Comber

A carding machine and a new type of technology, applied in the field of carding machines, can solve the problems of different splitting tension of wool web, large difference in feeding weight, easy waving of wool net, etc., so as to improve product quality, uniform splitting tension, and enhance fiber carding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

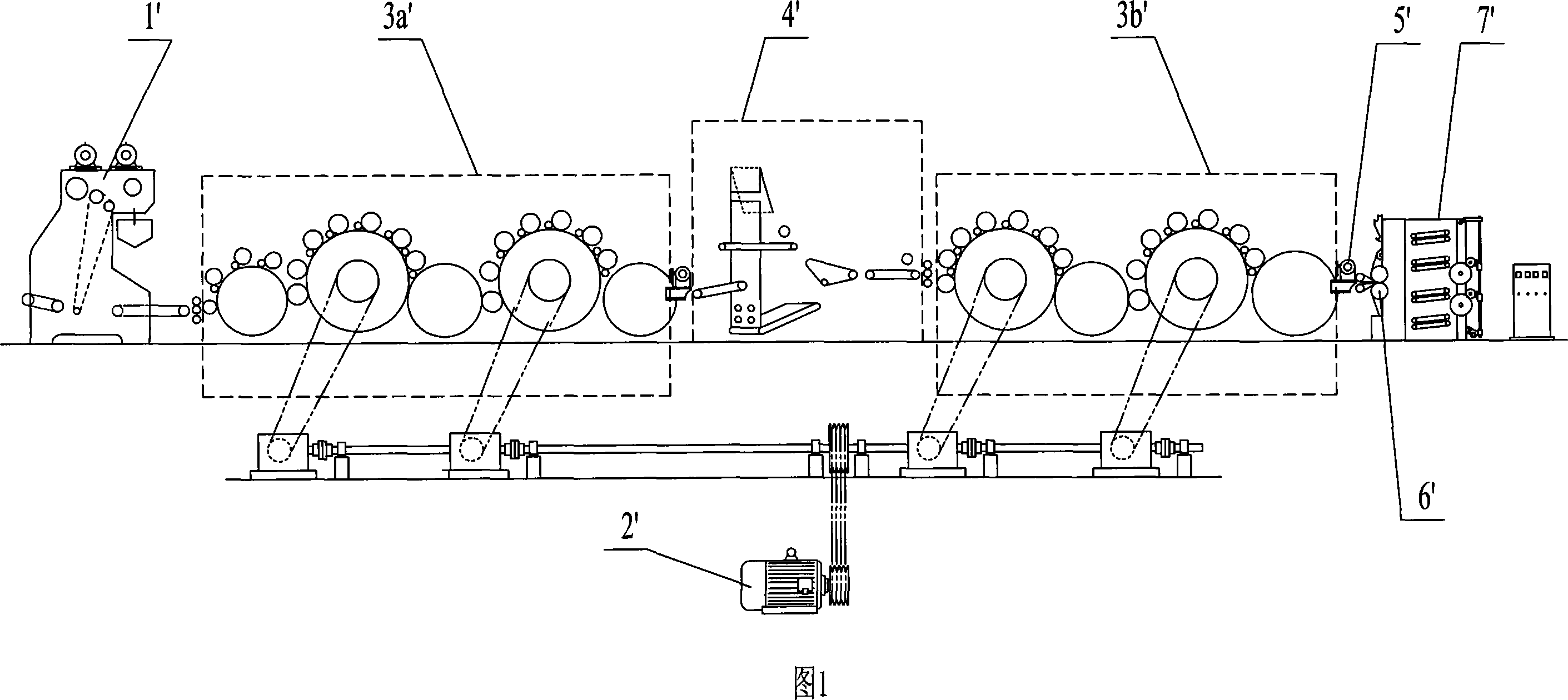

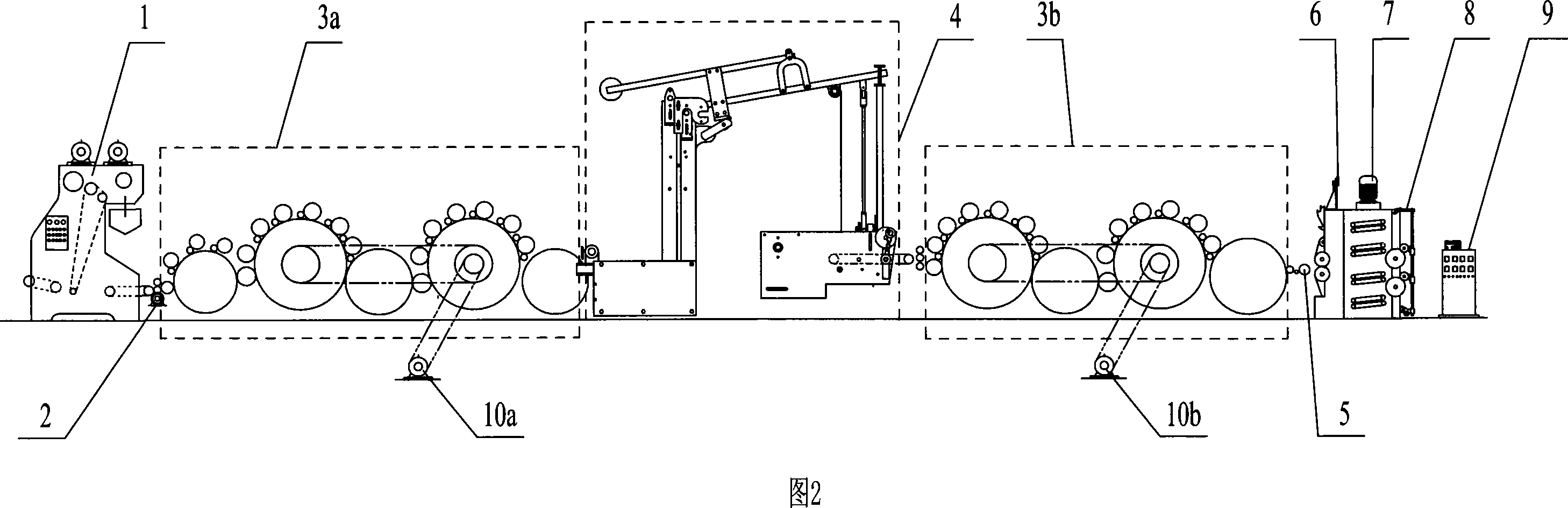

[0047] As shown in Figure 2, the new carding machine of the present invention includes an electronic wool feeding hopper 1 controlled by a program-controlled electric cabinet 9 and assembled in sequence, a metal anti-rolling device 2, a rear car three-group carding mechanism 3a, a middle car bridge device 4, Two