Drum-type vacuum pulsing temperature-variable drying method and apparatus

A vacuum pulsating, drum drying technology, used in lighting and heating equipment, non-progressive dryers, drying solid materials, etc., to achieve good results, shorten drying time, and inhibit biological and chemical changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

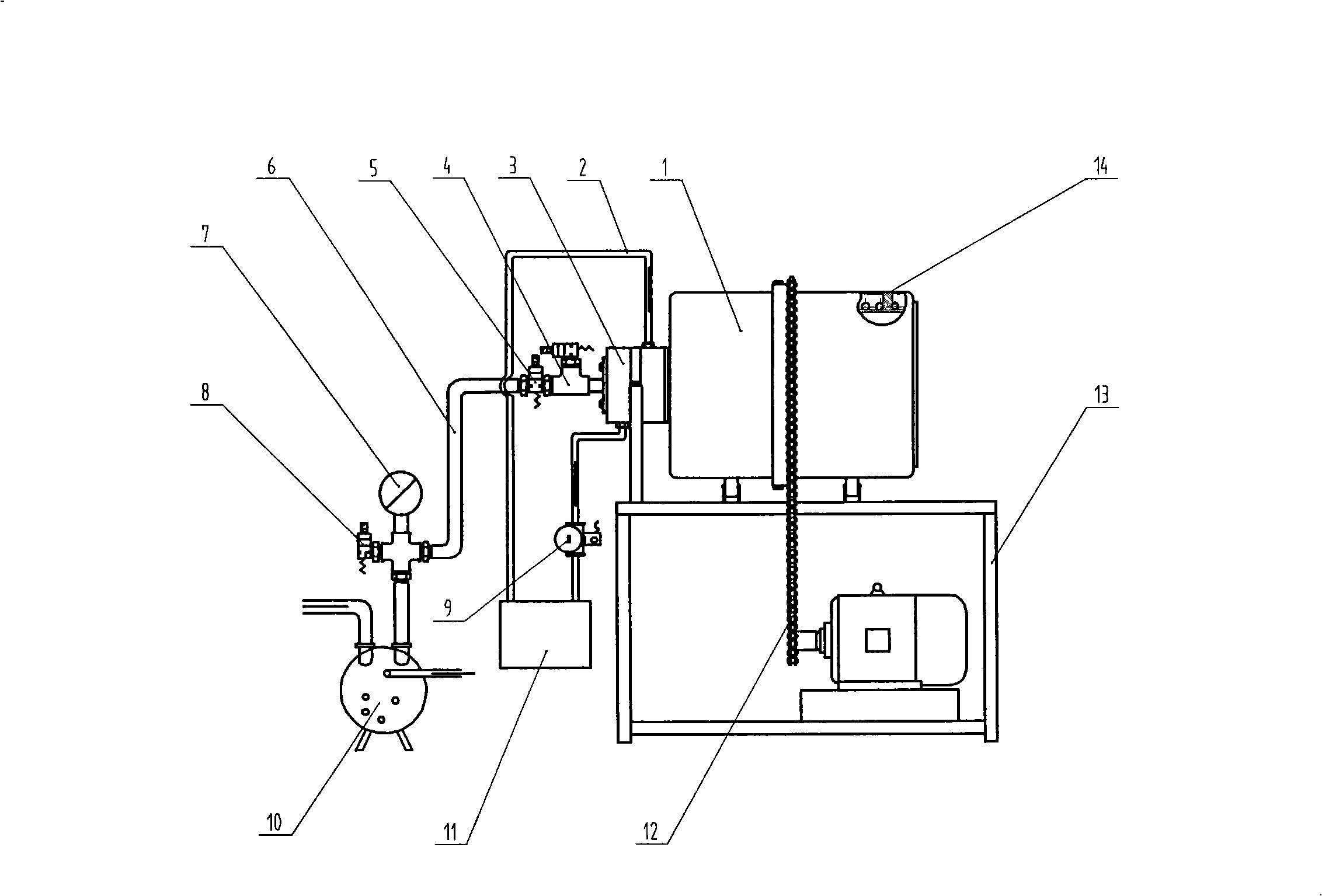

Image

Examples

Embodiment 1

[0023] Embodiment 1: Dried carrot diced with drum type vacuum pulse variable temperature drying equipment. In this embodiment, the airtight circular drum drying chamber is divided into 3 small drying chambers, such as image 3 shown.

[0024] The method of drying diced carrots with drum-type vacuum pulsation variable temperature drying equipment is as follows: ① cut a certain amount (40% of the volume of the drying chamber) into cube-shaped diced carrots (moisture content is about 90% wb) through the feed ②Set the temperature of the heating medium to 65°C, the temperature difference between the inlet and outlet of the circulating medium is 5°C, turn on the pressure pump 9, and the heating medium begins to circulate; ③Set the pulsation period of the pulsating pressure working system, that is, vacuum 0.095MPa, keep the vacuum degree for 15 minutes; change the vacuum degree to 0, keep it for 1 minute (the maintenance of the vacuum degree is controlled by the electromagnetic flow...

Embodiment 2

[0025] Embodiment 2: processing raisins with drum-type vacuum pulsation variable temperature drying equipment. In this embodiment, the airtight circular drum drying chamber is divided into 2 small drying chambers, such as figure 2 shown.

[0026]The method of processing raisins with the drum-type vacuum pulsation variable temperature drying equipment is as follows: 1. A certain amount (40% of the volume of the drying chamber) of grapes with ears (moisture content is about 83%wb) will be passed through the feed ②Set the initial temperature of the heating medium to 40°C, the temperature difference between the inlet and outlet of the circulating medium is 5°C, turn on the pressure pump 9, and the heating medium starts to circulate; ③Set the pulsation period of the pulsating pressure working system, that is Vacuum degree 0.075MPa, keep this vacuum degree for 10 minutes; change vacuum degree to 0, keep for 10 minutes (the maintenance of vacuum degree is controlled by the electrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com