Module coupling biomass microwave dry or semidry pretreatment reactor

A reactor and coupled technology, which is applied in the field of modular biomass microwave dry or semi-dry pretreatment reactors, can solve the problems of high cost and high energy consumption of pretreatment methods, and achieve high production efficiency and convenient process Adjustment, the effect of low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

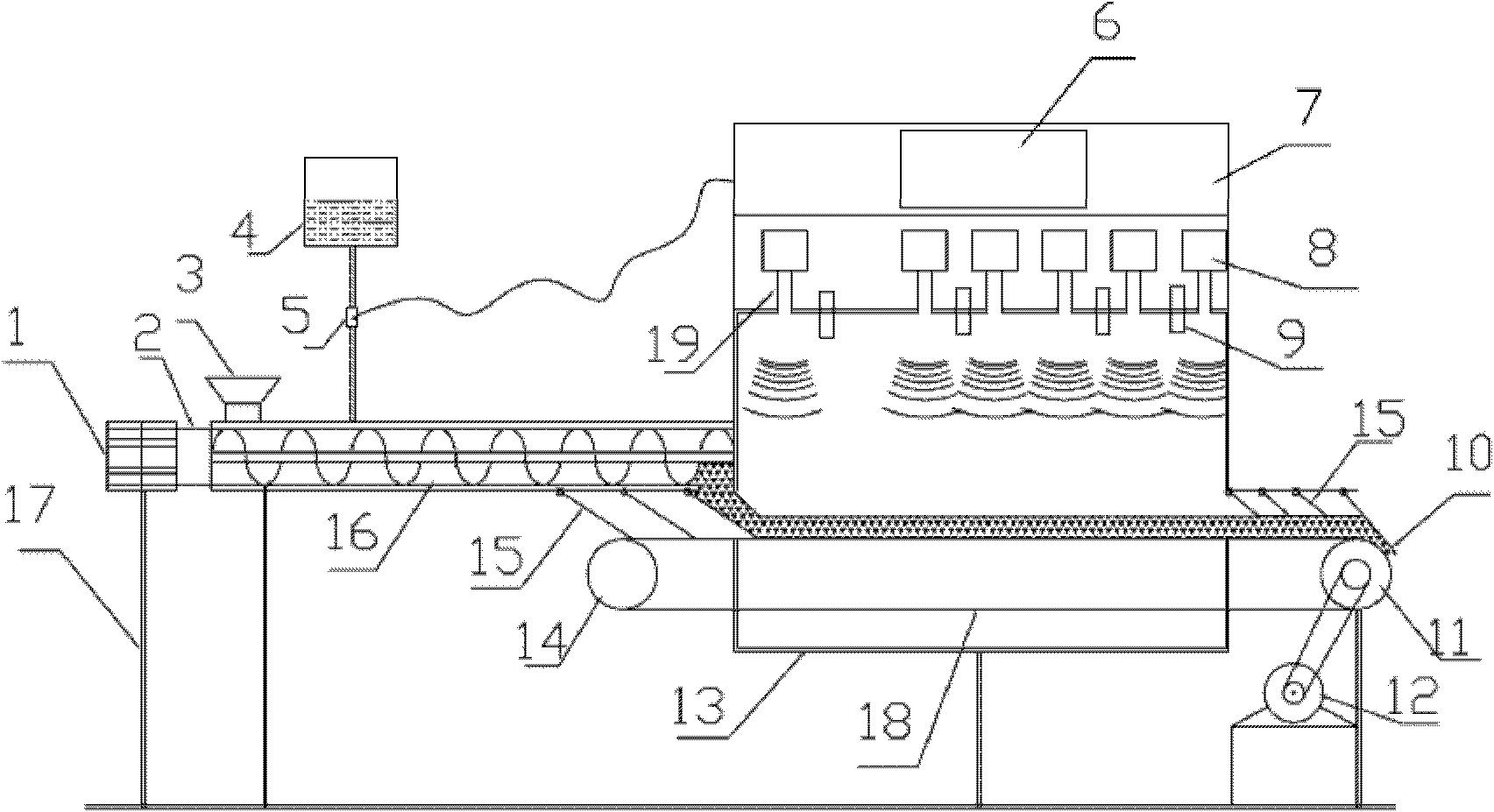

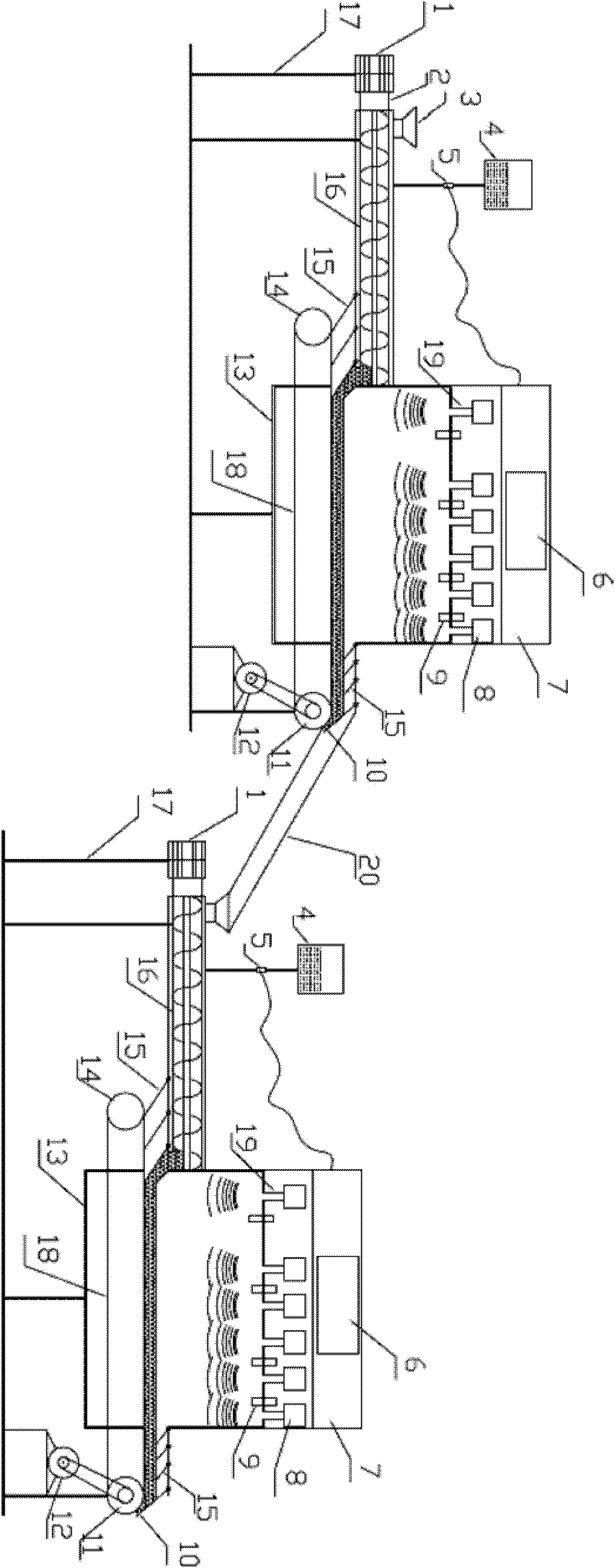

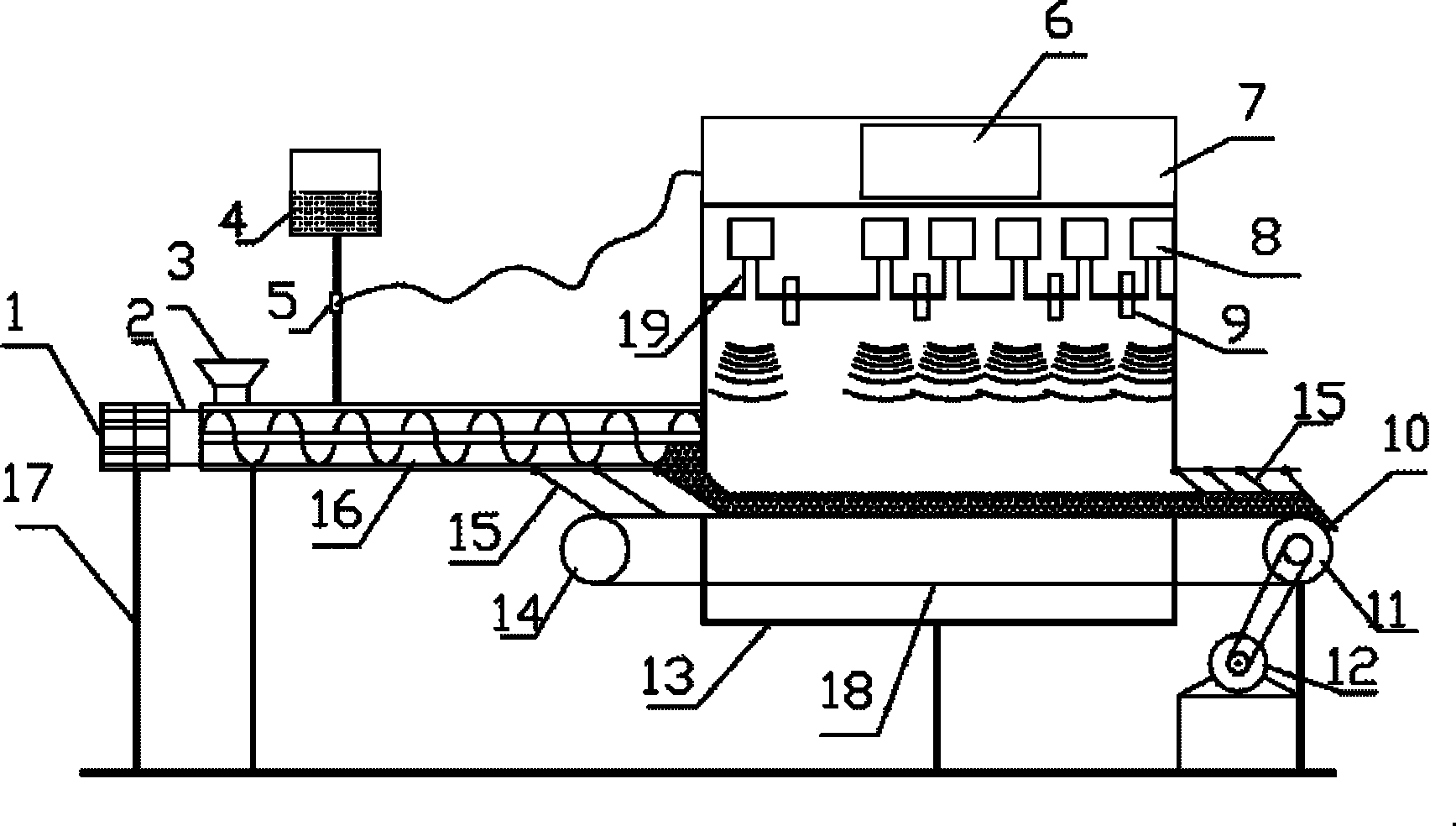

[0017] Modular coupled biomass microwave dry or semi-dry pretreatment reactor for processing 100kg of wheat straw per hour.

[0018] as attached figure 1 , the driving motor 1 drives the spiral material agitator 16 to rotate through the reducer 2 . After the material enters the spiral material agitator 16 from the feeding bin 3, according to the needs of water content adjustment, a certain amount of tap water is input from the water tank 4 to adjust the water content of the material to 30% (w / w). Controlled by the flow control solenoid valve 5, the moisture content of the material is adjusted during the operation of the spiral material