Tungsten electrode argon arc welding process control method and system, computer equipment and application

A technology of argon tungsten arc welding and process control, which is applied in the direction of arc welding equipment, welding equipment, metal processing equipment, etc., which can solve the random and uncertain process control, uncoordinated process parameters, and beautiful weld shape Poor quality and other problems, to achieve the effect of improving system integrity, fully controllable parameters, and facilitating process adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

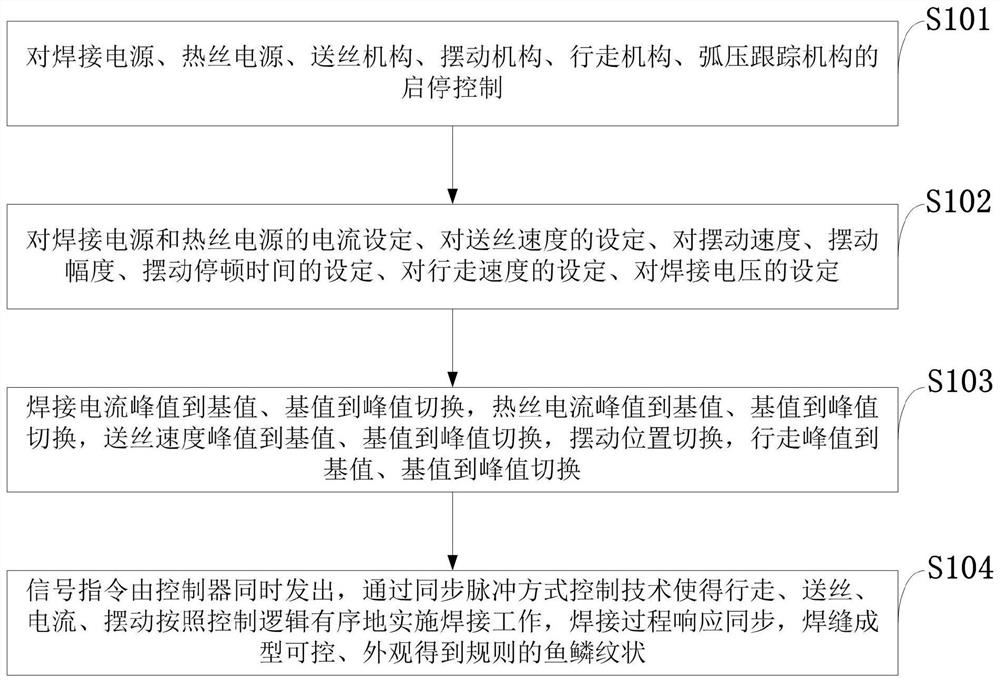

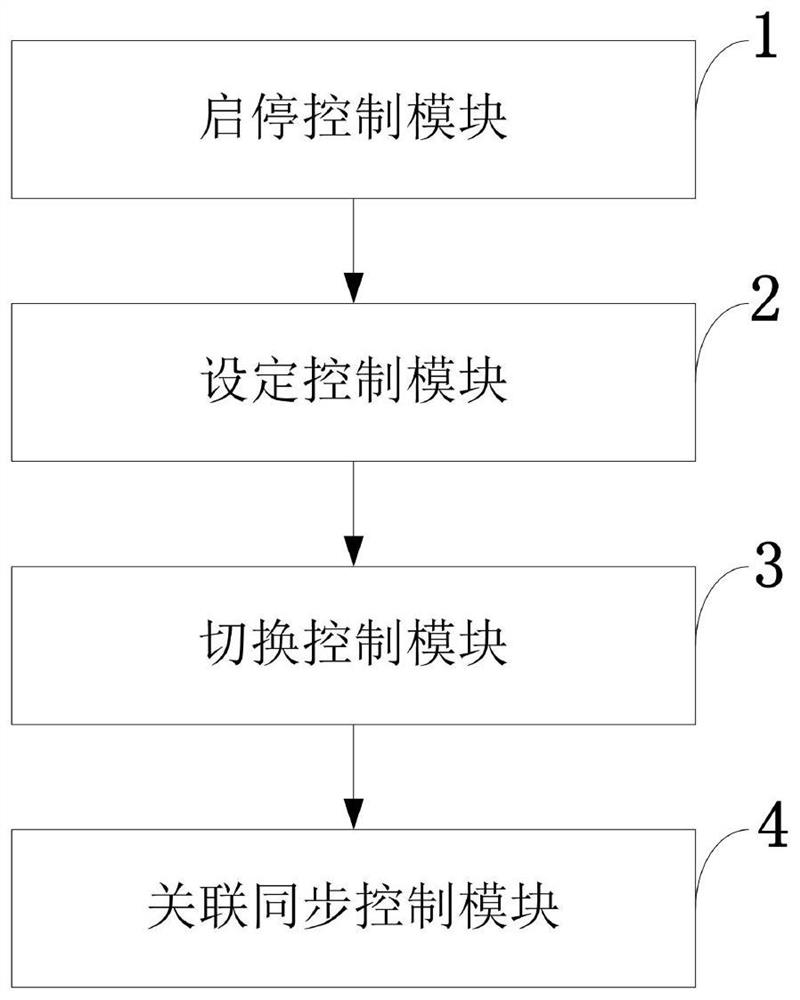

Method used

Image

Examples

Embodiment

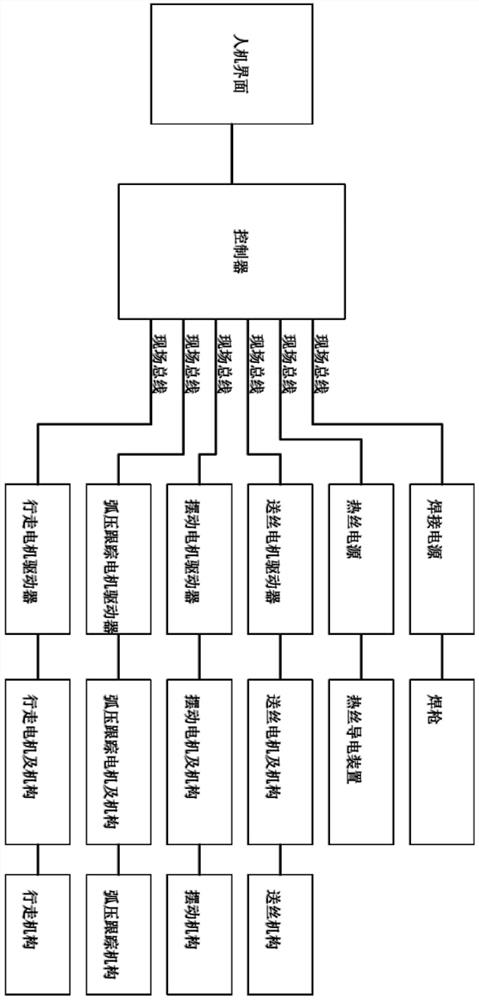

[0103] Embodiment: The controller adopts Beckhoff brand based computer controller CX5140, with EtherCAT bus interface, swing motor driver, AVC motor driver, walking motor driver, wire feeding motor driver adopts Maxon motor driver EPOS4_50 / 5, with EtherCAT bus interface, motor It adopts RE35 DC motor with encoder, and the welding power supply adopts EWM brand argon arc welding machine Tetrix552, which has a devicenet bus interface. The hot wire power supply adopts EWM brand hot wire power supply Tetrix180, which has an analog interface; the controller is connected to the motor driver through the EtherCAT bus. It is connected to the welding power supply through the EtherCAT bus to debicenet bus, and connected to the hot wire power supply through the EtherCAT bus to analog. The display is connected to the controller through the HDMI interface. For connections, see Figure 4 .

[0104] Process experiment data table:

[0105]

[0106]

[0107] It should be noted that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com