Additive for vehicle fuel oil

A fuel oil and additive technology, which is applied in the directions of fuel additives, fuels, and liquid carbon-containing fuels, can solve the problems of not improving gasoline combustion efficiency, reducing the normal operation of internal combustion engines, and wasting resources and the environment, so as to avoid nozzle parts or Complete blockage, good combustion performance, and the effect of protecting the fuel system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

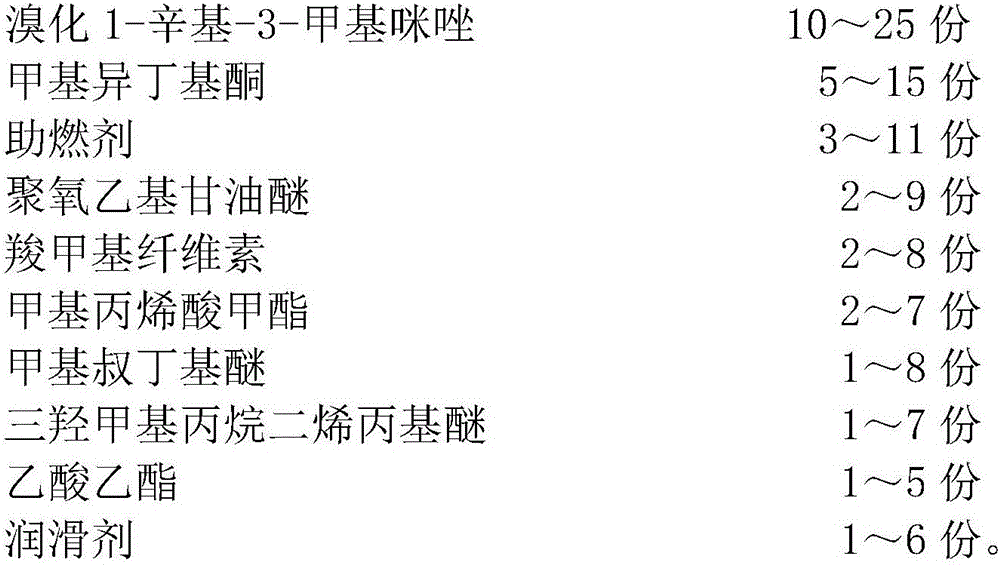

[0027] The fuel oil additive for vehicles is made of the following raw materials in parts by weight (mixed uniformly at room temperature):

[0028]

[0029]

[0030] The above-mentioned combustion enhancer is a mixture of 5 parts by weight of methyl isobutyl ketone, 5 parts by weight of dioctyl phthalate and 30 parts by weight of 3-hydroxybenzoic acid.

[0031] The above-mentioned lubricant is a mixture of 10 parts by weight of fatty acid glycerides, 25 parts by weight of methyl silicone oil and 5 parts by weight of di-n-butyl phosphite.

[0032] When gasoline fuel is prepared, the addition amount of the additive is 0.2% of the gasoline mass.