agitator 16, and the distribution of the moisture also becomes uniform. The material is output from the end of the spiral material agitator 16 and falls onto the conveyor belt 18, which is made of glass wool coated with Teflon. Conveyor belt 18 is driven by conveyor belt drive wheel 11, and conveyor belt driven wheel 14 is also configured in a...

Embodiment 2

[0021] Modular coupled biomass microwave dry or semi-dry pretreatment reactor that processes 150kg of corn stalks per hour.

[0022] as attached figure 1 , the driving motor 1 drives the spiral material agitator 16 to rotate through the reducer 2 . After the material enters the spiral material agitator 16 from the feed bin 3, according to the needs of water content adjustment, a certain amount of tap water is input from the water tank 4 to adjust the water content of the material to 28% (w / w), and the amount of water added is determined by Controlled by the flow control solenoid valve 5, the moisture content of the material is adjusted during the operation of the spiral material agitator 16, and the distribution of the moisture also becomes uniform. The material is output from the end of the spiral material agitator 16 and falls onto the conveyor belt 18, which is made of polyamide. Conveyor belt 18 is driven by conveyor belt drive wheel 11, and conveyor belt driven wheel 14...

Embodiment 3

[0025] Modular coupled biomass microwave dry or semi-dry pretreatment reactor for treating 50kg of field weeds per hour.

[0026] as attached figure 1, the driving motor 1 drives the spiral material agitator 16 to rotate through the reducer 2 . After the material enters the spiral material agitator 16 from the feed bin 3, according to the needs of water content adjustment, a certain amount of tap water is input from the water tank 4 to adjust the water content of the material to 25% (w / w). Controlled by the flow control solenoid valve 5, the moisture content of the material is adjusted during the operation of the spiral material agitator 16, and the distribution of the moisture also becomes uniform. The material is output from the end of the spiral material agitator 16 and falls onto the conveyor belt 18, which is made of polyamide. Conveyor belt 18 is driven by conveyor belt drive wheel 11, and conveyor belt driven wheel 14 is also configured in addition to the drive wheel....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com