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

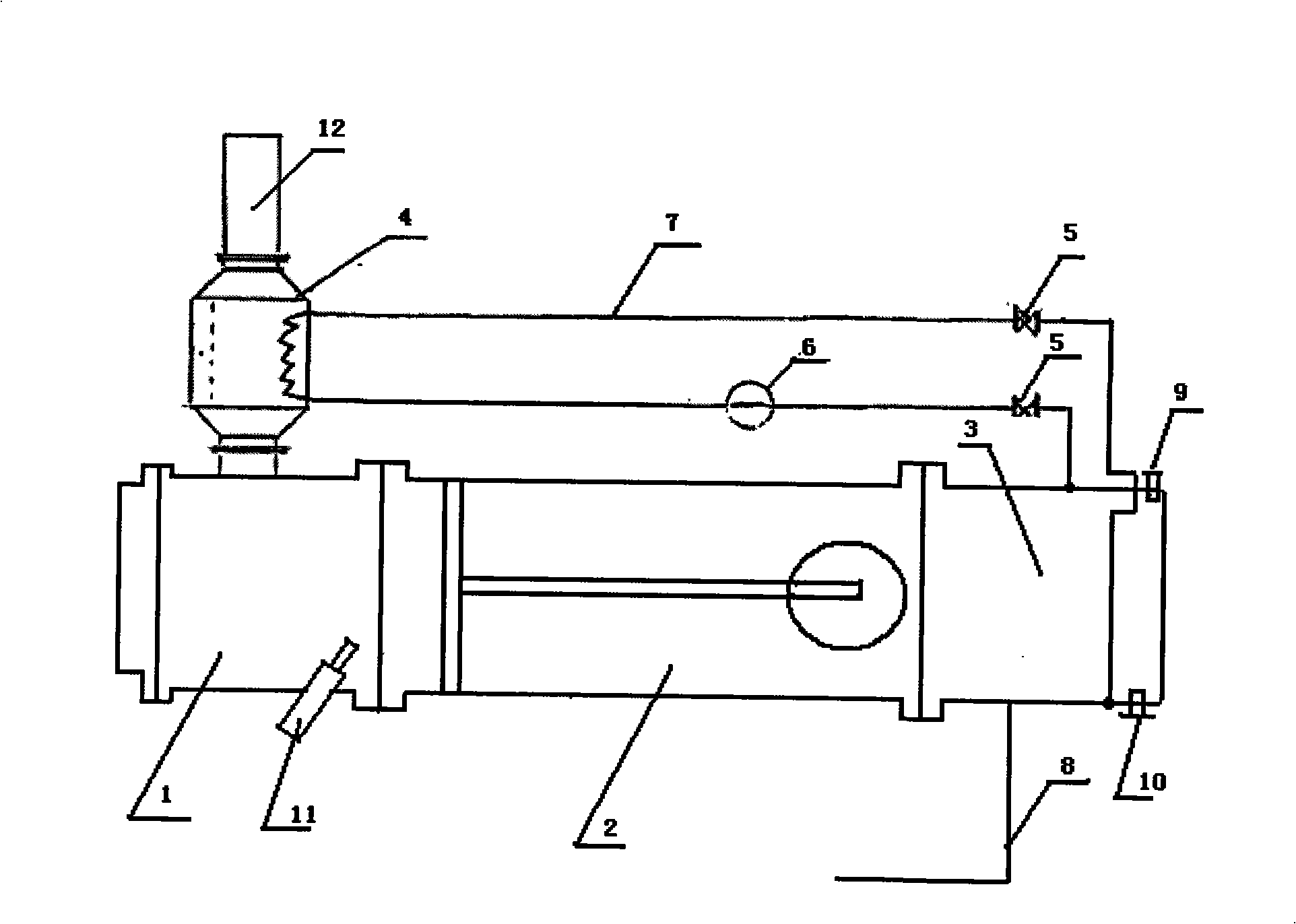

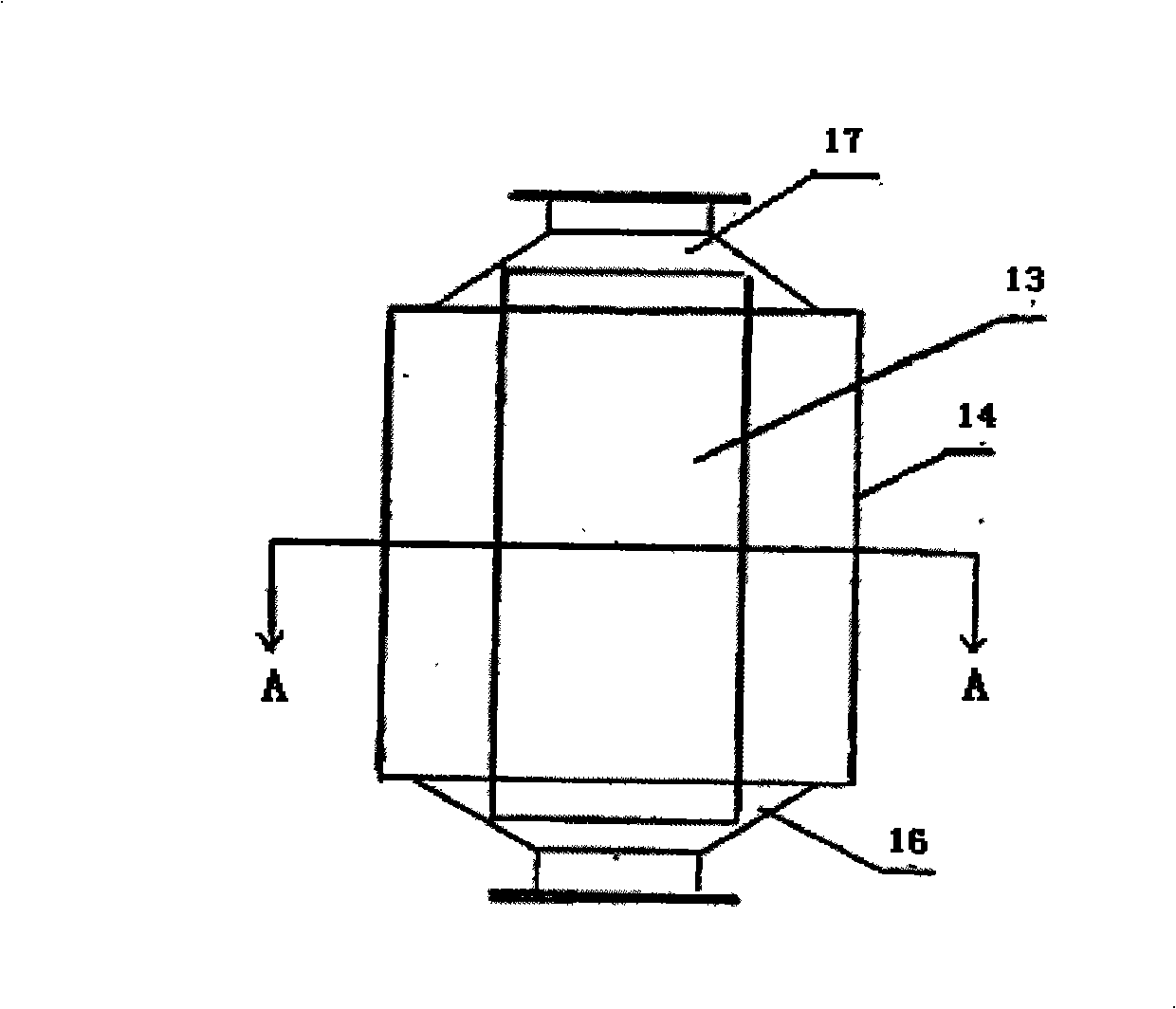

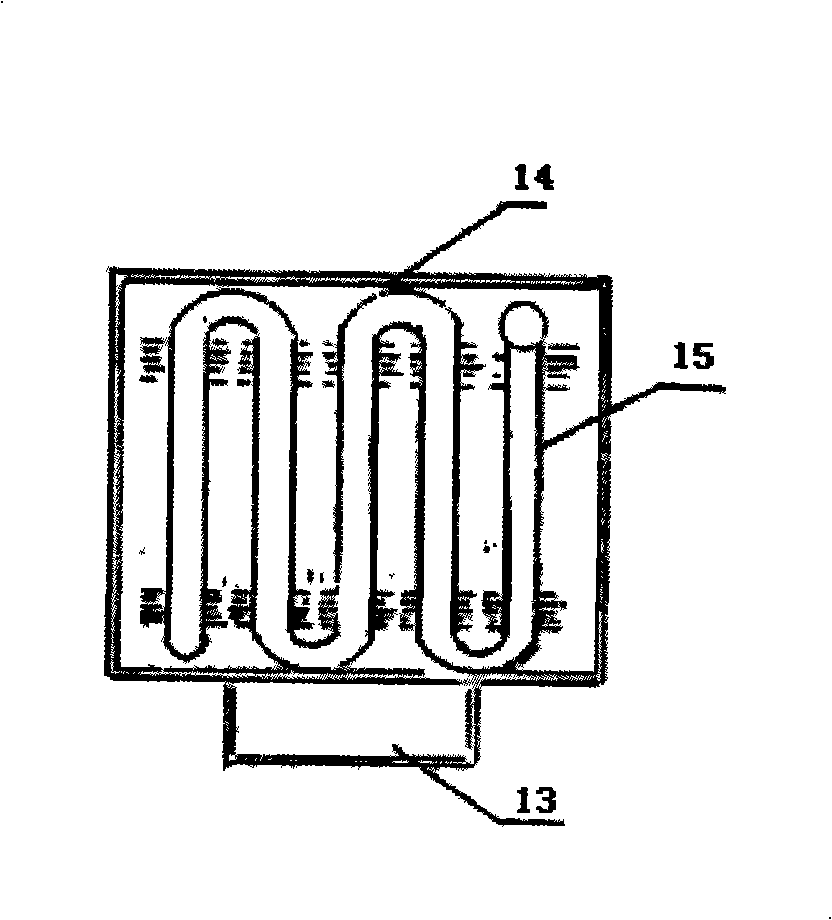

[0020] Below in conjunction with accompanying drawing, the present invention is done further explanation:

[0021] When the oil pressure sensor detects that the oil pressure is lower than a certain value, under the control of the ECU, the oil circuit switch valve 5 is opened, the oil pump 6 starts to work, and the heat preservation oil circuit oil starts to flow under the action of the oil pump. The oil first enters the heat exchanger. The heat exchanger is composed of an adjustable damper 13, a housing 14, a coil pipe 15, and smoke inlets and outlets 16, 17. The adjustable damper 13 can adjust the exhaust resistance and control the temperature rise. Coil 15 is to increase the oil and exhaust contact area. After the high-temperature exhaust gas enters the heat exchanger through the smoke inlet 14, the oil in the coil pipe 15 is heated, and the temperature of the machine oil rises through the heat exchange of the coil pipe. The heated engine oil enters the oil pan and the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com