Fuel cell thermal management system with phase change heat storage and preheating functions

A thermal management system and fuel cell technology, applied in the direction of fuel cell heat exchange, fuel cells, fuel cell additives, etc., can solve the problems of large power consumption, service life decay, battery material damage, etc., to reduce power consumption, Improve the cycle life and avoid the effect of corroding the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

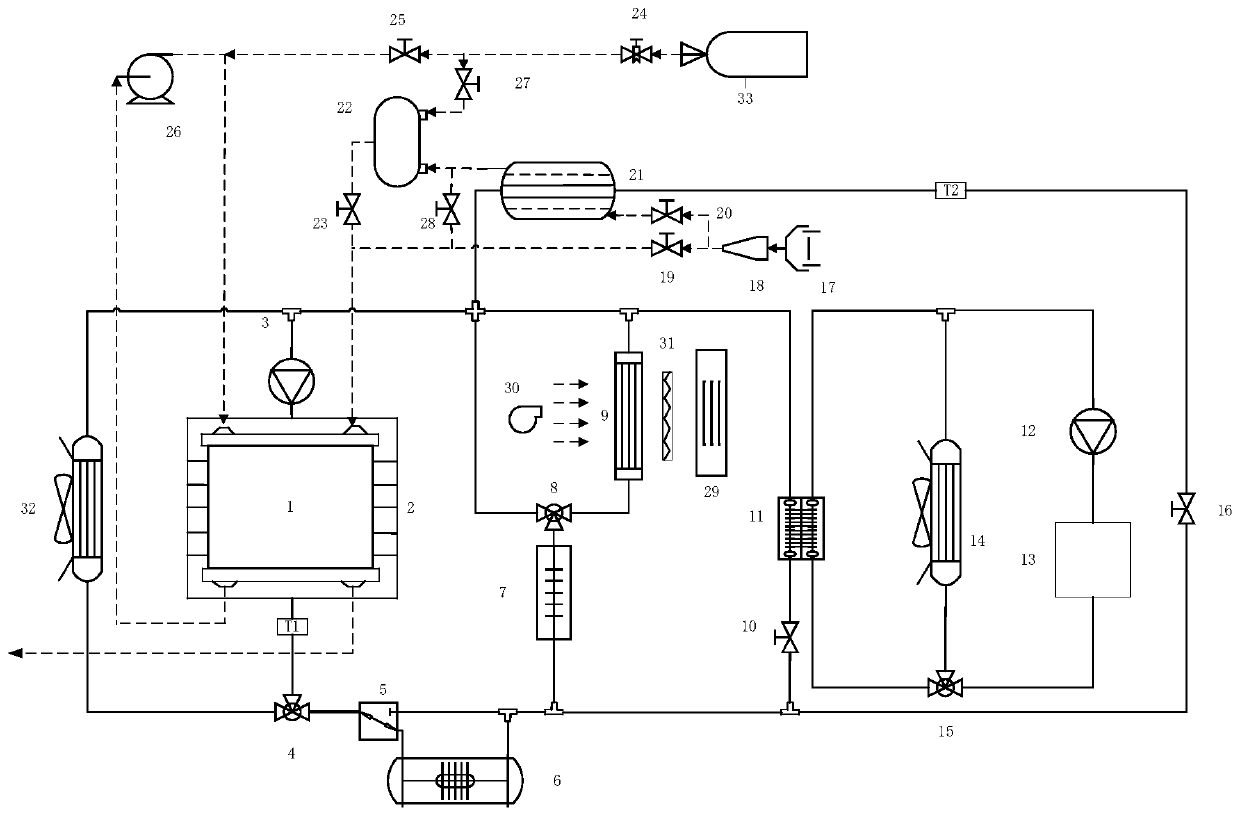

[0077] Embodiment 1, the thermal management system of the fuel cell 1 according to the present invention includes a cold start function, and the cold start is divided into two preheating cold starts: a liquid circuit and a gas circuit:

