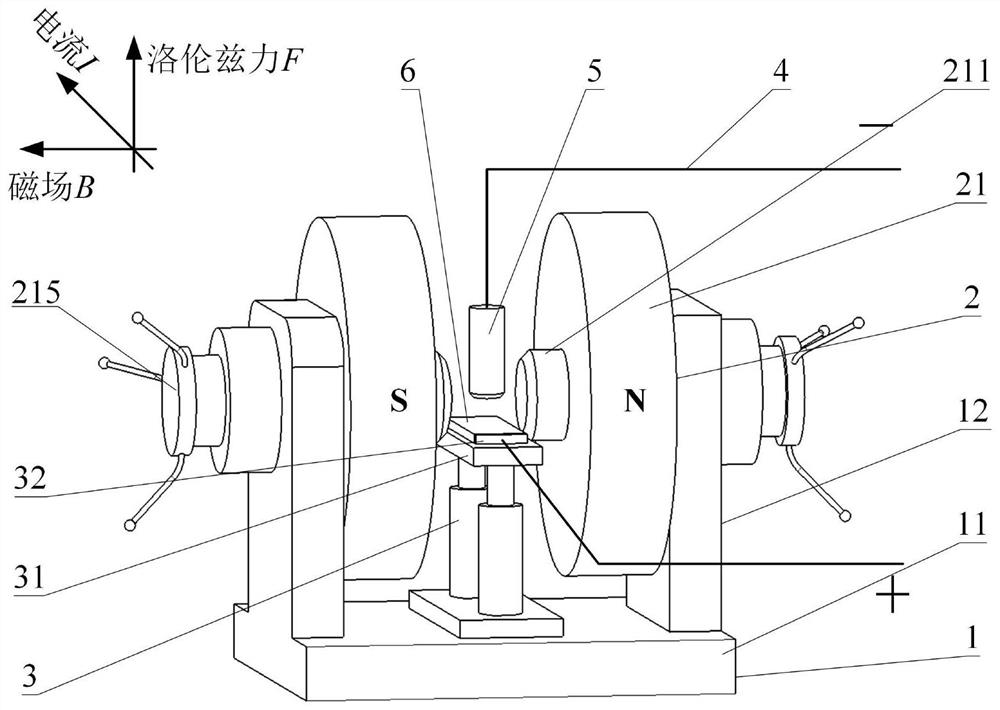

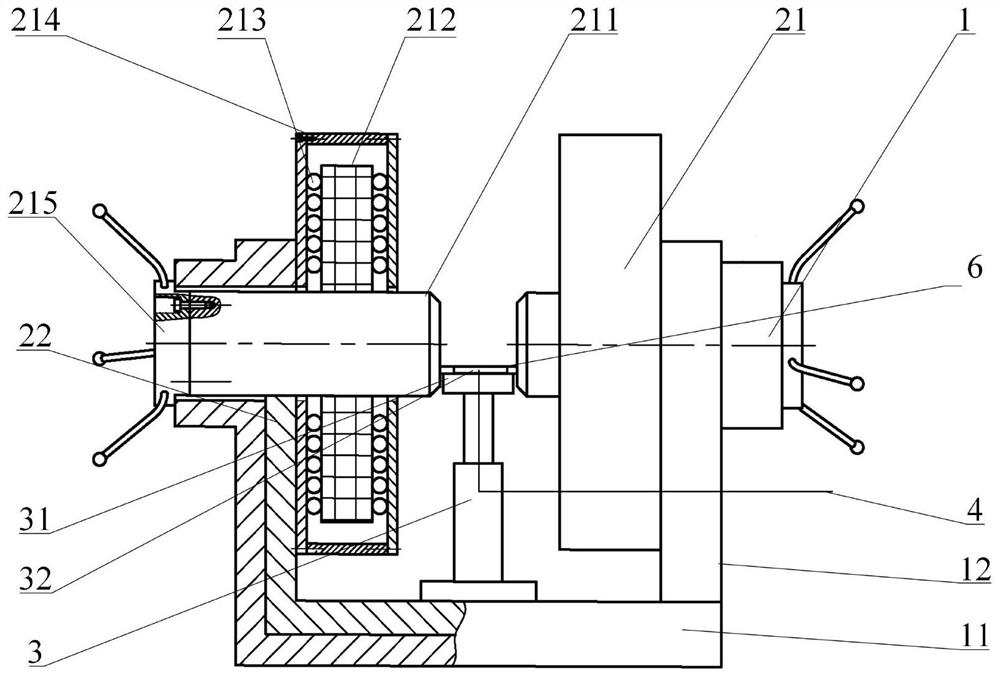

A method and device for preparing distribution-controllable wc-reinforced metal-based composite coatings assisted by an electromagnetic composite field

