Preparation method of dioctyl terephthalate and used catalyst

A technology of dioctyl terephthalate and dioctyl phthalate is applied in the field of catalysts for synthesizing dioctyl terephthalate, and can solve the problem of long catalyst catalysis time, darkening of product color, easy yellowing of products, etc. problem, to achieve the effect of recyclable post-processing separation, improving conversion rate, and convenient post-processing separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

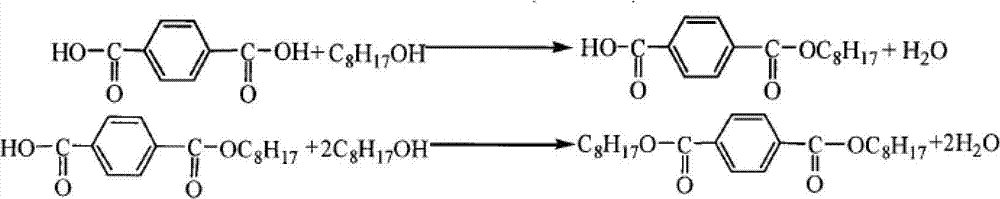

[0036] The preparation method of dioctyl terephthalate, step is as follows,

[0037] Step 1: Put terephthalic acid and isooctyl alcohol into the esterification reaction kettle in a weight ratio of 1:2 to 1:3, and heat while stirring;

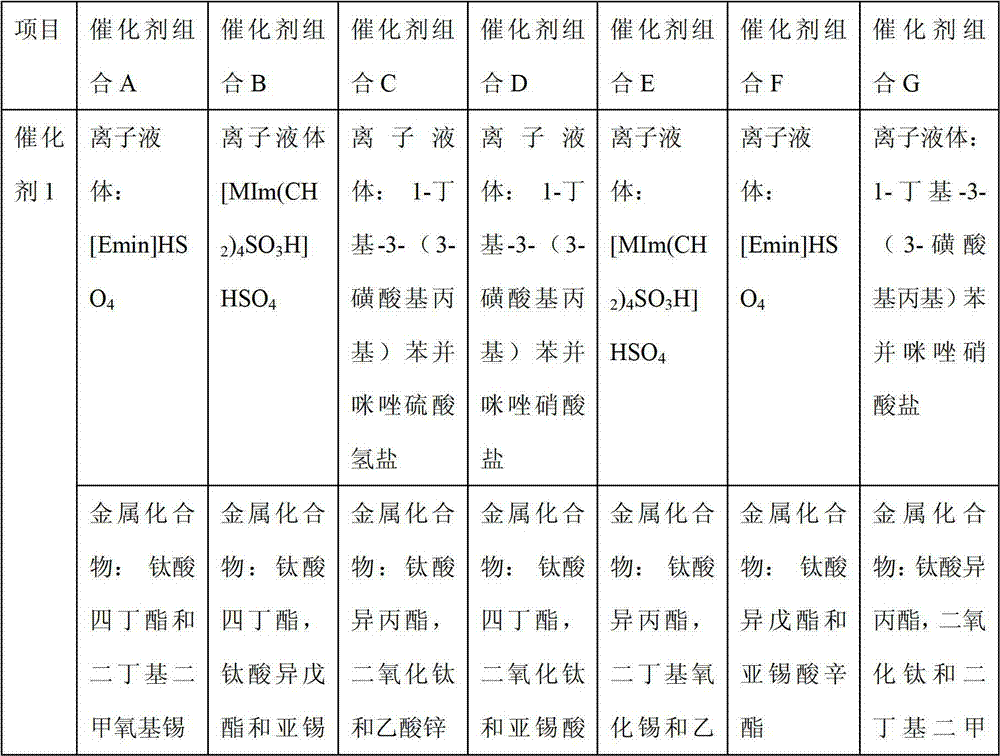

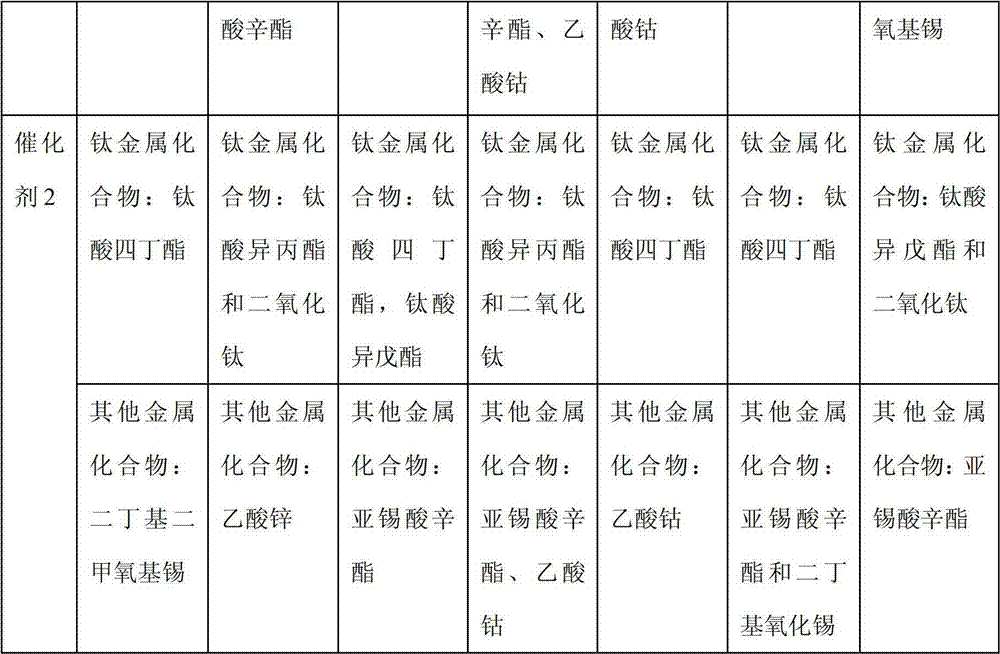

[0038] Step 2: When the temperature rises to 130~150°C (corresponding to temperature A in Table 3 below), add Catalyst 1 (see Table 1~2 below), the amount of which is terephthalic acid and isooctyl added in Step 1 1 ~ 8% of the total alcohol weight, continue to heat up;

[0039] Step 3: When the temperature rises to 160~220°C (corresponding to temperature B in Table 3 below), add Catalyst 2 (see Table 1~2 below), the amount of which is terephthalic acid and isooctyl added in Step 1 0.05~0.5% of the total weight of alcohol, then the esterification reaction temperature is controlled at 160-260°C (corresponding to the esterification reaction temperature C in the following table 3), and the reaction is 0.5~3 hours (corresponding to the reaction tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com