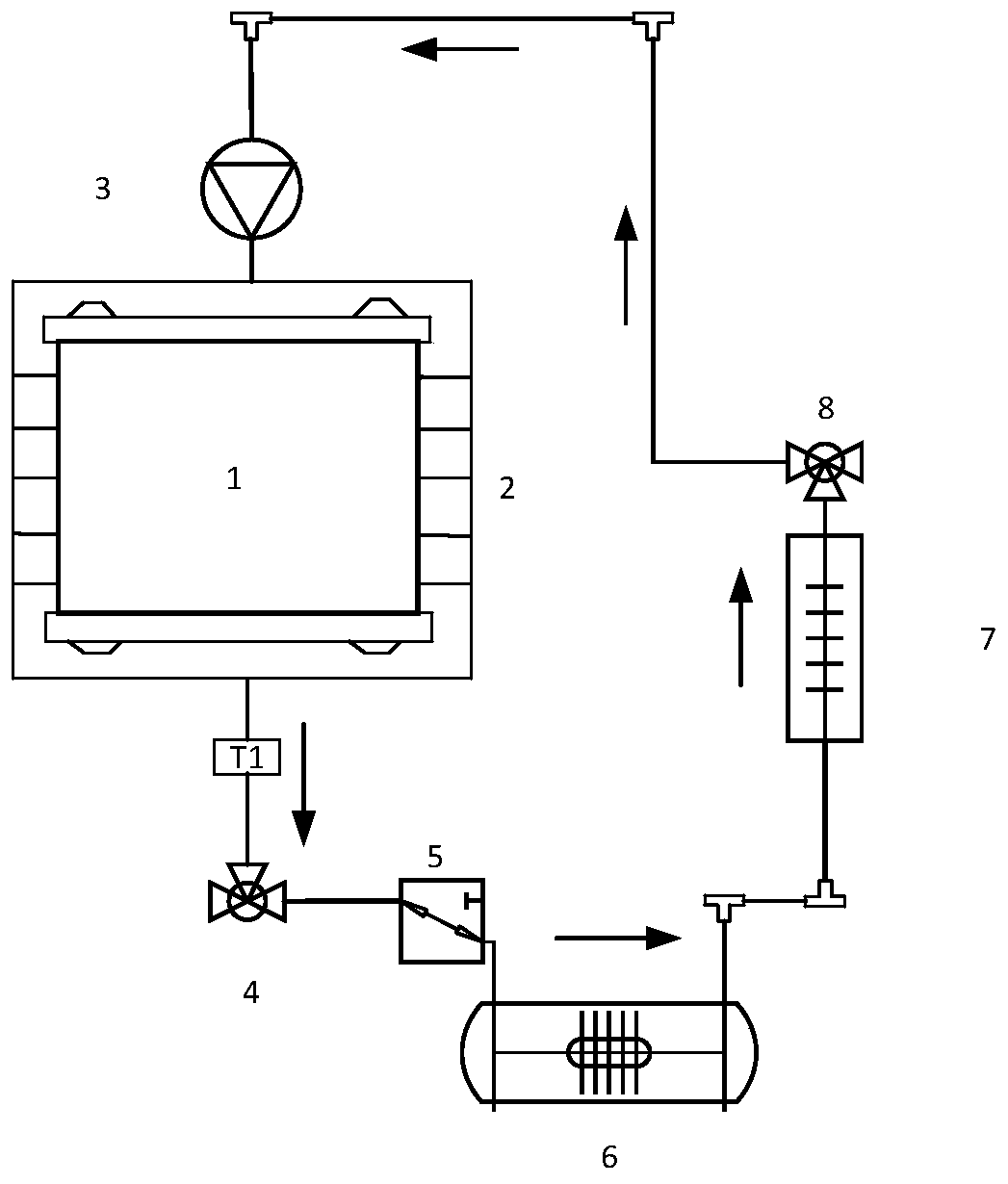

[0078] Such as figure 2 As shown, the liquid preheating circuit includes the first electronic water pump 3, heat exchange pipe 2, electronic thermostat 4, two-position reversing valve 5, first phase change heat exchanger 6, electric heater 7, The first three-way reversing valve 8; there are two modes for liquid circuit preheating. When the temperature is less than T1 but greater than T2, only the heat stored in the first phase change heat exchanger 6 is used to heat the liquid circuit. The details are as follows, in the first Under the action of the electronic water pump 3, the coolant flows through the heat exchange pipe 2 to the electronic thermostat 4, the electronic thermostat 4 remains closed and the two-position reversing valve 5 is con...

Embodiment 2

[0081] Embodiment 2, when the vehicle is not started and the temperature of the fuel cell 1 is lower than T0, the heat stored in the first phase-change heat exchanger 6 can be used to keep the fuel cell 1 warm through the liquid preheating circuit.

