High-strength converter tapping slag stopping mechanism capable of improving operating efficiency and processing technology thereof

A high-efficiency, high-strength technology, applied to furnaces, manufacturing tools, furnace types, etc., can solve problems such as the plane sliding slag blocking mechanism stuck in operation, the slag blocking mechanism is easily deformed by high temperature baking, and the success rate of slag blocking is low. , to achieve the effect of convenient and quick installation, prevent stuck, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

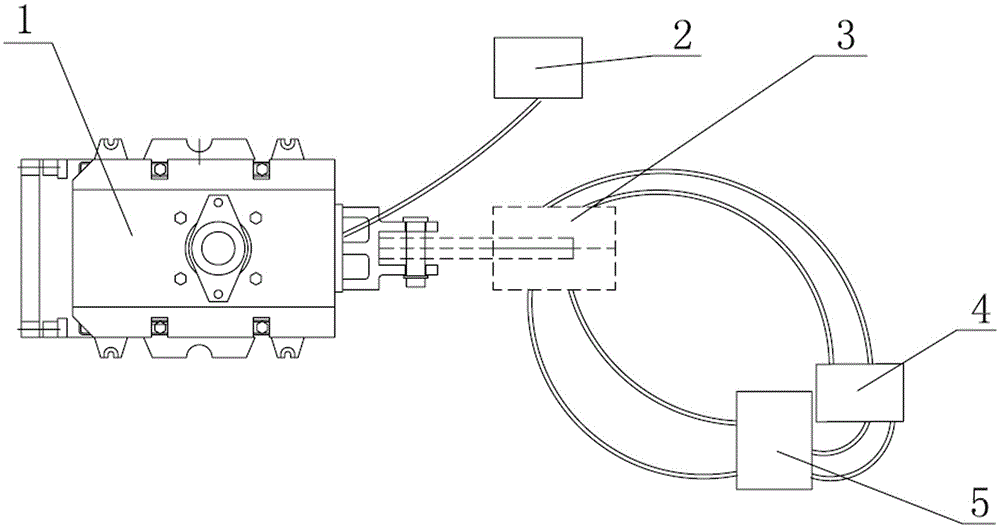

[0033] The high-strength converter tapping slag retaining mechanism that can improve operating efficiency in this embodiment, such as Figures 1 to 4 As shown, it includes a slag blocking mechanism 1, a mechanism cooling system 2, an oil cylinder 3, a hydraulic system 5, and a hydraulic cooling system 4. The mechanism cooling system 2 communicates with the slag blocking mechanism 1 through pipelines to cool the slag blocking mechanism 1. The output end of the oil cylinder 3 is connected with the slag blocking mechanism 1 for driving the slag blocking mechanism 1 to realize opening and closing. The oil cylinder 2, the hydraulic system 5 and the hydraulic cooling system 4 are connected in sequence through pipelines and form a circuit.

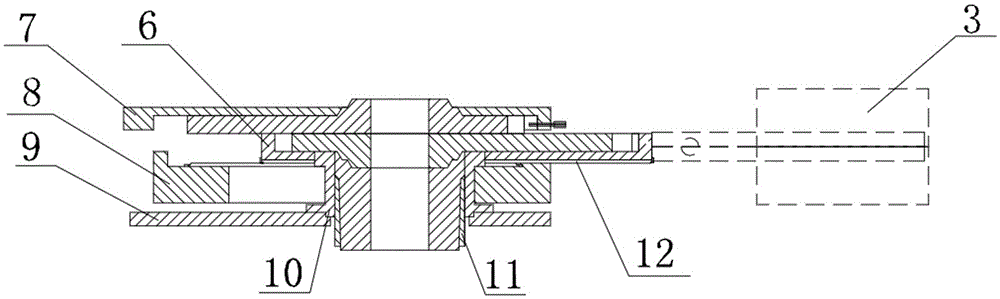

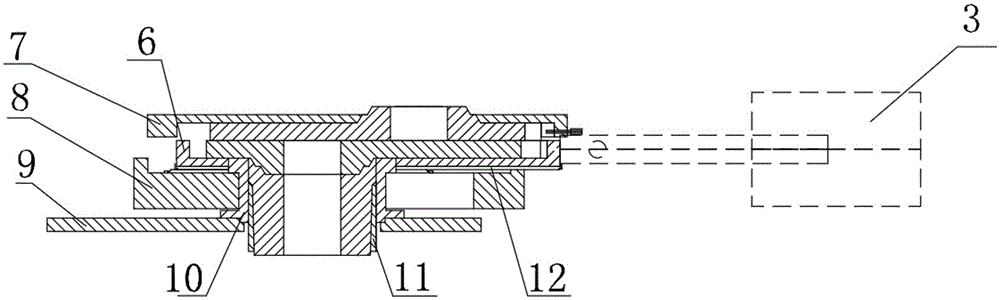

[0034]The slag blocking mechanism 1 comprises a fixed mold frame 7 , a sliding mold frame 6 , a switch mold frame 8 , a lower nozzle installation mold frame 10 , a lower nozzle fixed mold frame 11 and a slag retaining plate 9 . The fixed mold fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com