Automatic-lubricating drawing die

A deep drawing die and self-lubricating technology, applied in the field of cold stamping processing, can solve the problems of needing to stop lubrication, reduce system reliability, and high cost, and achieve the effects of no lubricating oil waste, high lubrication efficiency, and easy automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

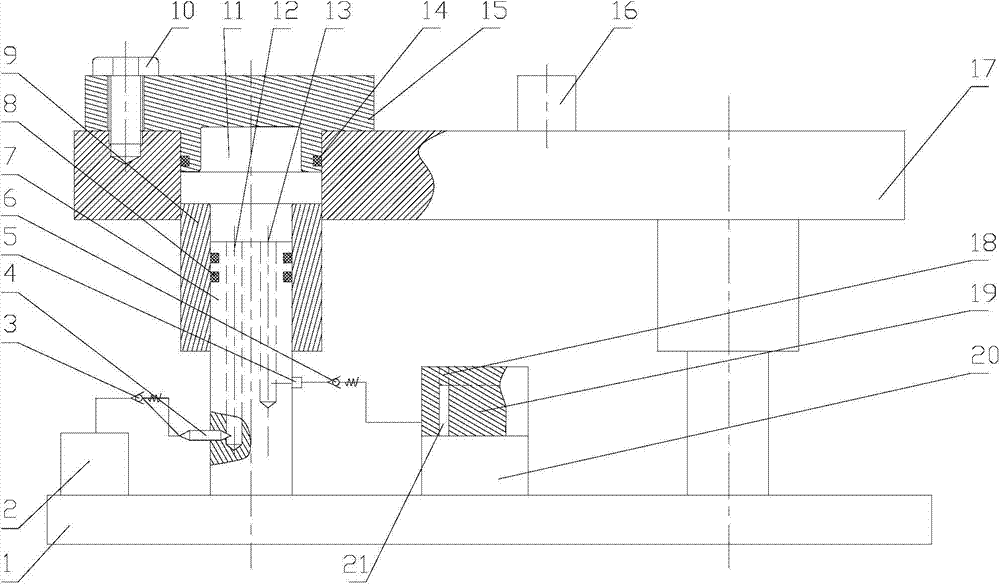

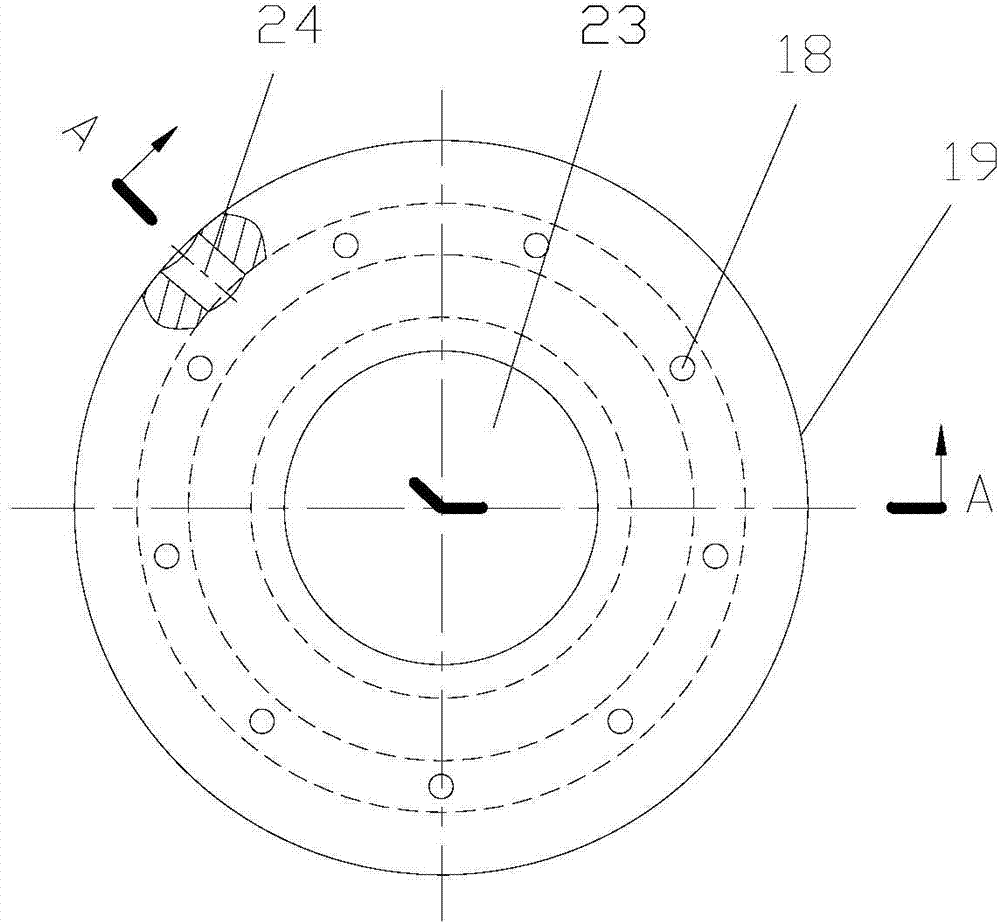

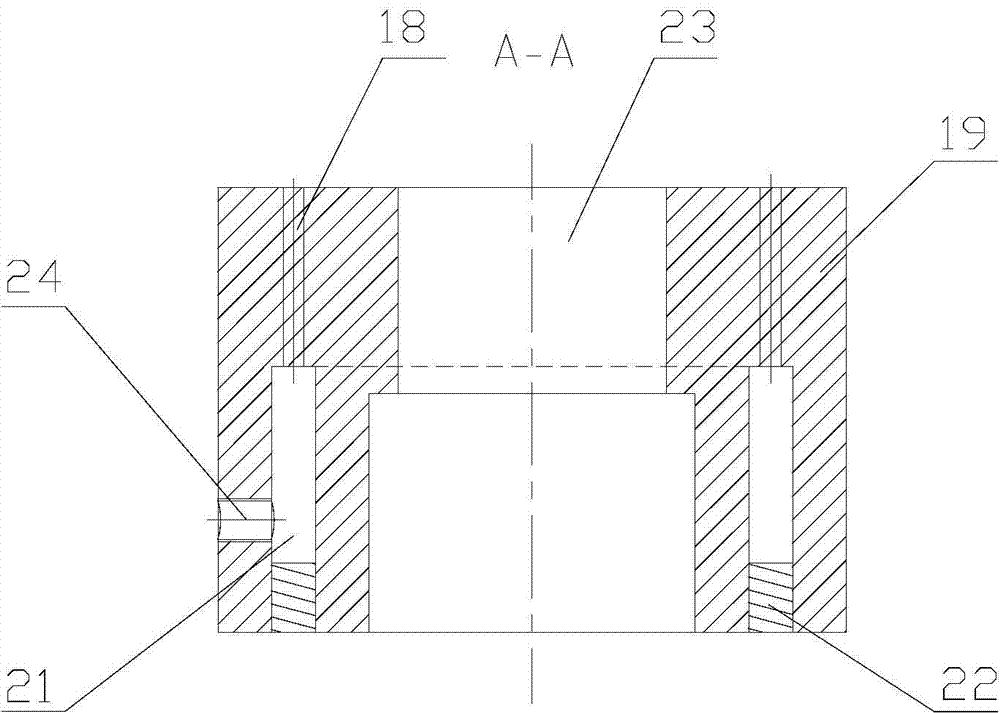

[0029] see Figure 1 to Figure 3 , a self-lubricating deep drawing die, comprising a lower die base 1, an upper die base 17 and a deep drawing die 19, the upper die base 17 is connected with a press through a die handle 16 provided thereon, and passes through a guide sleeve 9 along a vertical The set guide column 7 slides, and the workpiece is pressed into the cavity 23 of the drawing die 19 fixed on the lower die base 17, and the drawing die 19 is fixed on the lower die base 1 through the die holder 20 , the top of the guide sleeve 9 is closed by a plug 15, and the guide post 7 is inserted from the bottom end of the guide sleeve to form a variable pressure chamber 11 in the guide sleeve. communicate with a lubricating oil chamber 21, specifically, such as figure 1 As shown in , the oil inlet hole 12 and the oil outlet hole 13 are set on the guide post 7 to connect with the oil inlet pipeline and the oil outlet pipeline respectively. At the bottom of the guide post, an oil i...

Embodiment 2

[0033] As another preferred solution of Example 1, the manner in which the pressure chamber is connected to the oil inlet pipeline and the oil outlet pipeline is as follows: Figure 4 Shown: offer oil inlet hole 12 and oil outlet hole 13 on sealing plug 15 and be connected with oil inlet pipeline and oil outlet pipeline respectively.

[0034] For details, see Figure 5 , when the upper mold base 17 goes down, that is, when the mold is closed and working, the volume of the pressure chamber 11 decreases and the pressure increases. At this time, the oil inlet check valve 3 is closed, and the oil outlet check valve 6 is opened, and the pressure chamber The lubricating oil in the body 11 is pressed into the lubricating oil chamber through the oil outlet 13 through the oil outlet check valve 6, and the lubricating oil chamber gets oil and passes through the lubricating oil hole to the upper surface of the concave mold cavity of the deep drawing die under pressure. Oil injection to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com