Multifunctional cooking machine

A cooking machine, multi-functional technology, applied in cooking utensils, household utensils, roasters/barbecue grids, etc., can solve the problems of poor heating effect, poor heating effect, easy to scrape off the coating, etc., to extend life, avoid The effect of coating peeling and uniform heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

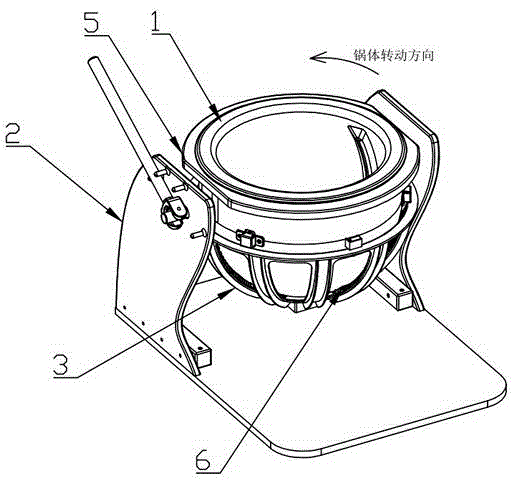

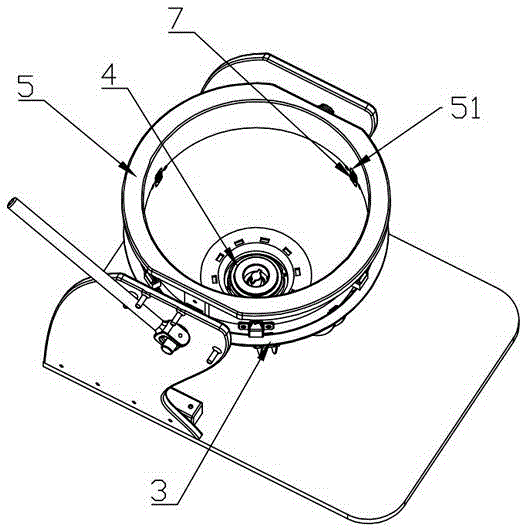

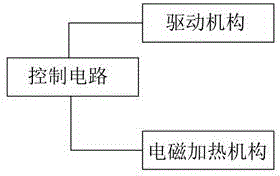

[0030] Embodiment one: if figure 1 , 2 , 5, its structure includes a pot gall 1, a host 2 that drives and controls the work of the pot gut 1, and the pot gut 1 and the host 2 are connected in a detachable manner. The main machine 2 consists of a main frame 21, a positioning mechanism 3 for adjusting and limiting the inclination angle of the inner pot 1, and a drive mechanism 4 for driving the inner pot 1 to rotate by connecting with the connector 12 at the bottom of the inner pot 1, and is placed and accommodated. The pot base 5 of the whole pot liner 1, the electromagnetic heating mechanism 6 and the control circuit that can heat the pot liner 1 in different regions and be close to the arc surface of the pot liner. like image 3 As shown, the control circuit is connected with the driving mechanism 4 and the electromagnetic heating mechanism 6 respectively. like figure 1 , 2 As shown in . The driving mechanism 4 is fixedly connected with the positioning mechanism 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com