sets of carding mechanisms 3b for the front car, 5 stripping roller devices, 6 single belt wire splitting mechanisms, frequency conversion motor washboard device 7, and sliver length-fixing instrument 8, of which the three sets of carding mechanisms 3a for the rear car and the two sets of carding mechanisms for the front car 3b are respectively synchronously driven by variable frequency synchronous motors 10a and 10b.

[0048] The electronic hair feeding hopper 1 is an electronic weighing structure.

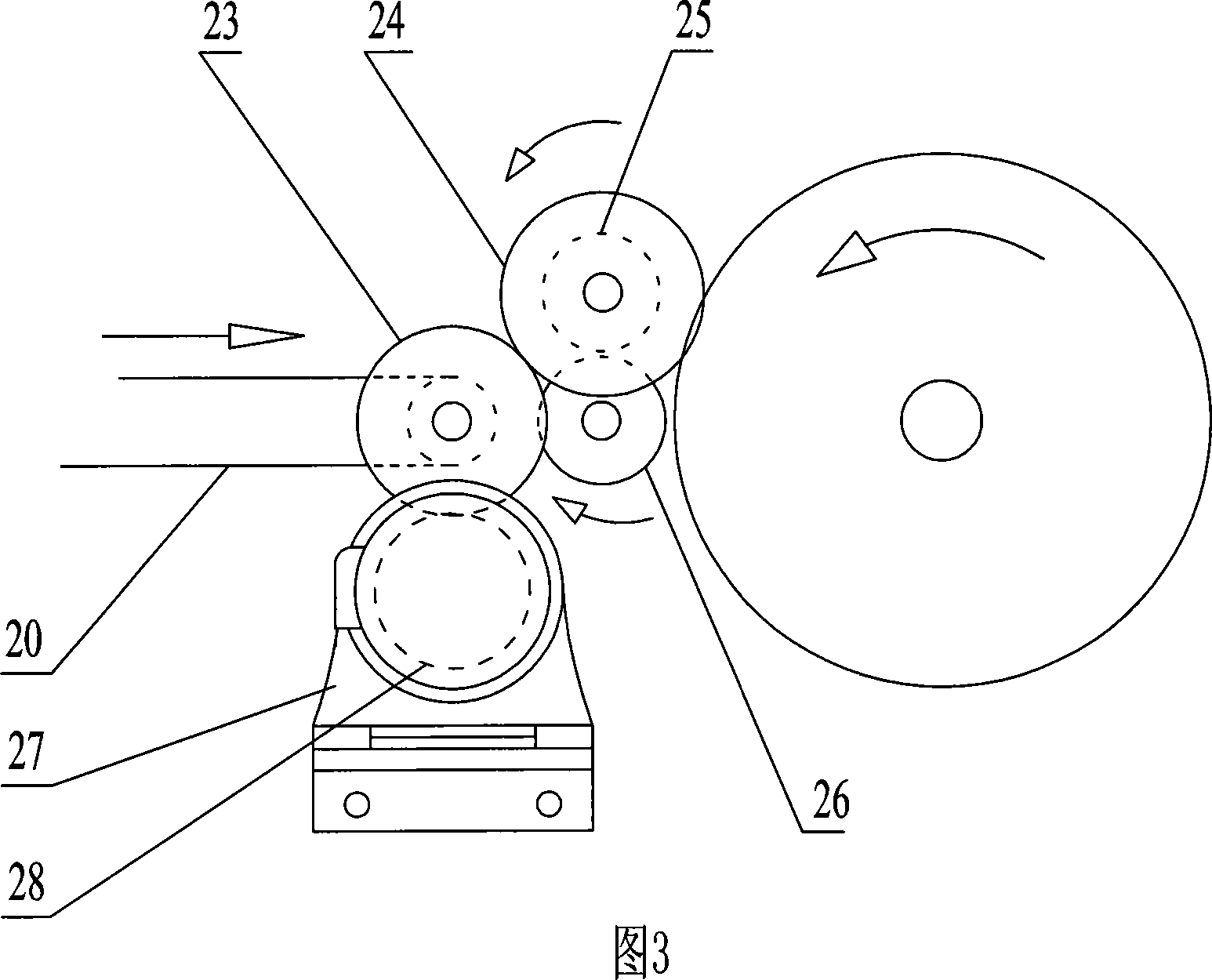

[0049] As shown in Figures 3, 4, and 5, the metal anti-rolling device 2 includes a gear 23, a gear 24, a gear 25, and a gear 26 respectively installed on the fur-feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com