Embodiment 3

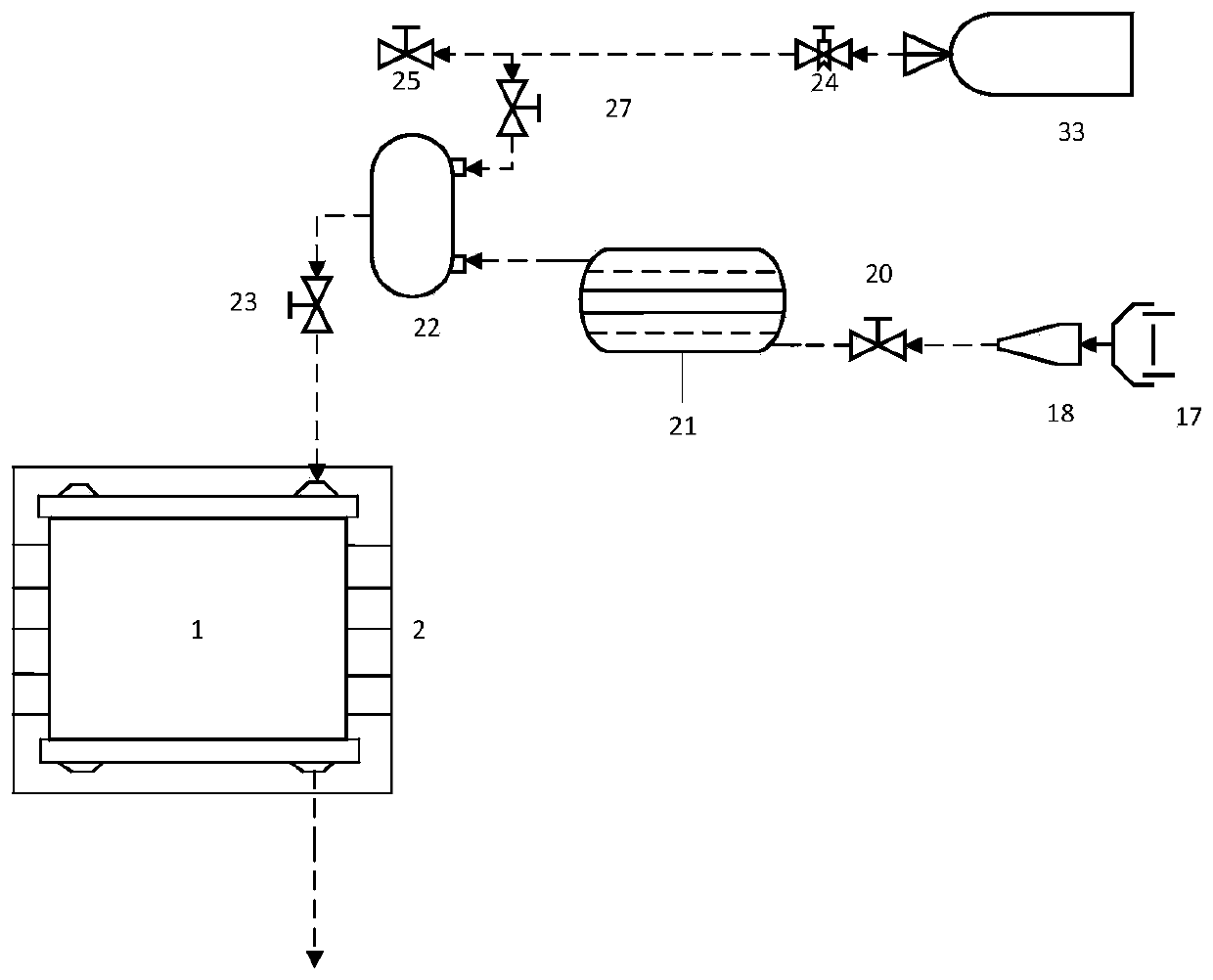

[0082] Embodiment 3, the present invention also has intake air heating function, as Figure 4 as shown,

[0083] In a low-temperature environment, if the intake air temperature is low, the performance of the fuel cell 1 will be affected. After the fuel cell 1 is normally cold-started, when the temperature of the coolant at the second temperature sensor is greater than Tp2, the gas circuit heating circuit is turned on, and the gas circuit pipeline Keep the third solenoid valve 20 and the sixth solenoid valve 28 open, close the fourth solenoid valve 27 and the fifth solenoid valve 23, the air is heated through the air passage in the second phase-change heat exchanger 21, and passes through the sixth solenoid valve 28 enters the fuel cell 1 cathode; in addition, the second electromagnetic valve 16 is opened in the liquid pipeline, so that the coolant inlet of the second phase-change heat exchanger 21 is connected with the outlet of the two-position reversing valve 5, and the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com