Universal centrifugal pump wear ring test bed

A test bench and mouth ring technology, applied in pump control, non-variable pumps, machines/engines, etc., can solve the problem of no measurement of mouth ring leakage, achieve simple and convenient operation, ensure stable operation, and reduce pressure changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

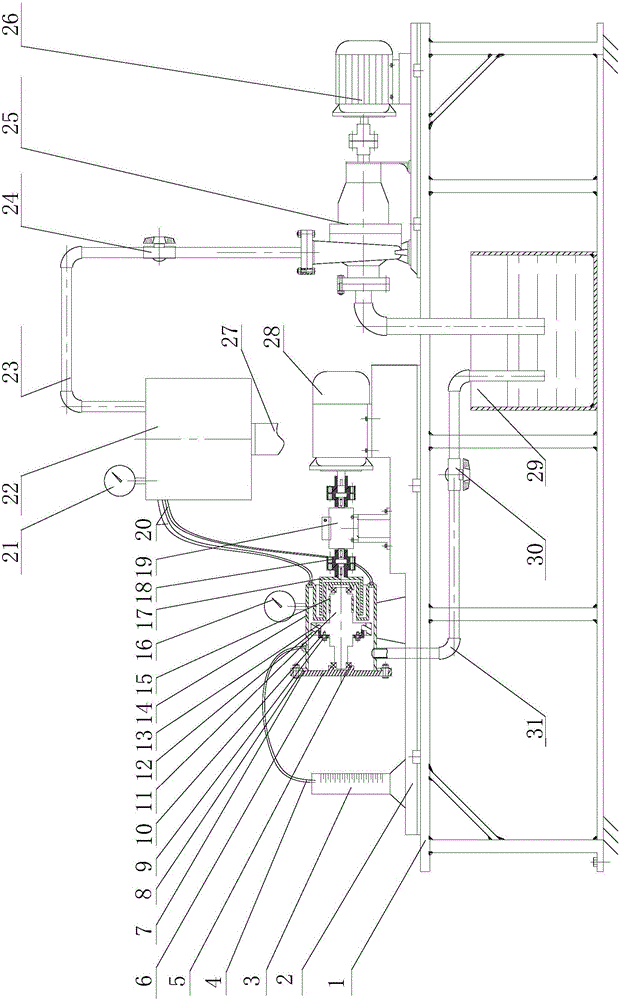

[0022] Embodiment 1 A universal centrifugal pump mouth ring test bench according to the present invention is characterized in that it includes a mouth ring test unit, a fluid medium supply unit, a leakage liquid collection unit and a test table, the fluid medium supply unit, the mouth ring The test unit and the leakage liquid collection unit are installed on the test table, the fluid medium supply unit communicates with the inlet of the sealing chamber of the mouth ring test unit, and the outlet of the seal chamber of the mouth ring test unit communicates with the leakage The pipeline of the liquid collection unit is connected;

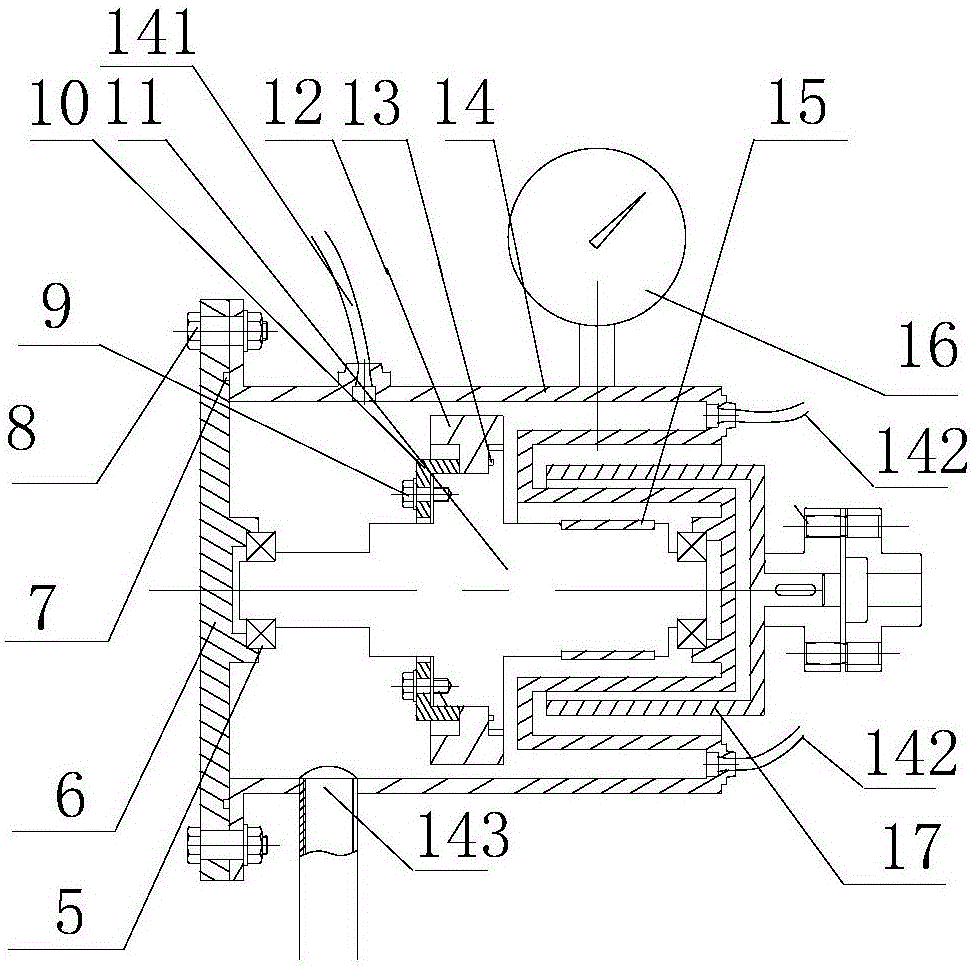

[0023] The mouth ring test unit includes a cavity 14, a front cover plate 6, a main shaft 11 for placing the mouth ring sample 12 to be tested, a gland 10, and a power drive device for providing a turning force to the cavity. There is an opening on one side of the body 14, the front cover 6 is arranged at the opening of the cavity 14, and is sealed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com