Airflow constraint type fine oil mist nozzle device

An oil mist nozzle and nozzle technology, which is applied in the field of lubrication and cooling, can solve the problems of inability to produce lubrication effect, short effective spray distance, uneven waste of spray, etc., and achieve the effect of simple structure, short residence time and reduced generation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

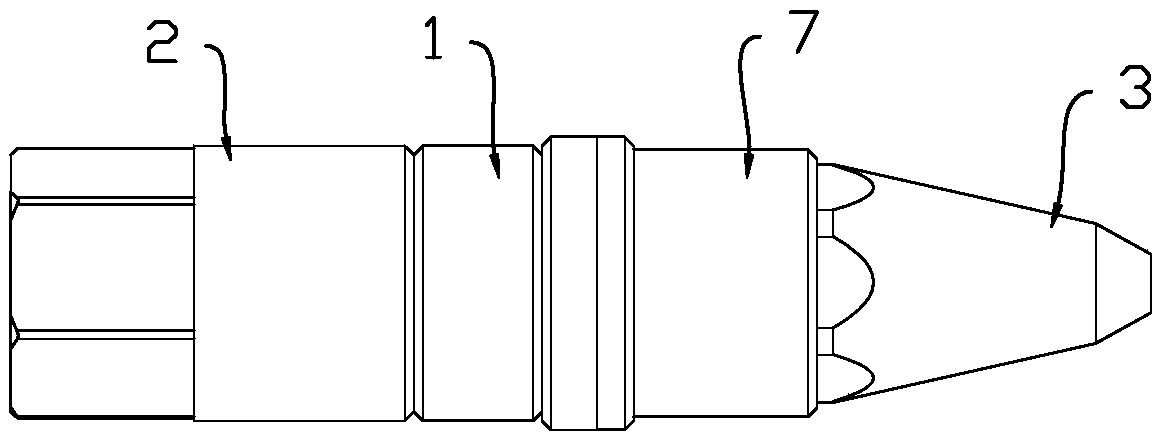

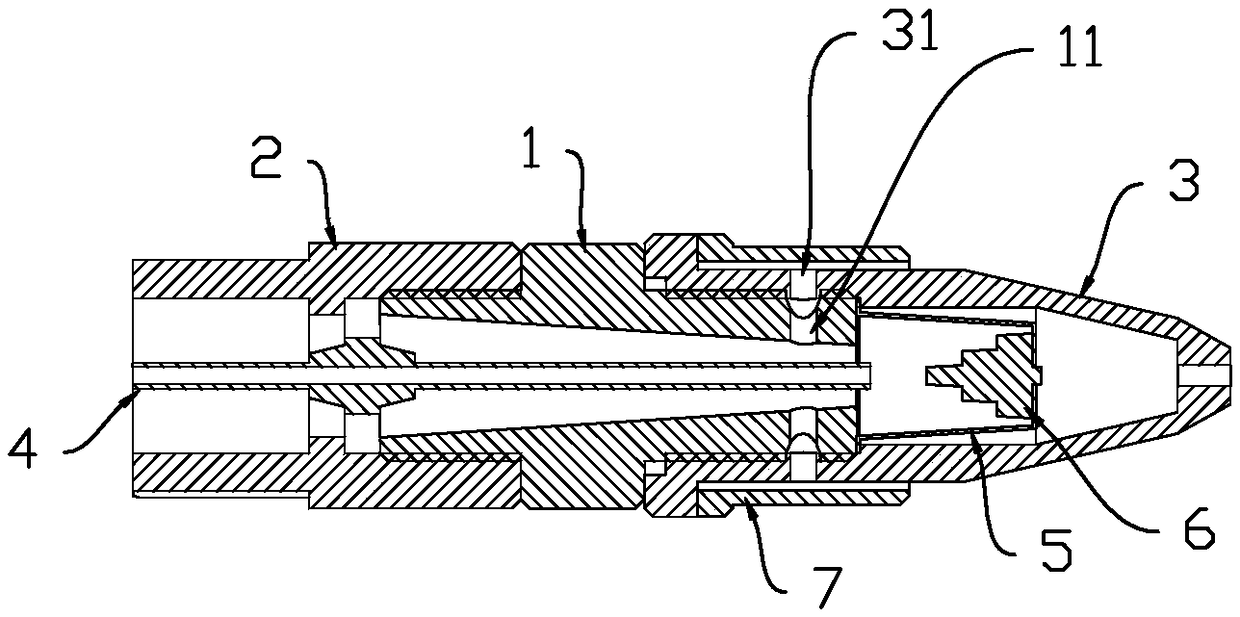

[0021] refer to Figure 1 to Figure 4 , the present invention is an airflow-restricted fine oil mist nozzle device, which includes a nozzle body 1 with a high-pressure airflow channel inside, and the two ends of the nozzle body 1 are respectively sleeved with a nozzle connecting pipe 2 for introducing high-pressure airflow and a nozzle for outputting oil mist. The nozzle cover 3 is provided with a spray port, the nozzle body 1 is provided with an oil pipe 4 for conveying oil, the nozzle cover 3 is provided with an elastic support 5, and the support 5 is provided with a device for promoting the atomization of the oil. Atomizing cone6.

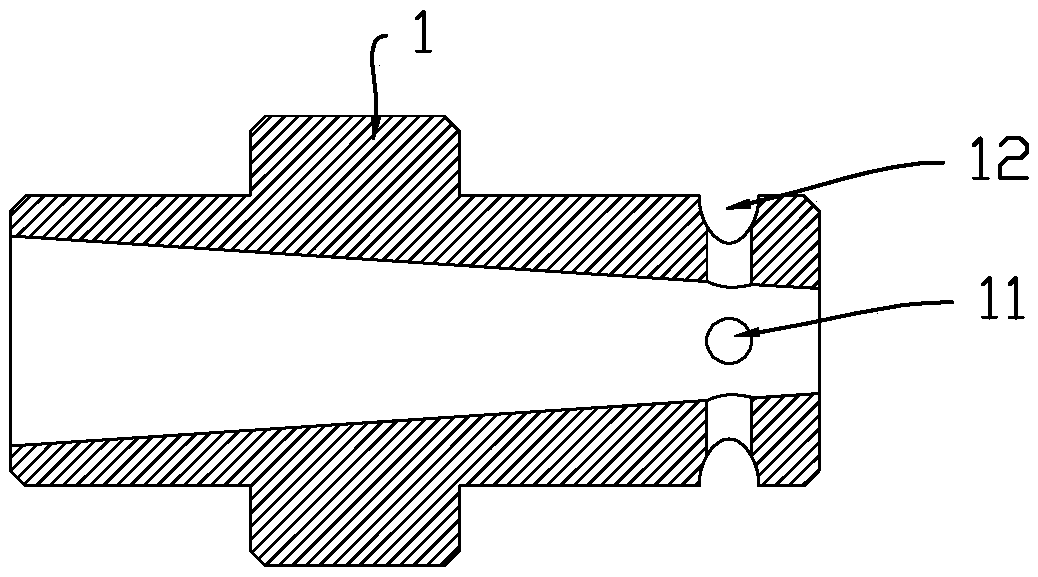

[0022] As a preferred embodiment of the present invention, the nozzle body 1 is provided with a number of internal high-pressure air holes 11 passing through the side wall at one end of the nozzle sleeve 3, and the side wall of the nozzle sleeve 3 is provided with several external high-pressure air holes 11 communicating with the inner high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com