Stainless steel pot with welded bottom, and its making method

A technology of stainless steel pot and manufacturing method, which is applied in the direction of manufacturing tools, welding equipment, applications, etc., can solve the problems of expensive materials, high production costs, and low melting point, and achieve saving of metal materials, good thermal conductivity, and uniform heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

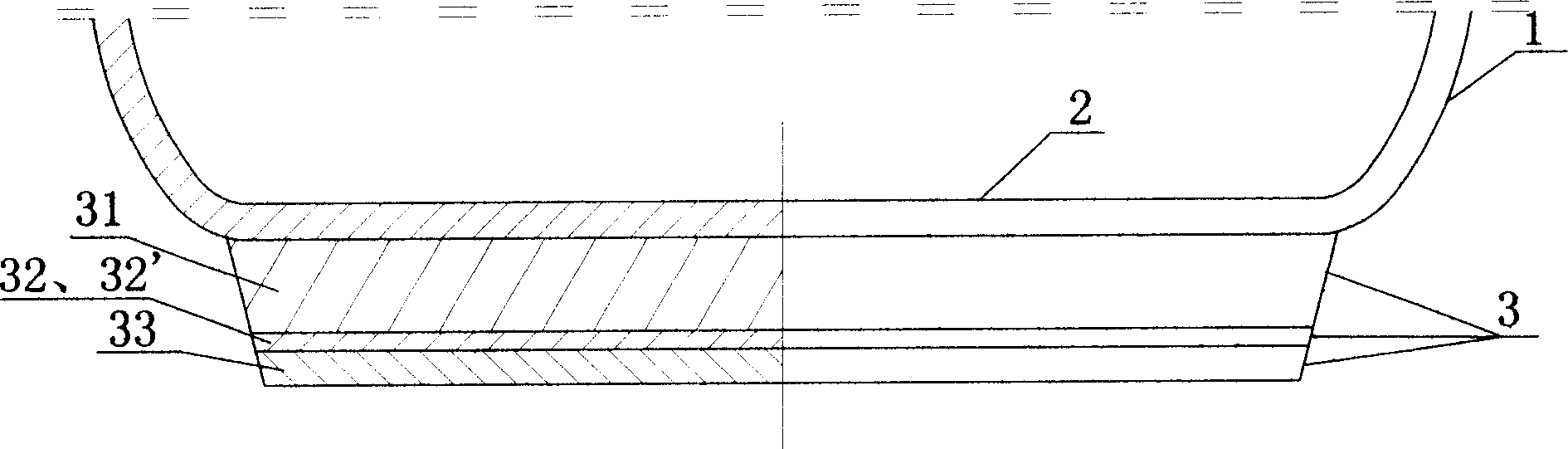

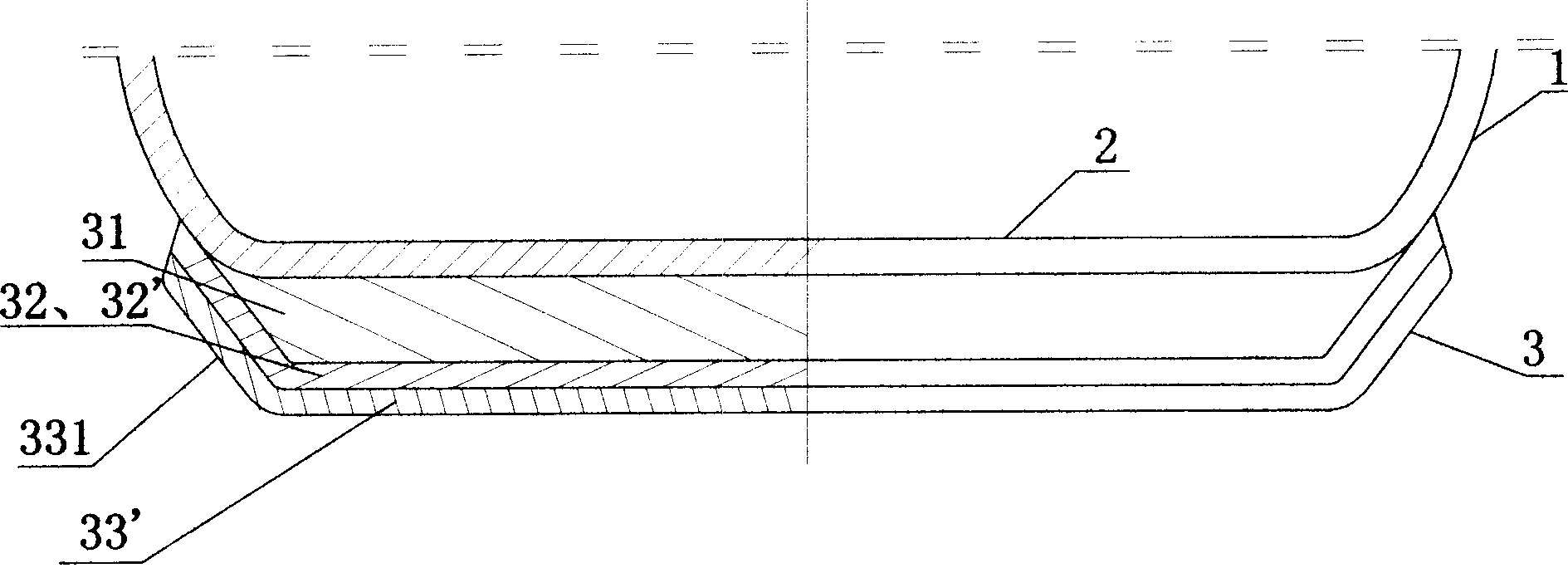

[0019] Such as figure 1 , figure 2 As shown, according to the size of the bottom of the stainless steel pot 2, an aluminum plate 31 of corresponding size, a stainless steel plate 32 or a stainless iron plate 32' disc, and a copper plate 33 or 33' disc are produced, wherein the stainless steel plate or the stainless iron plate should be thinner. Lay the copper plate 33 or 33' on the stainless steel plate 32 or the stainless iron plate 32', apply copper-based solder flux between the two, place it on a brazing machine, and perform brazing at a heating frequency of 300KHz to 350KHz . After the laminations obtained by brazing are trimmed, an aluminum plate 31 of a corresponding size is added. According to the order of copper plate-stainless steel plate-aluminum plate-stainless steel pot bottom (including pot body 1), the overall temperature is 400°C~550°C. Heating at a certain temperature, and then placing it on a pressure welding machine with an impact force of 1000T-2500T (to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com