Overhead-type excitation displacement velocity force value relation curve detection equipment

A relationship curve, testing equipment technology, applied in the direction of measuring device, mechanical component testing, machine/structural component testing, etc., can solve problems such as failure of testing results, high-frequency vibration of equipment, affecting testing accuracy, etc., and achieve accurate testing data. Reliable, vibration and noise elimination, good flexibility in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

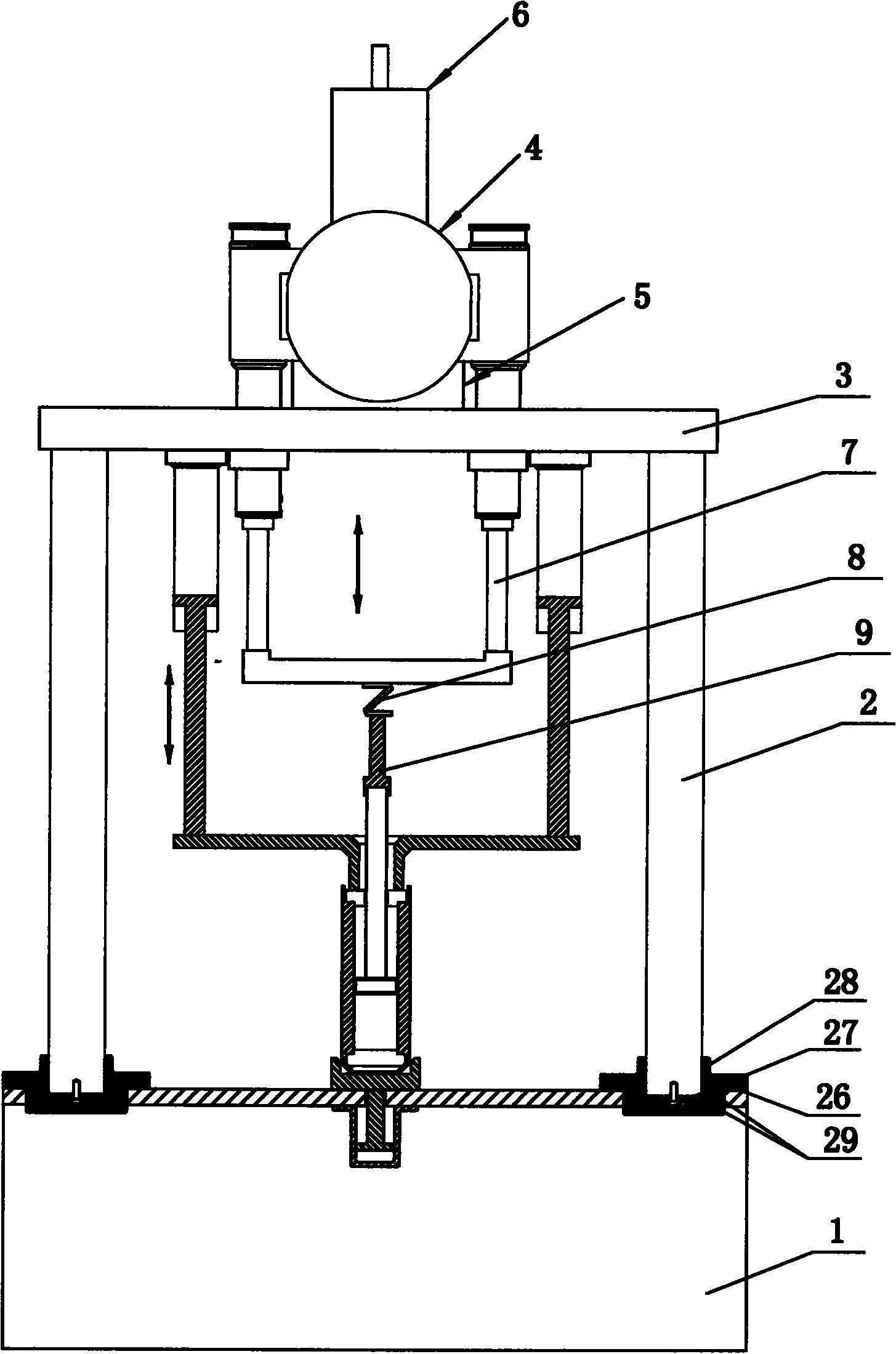

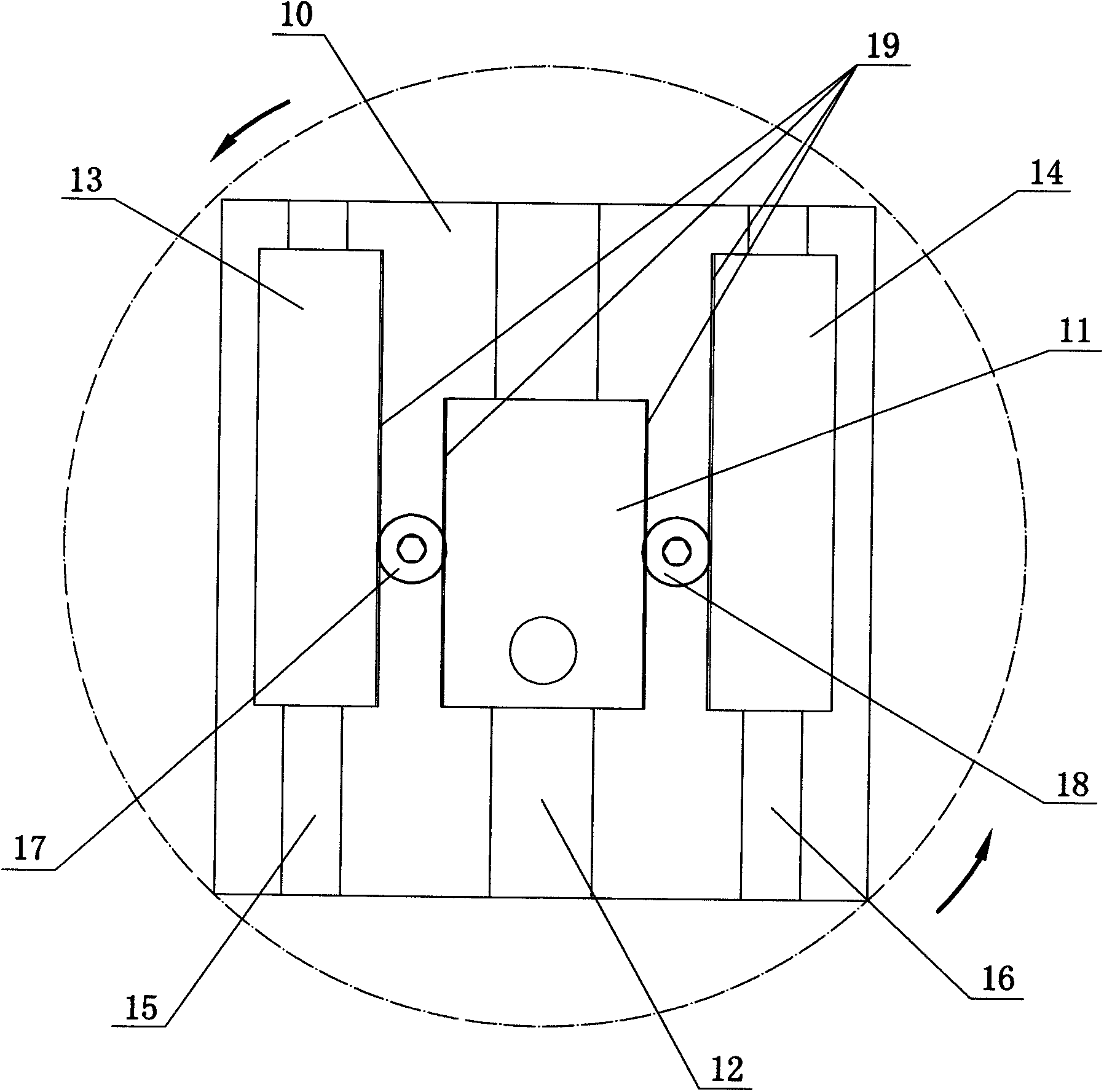

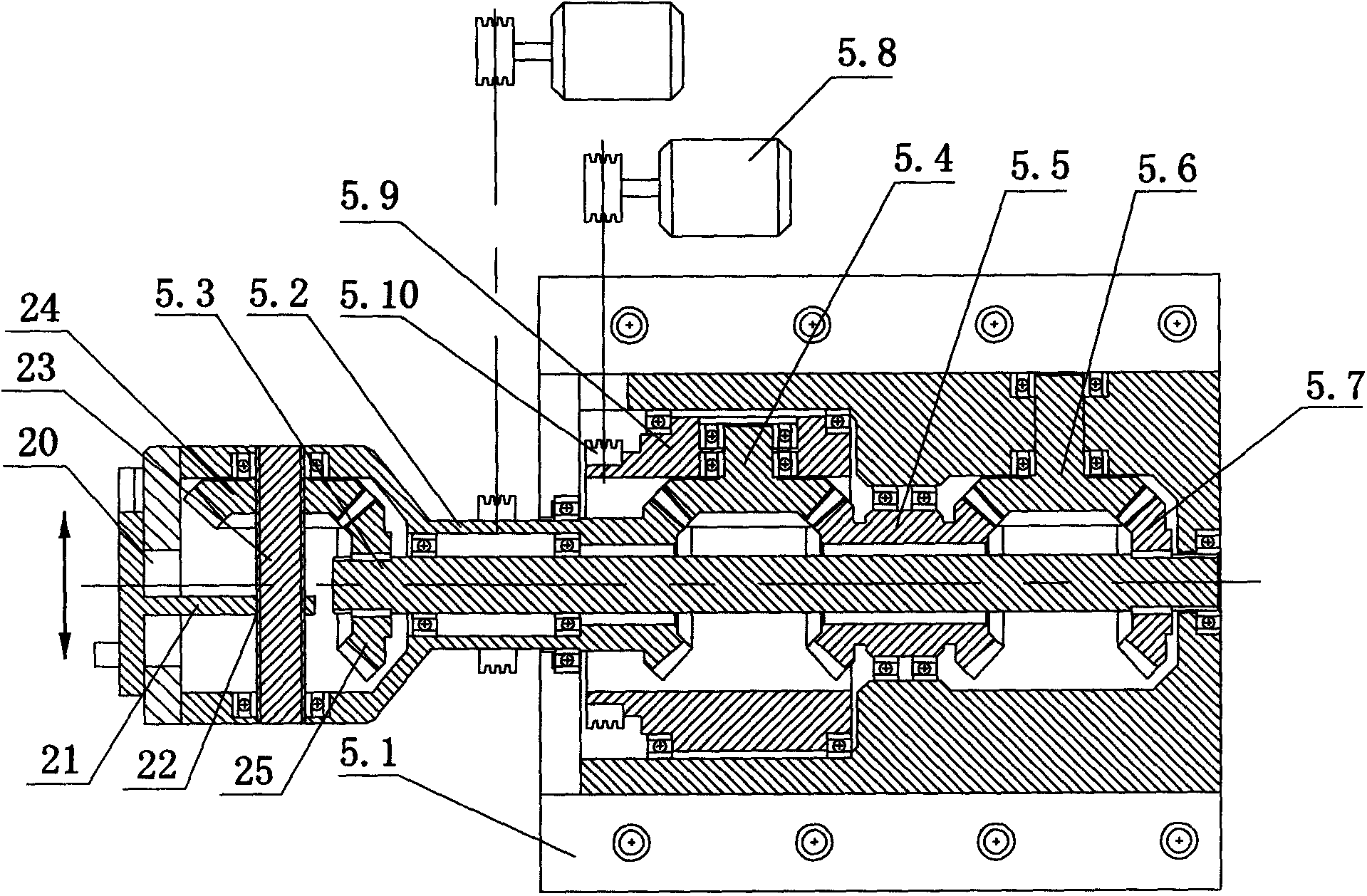

[0028] Such as figure 1 Shown, a kind of upper setting excitation type displacement velocity force value relation curve detection equipment, it comprises base 1, column 2, base plate 3 and crank mechanism 4 (certainly also includes other components, but because it does not involve the invention of the present invention Invention point, so do not go into details here), described column 2 is at least two (this example is four, also can be two, three or five etc.), one end of described column 2 is all connected with The base 1 is connected, and the other ends of the columns 2 are connected to the base plate 3, and the columns 2 are parallel to each other. It also includes a concentric shaft angle difference adjustment mechanism 5 and an anti-backlash mechanism 6. The base plate 3 is slidingly connected with a test The shaft 7 is generally provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com