A technology of auxiliary device and magnetic field generating device, which is applied in metal material coating process, coating, electromagnet and other directions, can solve the problem of less research on distribution regulation, and achieve the effect of simple structure, convenient use and avoiding sinking to the bottom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

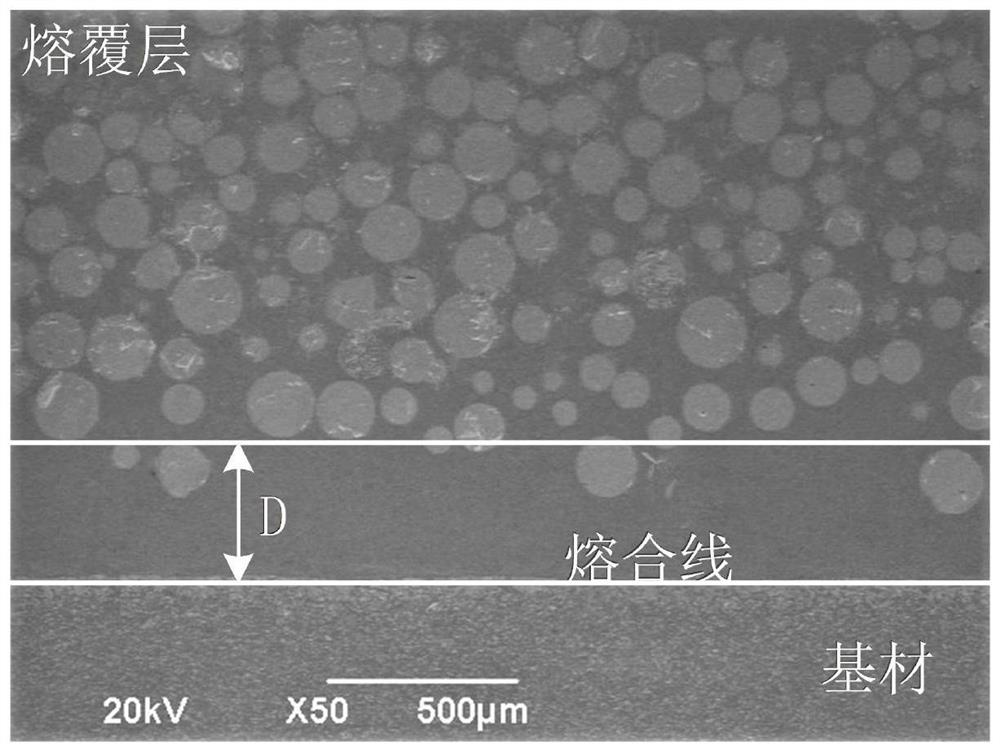

Examples

Embodiment 1

[0043] Using the above-mentioned electromagnetic field auxiliary device, this embodiment prepares a WC-enhanced metal-based composite coating with controllable distribution according to the following steps:

[0044] Step 1. The size of the substrate to be clad is 120mm×60mm×15mm, and the material is 20# steel. Firstly, the surface of the base material is polished, cleaned, and dried, and then placed on the table top of the liftable workbench of the electromagnetic field auxiliary device, and fixed with a chuck.

[0045] Step 2. Turn on the excitation power supply of the magnetic field generating device, and feed in a 3A direct current to generate a transverse steady-state magnetic field with a magnetic field strength of about 120mT, which is perpendicular to the longitudinal section of the workpiece.

[0046] Step 3. Add Ni60 powder with a particle size of 100-300 mesh and spherical nickel-coated WC powder with a particle size of 100-200 mesh into the corresponding powder feed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com