Rail-side solid-liquid-solid lubricating material and manufacturing method thereof

A kind of lubricating material, solid-liquid-solid technology, used in lubricating compositions, petroleum industry and other directions, can solve the problems of low extreme pressure resistance, low lubricating grease consistency, poor adhesion on the rail side surface, etc., to improve lubrication efficiency, The effect of low coefficient of friction and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

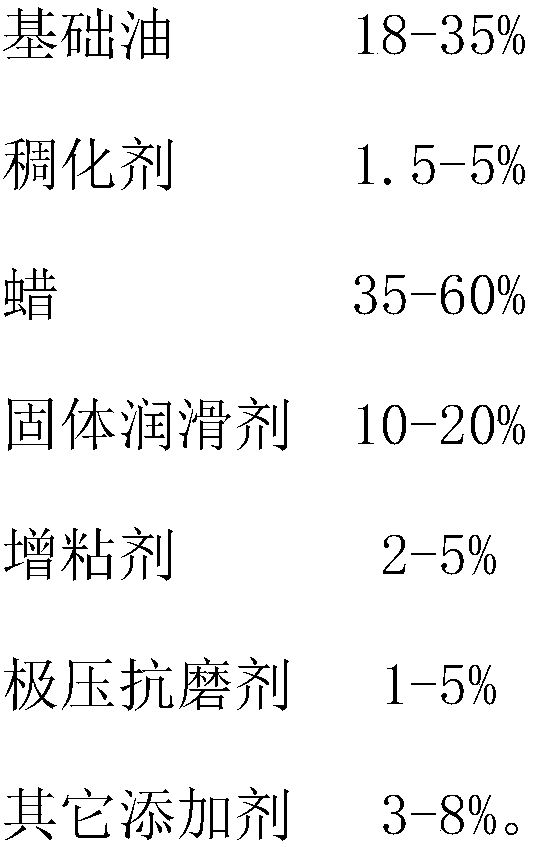

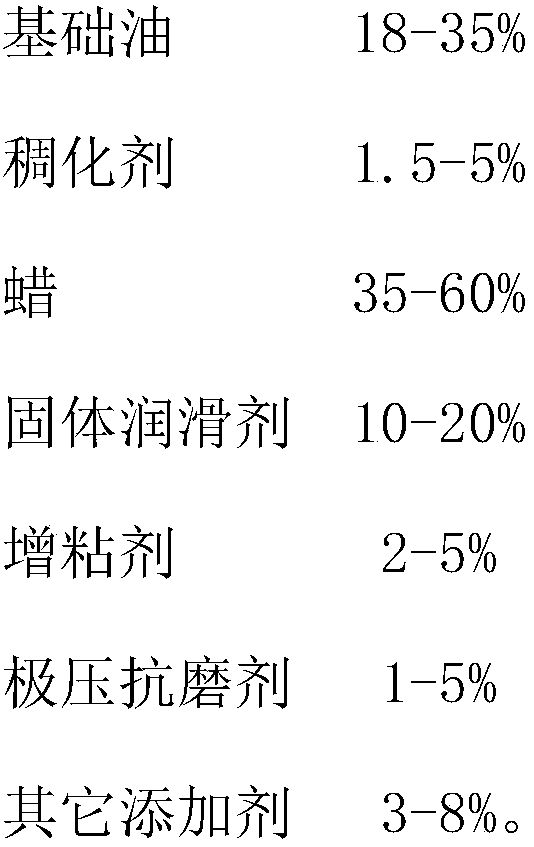

Method used

Image

Examples

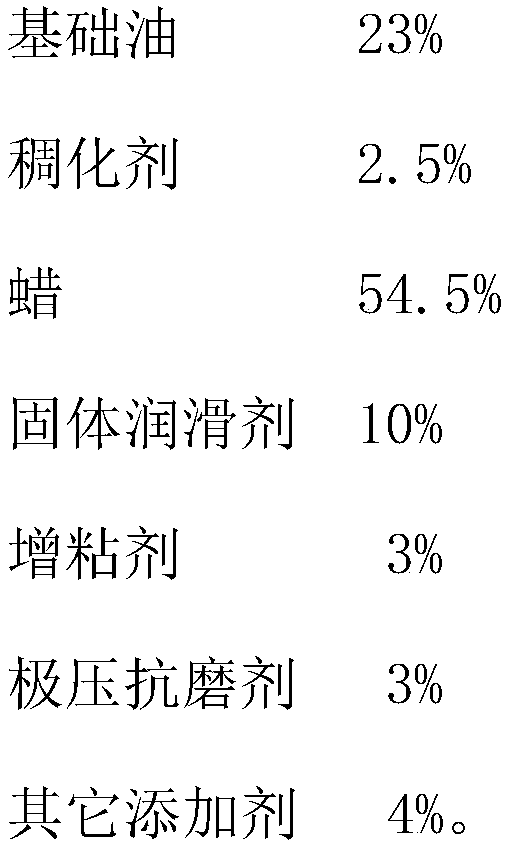

Embodiment 1

[0032] A rail-side solid-liquid-solid lubricating material. The rail-side solid-liquid-solid lubricating material is prepared from the following raw materials in weight percentage: 23% of base oil, 2.4% of thickener, 54.6% of wax, 10% of solid lubricant, and thickener Agent 3%, extreme pressure antiwear agent 3%, other additives 4%.

[0033] This embodiment provides a method for preparing a rail-side solid-liquid-solid lubricating material, including the following steps:

[0034] (1) firstly take various raw materials according to the above weight percentage;

[0035] (2) Weigh 23 parts of epoxidized soybean oil and 2.1 parts of stearic acid and put them into the reactor, stir and slowly heat up to 80° C., so that stearic acid is completely melted in the epoxidized soybean oil;

[0036] (3) Weigh 0.3 parts of lithium hydroxide and dissolve in 3 parts of distilled water, slowly add the prepared solution into the reaction kettle, and at the same time, the reaction temperature r...

Embodiment 2

[0042] A rail-side solid-liquid-solid lubricating material. The rail-side solid-liquid-solid lubricating material is prepared from the following raw materials in weight percentage: 34.2% base oil, 4.8% thickener, 35% wax, 10% solid lubricant, and thickener Agent 4%, extreme pressure antiwear agent 5%, other additives 7%.