Embodiment 2

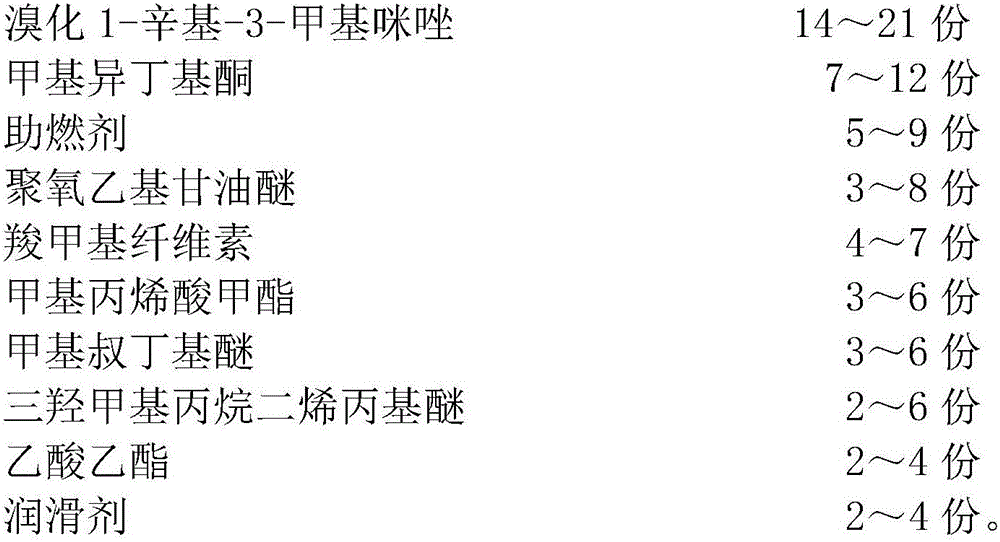

[0034] The fuel oil additive for vehicles is made of the following raw materials in parts by weight (mixed uniformly at room temperature):

[0035]

[0036] The above-mentioned combustion enhancer is a mixture of 8 parts by weight of methyl isobutyl ketone, 7 parts by weight of dioctyl phthalate and 27 parts by weight of 3-hydroxybenzoic acid.

[0037] The above-mentioned lubricant is a mixture of 12 parts by weight of fatty acid glycerides, 23 parts by weight of methyl silicone oil and 8 parts by weight of di-n-butyl phosphite.

[0038] When gasoline fuel is prepared, the addition amount of the additive is 0.3% of the gasoline mass.

Embodiment 3

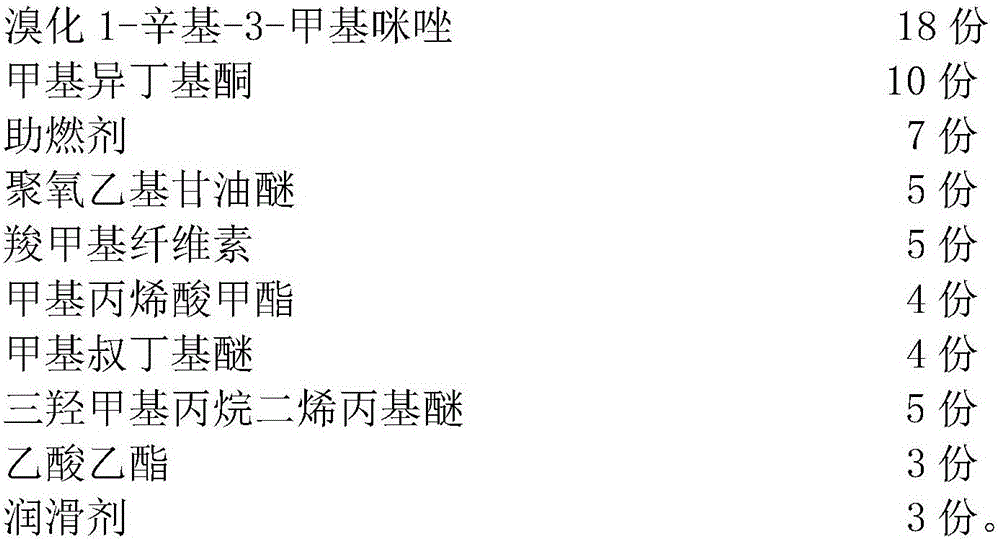

[0040] The fuel oil additive for vehicles is made of the following raw materials in parts by weight (mixed uniformly at room temperature):

[0041]

[0042] The above-mentioned combustion enhancer is a mixture of 10 parts by weight of methyl isobutyl ketone, 10 parts by weight of dioctyl phthalate and 25 parts by weight of 3-hydroxybenzoic acid.

[0043] The above-mentioned lubricant is a mixture of 15 parts by weight of fatty acid glycerides, 20 parts by weight of methyl silicone oil and 10 parts by weight of di-n-butyl phosphite.

[0044] When gasoline fuel is prepared, the addition amount of the additive is 0.4% of the gasoline mass.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com