Lithium battery pack thermal management system

A management system, lithium battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve problems such as poor reliability, low efficiency, battery energy efficiency, life and safety impact, to ensure safety and performance , Improve temperature uniformity, improve the effect of cold start speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

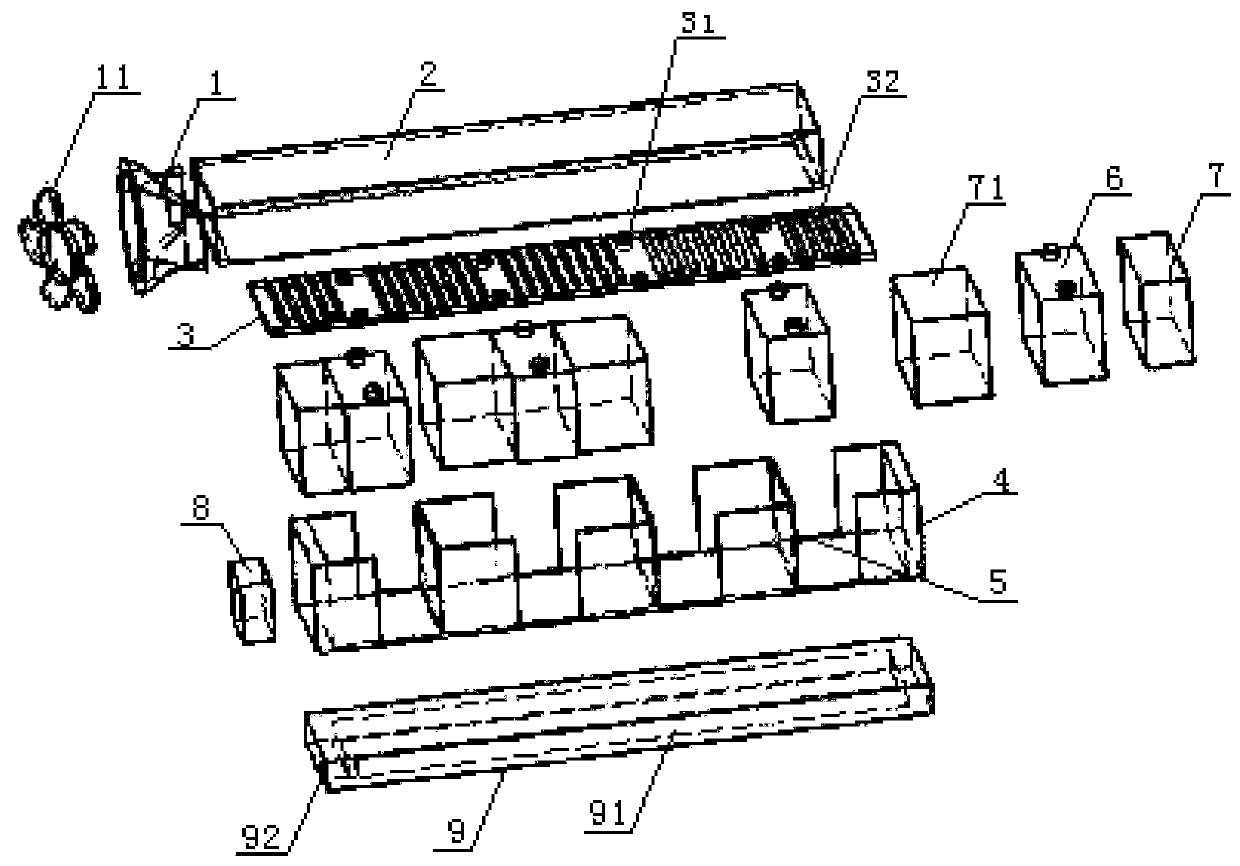

[0023] Such as figure 1 The shown lithium battery pack thermal management system includes a battery case 4 for installing batteries, a temperature regulating device arranged outside the battery case 4 and a battery case 4 arranged on the top of the battery case 4 Cover 2; each component is described in detail below:

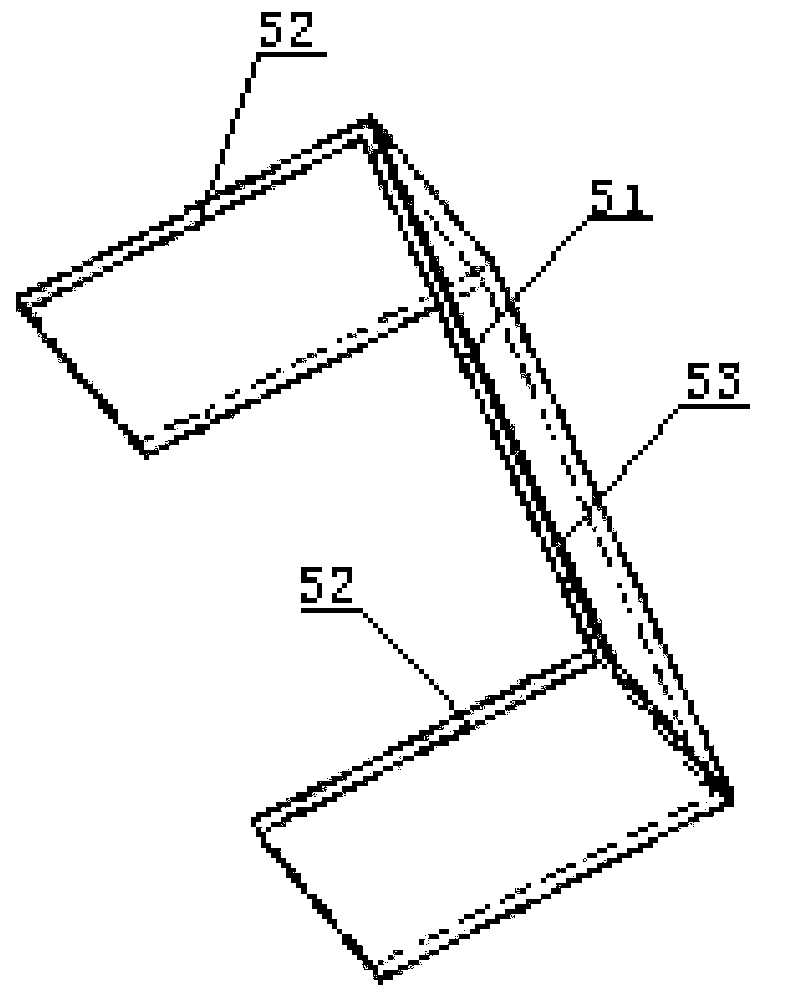

[0024] The above-mentioned battery case 4 includes a bottom plate, U-shaped end baffles arranged at both ends of the bottom plate, and a U-shaped heat-conducting separator 5 arranged between the two end baffles. Such as figure 2 As shown, the thermally conductive partition 5 includes a first partition 51 and a second partition 52 fixing both ends of the first partition 51, and the side of the first partition 51 away from the second partition 52 The surface is covered with a thermally conductive insulating sheet 53 (such as a silica gel sheet, etc.); wherein, the first separator 51 and the second separator 52 can select a thermally conductive metal plate, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com