[0043] This embodiment provides a method for preparing a rail-side solid-liquid-solid lubricating material, including the following steps:

[0044] (1) firstly take various raw materials according to the above weight percentage;

[0045] (2) Weigh 34.2 parts of epoxidized soybean oil and 4.2 parts of stearic acid into the reactor, stir and slowly heat up to 80° C., so that stearic acid is completely melted in the epoxidized soybean oil;

[0046] (3) Weigh 0.6 parts of lithium hydroxide and dissolve in 6 parts of distilled water, slowly add the prepared solution into the reaction kettle, and at the same time, the reaction temperature rises to 120 °C; after 1...

Embodiment 3

[0052] A rail-side solid-liquid-solid lubricating material. The rail-side solid-liquid-solid lubricating material is prepared from the following raw materials in weight percentage: 26.6% of base oil, 2.4% of thickener, 50% of wax, 10% of solid lubricant, and thickener Agent 3%, extreme pressure antiwear agent 4%, other additives 4%.

[0053] This embodiment provides a method for preparing a rail-side solid-liquid-solid lubricating material, including the following steps:

[0054] (1) firstly take various raw materials according to the above weight percentage;

[0055] (2) Weigh 26.6 parts of epoxidized soybean oil and 2.1 parts of stearic acid into the reactor, stir and slowly heat up to 80° C., so that stearic acid is completely dissolved in the epoxidized soybean oil;

[0056](3) Weigh 0.3 parts of lithium hydroxide and dissolve in 3 parts of distilled water, slowly add the prepared solution into the reaction kettle, and at the same time, the reaction temperature rises to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com