Novel engine main bearing cover tile locking trough testing fixture

A technology for engines and main bearings, applied in the direction of mechanical diameter measurement, etc., to achieve the effect of high measurement reliability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

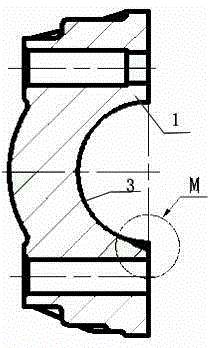

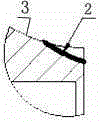

[0022] The utility model such as Figure 4 , 5 shown.

[0023] A new type of engine main bearing cover lock tile groove inspection tool, including a detection platform 4, a neutral opening 5 is provided in the middle of the detection platform 4; a mandrel 6 is arranged laterally from one side of the detection platform 4, and the mandrel 6 runs through The detection platform 4 passes through the other side, and the other side of the detection platform 4 is provided with a table seat 7, and the table seat 7 is provided with a dial indicator 8, wherein the measuring head of the dial indicator 8 corresponds to the top of the mandrel 6;

[0024] A clamper 9 is arranged on the top of the detection platform 4, and the indenter 10 of the clamper 9 corresponds to the upper part of the neutral opening 5. On the detection platform 4 on both sides of the neutral opening 5, a floating positioning pin is also provided, and the floating positioning pin Corresponding to the pin holes on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com